Method for preparing rhenium disulfide thin film through chemical vapor deposition

A chemical vapor deposition, rhenium disulfide technology, applied in gaseous chemical plating, metal material coating process, coating, etc. problems such as poor grid quality, to achieve the effect of promoting epitaxial growth, uniform number of layers, and low requirements for equipment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

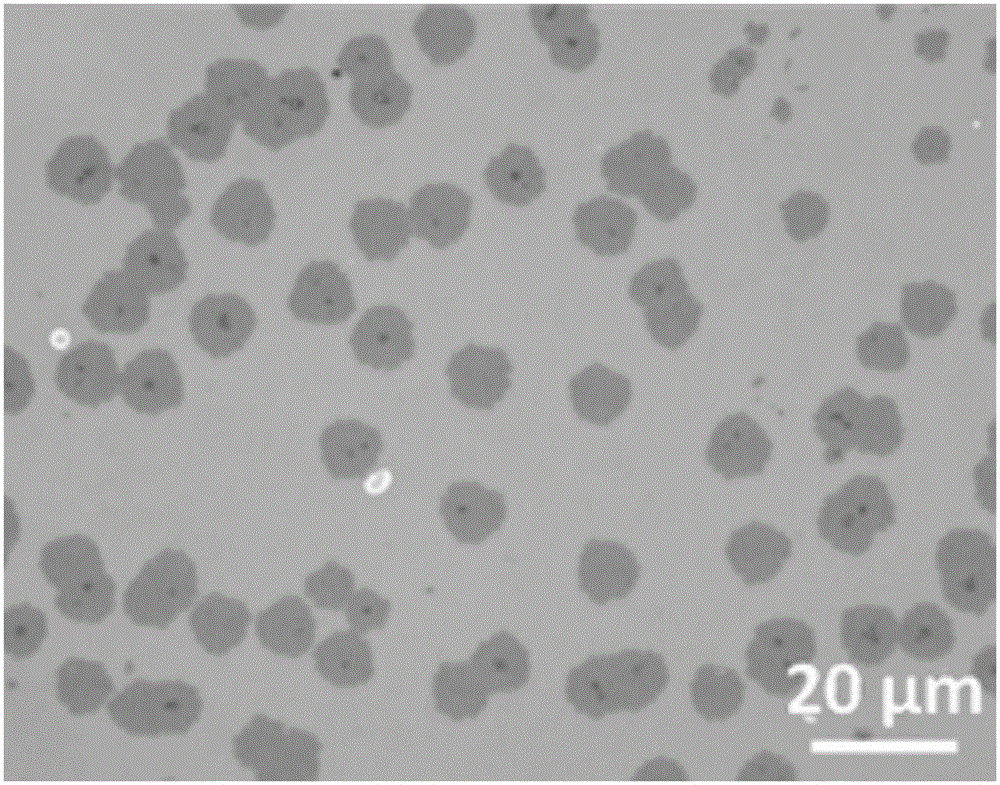

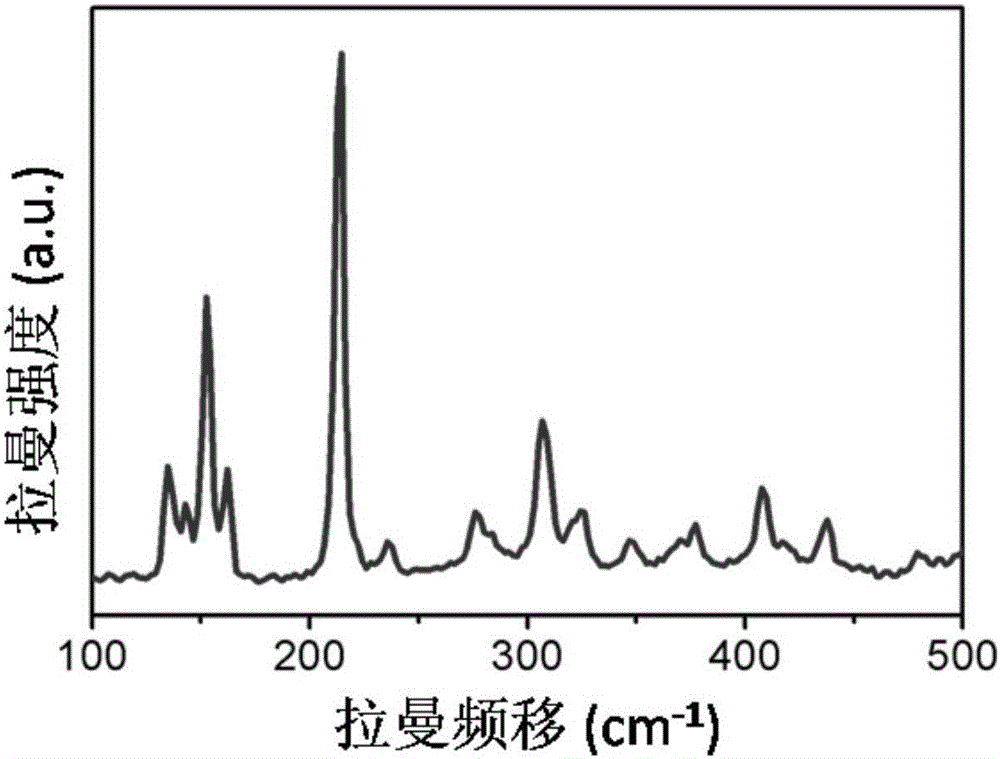

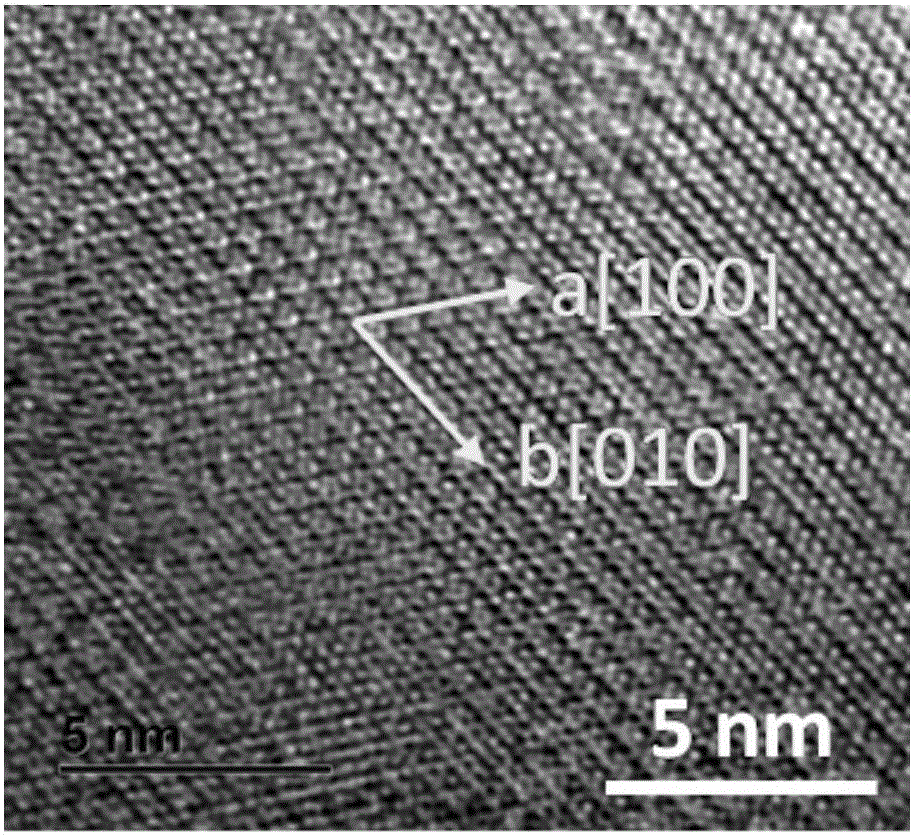

[0025] Mix 1 mg of rhenium powder with a purity of 99.99% and 8 mg of tellurium powder with a purity of 99.9% evenly and spread them evenly in a ceramic boat, then place the freshly stripped mica sheet upside down on the ceramic boat, and push the ceramic boat into the To the central position of the tube furnace heating zone; 80 mg of sulfur powder with a purity of 99.8% is put into another ceramic boat, and the ceramic boat is also pushed into the tube furnace; The furnace temperature was raised to 800°C within 22 minutes, the heating temperature of the sulfur powder was controlled to 200°C, and the temperature was kept constant for 10 minutes, and then naturally cooled to room temperature with the furnace to obtain a two-dimensional rhenium disulfide thin film. Depend on figure 1 It can be seen that the shape, size and number of layers of the obtained sample film are very uniform, and it can be seen from the optical contrast that it is a single layer. figure 2 The Raman sp...

Embodiment 2

[0027] Mix 1 mg of rhenium powder with a purity of 99.99% and 3 mg of tellurium powder with a purity of 99.9% evenly and spread them evenly in a ceramic boat, then put the freshly stripped mica sheet upside down on the ceramic boat, and push the ceramic boat into the To the central position of the tube furnace heating zone; 100mg of sulfur powder with a purity of 99.8% is put into another ceramic boat, and the ceramic boat is also pushed into the tube furnace; under the argon flow of 20 sccm, put The furnace temperature was raised to 900°C within 25 minutes, the heating temperature of the sulfur powder was controlled to 200°C, and the temperature was kept constant for 10 minutes, and then naturally cooled to room temperature with the furnace to obtain a two-dimensional rhenium disulfide thin film. Depend on Figure 5-6 It can be seen that the thickness of the obtained sample is uniform and the shape is relatively regular, and the two characteristic peaks of the Raman spectrum ...

Embodiment 3

[0029] Mix 1 mg of rhenium powder with a purity of 99.99% and 7 mg of tellurium powder with a purity of 99.9% evenly and spread them evenly in a ceramic boat, then put the freshly stripped mica sheet upside down on the ceramic boat, and push the ceramic boat into the To the central position of the tube furnace heating zone; 60 mg of sulfur powder with a purity of 99.8% is put into another ceramic boat, and the ceramic boat is also pushed into the tube furnace; under the argon flow of 20 sccm, put The furnace temperature was raised to 600°C within 20 minutes, the heating temperature of the sulfur powder was controlled to 200°C, and the temperature was kept constant for 10 minutes, and then naturally cooled to room temperature with the furnace to obtain a two-dimensional rhenium disulfide thin film. Depend on Figure 7-8 It can be seen that the size and thickness of the obtained sample are uniform, the shape is hexagonal, and the two characteristic peaks of the Raman spectrum ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com