Method used for limiting composite material matrix internal crack expansion

A composite material and internal crack technology, which is applied in the field of limiting the internal crack propagation of the composite material matrix, can solve the problems of poor damage resistance of the composite material matrix, weakening the enhancement efficiency of SiC nanowires, and uneven distribution of SiC nanowires, and achieves feasibility. High, controllable growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

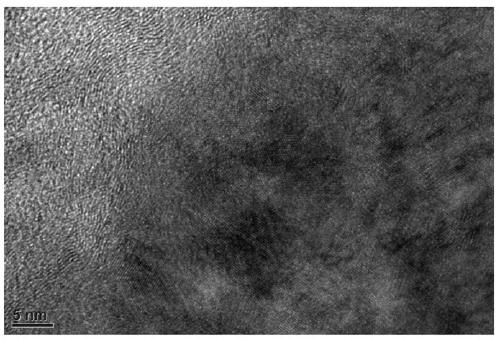

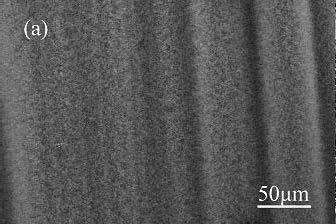

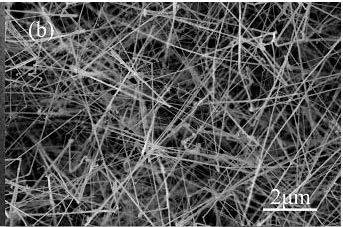

[0045] The carbon fiber preform was vacuum impregnated in 0.5 mol / L Ni(NO 3 ) 2 in acetone solution for 10h, take out and dry. Put the dry catalyst-loaded carbon fiber braid into a chemical vapor deposition device, and raise the temperature to 1200° C. under an argon atmosphere. Close the argon, pass through methyltrichlorosilane (MTS) and H 2 ,MTS / H 2 The mole fraction ratio is 0.1, the furnace pressure is 3KPa, and the reaction time is 1h, and the SiC nanowire reinforcement is obtained. Close MTS and H 2 , pass in argon, after the temperature drops to 1000°C, turn off the argon, and pass in CH 4 The gas provides the carbon source, the furnace pressure is 3KPa, and the reaction time is 2h. After the reaction, the gas was turned off, and the SiCNWs / PyC reinforcement was obtained by cooling to room temperature under the protection of an argon atmosphere. The SiC matrix was prepared by the CVI process to realize the densification of the composite material, with MTS as the...

Embodiment 2

[0050] Access to CH 4 The reaction time of the gas was 4h, and the thickness (200nm) of the layered PyC interface was increased. Others were the same as in Example 1. As a result, a SiCNWs / PyC synergistically reinforced composite material was obtained.

[0051] Image 6 Comparing the optical macroscopic morphology of the SiCNWs / PyC synergistically reinforced composite material prepared for this example without external force and with 180MPa external force, it was found that the composite material did not change after the external force was applied.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com