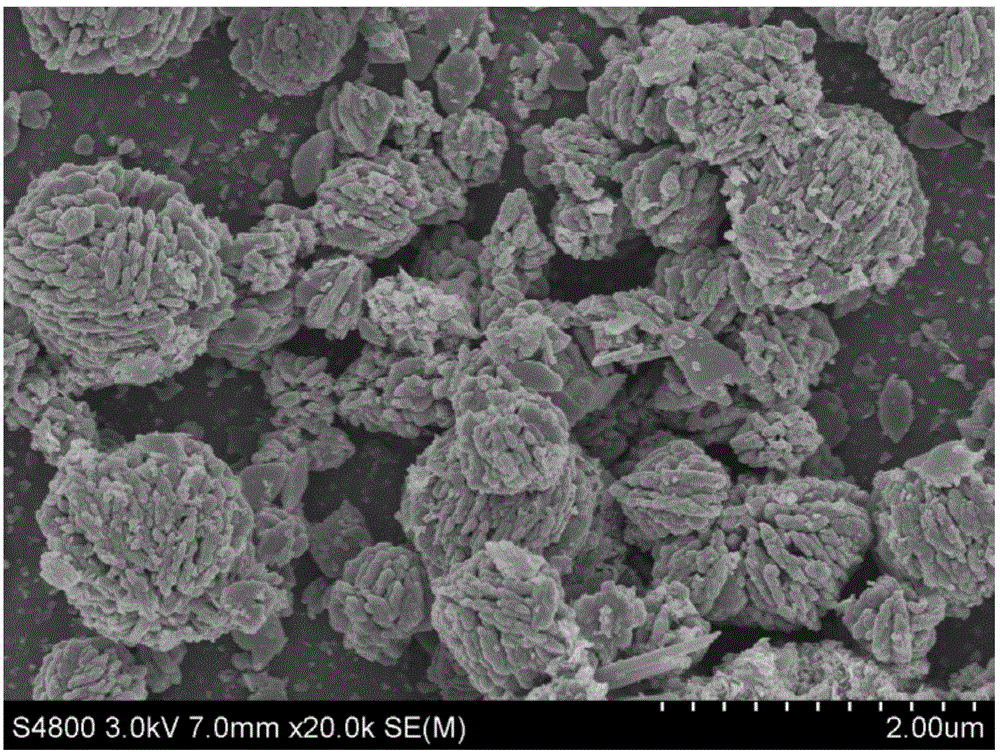

Method for self-assembling near-spherical Sm2O3/CuO nanometer composite

A nano-composite and spherical-like technology, which is applied in chemical instruments and methods, chemical/physical processes, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low visible spectrum responsivity and achieve process equipment Simple, good crystallinity, uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) First, the analytically pure SmCl 3 ·6H 2 O was dissolved in an appropriate amount of deionized water under magnetic stirring to obtain a solution A with a concentration of 0.5mol / L; the CuCl 2 2H 2 O is dissolved in deionized water under magnetic stirring to form a solution B with a concentration of 0.5mol / L;

[0022] 2) Next, mix the two solutions of A and B according to the volume ratio of 1:1, heat and adjust the pH of the solution to 7 with an ammonia solution with a mass percentage of 5% to form a reaction precursor;

[0023] 3) Then, pour the reaction precursor solution into a hydrothermal kettle with a filling degree of 55%, seal the kettle and put it into a microwave hydrothermal reaction apparatus, react at 200° C. for 2 hours, and naturally cool to room temperature after the reaction;

[0024] 4) Finally, the sample was centrifuged and washed with distilled water and absolute ethanol for 4 to 6 times, and then placed in a muffle furnace for calcination ...

Embodiment 2

[0026] 1) First, the analytically pure SmCl 3 ·6H 2 O was dissolved in an appropriate amount of deionized water under magnetic stirring to obtain a solution A with a concentration of 1mol / L; the CuCl 2 2H 2 O is dissolved in deionized water under magnetic stirring to form a solution B with a concentration of 0.5mol / L;

[0027] 2) Next, mix the two solutions of A and B according to the volume ratio of 1:0.5, heat and adjust the pH of the solution to 5.5 with an ammonia solution with a mass percentage of 8% to form a reaction precursor;

[0028] 3) Then, pour the reaction precursor solution into a hydrothermal kettle with a filling degree of 60%, seal the kettle and put it into a microwave hydrothermal reactor, react at 150° C. for 2 hours, and naturally cool to room temperature after the reaction;

[0029] 4) Finally, the sample was centrifuged and washed with distilled water and absolute ethanol for 4 to 6 times, and then placed in a muffle furnace for calcination at 800 °C...

Embodiment 3

[0031] 1) First, the analytically pure SmCl 3 ·6H 2 O was dissolved in an appropriate amount of deionized water under magnetic stirring to obtain a solution A with a concentration of 2mol / L; the CuCl 2 2H 2 O is dissolved in deionized water under magnetic stirring to form a solution B with a concentration of 1mol / L;

[0032] 2) Next, mix the two solutions of A and B according to the volume ratio of 1:2, heat and adjust the pH of the solution to 8 with an ammonia solution with a mass percentage of 10% to form a reaction precursor;

[0033] 3) Then, pour the reaction precursor solution into a hydrothermal kettle with a filling degree of 75%, seal the kettle and put it into a microwave hydrothermal reactor, react at 120° C. for 2 hours, and naturally cool to room temperature after the reaction;

[0034] 4) Finally, the sample was centrifuged and washed with distilled water and absolute ethanol for 4 to 6 times, and then placed in a muffle furnace for calcination at 600°C for 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com