Patents

Literature

63results about How to "No temperature gradient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting high-valence manganese from manganese carbonate ore

This invention has provided one kind of method to leach high price manganese from manganese carbonateore, which belongs to the hydrometallurgy domain. It takes the glucose or the plant biomass and sulfuric acid as reducing agent of high pricemanganese in manganese carbonate ore, adopting microwave radiation glucose to promote high price manganese to revert, the concrete step includes: Takes 1 copy 100-200 sieve manganese carbonateore, add 10 -20 copy water to modulate the pulp; Again add 60% density sulfuric acid to pulp, the load ratio of mineral powder and sulfuric acid is 1: 6 -9; Simultaneously, add glucose or plant biomass, the load ratio of mineral powder and glucose or plant biomass is 10 -15: 1, stir evenly; radiate under 500 -1000W microwave, stir and respond for 4-10min, leach temperature is controlled at 50degree C-60 degree C, then get lixivium by filtering. This invention has the merits of lower reaction temperature, reducing acid consume and reduce leaching time of the manganese ore, high thermal using and respond rapidly.

Owner:CHONGQING UNIV

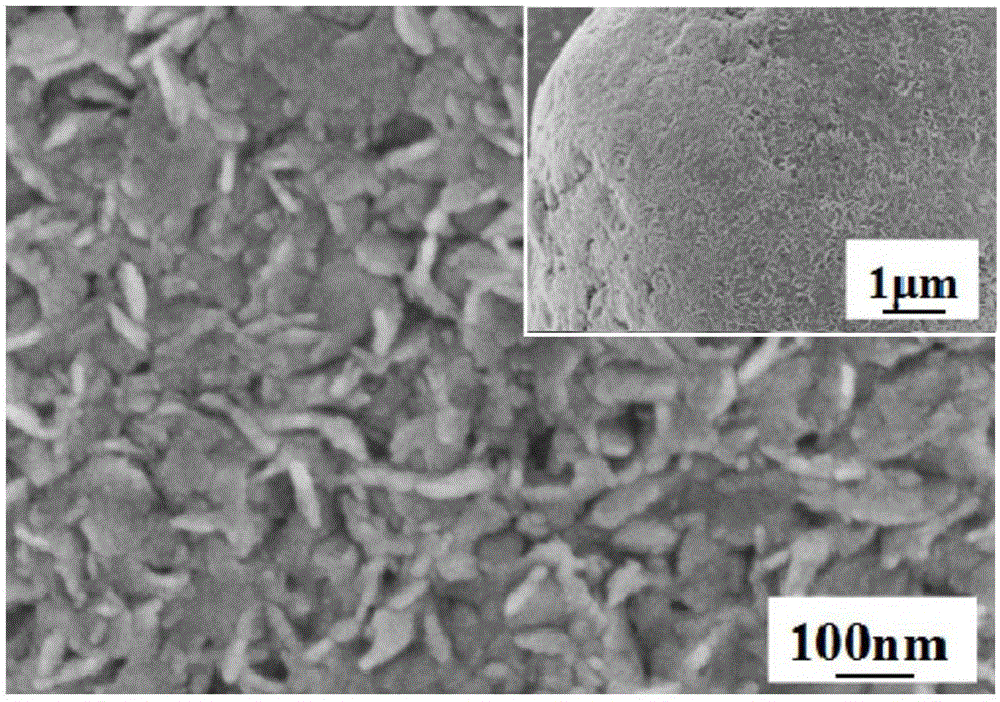

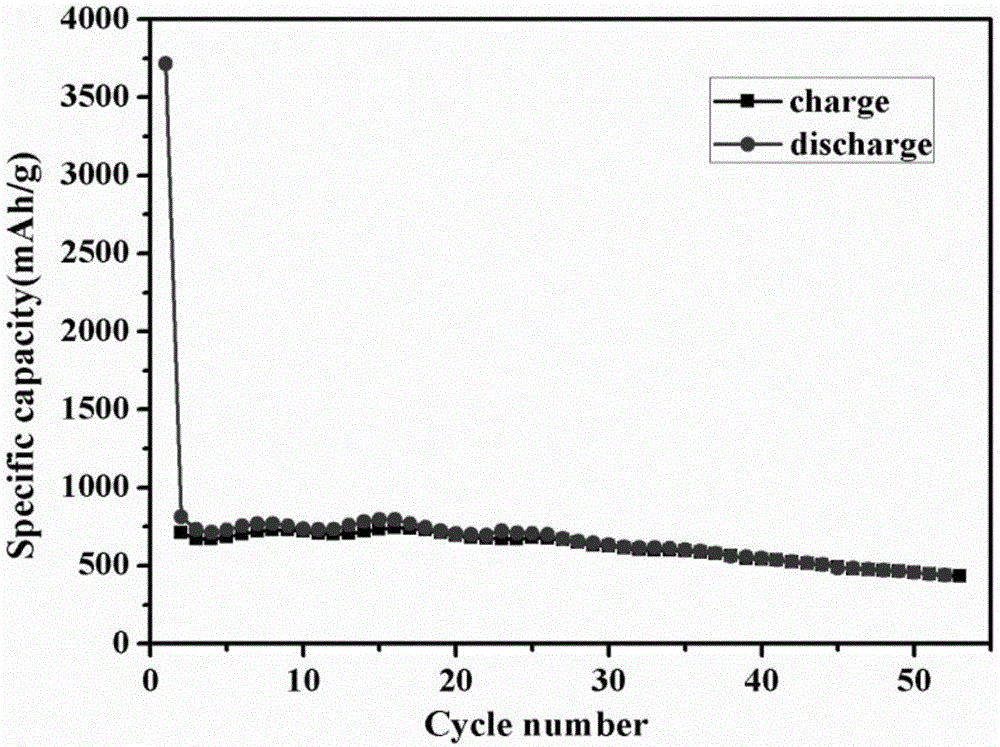

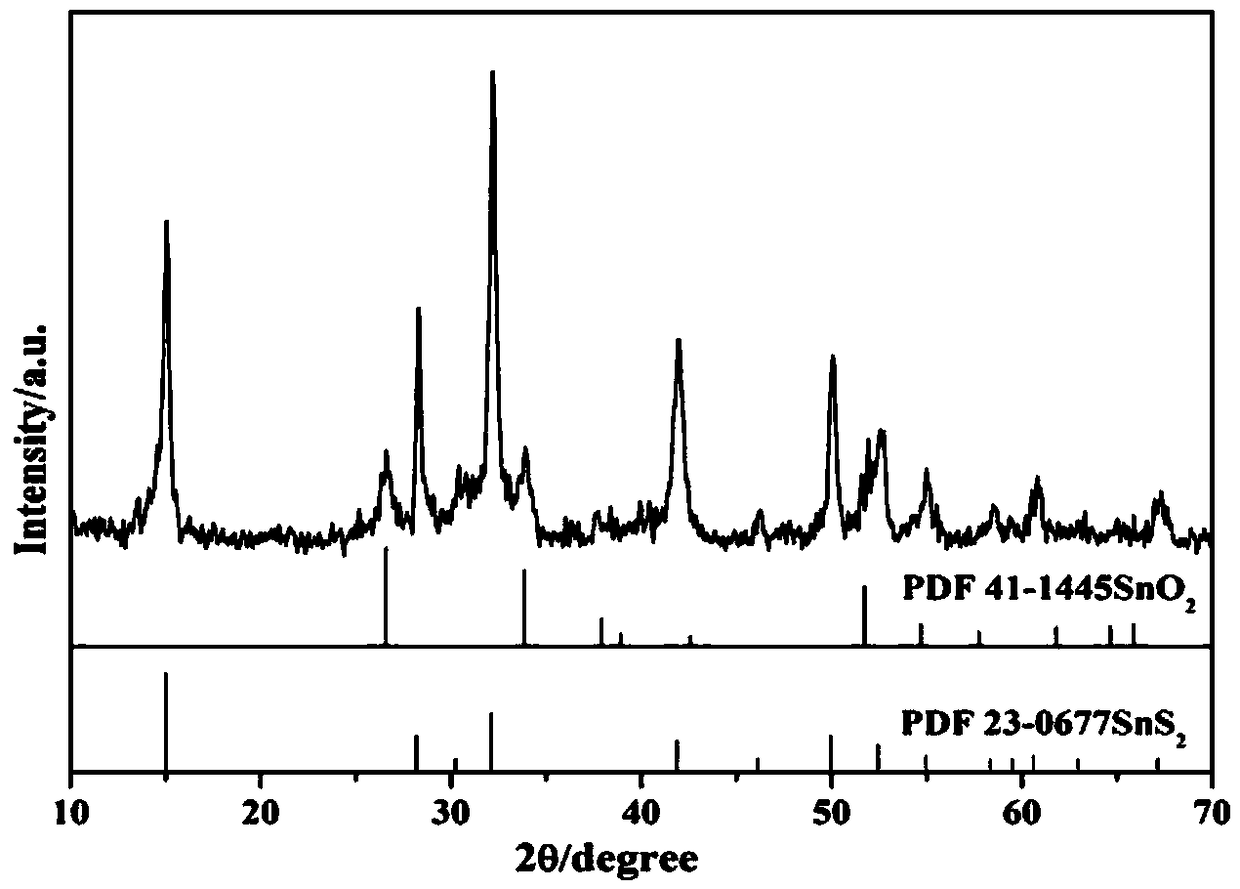

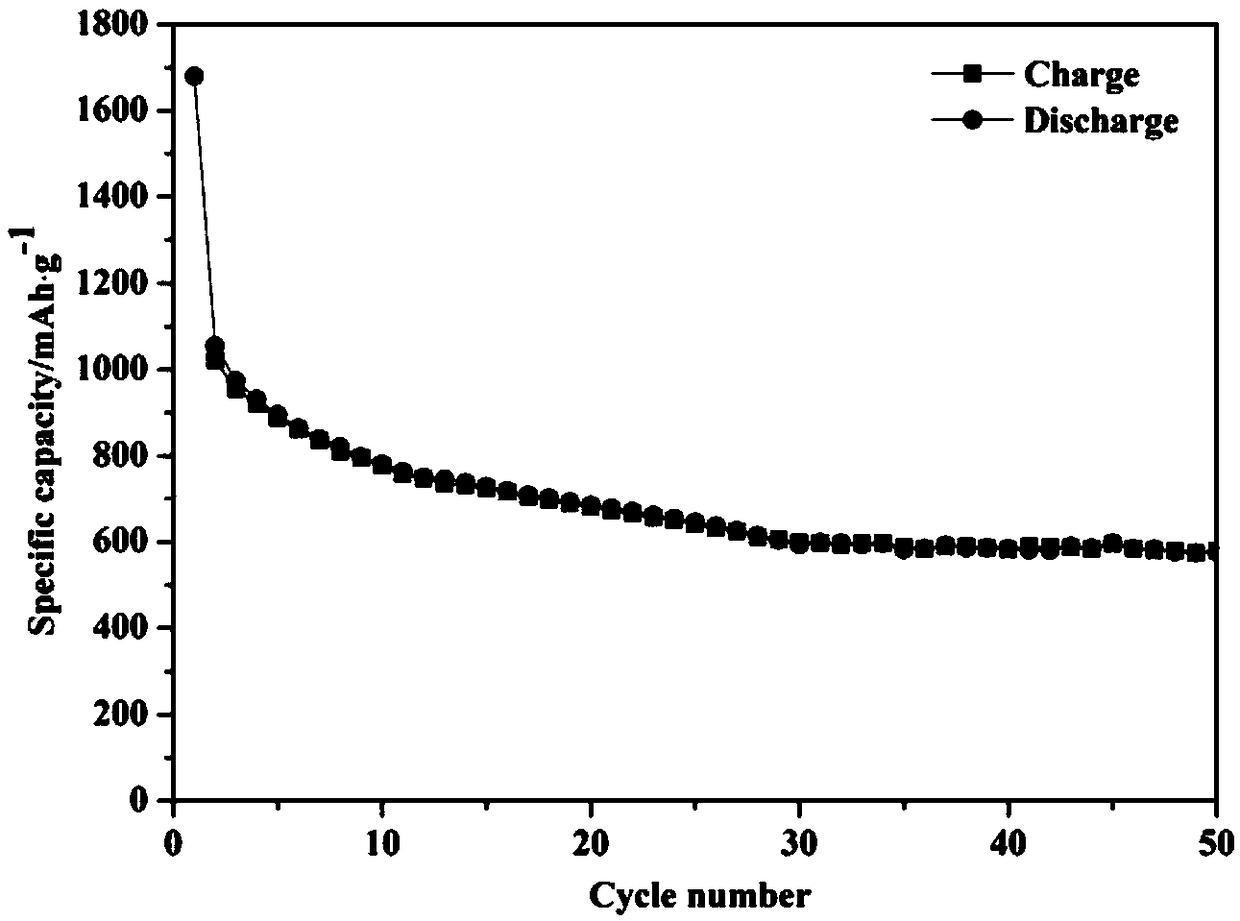

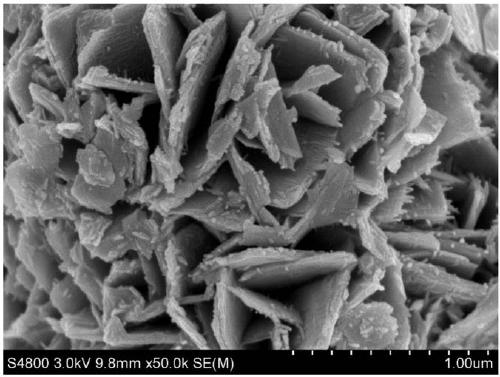

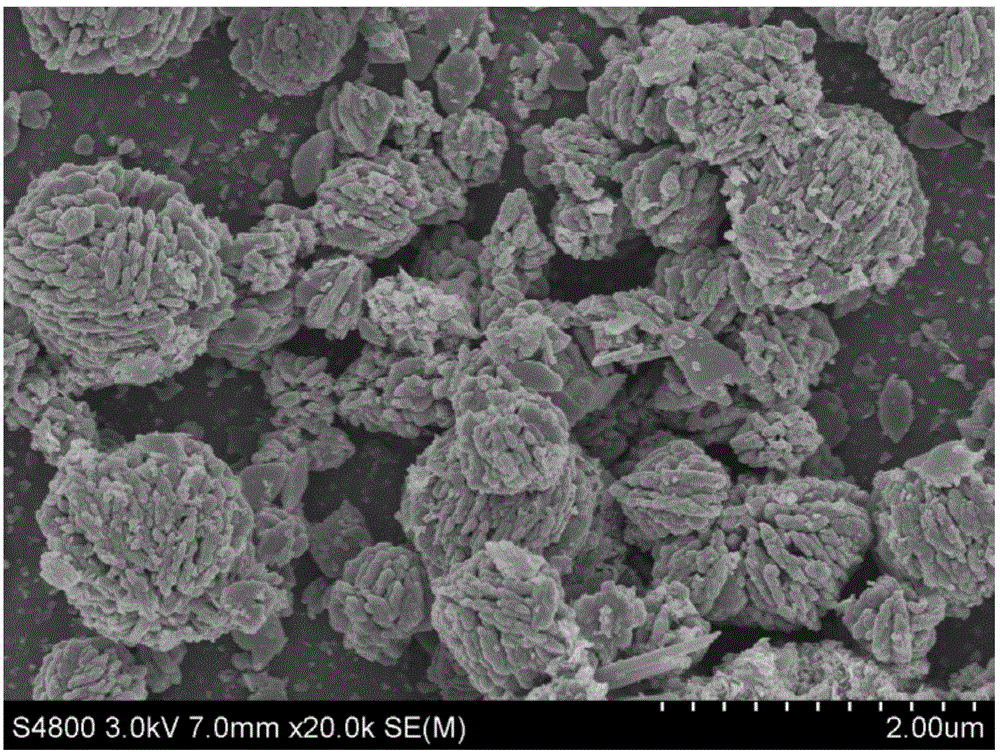

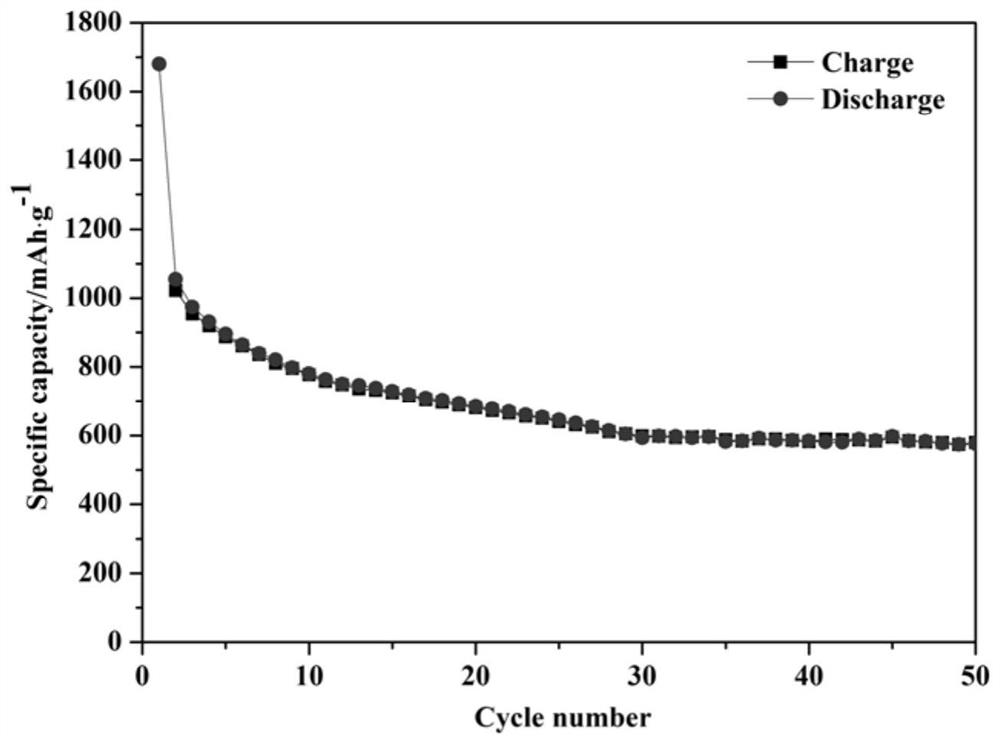

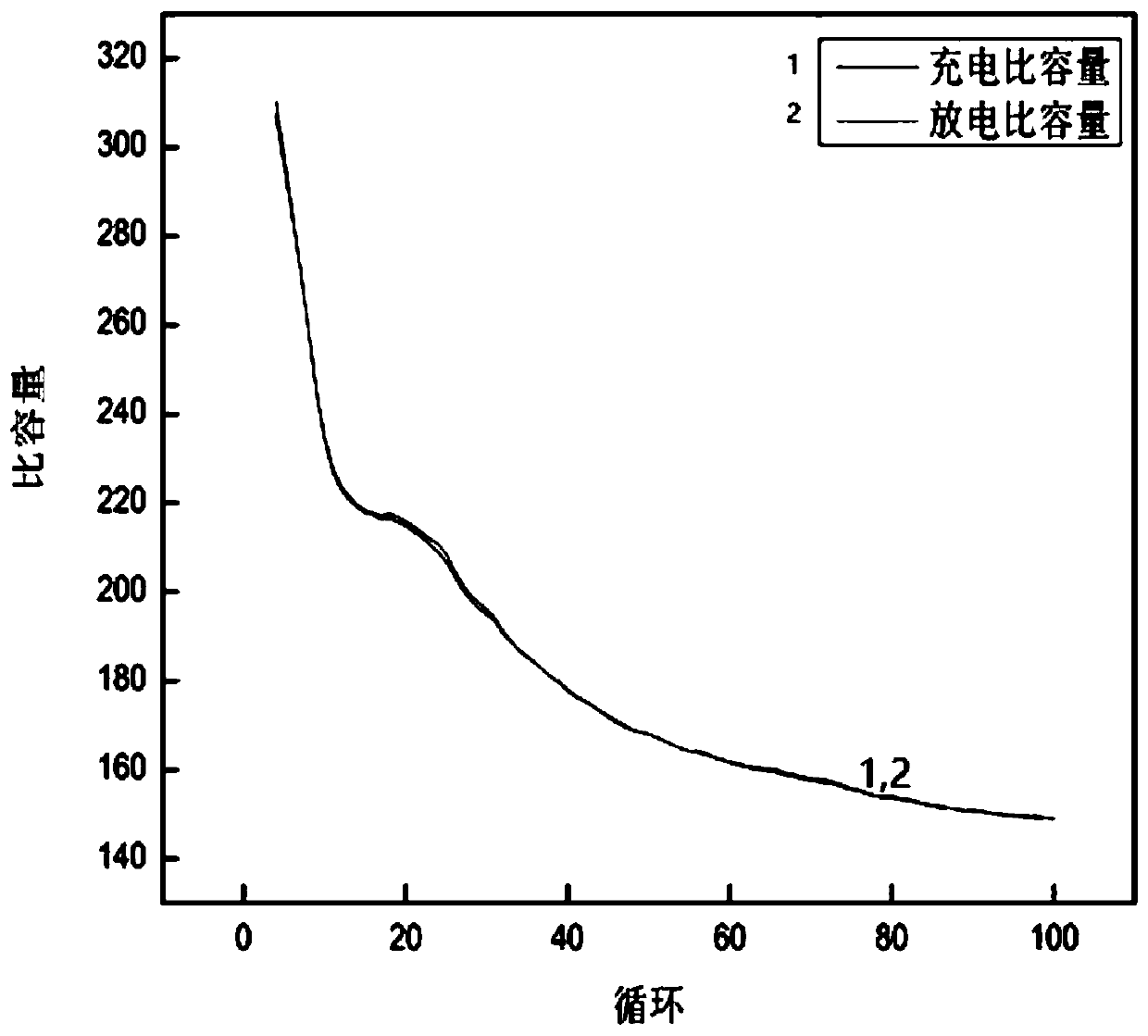

Preparation method for nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability

InactiveCN105098181AReduce manufacturing costImprove charge and discharge performanceNegative electrodesSodium-ion batteryChemistry

The invention discloses a preparation method for a nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability, comprises: 1) preparing an Sn source solution A with the concentration of 0.5-1.2 mol / L, regulating the pH of the solution A to be 1-9; and preparing an S source solution B with the concentration of 0.1-2.4 mol / L; 2) mixing the solution A and the solution B at an element molar ratio of nSn: nS being equal to (1.0-2.5): (2.0-4.3), and uniformly stirring to form a solution D; 3) putting the solution D into a homogenous phase hydrothermal reaction kettle for performing a homogenous phase hydrothermal reaction; and 4), cooling the reaction kettle, then centrifuging, washing, separating and drying to obtain the nano-flake SnS2 sodium-ion battery negative electrode material, wherein under 100 mA / g current density, the initial discharge capacity of the negative electrode material reaches 745 mAh / g; and after circulating for 100 times, the capacity is kept at 560 mAh / g.

Owner:SHAANXI UNIV OF SCI & TECH

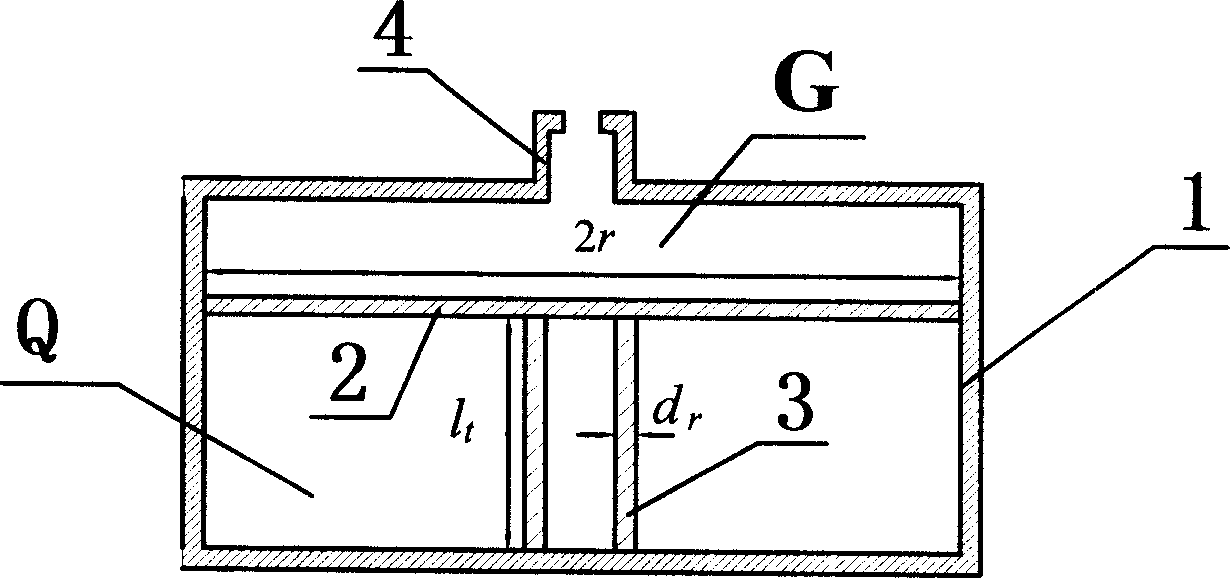

Method for microwave roasting of molybdenite concentrate to produce high-purity molybdenum oxide

ActiveCN104326509AEvenly heatedUniform compositionMolybdenum oxides/hydroxidesMicrowave cavityThermal insulation

Belonging to the technical field of molybdenum metallurgy, the invention relates to a method for microwave roasting of molybdenite concentrate to produce high-purity molybdenum oxide. The method includes: firstly conducting crushing and ball milling on molybdenite concentrate, then spreading the crushed molybdenite concentrate to a thickness of 1-4cm, and placing the product in a microwave cavity; turning on a microwave output switch, blowing in compressed air, regulating the microwave output power, and carrying out pre-oxidation on the crushed molybdenite concentrate; heating the pre-oxidized molybdenite concentrate to a sublimation temperature and performing thermal insulation for 30-60min, in the process, letting the molybdenum trioxide steam generated by oxidizing roasting overflow through a microwave reactor top, performing water-cooling and then conducting collection by a bag dust collector, thus obtaining high-purity molybdenum trioxide reaching the nonferrous metal industry grade 2 standard. The method provided by the invention has the advantages of short technological process, low energy consumption, and high product purity, etc.

Owner:徐州宇帆机电科技有限公司

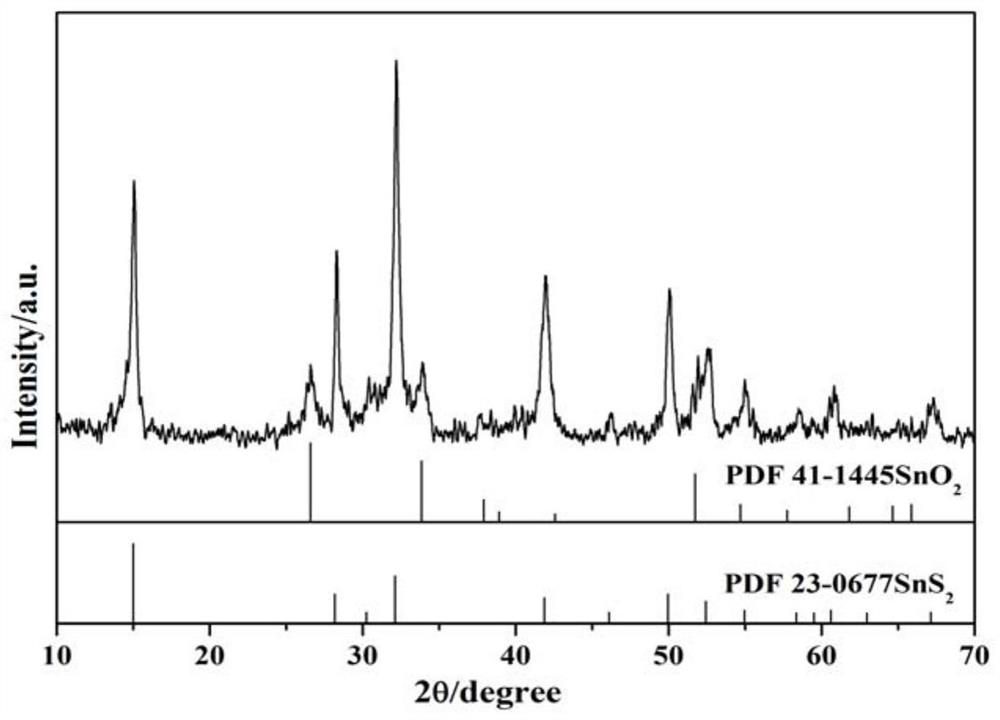

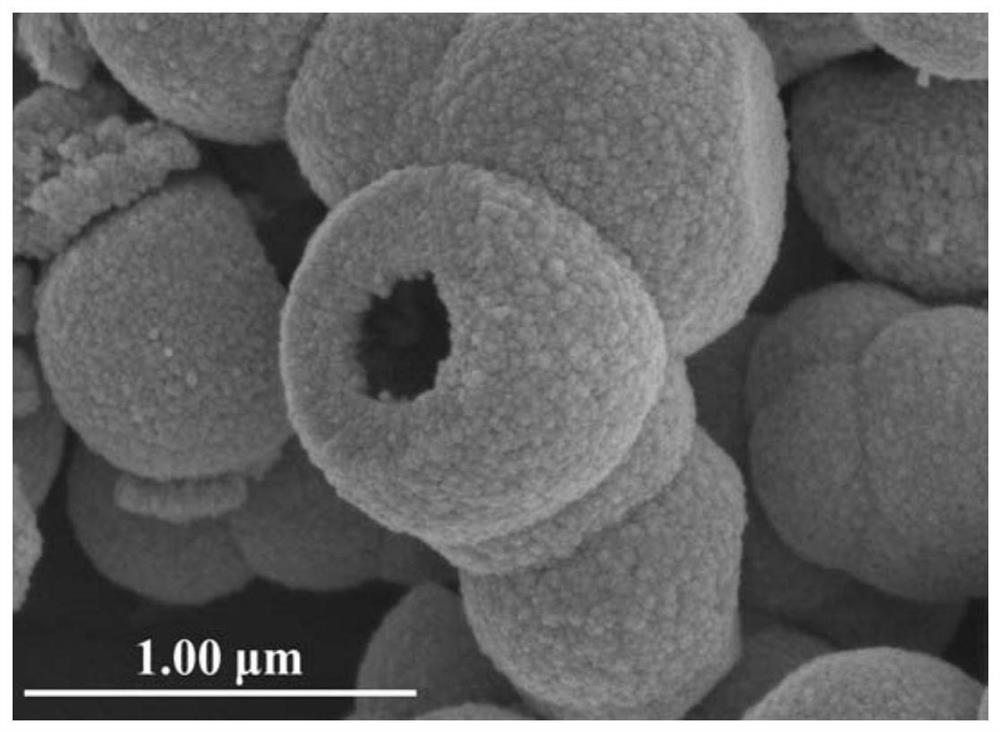

Preparation method of SnS2/SnO2 lithium ion battery anode material in hollow-sphere structure

ActiveCN109301204ALight in massLarge specific surface areaCell electrodesSecondary cellsAnhydrous ethanolEthanol

The invention discloses a preparation method of a SnS2 / SnO2 lithium ion battery anode material in hollow-sphere structure. The method includes: 1) adding SnCl4.5H2O in a mixed liquid of deionized water and anhydrous ethanol to fully dissolve the component for forming a solution A, and dissolving NaOH in the solution A to prepare a solution B; 2) under stirring, adding urea to the solution B and continuously stirring the solution to prepare a uniform mixed solution C, and performing a homogeneous hydrothermal reaction on the mixed solution C; 3) after the reaction is finished, washing and drying a product to obtain a SnO2 precursor; 4) heating the SnO2 precursor to burning to prepare SnO2 powder; 5) dispersing the SnO2 powder in ethanol with stirring to prepare a uniform mixed suspension D;6) adding SnCl4.5H2O and TAA to the suspension D with stirring until the components are completely dissolved to obtain a homogenous suspension E; 7) performing a microwave thermal reaction on the suspension E, when the reaction is finished, moving-out and washing and drying the product to prepare the SnS2 / SnO2 lithium ion battery anode material in hollow-sphere structure.

Owner:SHAANXI UNIV OF SCI & TECH

Low-voltage microwave radiation carbon nanotube hydroxyl modification method

The invention provides a hydroxy modification method for a low-pressure microwave radiation carbon nanometer tube, it relates to the hydroxy modification method of the carbon nanometer tube and solves the problems of the existing modification technology on nanometer tube that the technical process is complex, the reaction time is long, and the energy consumption and the cost are high. The modification method includes the steps of: 1. soaking carbon nanometer tube into alkali solution, then heat by microwave under low pressure, and remove the upper layer of alkali solution after the cooling and precipitation to obtain the precipitate; 2. cleaning and dry the precipitate to obtain the hydroxy-modified carbon nanometer tube. The invention greatly shortens the reaction time and has the advantages of simple technique, low energy consumption and low cost.

Owner:HARBIN INST OF TECH

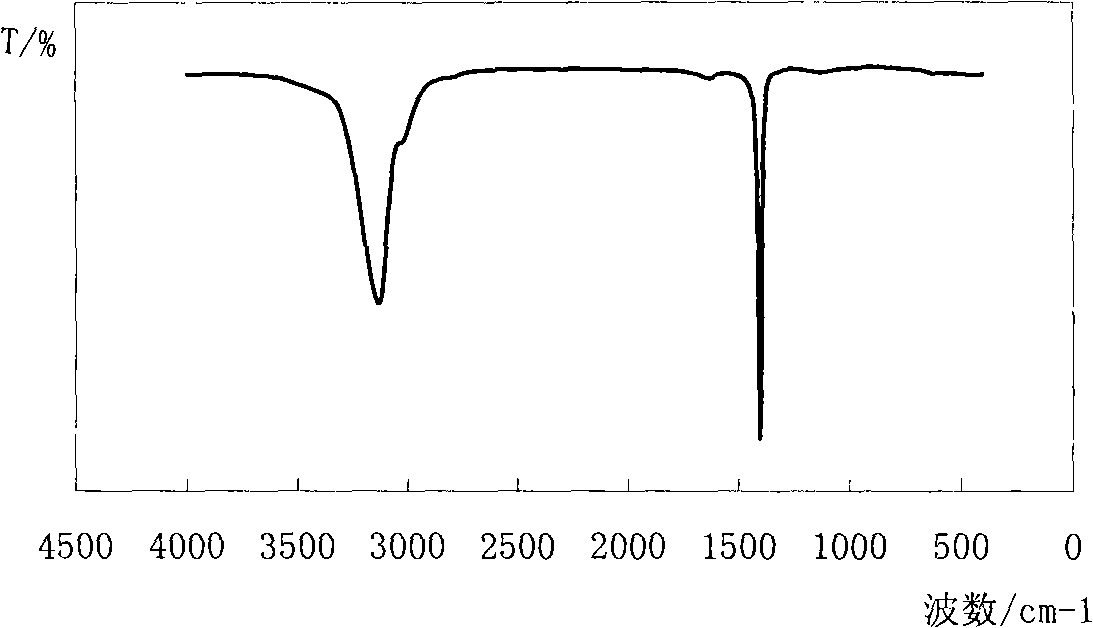

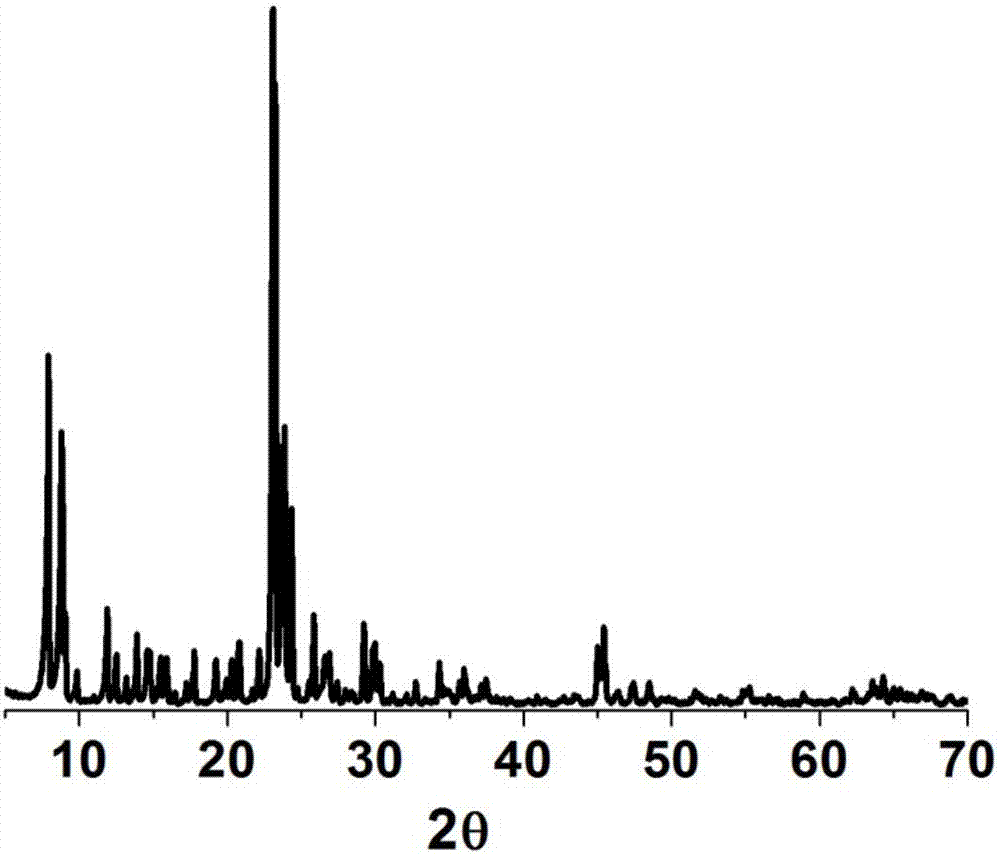

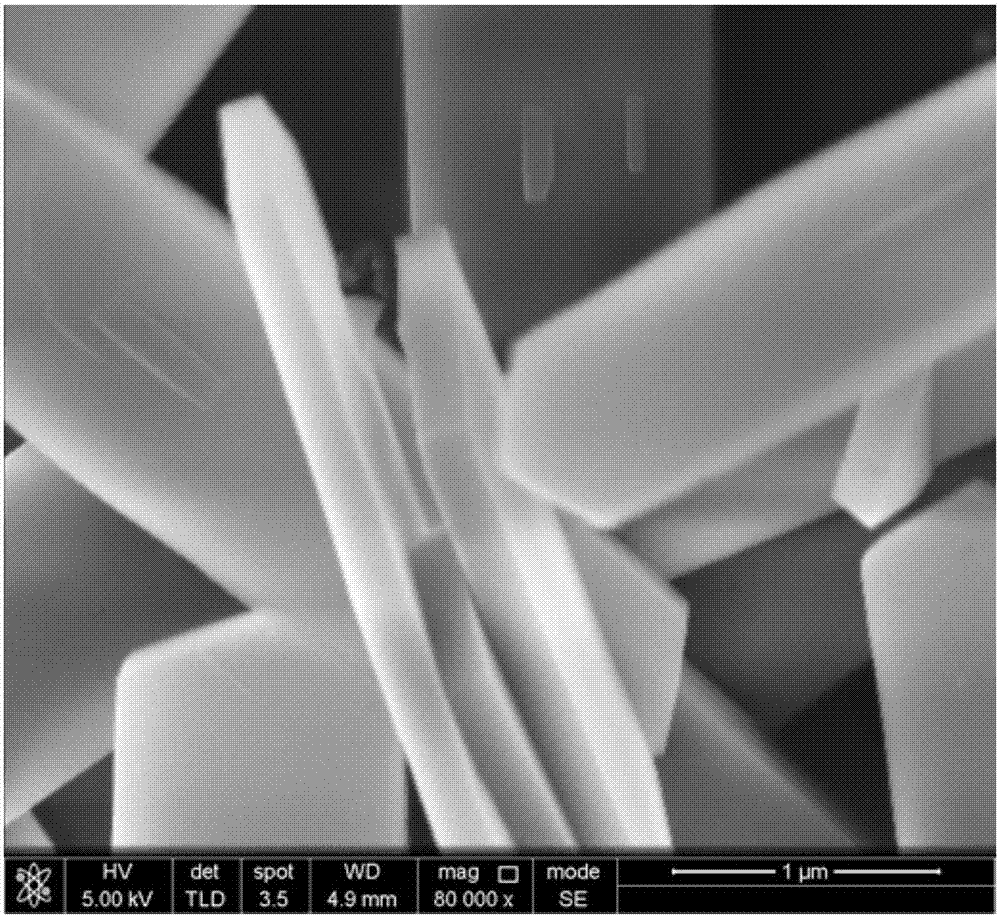

High-silicon ZSM-5 molecular sieve and preparation method and application thereof

ActiveCN107285339AHigh selectivitySmall sizeMolecular sieve catalystsMolecular sieve catalystButaneSeed crystal

The invention relates to the field of methanol-to-olefin catalysts, discloses a high-silicon ZSM-5 molecular sieve and a preparation method and application thereof, in particular to a preparation method of the high-silicon ZSM-5 molecular sieve. The preparation method comprises the following steps: mixing a solid silicon source, an aluminum source, a ZSM-5 molecular sieve seed crystal, a template, an alkali, urea and water uniformly in sequence, and carrying out aging and hydro-thermal synthesis crystallization, wherein urea is added in the stage of uniformly mixing the raw materials, the liquid silicon source is SiO2, the aluminum source is Al2O3, and the mixing ratio of the raw materials meets that the molar ratio of the solid silicon source, the aluminum source, the template, the alkali, the urea to the water is 1: (0.001 to 0.01): (0.025 to 0.25): (0.02 to 0.2): (0.3 to 4): (2 to 50), and the weight ratio of the ZSM-5 molecular sieve seed crystal to SiO2 in the solid silicon source is (1 to 10): 100. The invention also relates to the high-silicon ZSM-5 molecular sieve prepared by the invention and application thereof. When the prepared flaky high-silicon ZSM-5 molecular sieve is used for reactions for catalyzing methanol to propylene and / or butane, the selectivity of C3 and / or C4 olefin products is improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

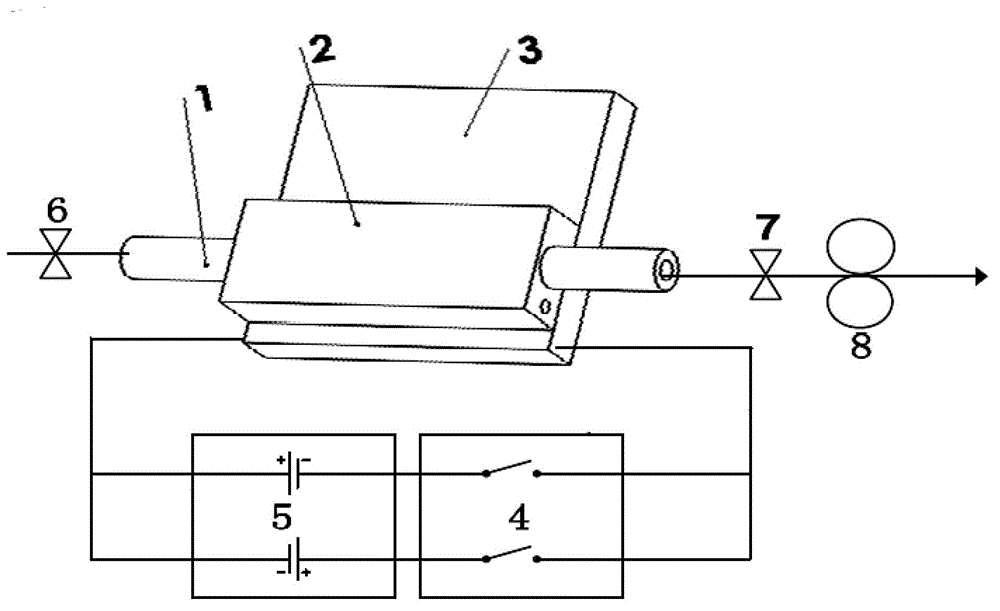

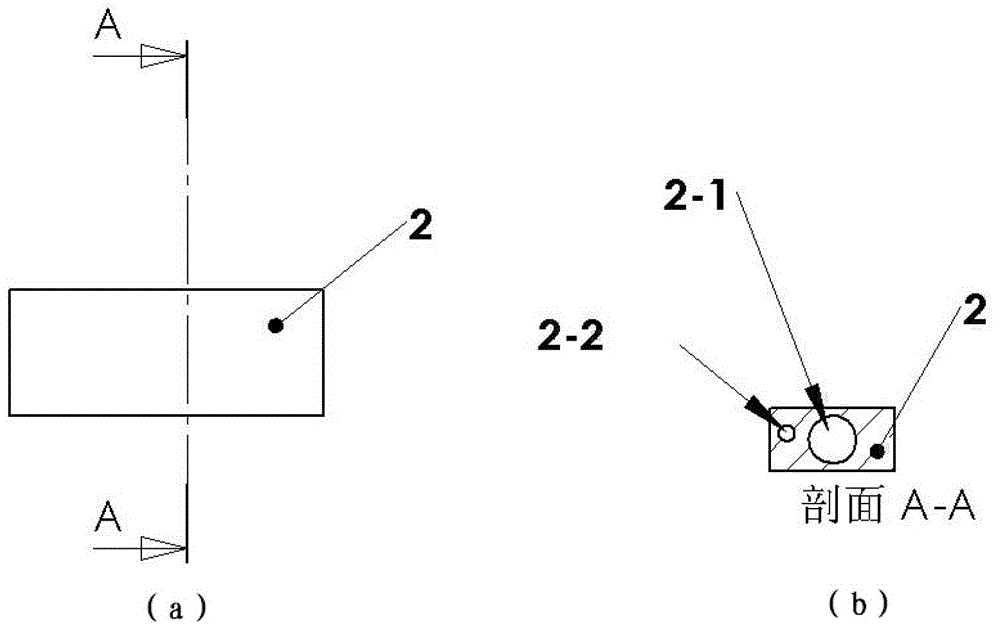

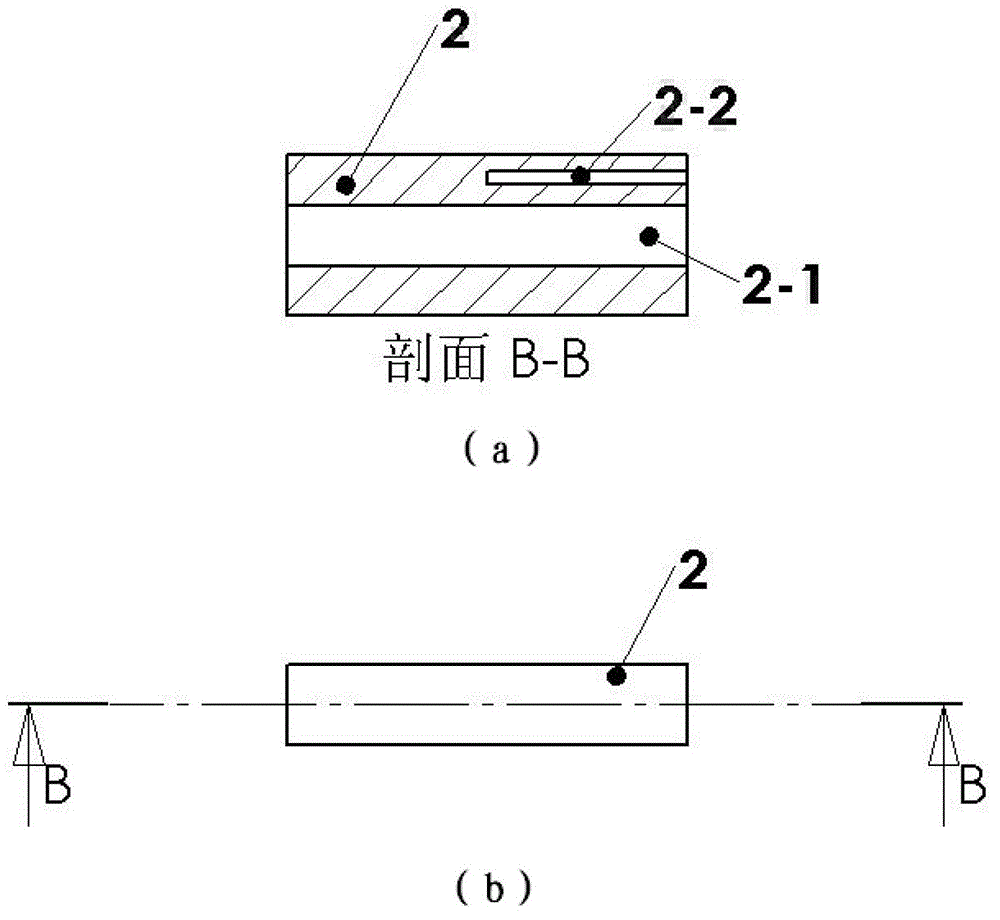

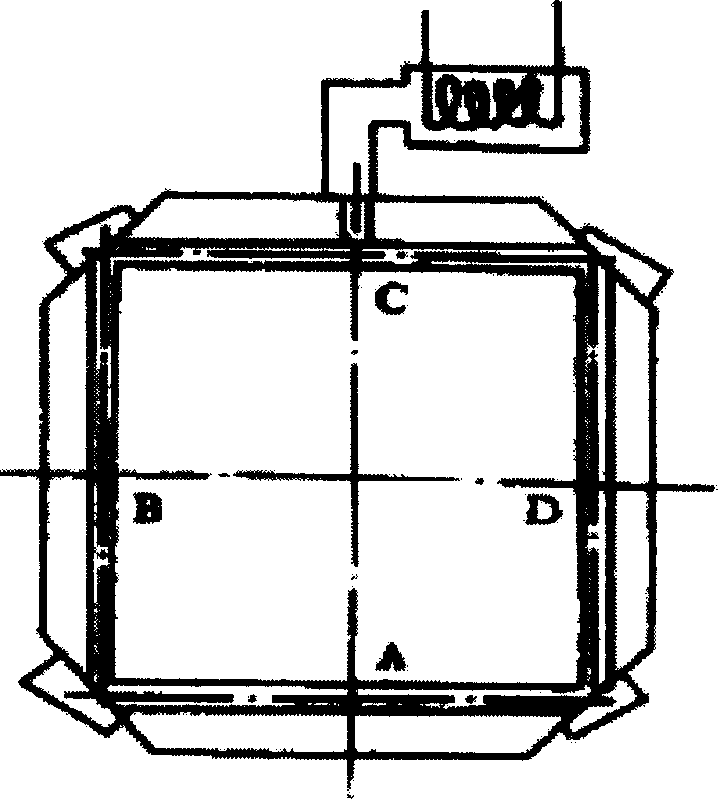

Convenient-to-integrate device for achieving PCR (polymerase chain reaction) and operating method

InactiveCN103333789AEasy to injectUniform temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsReverse currentPolymerase chain reaction

The invention discloses a convenient-to-integrate device for achieving a PCR (polymerase chain reaction) and an operating method. The device comprises a temperature control module, a semiconductor cooler module, a heat conduction module, a sample injection module, a power module and a reaction pipeline module, wherein the temperature control module is used for outputting two channels of control signals according to the set temperature parameters to achieve connection or disconnection of forward and reverse currents of a semiconductor cooler; one side of the semiconductor cooler clings to a heat radiating block and the other side of the semiconductor cooler clings to the heat conduction module; and the reaction pipeline module is embedded in the heat conduction module. During experiments, the sample injection module sucks reaction liquid into a reaction pipeline to reach the heat conduction module, and valves at the two ends are closed to complete sample injection and sealing; the temperature control module is started to heat the heat conduction module when the forward current of the semiconductor cooler is connected and to refrigerate the heat conduction module when the reverse current of the semiconductor cooler is connected; and temperature control of the reaction pipeline is achieved through variation of the temperature of the heat conduction module and the PCR is finally achieved in the reaction pipeline.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

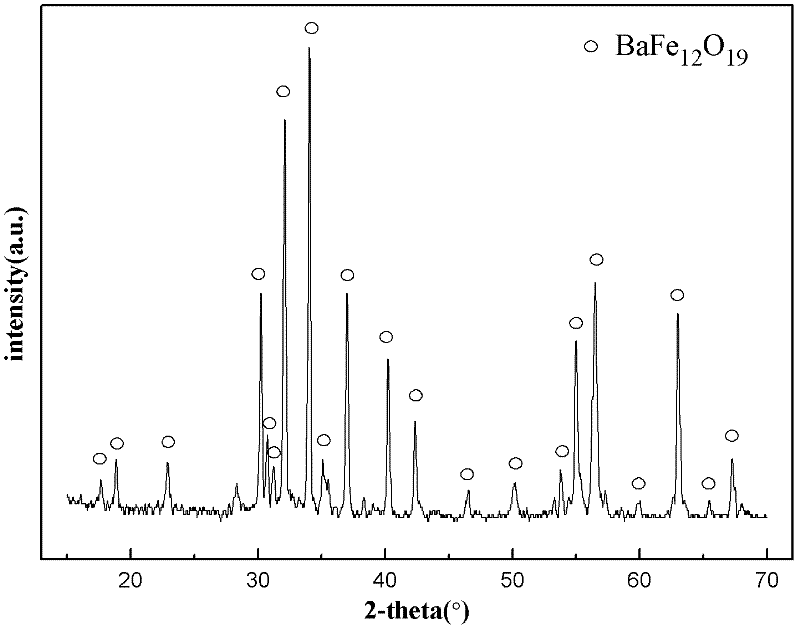

Method for preparing hexagonal BeFe12O19 (barium ferrite) magnetic nano powder by microwave-hydrothemal method

The invention provides a method for preparing hexagonal BeFe12O19 (barium ferrite) magnetic nano powder by a microwave-hydrothemal method, which includes the steps of utilizing iron nitrate nonahydrate and barium nitrate as precursors to be dissolved in deionized water; then dropwise adding sodium hydroxide into liquor and adjusting pH (potential of hydrogen) within the range from 9 to 14 so that uniform precursor liquor is generated; pouring the precursor liquor into a hydrothermal reaction kettle prior to sealing; and performing microwave-hydrothermal synthesis for the hydrothermal reaction kettle placed in a microwave digestion system prior to cooling the reaction kettle to the room temperature, scrubbing products with deionized water and absolute ethyl alcohol for several times and calcining the scrubbed products at the temperature ranging from 800 DEG C to 1000 DEG C so that the hexagonal BeFe12O19 magnetic nano powder is obtained. The method for preparing the hexagonal BeFe12O19 magnetic nano powder by the microwave-hydrothemal method is low in preparing cost, simple in operation, short in reaction period and high in purity after the products are calcined, and crystal grains are complete in growth and uniform in distribution.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing triuranium octoxide by calcining ammonium uranyl tricarbonate with microwaves

The invention discloses a method for producing triuranium octoxide by calcining ammonium uranyl tricarbonate with microwaves, which comprises the following steps: putting ammonium uranyl tricarbonate into a microwave reactor, turning on a microwave heating switch, adjusting the microwave output power to 5-60kW, heating the materials to 400-700 DEG C from room temperature at the speed of 20-100 DEG C / minute, preserving heat for 5-30 minutes, and then naturally cooling to the room temperature to acquire a triuranium octoxide product. The production method has low energy consumption as well as uniform product ingredients and granularity, and the calcining time in the whole technical process is only one third of a conventional method.

Owner:KUNMING UNIV OF SCI & TECH

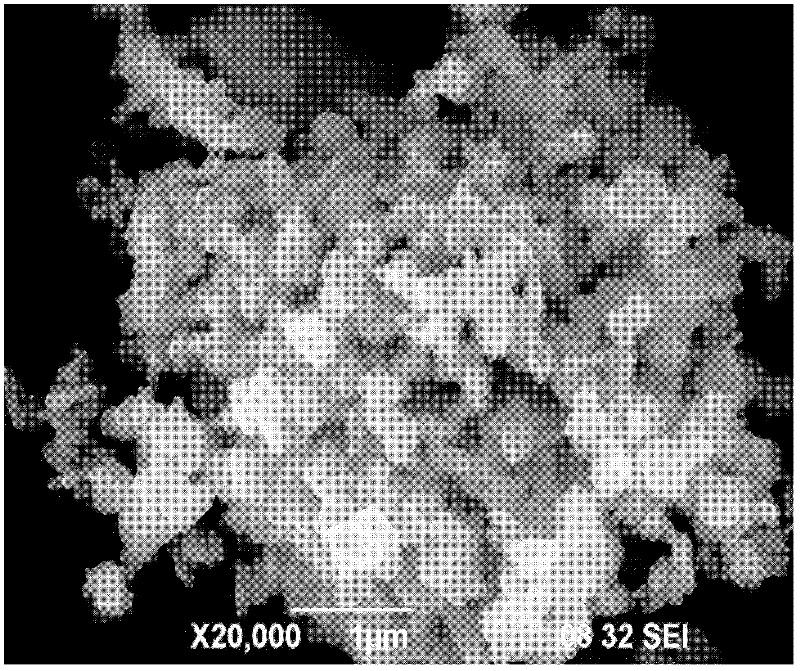

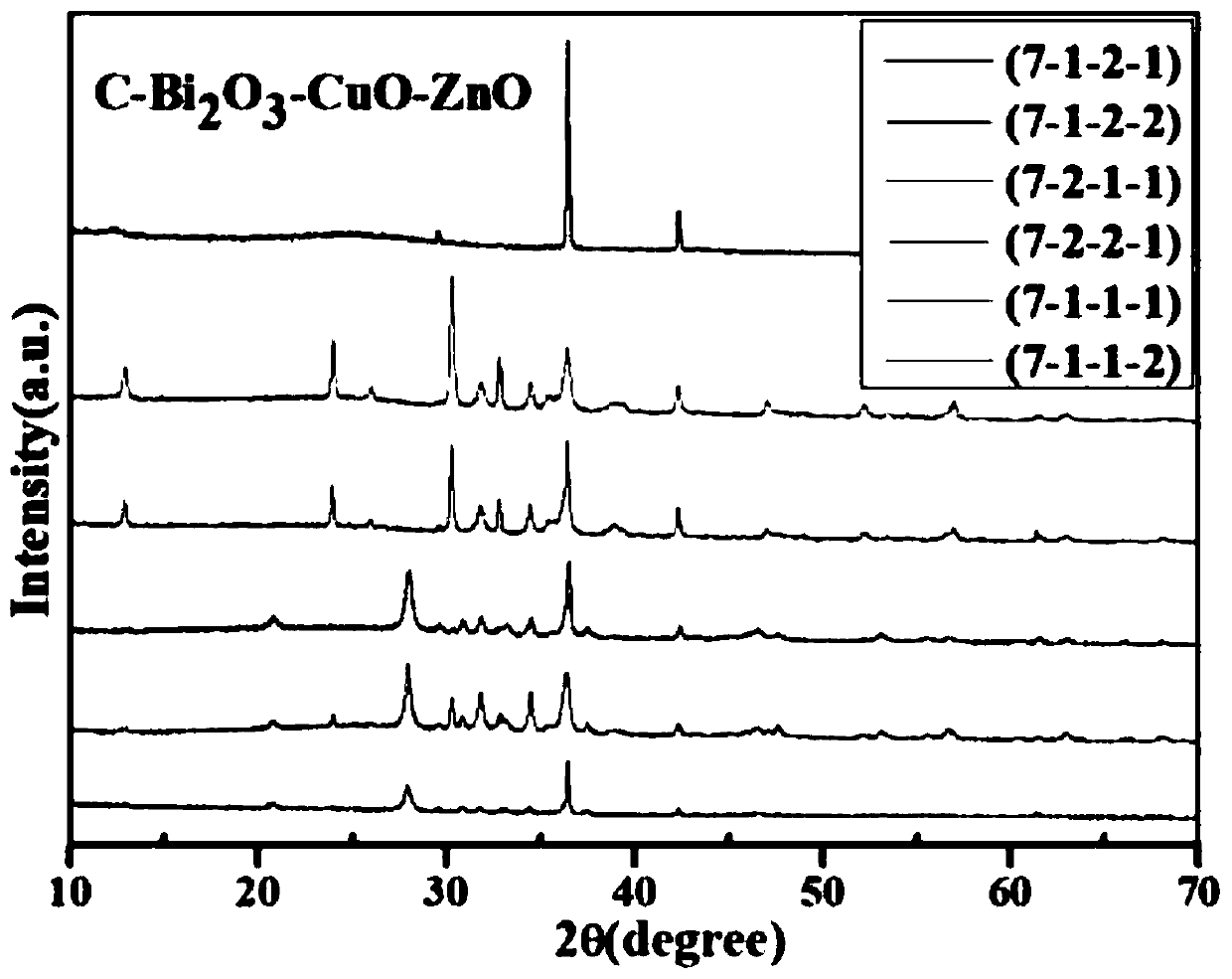

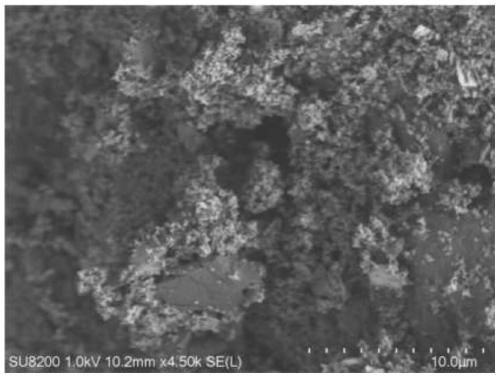

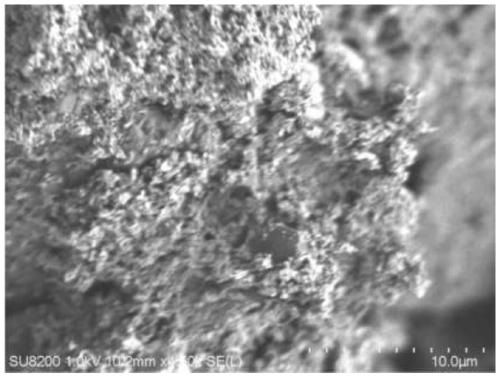

C-Bi2O3-CuO-ZnO adsorbing material and preparation method and application thereof

ActiveCN111097384AAchieving stirringDisadvantages of achieving uneven heatingOther chemical processesWater contaminantsActivated carbonPhysical chemistry

The invention discloses a C-Bi2O3-CuO-ZnO adsorbing material and a preparation method and application thereof. The preparation method comprises the following steps of S1, adding copper salt, bismuth salt, zinc salt and activated carbon into a dilute nitric acid solution, dissolving the copper salt, the bismuth salt and the zinc salt, and obtaining a mixed solution; S2, adjusting the pH value of the mixed solution obtained in the step S1 to 5-12 to obtain a reaction solution; and S3, carrying out hydrothermal reaction on the reaction solution obtained in the step S2 under the conditions of stirring and microwaves to obtain the C-Bi2O3-CuO-ZnO adsorbing material. The C-Bi2O3-CuO-ZnO adsorbing material provided by the invention has a good adsorption and removal effect on heavy metal ions, andcan be applied to environmental treatment of industrial sewage and wastewater containing heavy metals.

Owner:HEFEI UNIV

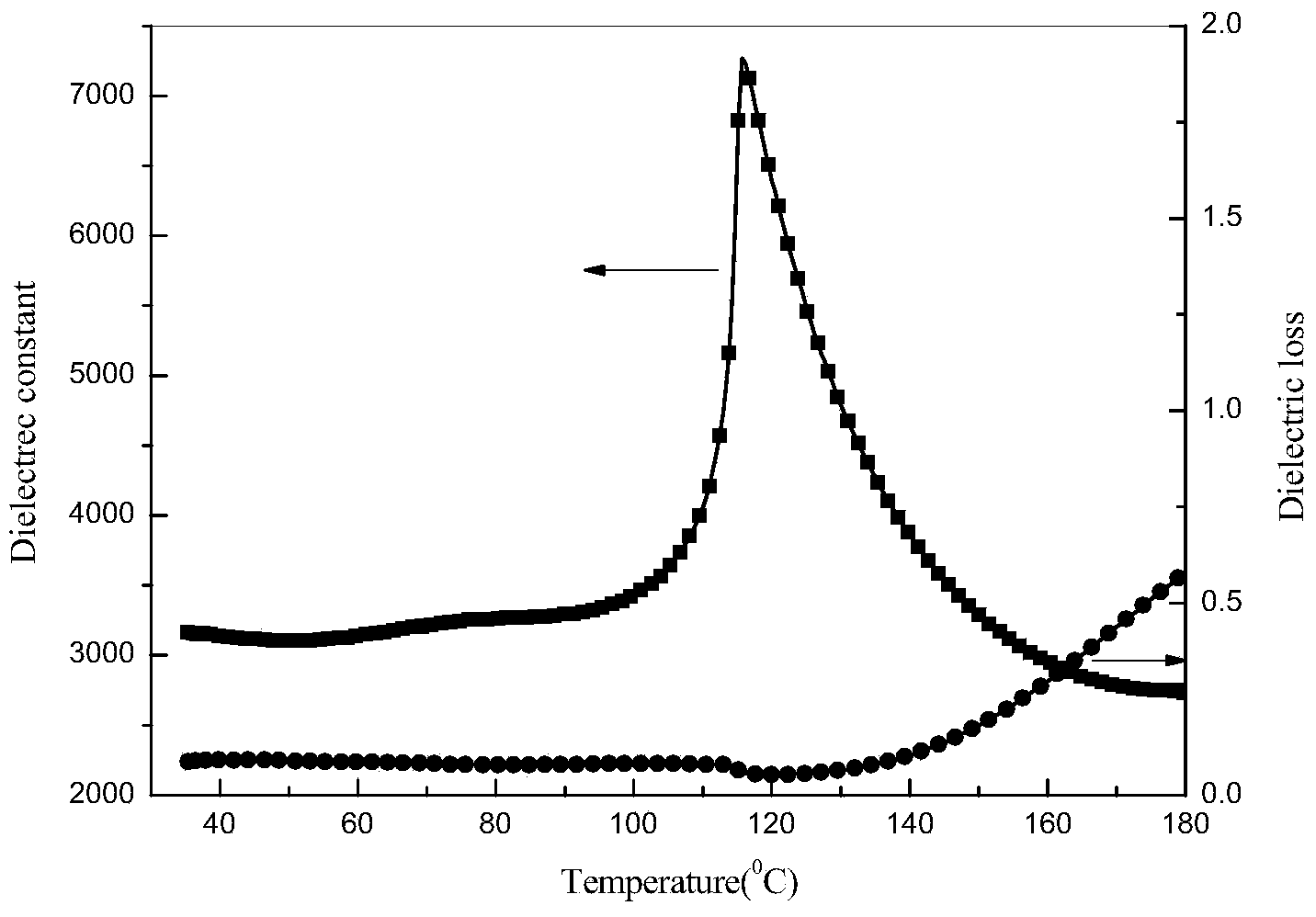

Method for preparing binderless BaTiO3 ceramic through microwave-assisted method

The invention discloses a method for preparing a binderless BaTiO3 ceramic through a microwave-assisted method. The method comprises the following steps: dissolving BaCl2.H2O and TiCl4 into deionized water, adding mineralizer NaOH, and uniformly stirring to obtain a coprecipitation precursor A; pouring the coprecipitation precursor A into the lining of a microwave hydrothermal reaction kettle, then placing the lining into the microwave hydrothermal reaction kettle for reaction, taking a reactant out after furnace temperature is naturally cooled to room temperature, washing, and drying to obtain nanometer BaTiO3 powder; briquetting the obtained BaTiO3 powder, and then screening and granulating obtained BaTiO3 powder blocks through a mesh screen to obtain powder with the granularity of 75-48 micrometers; and forming the obtained powder, sintering a formed billet to obtain the BaTiO3 ceramic after furnace cooling. The method disclosed by the invention omits the step of bonding agent addition in a preparation process, has the advantages of low preparation cost, easiness for operation, short reaction period, low sintering temperature, good ceramic density and excellent dielectric property of a product and achieves the dielectric constant up to 3000 and the dielectric loss less than 0.1 at the room temperature of a sample.

Owner:JIANGSU SHUSHI LIGHTING CO LTD

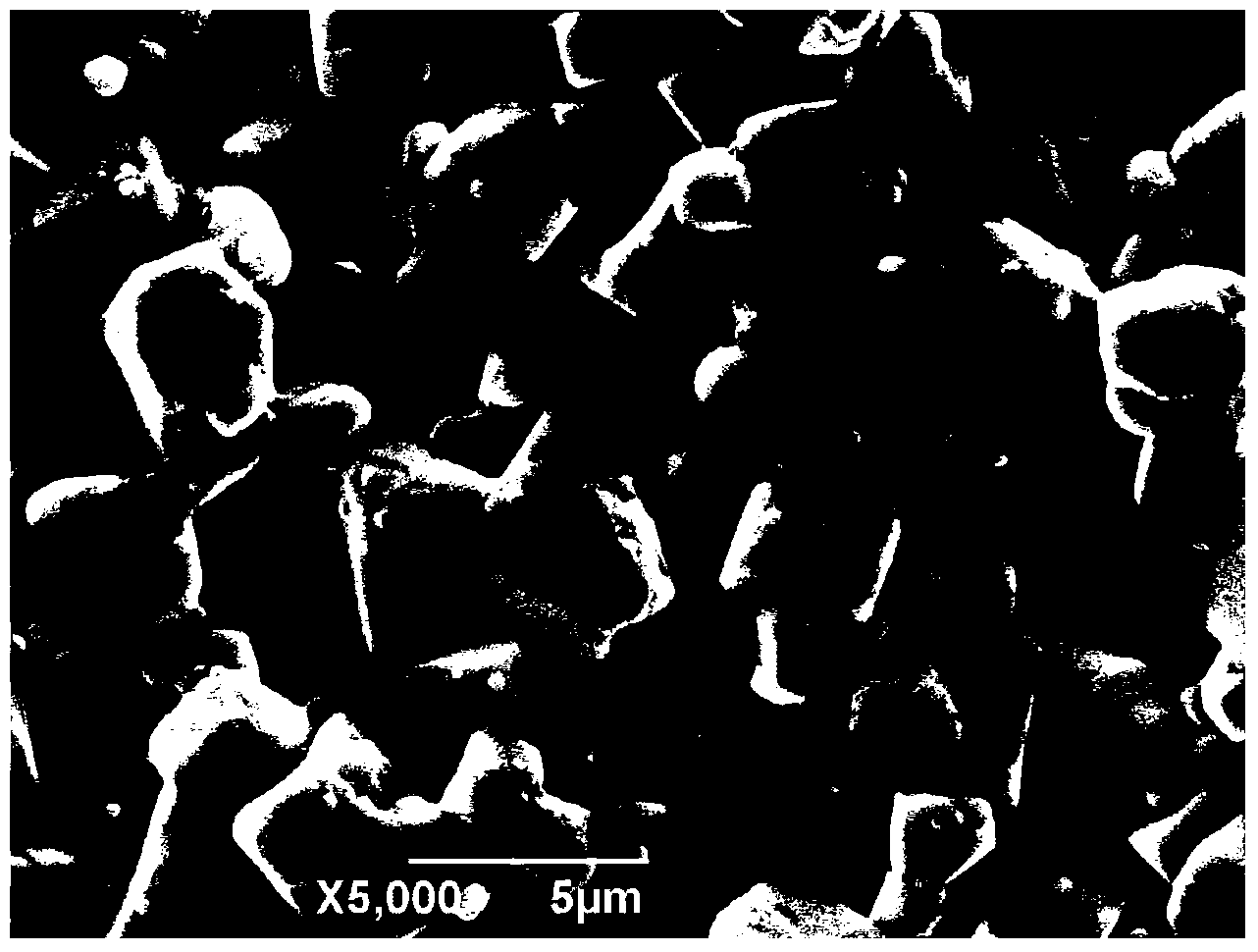

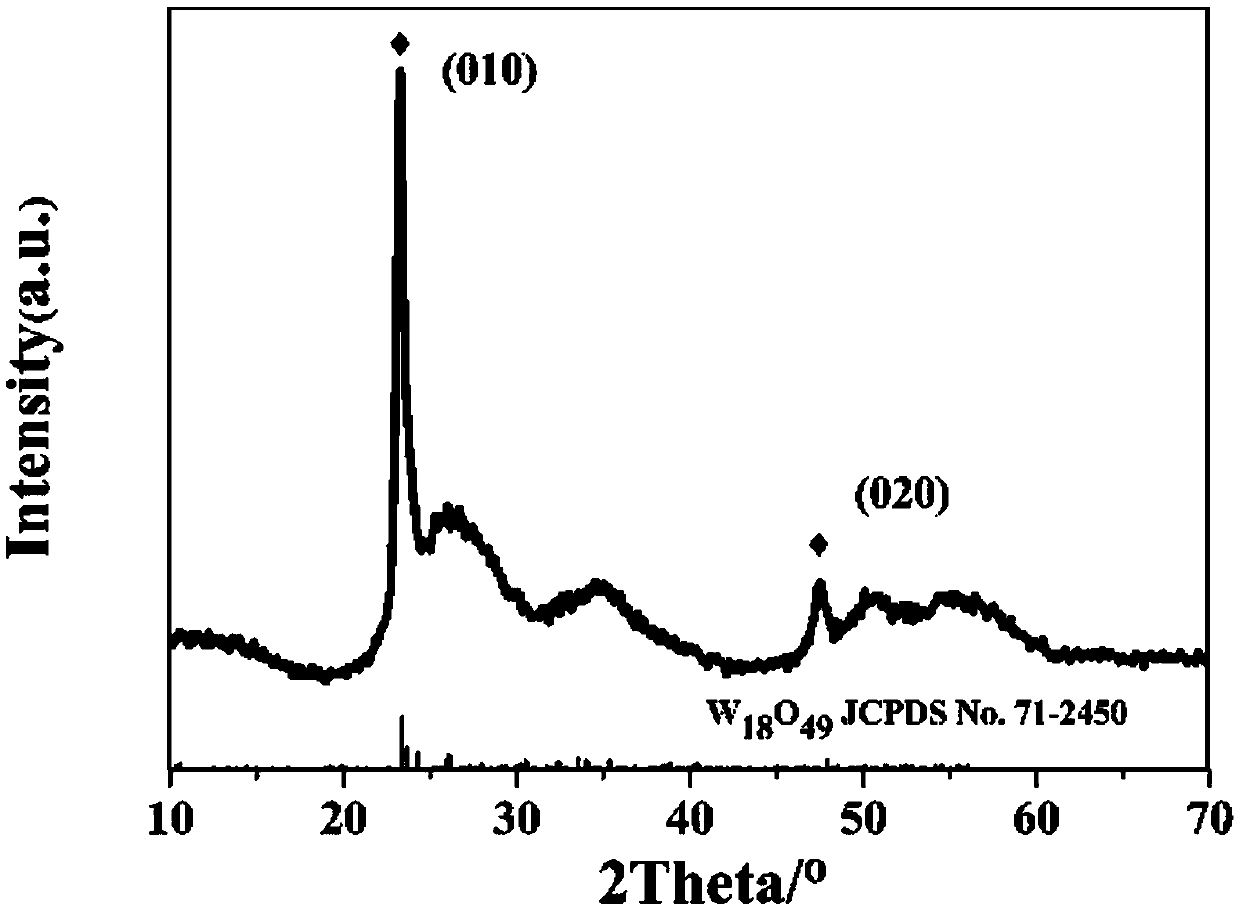

Method for synthesizing W18O49 nano material through microwave assistance

InactiveCN109650454AOvercome the disadvantage of uneven heatingFast heatingTungsten oxides/hydroxidesNanotechnologyHysteresisPropylamine

The invention relates to a method for synthesizing a W18O49 nano material through microwave assistance. The method comprises the steps that analytical pure (NH4)10W12O41.5H2O is added to alcohol, anda solution A is prepared; sodium oleate and n-propylamine are added to the solution A to obtain a solution B; the mixed solution B is placed in a microwave hydrothermal reaction kettle, and a microwave hydrothermal instrument is adopted for conducting a hydrothermal reaction; after the reaction is completed, the mixture is naturally cooled to the room temperature, a final reactant is centrifuged and washed through deionized water and absolute ethyl alcohol separately, and the centrifuged and washed substance is dried to obtain the pure-phase W18O49 nano material. According to the method, by adopting a microwave technology, the microwave is used as a heating tool, and compared with a traditional preparation method, stirring in the molecular level can be achieved, and the method has the advantages that the heating speed is high, heating is even, and the temperature gradient or the hysteresis effect exists. The defect is overcome that heating of a hydrothermal container is uneven, the reaction time is shortened, and the working efficiency is improved.

Owner:SHAANXI UNIV OF SCI & TECH

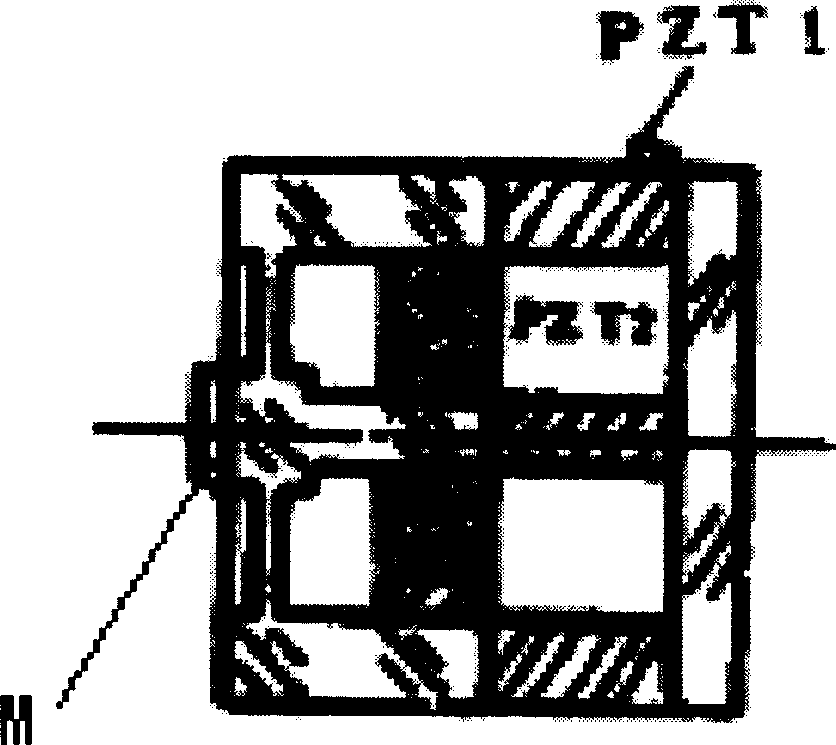

Apparatus and method for controlling ring laser optical cavity length

The present invention discloses device and method of controlling optical cavity length of annular laser. The device consists of mainly a heat insulated container, a heat insulted elastic diaphragm and a piezoelectric ceramic chip. The heat insulted elastic diaphragm is fixed onto the heat insulated container, and the piezoelectric ceramic chip has its two ends connected separately with the heat insulted elastic diaphragm and the heat insulated container. The method includes connected the device with annular laser, filling the capillary of the annular laser with dry air, altering the voltage applied onto the piezoelectric ceramic chip to change the refractive index of dry air, to change the compensation amount of the optical cavity length of annular laser for being near to the variance in the optical cavity length of annular laser caused by outer environment change, and to realize the control on the optical cavity length of annular laser. The present invention has the advantages of fast response, high sensitivity, low power consumption, etc.

Owner:XIDIAN UNIV

Method for self-assembling near-spherical Sm2O3/CuO nanometer composite

ActiveCN104588025AUniform sizeGood dispersionMetal/metal-oxides/metal-hydroxide catalystsProcess equipmentFree cooling

The invention discloses a method for self-assembling a near-spherical Sm2O3 / CuO nanometer composite. The method comprises the following steps: adding SmCl3.6H2O to deionized water under magnetic stirring to prepare a solution A; dissolving CuCl2.2H2O in deionized water under magnetic stirring to form a solution B; mixing the solution A with the solution B according to different volume ratios and regulating pH of the solution to 5-8 by using an ammonia water solution to form a reaction precursor solution; pouring the reaction precursor solution into a hydrothermal kettle, placing into a microwave hydrothermal reaction instrument to perform a hydrothermal reaction after sealing the kettle, naturally cooling to room temperature after the reaction is ended; and centrifugally washing a sample and drying, and calcining in a muffle furnace at temperature of 500-800 DEG C for 2-5h to obtain the self-assembled near-spherical Sm2O3 / CuO nanometer composite. A reaction medium adopted by the method disclosed by the invention is a water solution; the method is high in safety, easily available in reaction raw materials, strong in feasibility, and simple in process equipment.

Owner:深圳市汇益德环保材料有限公司

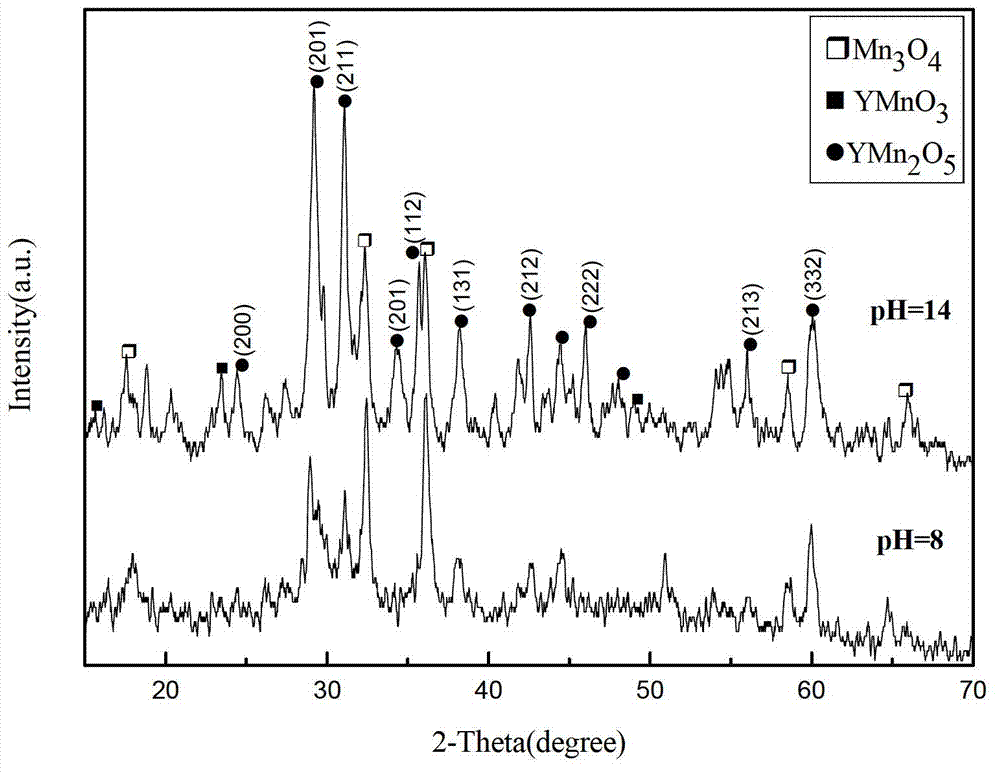

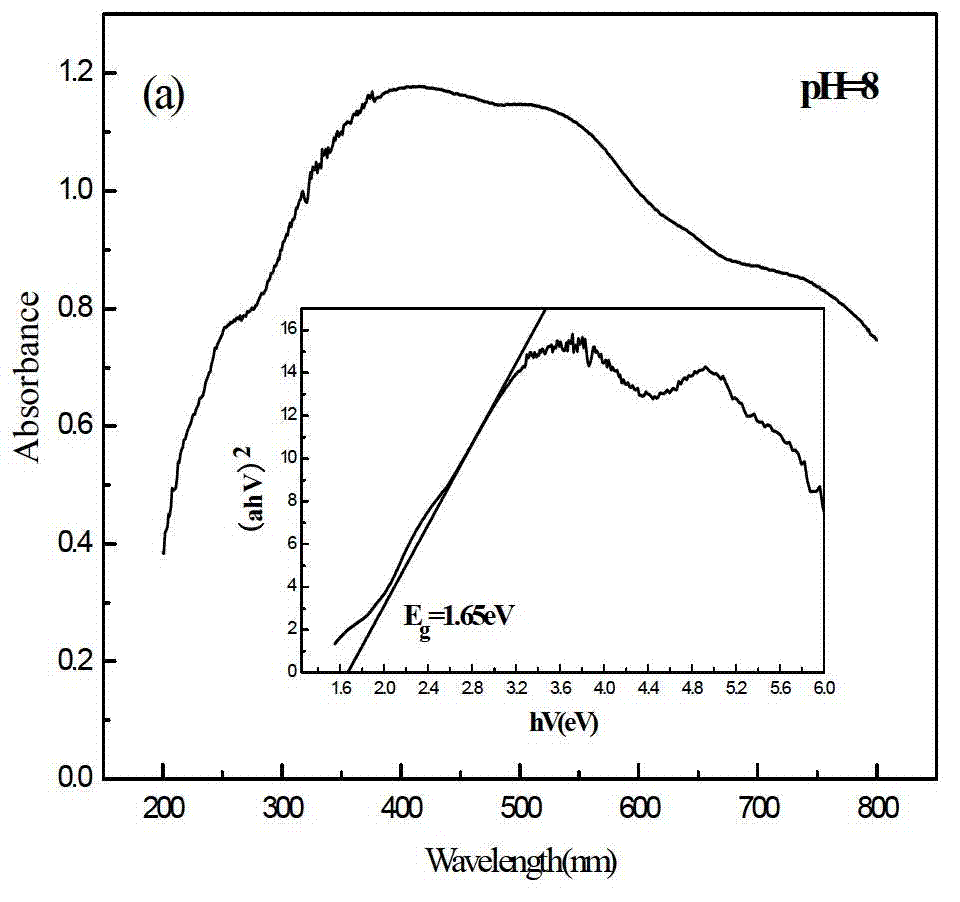

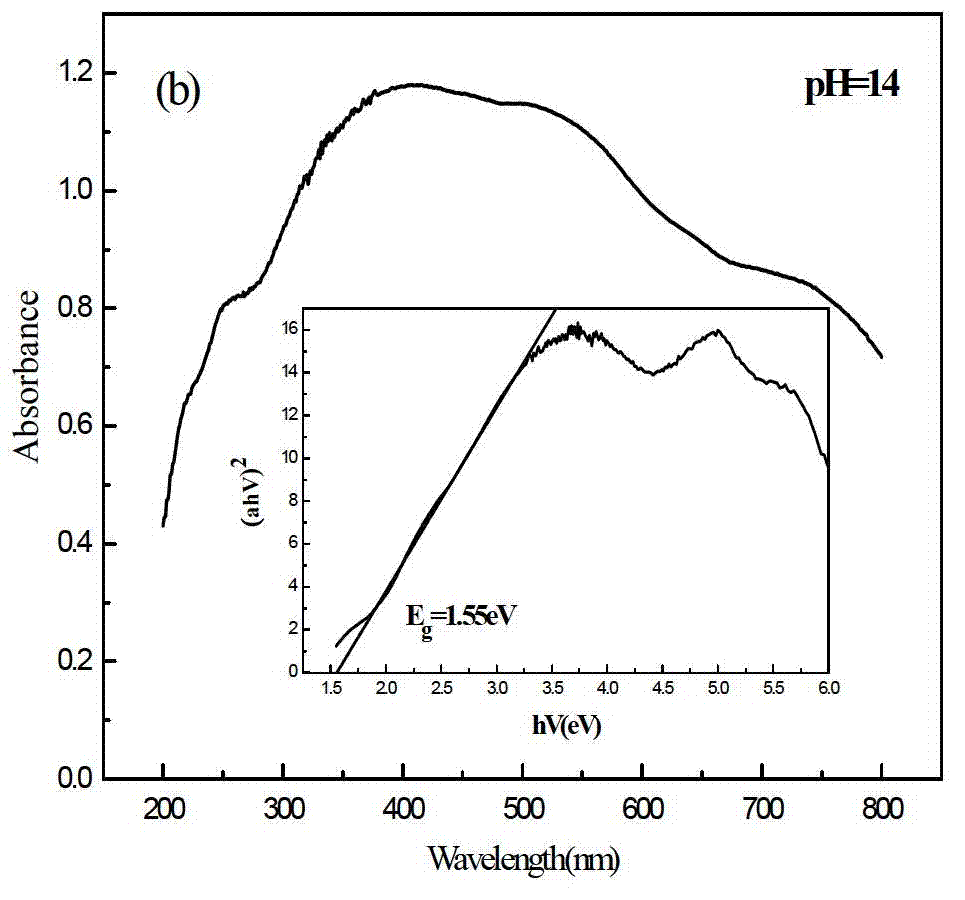

Preparation method of manganese oxide yttrium semiconductor photocatalytic powder

InactiveCN102895968ANarrow optical bandgapHigh chemical activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRoom temperatureHydrothermal synthesis

The invention provides a preparation method of manganese oxide yttrium semiconductor photocatalytic powder. The method comprises dissolving yttrium nitrate, potassium permanganate and manganese nitrate into deionized water in accordance with a Y / Mn mole ratio of 1 : 1.5 and a Mn<7+> : Mn<2+> mole ratio of 1 : 4; adding sodium hydroxide into the solution in drops, adjusting a pH value to 8 to 14 and forming a uniform precursor solution; pouring the precursor solution into a hydrothermal reactor and sealing; putting into a microwave digestion system for microwave hydrothermal synthesis, cooling to room temperature, washing the product for several times with the deionized water and absolute ethyl alcohol, and then calcining under 1100 DEG C. By using a microwave hydrothermal method in addition to a solid-phase method, the preparation method can effectively reduce reaction temperature and improve powder activity. The manganese oxide yttrium powder prepared by the method has a narrow optical band gap (Eg=1.55 eV), and meanwhile, has an absorption wavelength of more than 800 nm, thereby being of great significance for exploring new types of semiconductor photocatalytic materials capable of responding to visible light.

Owner:SHAANXI UNIV OF SCI & TECH

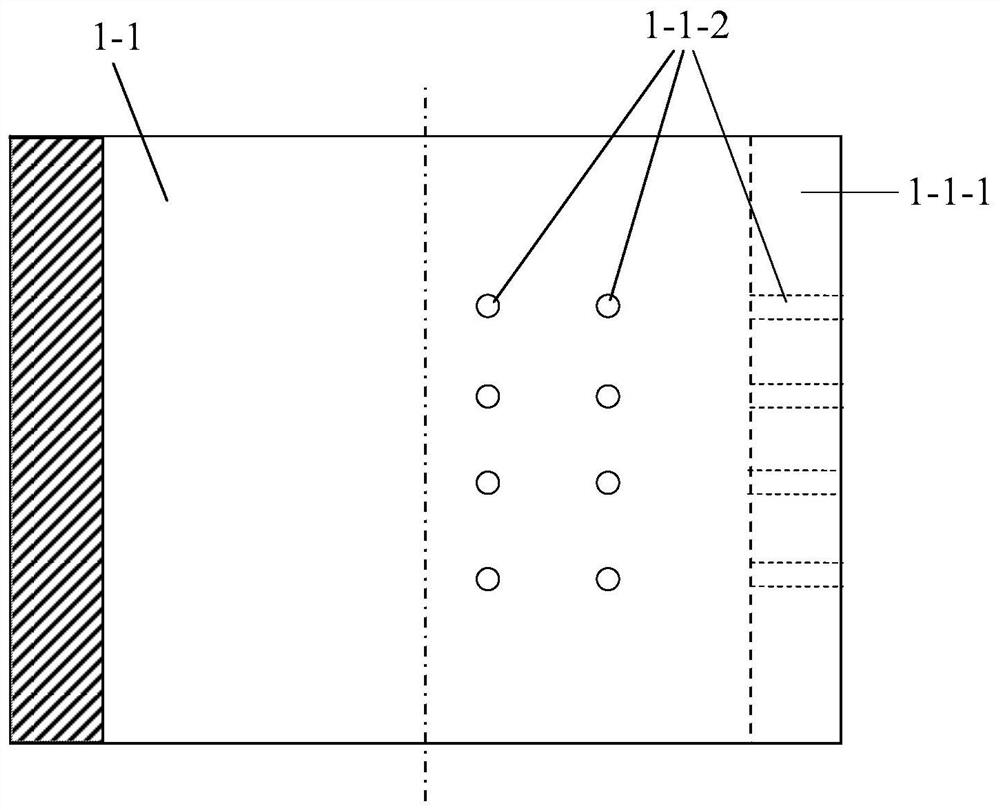

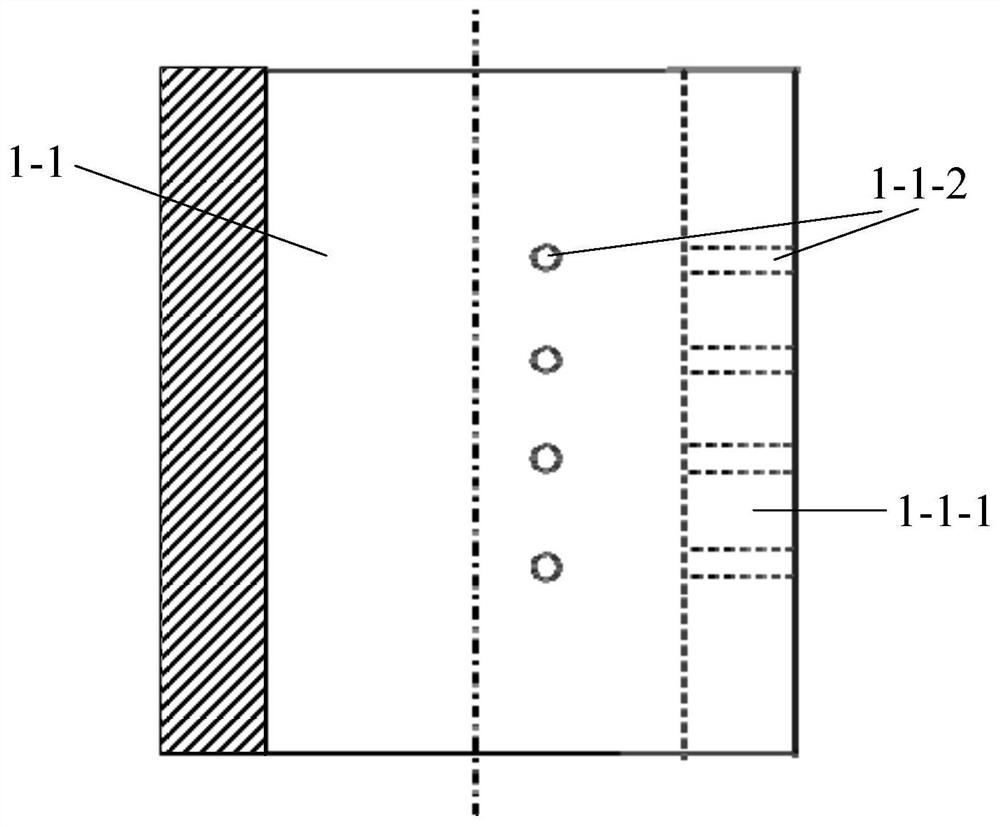

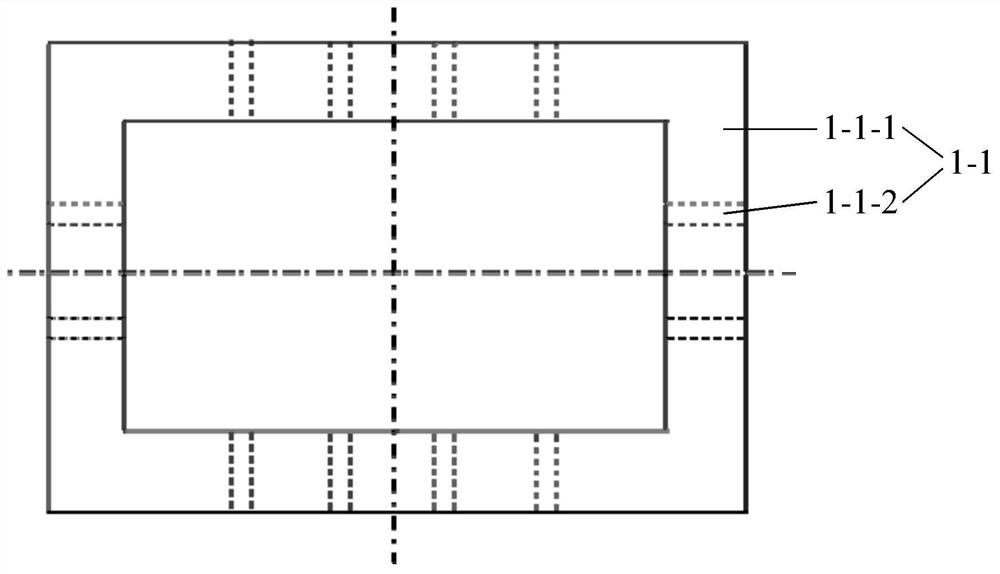

Quasi-temperature isostatic pressing forming method and die

ActiveCN113172731ASmall expansion coefficientAvoid damageMouldsMould auxillary partsMechanical engineeringOrthographic projection

The invention discloses a quasi-temperature isostatic pressing forming method and a die. An outer die comprises a female die and male dies arranged at the two ends of the female die, the female die is of a transparent cylinder structure, exhaust holes are evenly and symmetrically formed in the wall face of the female die, and a cavity defined by the female die and the male dies is filled with an inner die; a first cavity used for containing a sample is formed in the inner die, the first cavity is in a cuboid shape, the inner die comprises a plurality of inner die blocks, the inner die blocks comprise contact inner die blocks and supporting inner die blocks, and the orthographic projection range from each face of the first cavity to the inner wall face of the outer die is provided with the contact inner die blocks used for making contact with the surface of the sample; and the sizes of the contact inner die blocks corresponding to the two opposite faces in the first cavity are the same, and the area, outside the contact inner die blocks, of an inner cavity of the outer die is filled with the supporting inner die blocks. According to the quasi-temperature isostatic pressing forming method and the die, through reasonable arrangement of the component structure, uniform and compact forming of a green body is achieved, the quasi-temperature isostatic pressing forming method and the die are suitable for the conditions with and without gas product discharging in the forming process, and the application range is wide.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

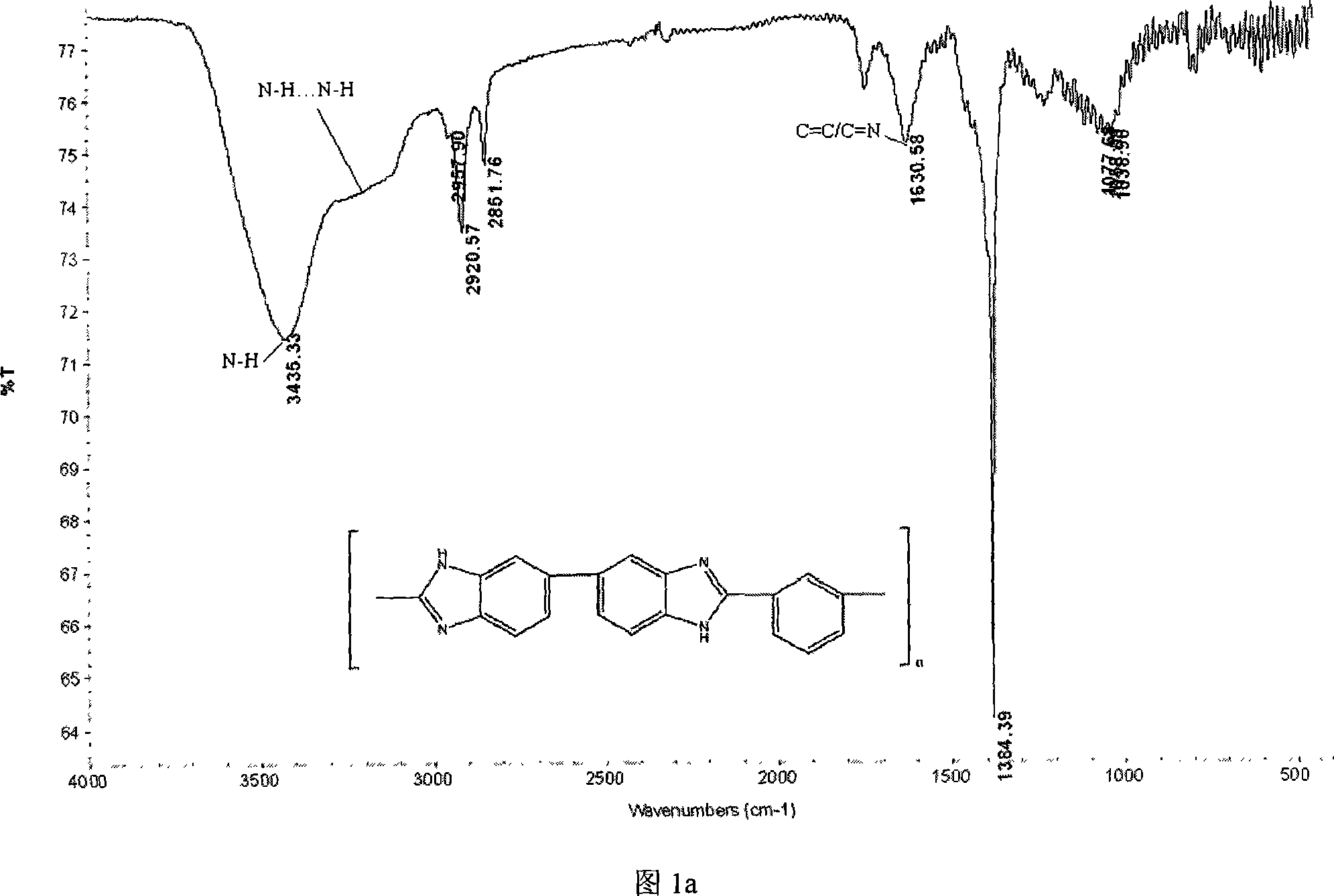

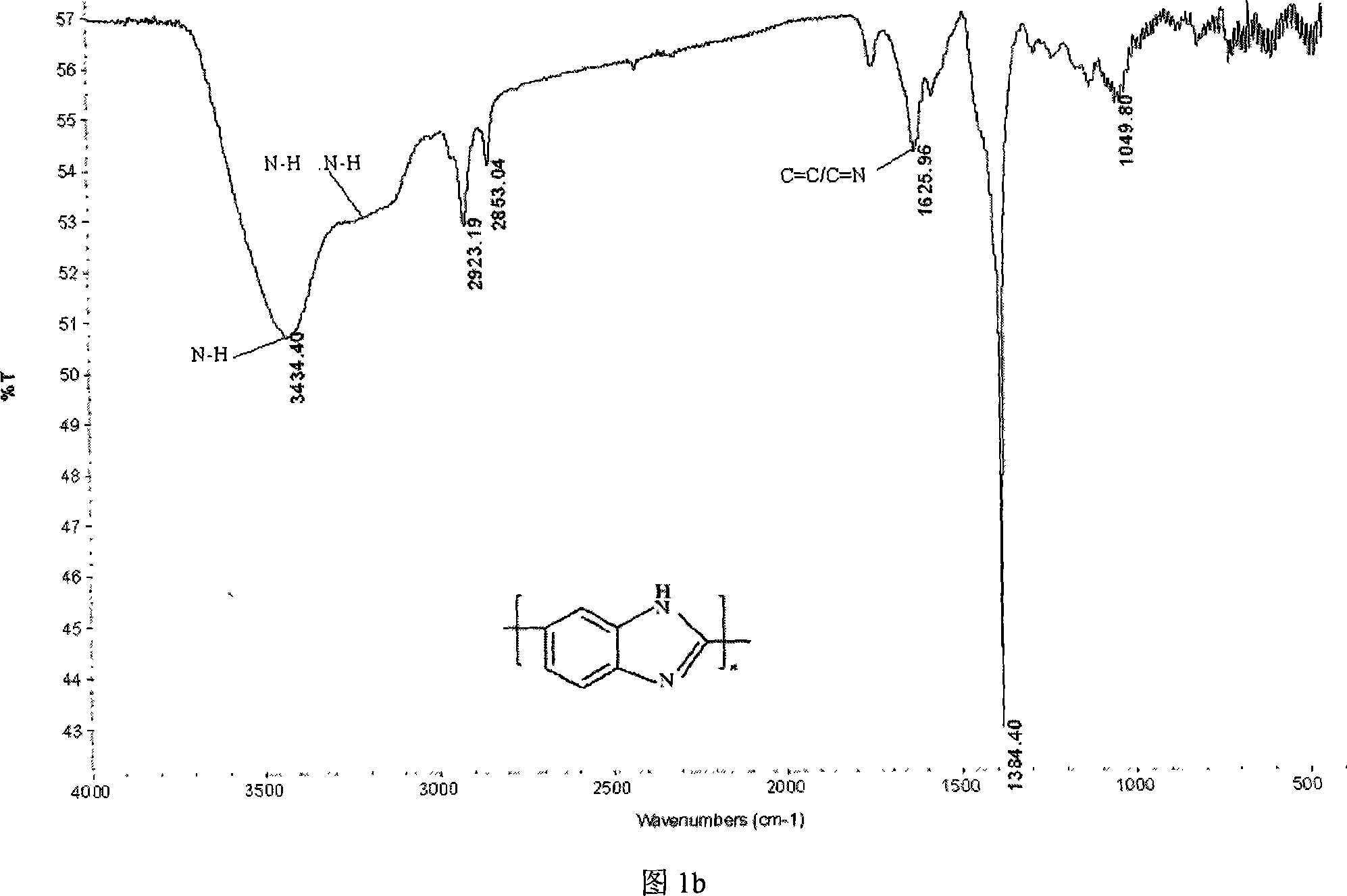

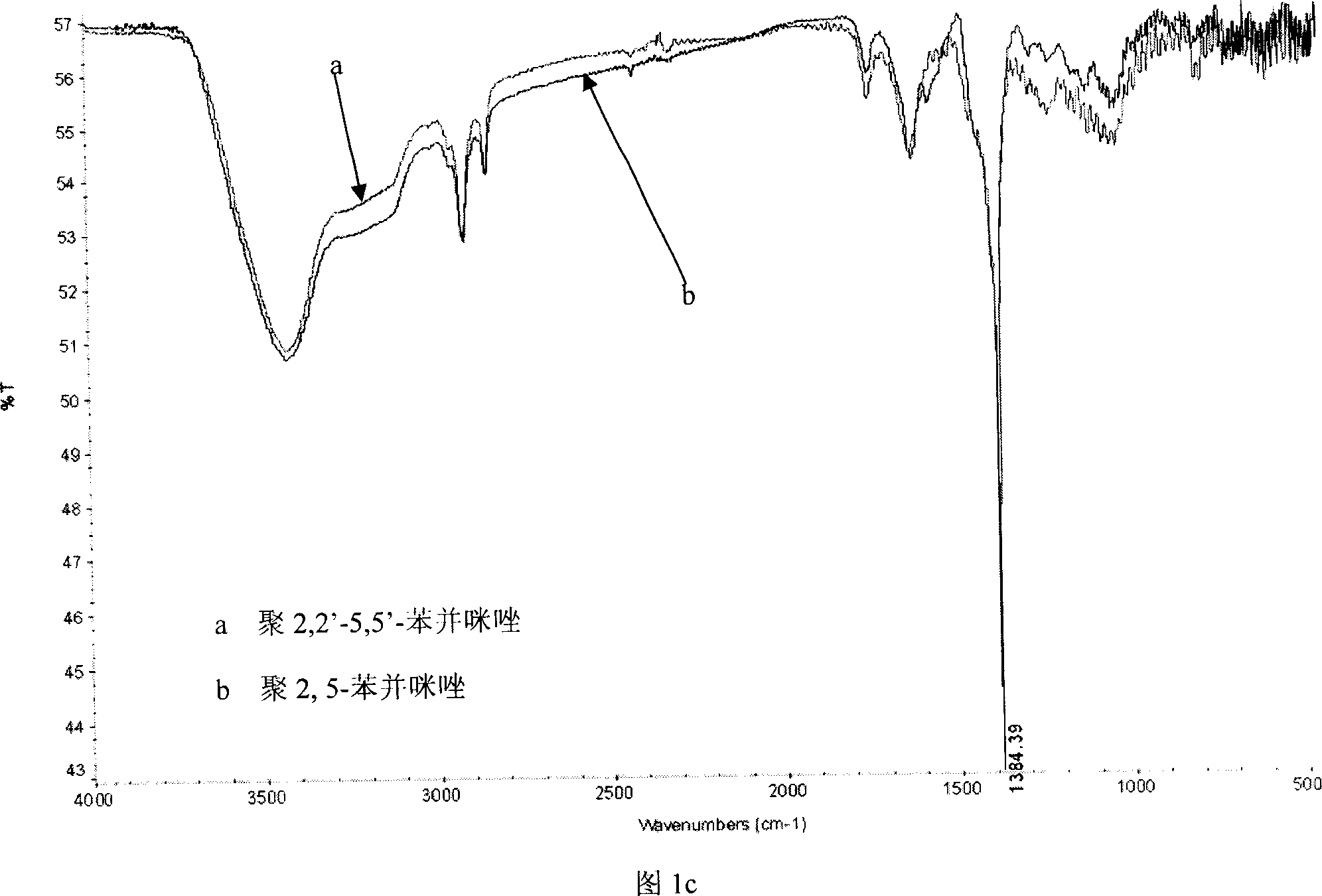

Microwave synthesis of poly-2,2',5,5'-benzmidazole and poly-2,5-benzimidazole

Microwave synthesis of poly-2, 2'-5, 5'-benzimidazole and poly-2, 5-benzimidazole are disclosed. The process of poly-2, 2'-5, 5'-benzimidazole is carried out by taking paraphosphoric acid PPA as solvent, condensation polymerizing under nitrogen protection, adding into 3,3'-diamino-benzidine, dissolving, adding into isophthalic acid, putting mixed liquid into microwave oven, programmed raising temperature at 300-500W, pouring reactant into deionized water, washing by water to become neutral, adding into saturated sodium bicarbonate solution, neutralizing, decompressing, extraction filtering, washing by water, washing by alcohol, drying and grinding into powders; process of poly-2, 5-benzimidazole is carried out by taking PPA as solvent, condensation polymerizing under nitrogen protection, agitating while heating to 200 degree, adding into 3, 4-diamino-benzoic acid, putting mixed liquid into microwave oven, programmed raising temperature at 300-500W, pouring reactant into deionized water, washing by water to become neutral, adding into caustic soda solution 1 mol / L, neutralizing, boiling at 100 degree for 6 hrs remove caustic soda, decompressing, extraction filtering, washing by water, washing by alcohol, drying and grinding into powders. It' efficient, has better radiant energy and shorter reactive time.

Owner:NORTHEASTERN UNIV

A kind of preparation method of hollow sphere structure tin sulfide/tin oxide lithium ion battery negative electrode material

ActiveCN109301204BLight in massLarge specific surface areaCell electrodesSecondary cellsLithium electrodeTin oxide

Owner:SHAANXI UNIV OF SCI & TECH

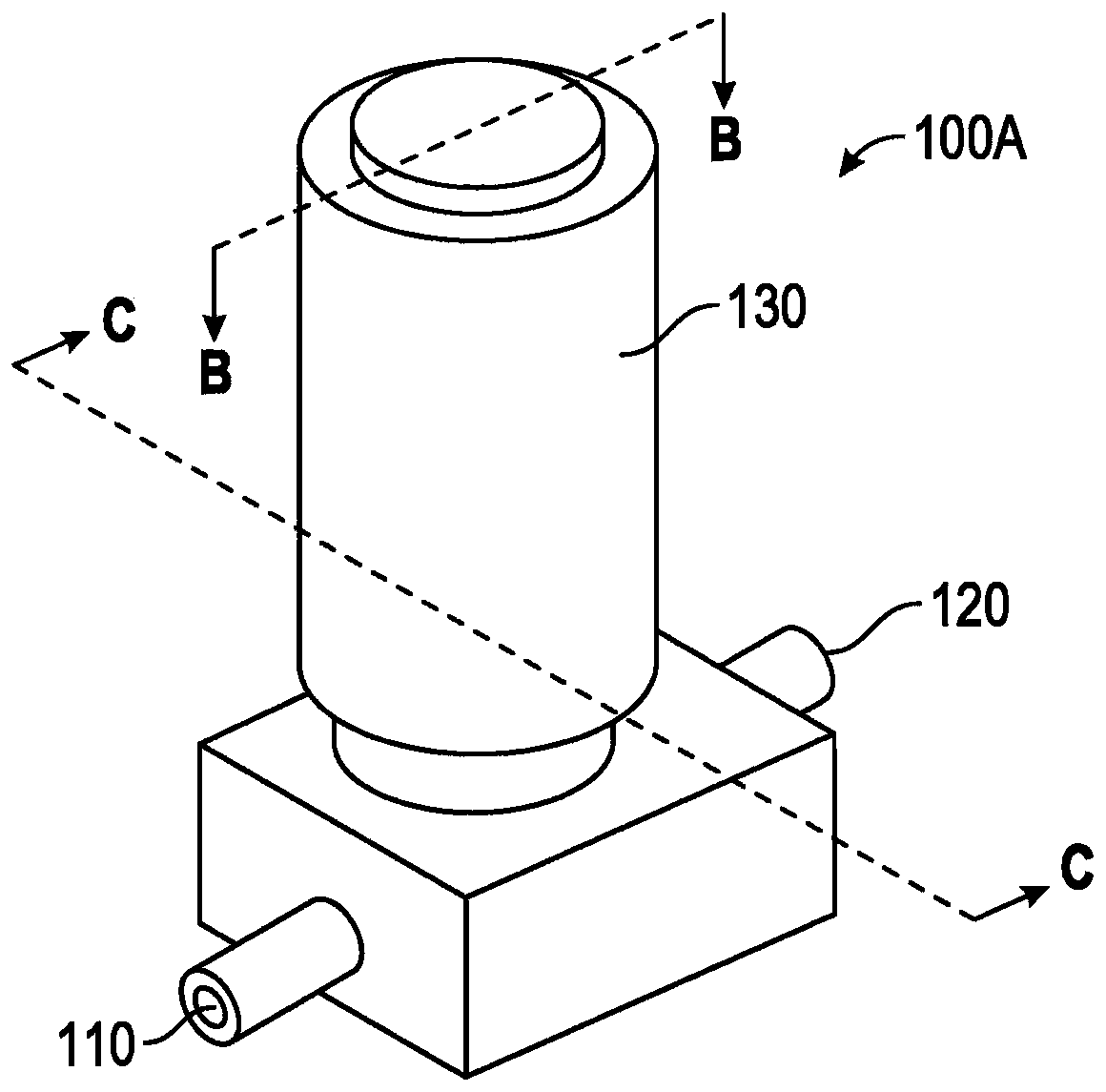

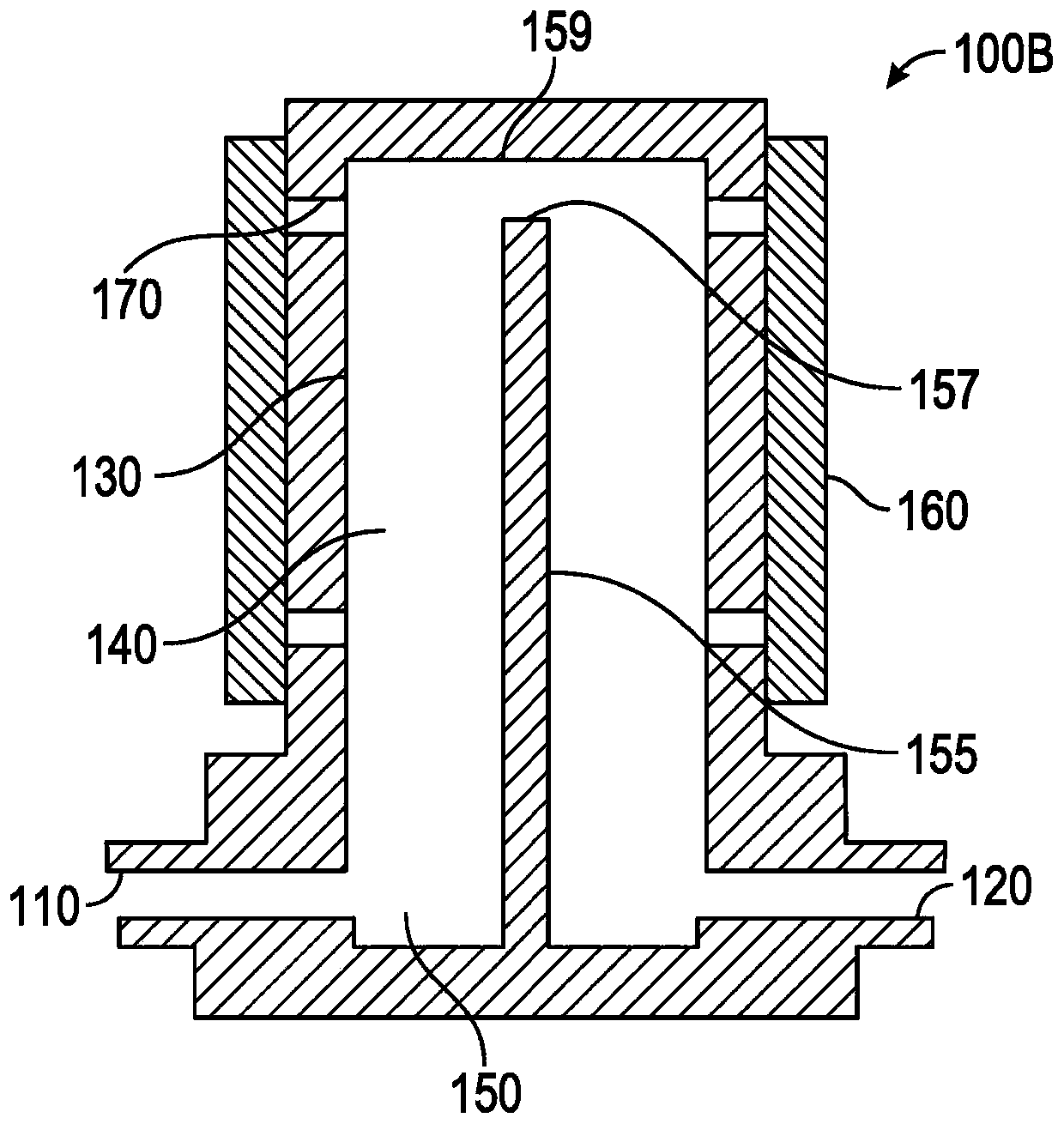

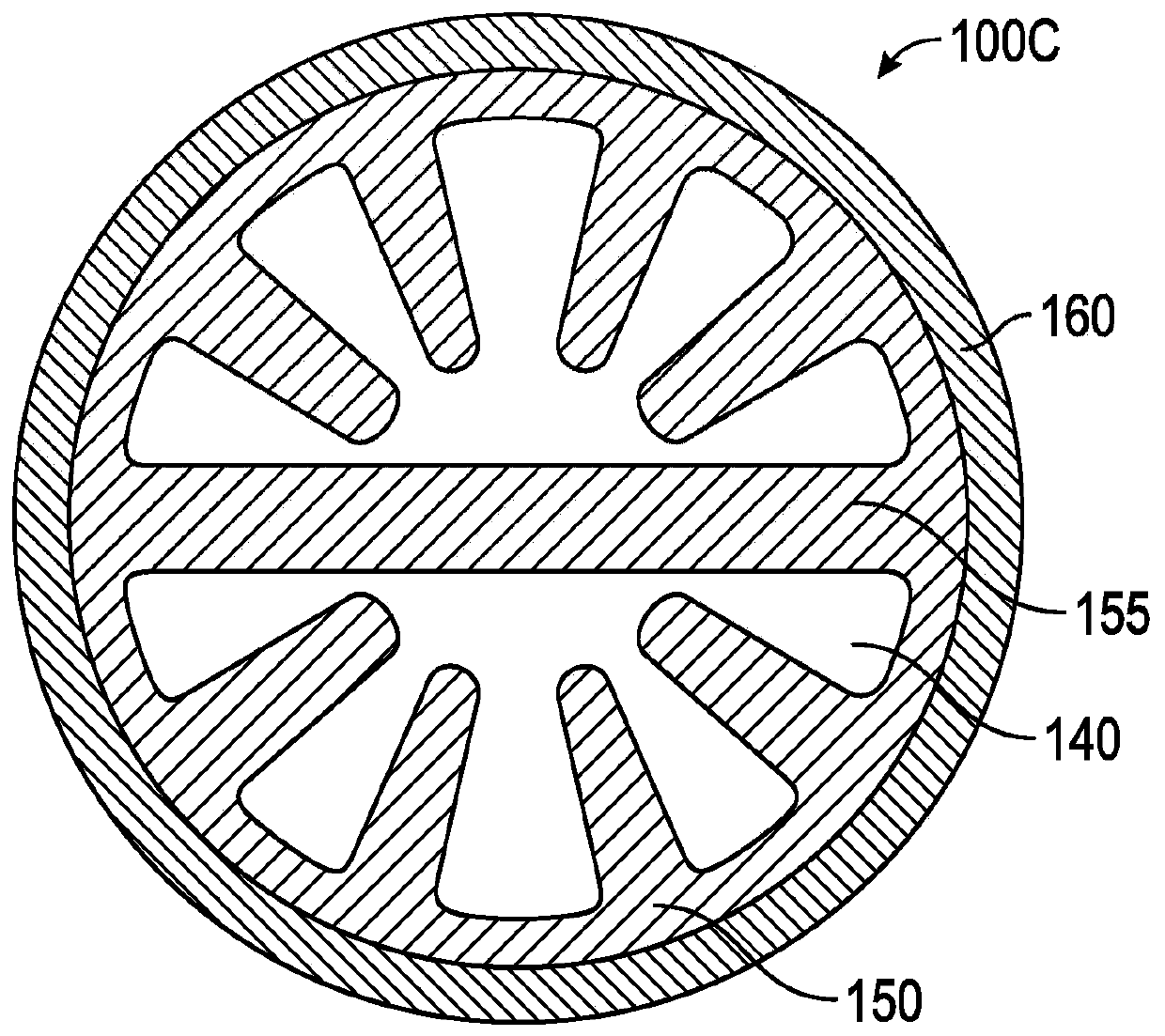

Systems and methods for reference volume for flow calibration

ActiveCN109891199AGuaranteed to workNo temperature gradientTesting/calibration apparatusLevel controlEngineeringThermal contact

A reference volume for use with pressure change flow rate measurement apparatus has an internal structure comprising elements with cross section and length comparable to the cross section and length of adjacent interstitial fluid regions. The reference volume may have one or more heat conduction elements exterior to and in good thermal contact with a corrosion resistant material that defines the internal fluid holding region.

Owner:FLOW DEVICES & SYST INC

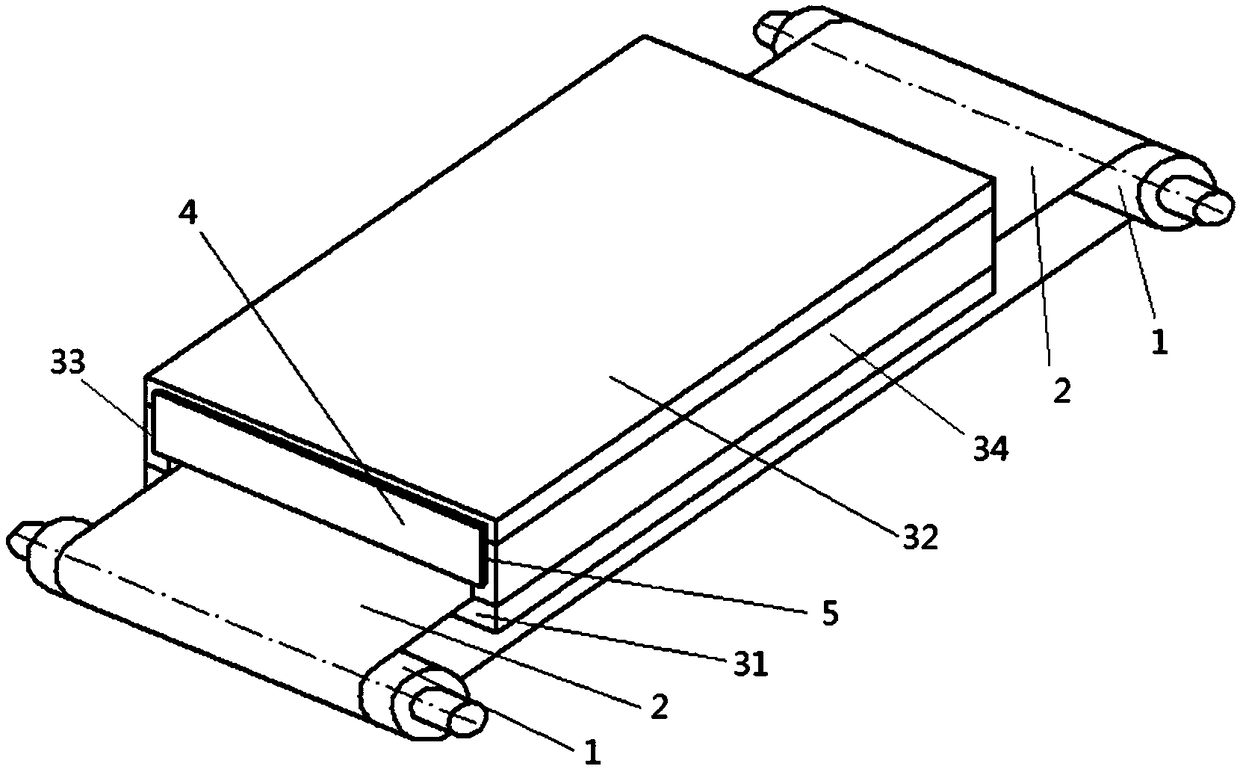

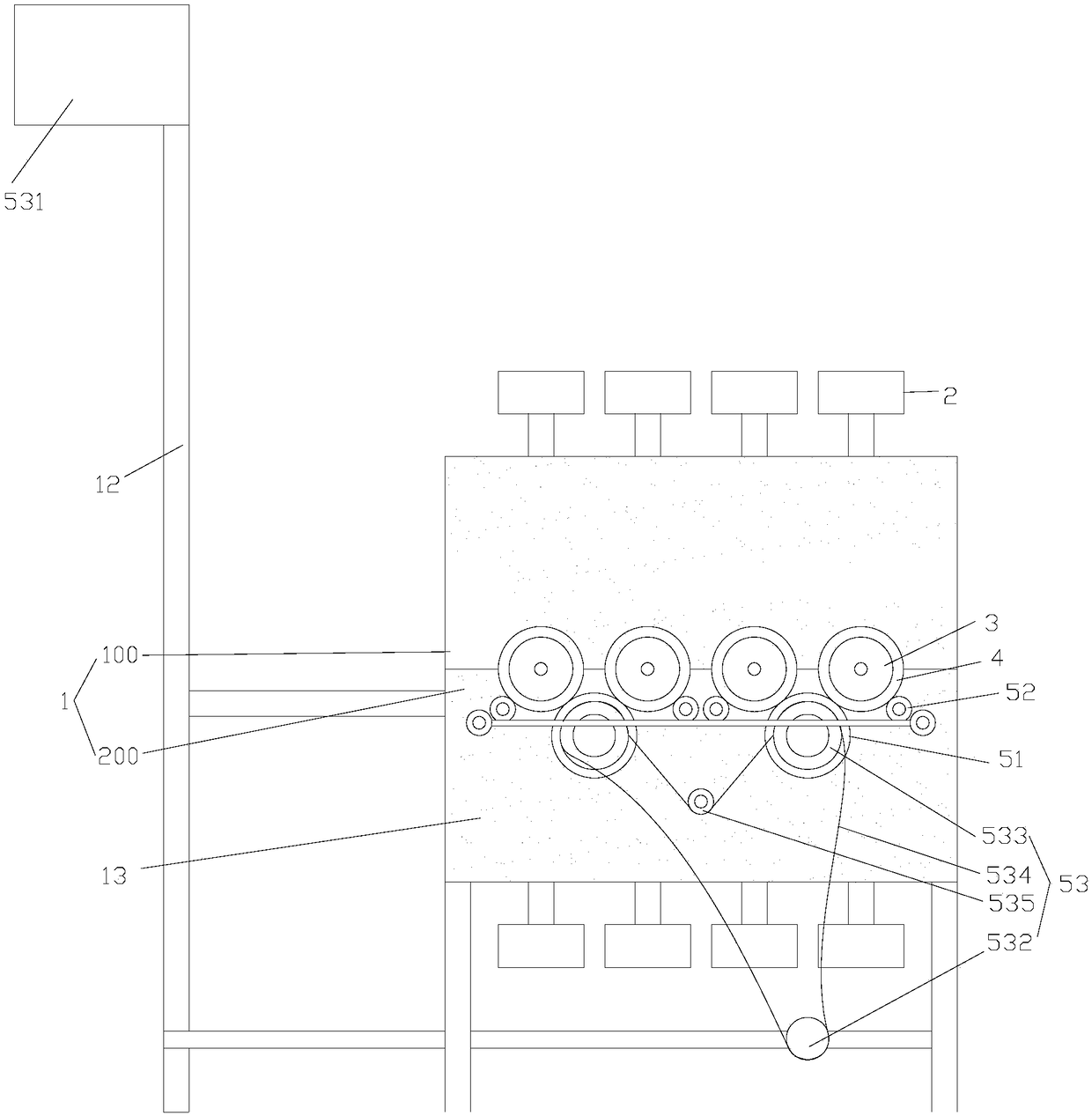

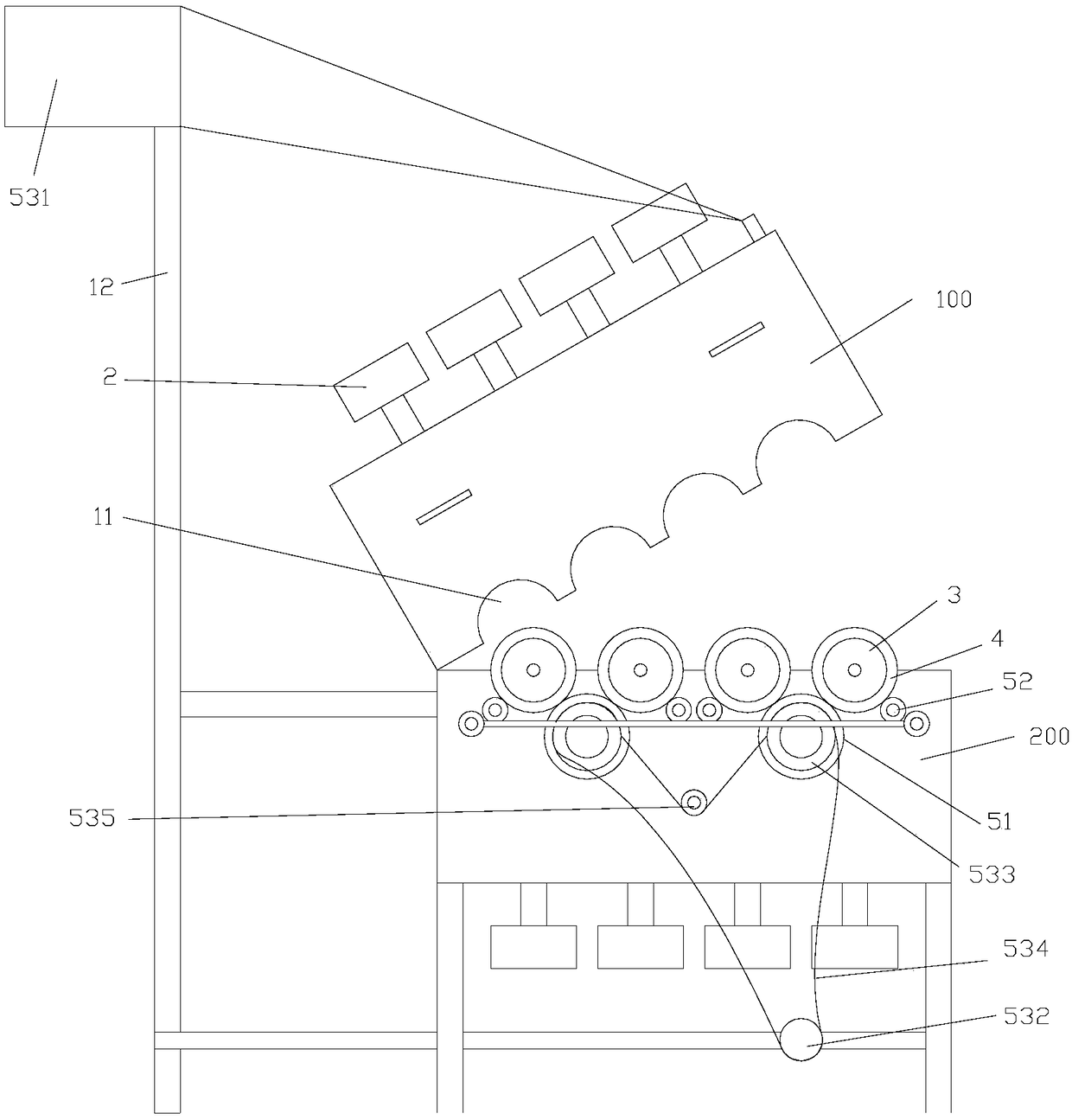

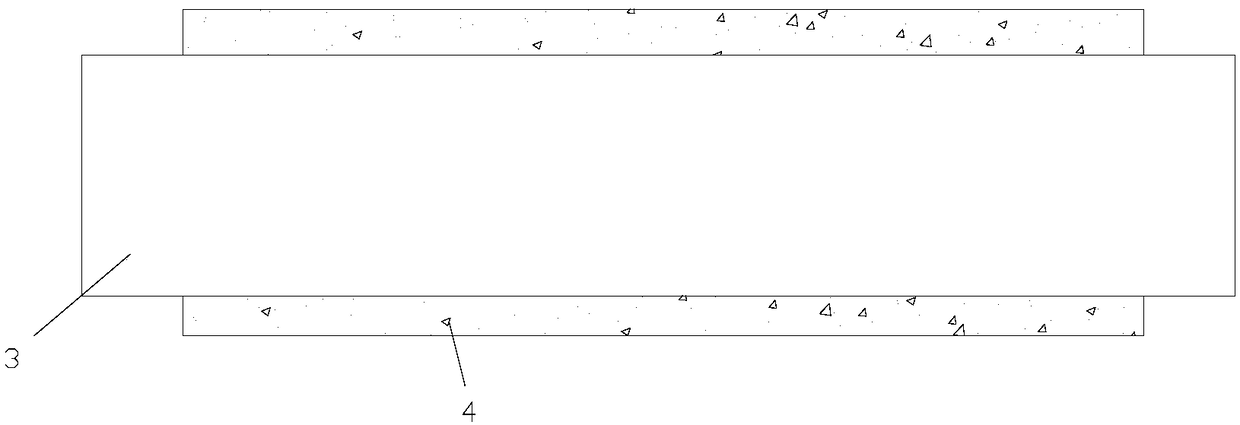

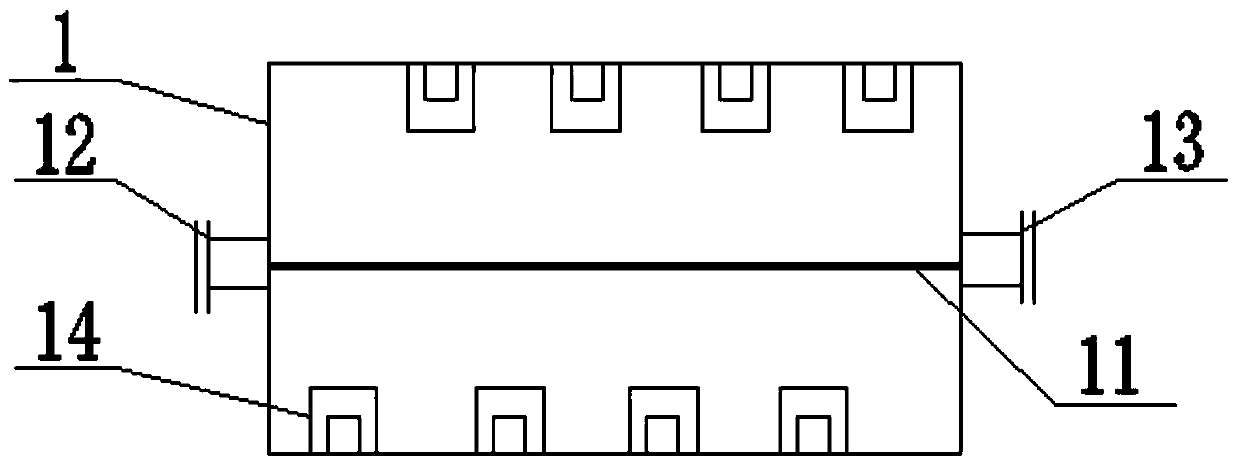

Tunnel-type constant-temperature heating furnace

The invention relates to a tunnel-type constant-temperature heating furnace. According to the tunnel-type constant-temperature heating furnace, a constant-temperature tunnel is formed by an upper heating plate, a lower heating plate and two side plates connected with the upper heating plate and the lower heating plate, and the front end and the rear end of the constant-temperature tunnel are provided with openings. Two gates are separately mounted at the openings in the front end and the rear end of the constant-temperature tunnel. Two wheels are located on the front portion and the rear portion of the constant-temperature tunnel correspondingly. A conveying belt penetrates through the constant-temperature tunnel and surrounds the two wheels. The portion, located in the constant-temperature tunnel, of the conveying belt is attached to the lower heating plate. The temperature in the tunnel is uniform, and a temperature gradient hardly exists; heat convection is avoided, and air can be isolated to prevent material contamination; heat conduction is rapid, and the heat efficiency is high; continuous material work is achieved, and a reliable guarantee is provided for an automatic production line; and the tunnel-type constant-temperature heating furnace can be widely applied to the food industry, the medical industry, the fine chemical engineering industry and the electronic industryand particularly to automatic production lines for liquid crystal screen hydrosol OCR and has irreplaceable functions for pre-curing hydrosol on adhesive-coated screens.

Owner:CHANGSHUN GUANGHUA MICRO ELECTRONICS EQUIP ENG CENT

Method for extracting high-valence manganese from manganese carbonate ore

This invention has provided one kind of method to leach high price manganese from manganese carbonateore, which belongs to the hydrometallurgy domain. It takes the glucose or the plant biomass and sulfuric acid as reducing agent of high pricemanganese in manganese carbonate ore, adopting microwave radiation glucose to promote high price manganese to revert, the concrete step includes: Takes 1 copy 100-200 sieve manganese carbonateore, add 10 -20 copy water to modulate the pulp; Again add 60% density sulfuric acid to pulp, the load ratio of mineral powder and sulfuric acid is 1: 6 -9; Simultaneously, add glucose or plant biomass, the load ratio of mineral powder and glucose or plant biomass is 10 -15: 1, stir evenly; radiate under 500 -1000W microwave, stir and respond for 4-10min, leach temperature is controlled at 50degree C-60 degree C, then get lixivium by filtering. This invention has the merits of lower reaction temperature, reducing acid consume and reduce leaching time of the manganese ore, high thermal using and respond rapidly.

Owner:CHONGQING UNIV

Method for preparing degradable high water-absorbing resin by using ultrasonic wave

The invention discloses a preparation method of a degradable super absorbent resin by using ultrasonic wave. Based on ultrasonic treatment technology, the invention adopts a new synthesis technology to prepare the degradable super absorbent resin. The invention is realized through the following procedures: 1. modification treatment of corn stalks; 2. ultrasonic treatment of the corn stalks; and 3. preparation of the super absorbent resin. The invention applies the ultrasonic treatment technology into the absorbent resin preparation, and greatly shortens the reaction time; after treatment, the solution polymerization occurs immediately at high temperature; the invention has simple preparation technology without nitrogen protection, and the prepared products have good water-absorption capacity. The products can improve water conditions of the soil, can be degraded into organic fertilizer, and improve crop growth environment, which is suitable for agricultural extension and utilization.

Owner:黑龙江笃信农业高科有限公司

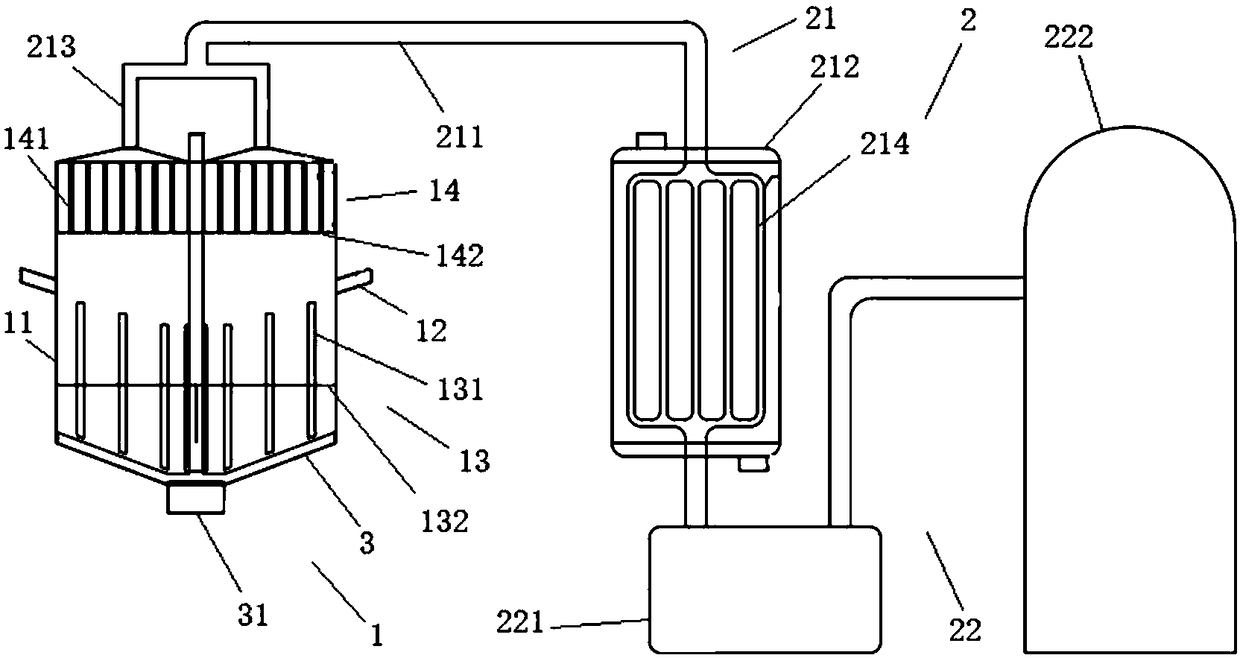

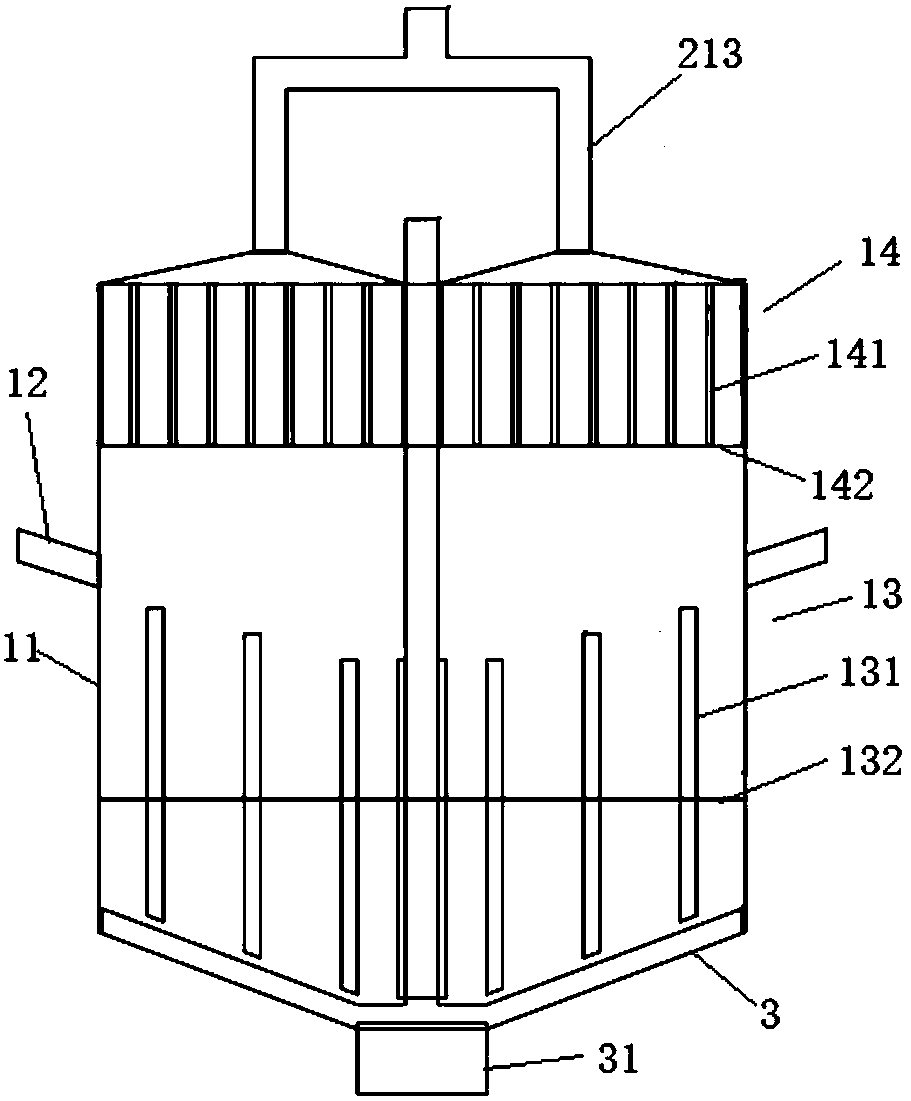

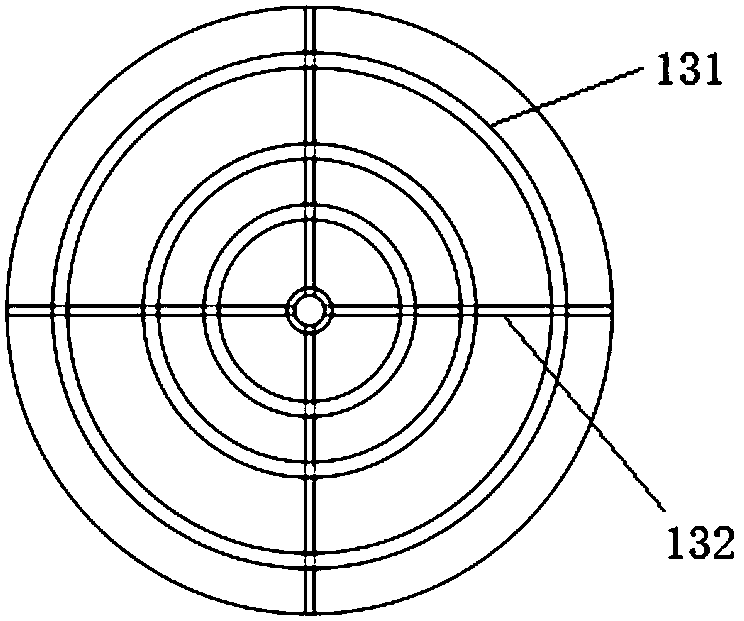

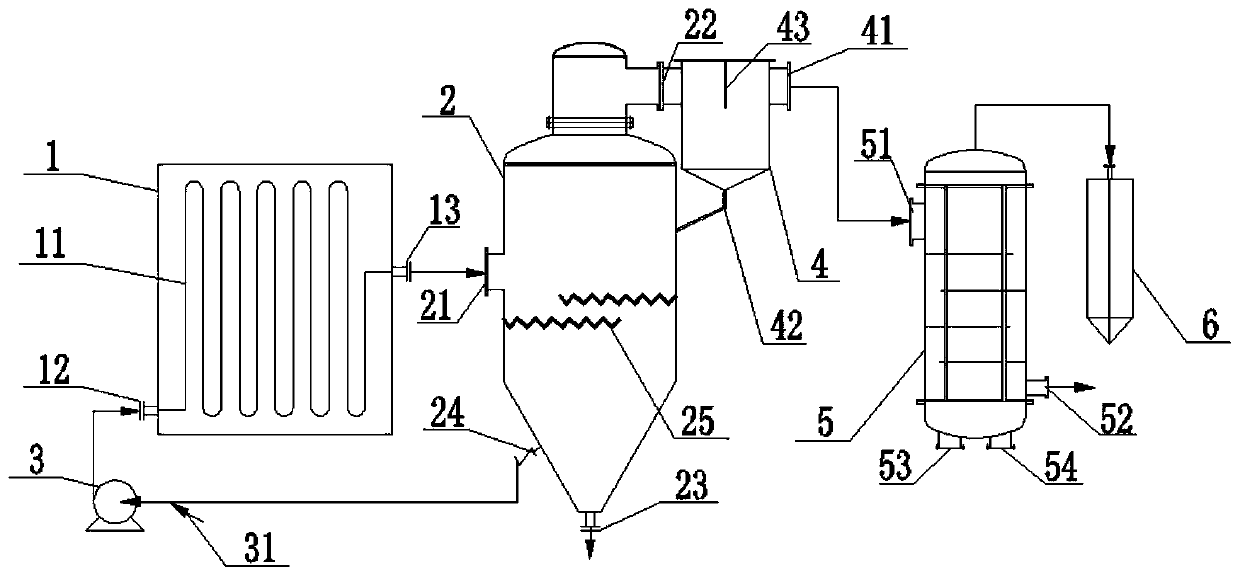

Reaction apparatus of microwave pyrolysis biomass

PendingCN108587653AIncrease the proportion of pyrolysis gasImprove economyGasification catalystsChemical industryMicrowave pyrolysisGas phase

The invention discloses a reaction apparatus of a microwave pyrolysis biomass. The reaction apparatus comprises a microwave pyrolysis unit, the microwave pyrolysis unit comprises a microwave thermal decomposition furnace, and at least a feed inlet arranged outside the microwave thermal decomposition furnace, the microwave thermal decomposition furnace comprises a solid-phase pyrolysis part and a gas-phase pyrolysis part connected in order from down to up, the solid-phase pyrolysis part comprises a solid-phase hollow circular column composed of metal mesh, and the solid-phase hollow circular column is filled with a solid-phase microwave absorbent and a catalyst. The reaction apparatus increases the pyrolysis heating rate, reduces the generation amount of solid carbon residue, increases theproportion of pyrolysis gas in products, and optimizes the pyrolysis reaction process, has the advantages of simple equipment, less land occupation, and convenient operation, can complete operation ofcontinuous feeding and deslagging, and is convenient for operation and management.

Owner:司宸

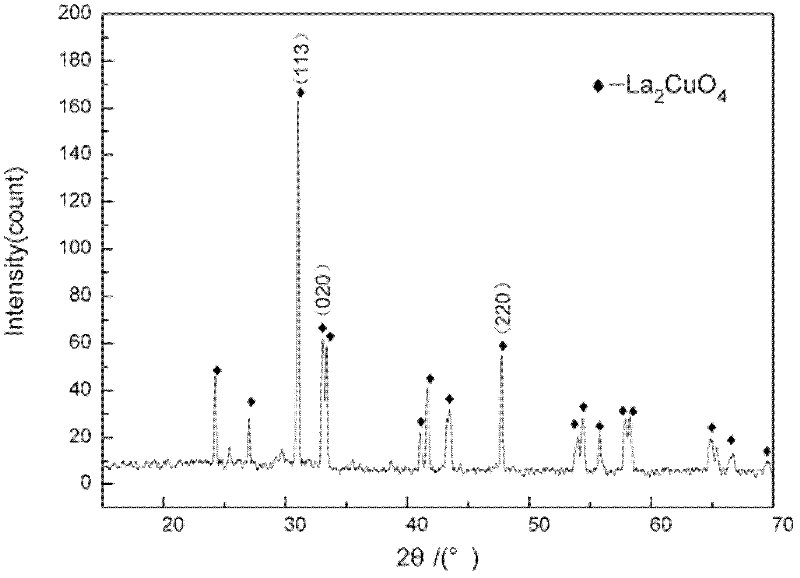

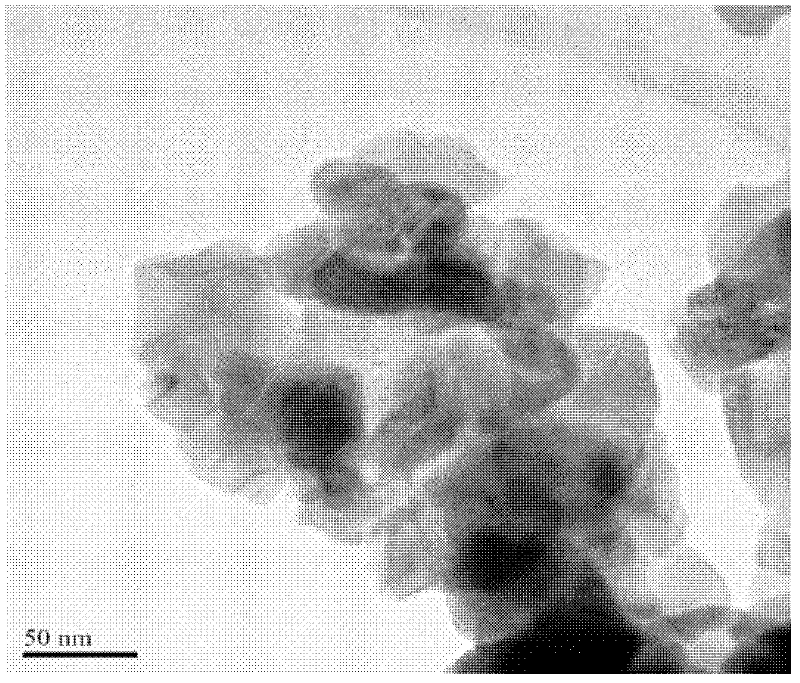

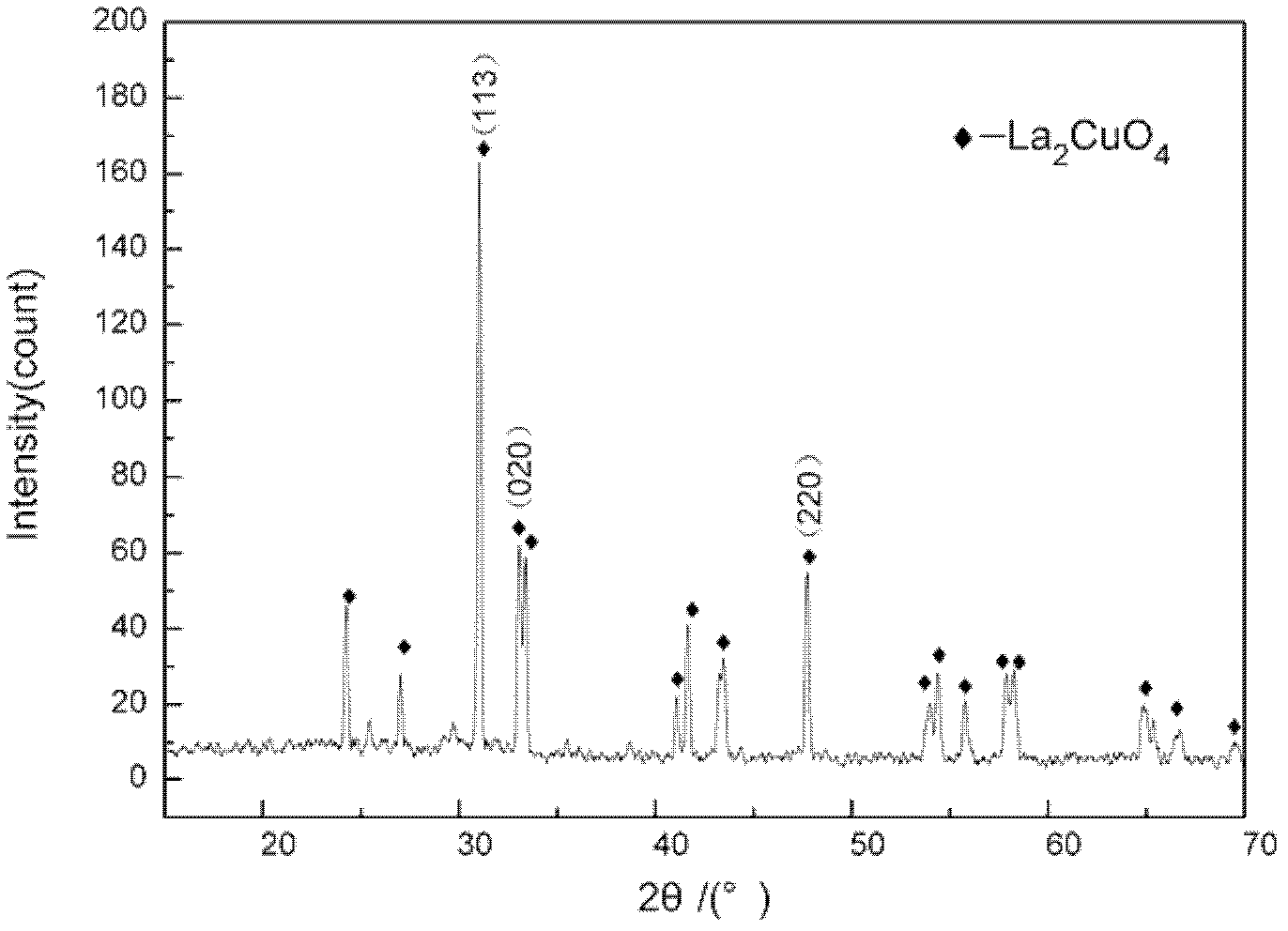

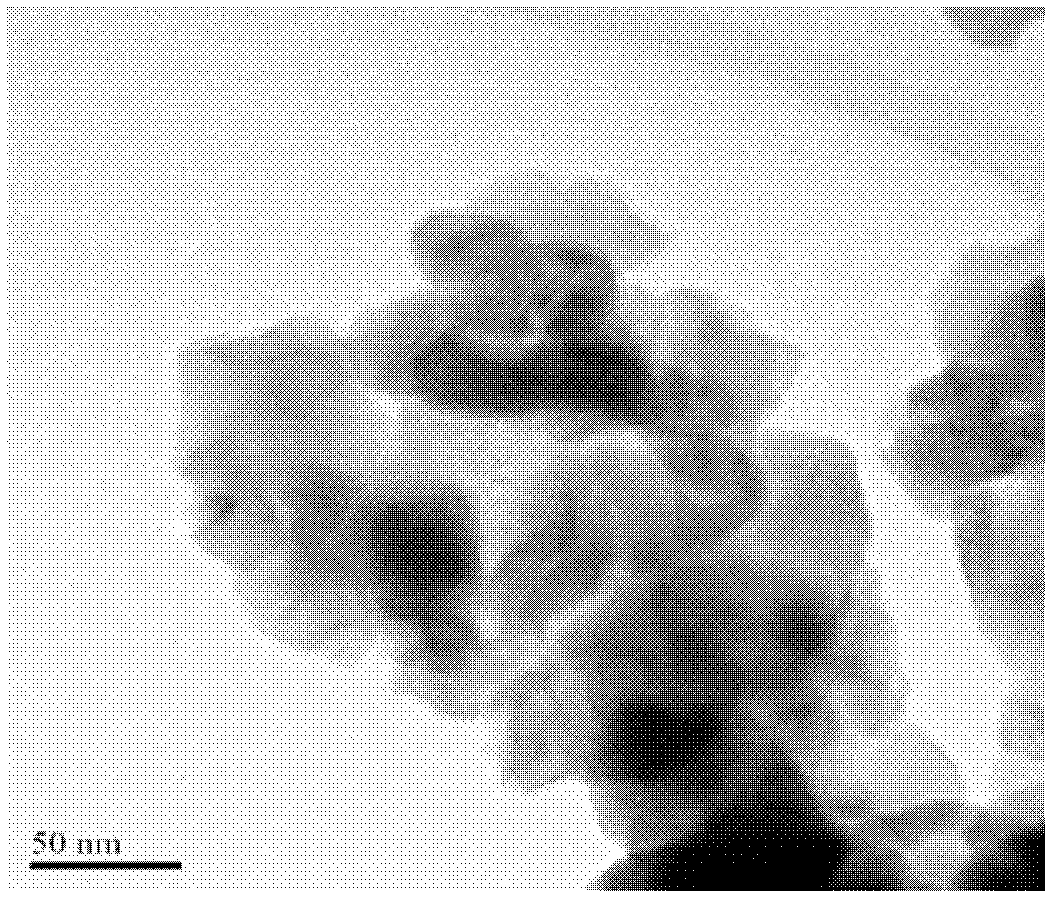

Method for preparing lanthanum cuprate (La2CuO4) powder by means of microwave-hydrothermal method

A method for preparing lanthanum cuprate (La2CuO4) powder by means of the microwave-hydrothermal method includes the following steps: lanthanum nitrate is added into distilled water, so that solution A is obtained; copper nitrate is added into the solution A, so that solution B is obtained; citric acid is added into the solution B, so that solution C is obtained; the pH of the solution C is regulated to 1.5 to 7, so that solution D is obtained; the solution D is added into a microwave-hydrothermal reactor, the reactor is sealed and then put into a microwave-hydrothermal instrument to carry out hydrothermal reaction, and after reaction is finished, the reactor is naturally cooled to the room temperature; sample is collected by centrifugal separation and then repetitively washed by distilled water and acetone, and after drying, the La2CuO4 powder is obtained. Since the method adopts the microwave-hydrothermal method to prepare the La2CuO4 powder, the electric field and the magnetic field can be changed in the space, so that molecular motion can be intensified, as a result, heat energy can be obtained, and thereby the synthesis of the La2CuO4 powder becomes highly efficient, simple and highly repetitive. Moreover, the heating speed is high, heating is uniform and does not have the temperature gradient and the hysteresis effect, consequently, the defect of ununiform heating of a hydrothermal container is overcome, the reaction time is shortened, energy consumption is reduced, and the working efficiency is increased.

Owner:山东格新精工有限公司

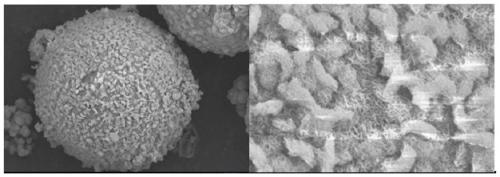

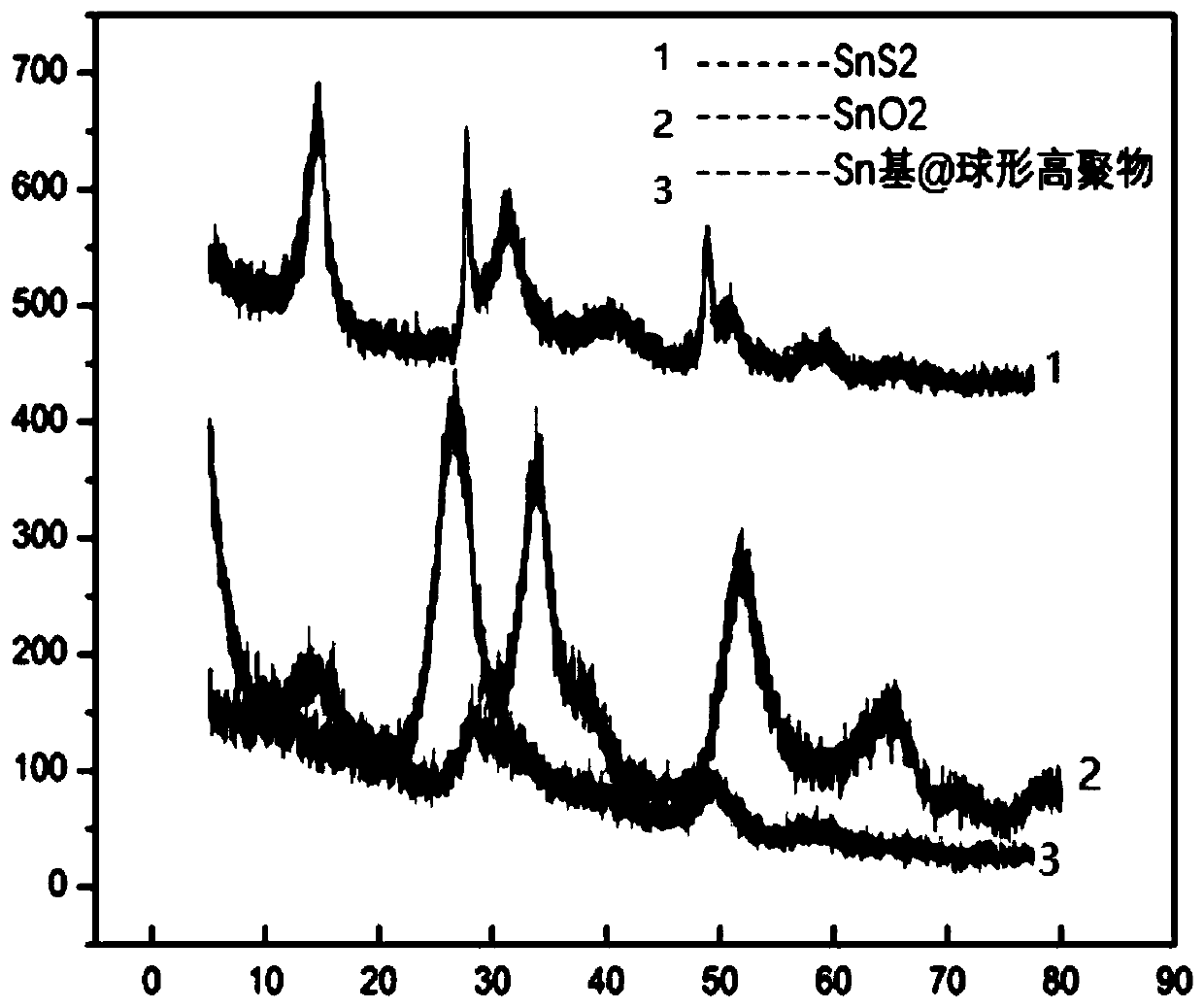

Transition Sn-based heterojunction material@spherical high polymer, and preparation method and application thereof

PendingCN111313001AFast reaction rateStrong crystallinityNegative electrodesSecondary cellsChemistryThio-

The invention discloses a transition Sn-based heterojunction material@spherical high polymer, and a preparation method thereof and application thereof. The preparation method comprises the following steps: adding a spherical high polymer obtained by hydrothermal reaction of glucose into ethanol, adding SnCl4.5H2O, stirring for a certain time, and adding thioacetamide; and heating, adding ethanol at intervals, taking out a precursor after the reaction is finished, and carrying out centrifugal washing and vacuum drying to obtain a composite material. The preparation method is low in preparationcost, simple to operate and short in preparation period, and the prepared material is high in purity, high in crystallinity and uniform in morphology and has certain charge-discharge cycle performancewhen applied to a negative electrode of a sodium-ion battery.

Owner:YANGZHOU UNIV

Vacuum tube type microwave heating carbon furnace

PendingCN108172354AShort sintering timeUniform temperatureOhmic-resistance heatingMicrowave heatingCarbon filmHigh rate

The invention provides a vacuum tube type microwave heating carbon furnace, relates to the technical field of high temperature vacuum coating equipment, and solves the technical problems that a heating temperature field inside the furnace is non-uniform and the resistance value of a resistor carbon film is not inconsistent. The vacuum tube type microwave heating carbon furnace comprises a furnacebody, a magnetron, a double-layer vacuum quartz tube with a jacket, and a microwave absorbing heating material, wherein the magnetron is arranged on a furnace body, and the magnetron can emit microwaves inside an inner cavity of the furnace body after being electrified; the vacuum quartz tube is arranged inside the furnace body in a rotating manner, and treated workpieces are placed inside the vacuum quartz tube for carbon coating film treatment; and the microwave absorbing heating material inside the jacket of the vacuum quartz tube can emit heat after absorbing microwaves, and the furnace body is further internally provided with a heat insulation layer made of a microwave-transmitting material. A novel material sintering method has the characteristics of high heating rate, high energy utilization rate, high heating efficiency, uniform material temperature field, good technological controllability, short technological period, good product uniformity and high rate of finished products.

Owner:宁波拓源新材料科技有限公司

Device and method for microwave heating and concentratimg of tobacco extract

InactiveCN110496409ASmall footprintGrowth inhibitionEvaporator accessoriesEvaporators with forced circulationVapor liquidMicrowave

The invention discloses a device and a method for a microwave heating and concentrating of a tobacco extract. The device comprises a microwave heater used for heating the tobacco extract, an evaporating tank used for collecting the heated tobacco extract, a vapor-liquid separator used for collecting vapor generated in the evaporating tank and carrying out vapor-liquid separation on the vapor, a condenser used for condensing the vapor generated at the vapor outlet of the vapor-liquid separator, and the like. The concentrating method comprises the following steps: a forced circulation pump, themicrowave heater and the vacuum pump are turned on, the tobacco extract enters the microwave heater through the forced circulation pump, and is heated to a preset temperature, the heated tobacco extract enters the evaporating tank, the vapor generated in the evaporating tank enters the vapor-liquid separator, and vapor free from water drops enters the condenser. The tobacco extract is heated and then evaporated in the evaporating tank under a vacuum condition at a low temperature through microwave energy, the structure is simple, and the concentrating temperature is low, so scaling of the tobacco extract is greatly reduced, growth of bacteria is inhibited through microwaves, and the product quality is improved.

Owner:CHINA HAISUM ENG

Method for preparing lanthanum cuprate (La2CuO4) powder by means of microwave-hydrothermal method

ActiveCN102398915BAchieving stirringOvercome the disadvantage of uneven heatingCopper compoundsCopper nitrateCuprate

A method for preparing lanthanum cuprate (La2CuO4) powder by means of the microwave-hydrothermal method includes the following steps: lanthanum nitrate is added into distilled water, so that solution A is obtained; copper nitrate is added into the solution A, so that solution B is obtained; citric acid is added into the solution B, so that solution C is obtained; the pH of the solution C is regulated to 1.5 to 7, so that solution D is obtained; the solution D is added into a microwave-hydrothermal reactor, the reactor is sealed and then put into a microwave-hydrothermal instrument to carry out hydrothermal reaction, and after reaction is finished, the reactor is naturally cooled to the room temperature; sample is collected by centrifugal separation and then repetitively washed by distilled water and acetone, and after drying, the La2CuO4 powder is obtained. Since the method adopts the microwave-hydrothermal method to prepare the La2CuO4 powder, the electric field and the magnetic field can be changed in the space, so that molecular motion can be intensified, as a result, heat energy can be obtained, and thereby the synthesis of the La2CuO4 powder becomes highly efficient, simple and highly repetitive. Moreover, the heating speed is high, heating is uniform and does not have the temperature gradient and the hysteresis effect, consequently, the defect of ununiform heating of a hydrothermal container is overcome, the reaction time is shortened, energy consumption is reduced, and the working efficiency is increased.

Owner:山东格新精工有限公司

Method for preparing doped nano titanium dioxide powder by microwave hydrothermal method

ActiveCN108408769AGood crystal formHigh purityMaterial nanotechnologyTitanium dioxideHysteresisAlcohol

The invention discloses a method for preparing doped nano titanium dioxide powder by a microwave hydrothermal method, wherein the method comprises the following steps: firstly, dropwise adding a InCl3.4H2O solution completely dissolved in absolute ethyl alcohol into a NbCl5 solution completely dissolved in absolute ethyl alcohol; then dropwise adding the obtained solution into a uniform mixed solution of absolute ethyl alcohol and tetrabutyl titanate; then dropwise adding concentrated hydrochloric acid to adjust the pH, and forming a (In0.05Nb0.05)Ti0.9O2 precursor solution; heating the (In0.05Nb0.05)Ti0.9O2 precursor solution by using a microwave hydrothermal system; and finally, cleaning powder obtained after the reaction with absolute ethyl alcohol, filtering and drying, to obtain a nano-sized (In0.05Nb0.05)Ti0.9O2 powder. The period of preparation of the powder by the microwave hydrothermal method is short, the purity of the product is high, and the crystal grain size can reach nano scale, so that the solution is evenly heated in a shorter time without temperature gradient or hysteresis effect; the nano (In0.05Nb0.05)Ti0.9O2 powder prepared by the method has the advantages of high purity, good dispersibility and uniform particle size distribution, and the particle size distribution is 700 nm-800 nm.

Owner:SHAANXI UNIV OF SCI & TECH

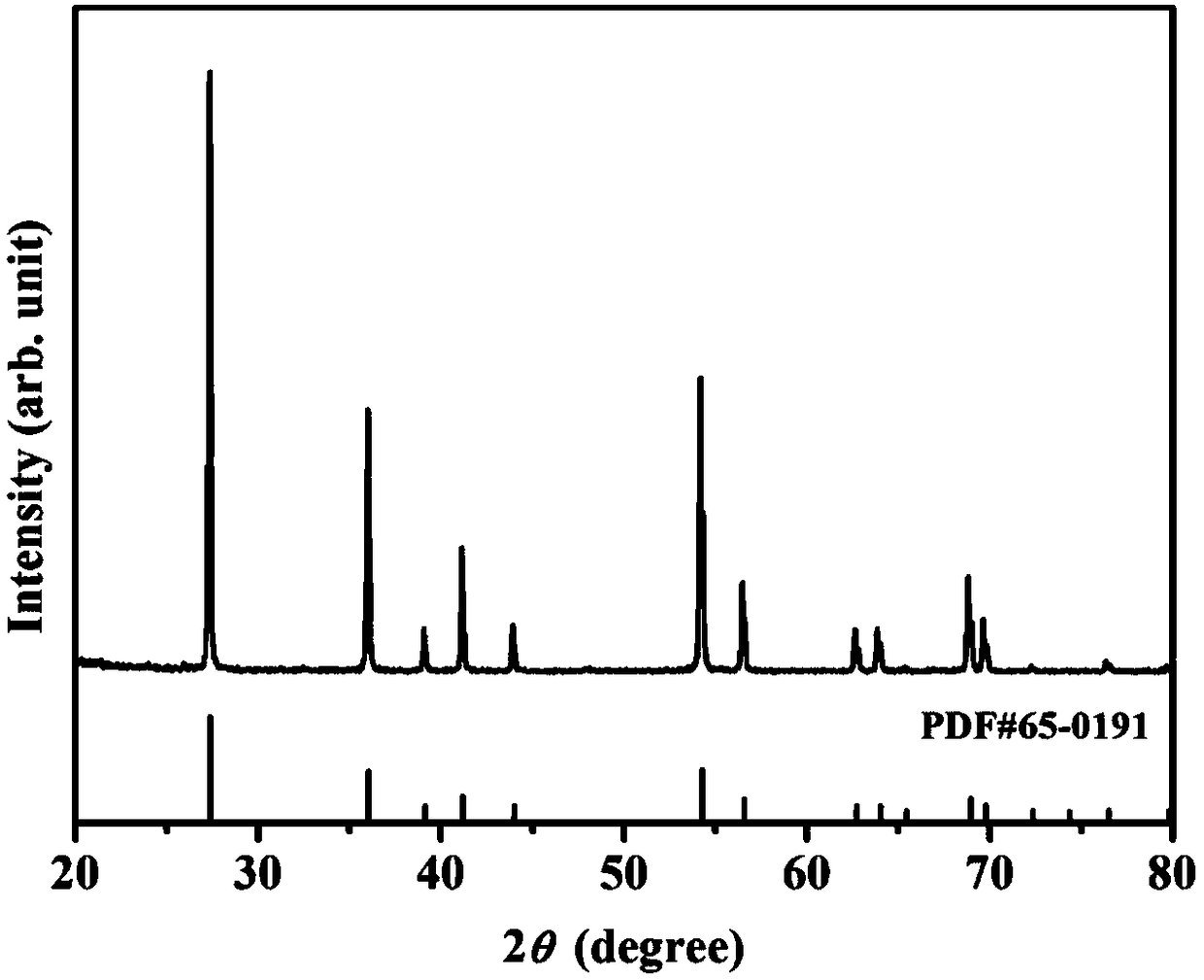

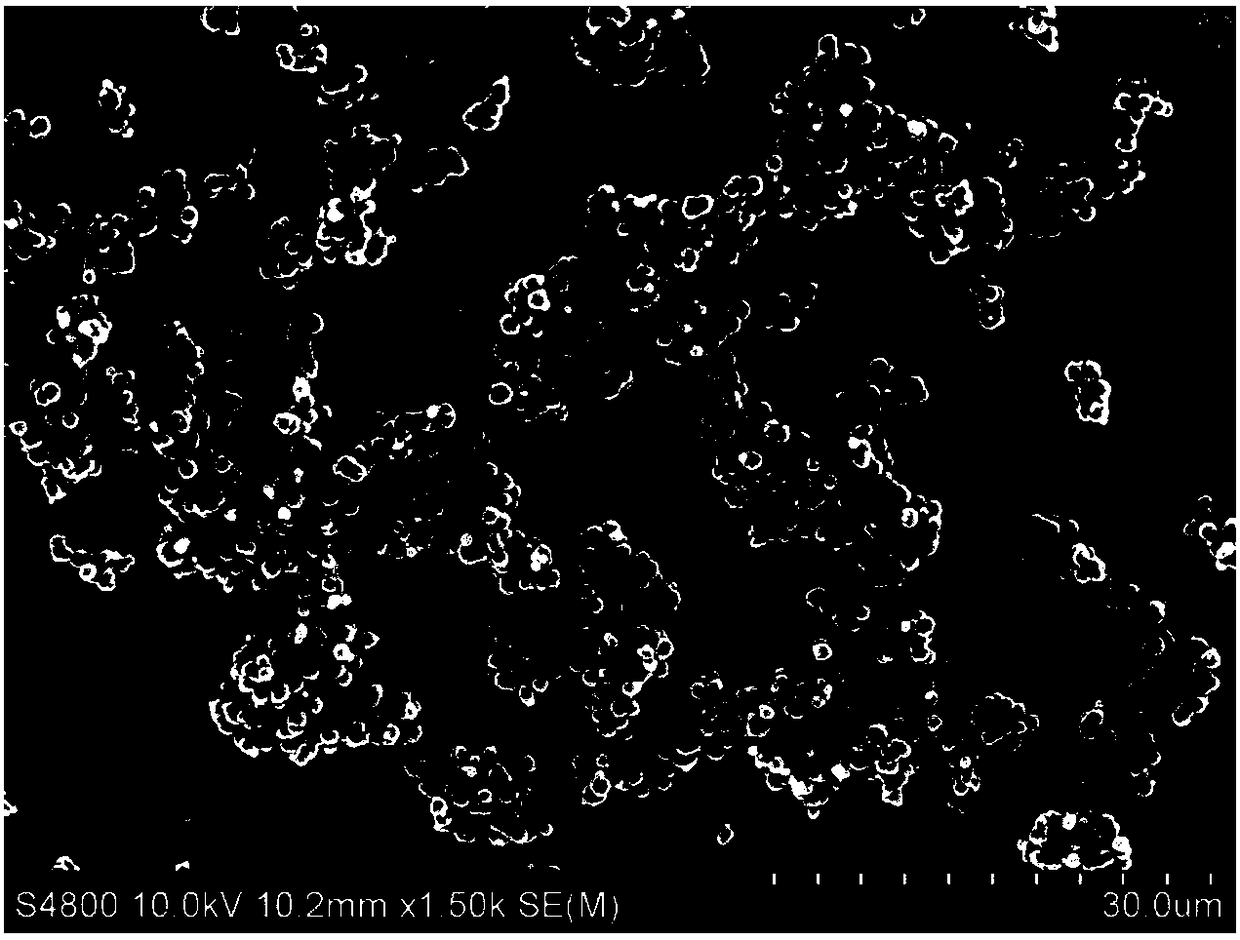

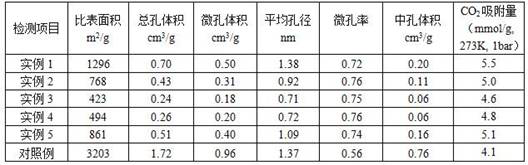

A method for preparing activated carbon by microwave-assisted hydrothermal treatment of Chinese fir bark

ActiveCN108821283BImprove production efficiencyOvercome the disadvantage of uneven heatingCarbon compoundsActivated carbonPotassium hydroxide

The invention relates to a method for preparing activated carbon by utilizing Chinese fir bark microwave-assisted hydrothermal. The invention takes Chinese fir bark powder as a raw material; pours the Chinese fir bark powder into a beaker, adds potassium hydroxide and deionized water, and stirs. Obtain a mixed solution; transfer the mixed solution to a high-pressure reactor, react in a microwave hydrothermal synthesizer, dry the reacted mixed solution, sinter in a muffle furnace, and wash the sintered raw materials with acid to Neutral, dry, that is a fir bark microwave hydrothermal activated carbon, which has a good potential in carbon dioxide capture.

Owner:陕西华拓新能源材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com