Antibacterial polyvinyl chloride sole material and preparation method thereof

A polyvinyl chloride and shoe sole material technology, applied in the field of shoe sole materials, can solve the problems of not having antibacterial properties, unable to meet antibacterial requirements, etc., and achieve the effects of prolonging antibacterial durability, good antibacterial effect, and improving antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

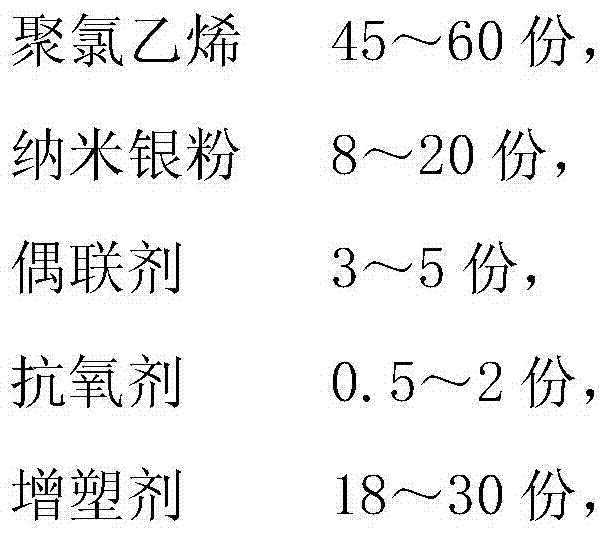

[0021] A kind of antibacterial polyvinyl chloride sole material, its parts by weight consist of:

[0022]

[0023] Its manufacturing method comprises the following steps:

[0024] (1) Weigh the raw materials according to the formula, add the nano-silver powder into the coupling agent, fully stir, and dry after suction filtration to obtain the nano-mixture;

[0025] (2) Add other raw materials in the formula and the nano-mixture obtained in step (1) into a high-mixer and mix to obtain a blend;

[0026] (3) adding the blend obtained in step (2) into a twin-screw extruder to extrude and granulate to obtain an antibacterial polyvinyl chloride shoe sole material.

Embodiment 2

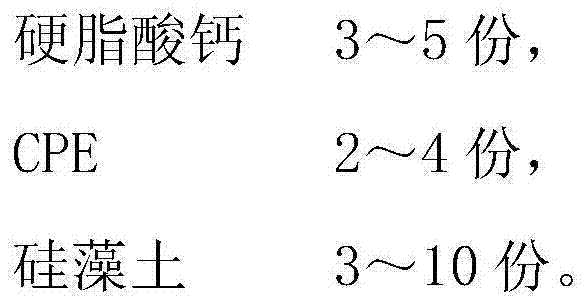

[0028] A kind of antibacterial polyvinyl chloride sole material, its parts by weight consist of:

[0029]

[0030]

[0031] Its manufacturing method comprises the following steps:

[0032] (1) Weigh the raw materials according to the formula, add the nano-silver powder into the coupling agent, fully stir, and dry after suction filtration to obtain the nano-mixture;

[0033] (2) Add other raw materials in the formula and the nano-mixture obtained in step (1) into a high-mixer and mix to obtain a blend;

[0034] (3) adding the blend obtained in step (2) into a twin-screw extruder to extrude and granulate to obtain an antibacterial polyvinyl chloride shoe sole material.

Embodiment 3

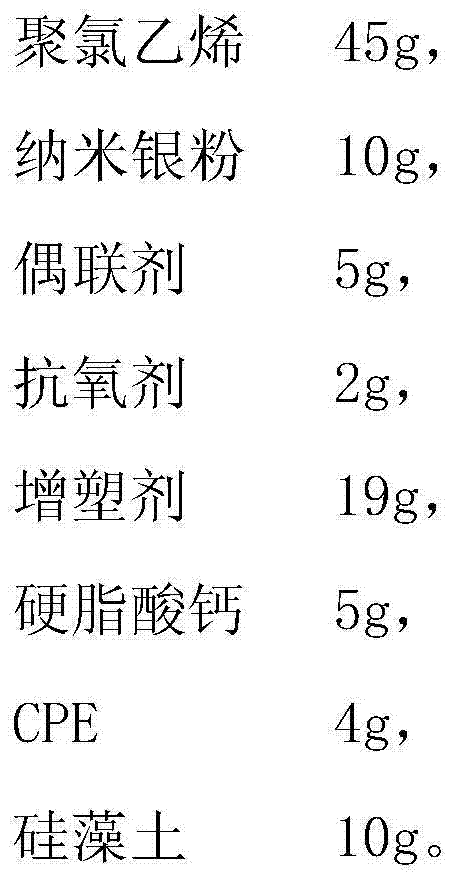

[0036] A kind of antibacterial polyvinyl chloride sole material, its parts by weight consist of:

[0037]

[0038] Its manufacturing method comprises the following steps:

[0039] (1) Weigh the raw materials according to the formula, add the nano-silver powder into the coupling agent, fully stir, and dry after suction filtration to obtain the nano-mixture;

[0040] (2) Add other raw materials in the formula and the nano-mixture obtained in step (1) into a high-mixer and mix to obtain a blend;

[0041] (3) adding the blend obtained in step (2) into a twin-screw extruder to extrude and granulate to obtain an antibacterial polyvinyl chloride shoe sole material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com