Tunnel-type constant-temperature heating furnace

A constant temperature heating, tunnel-type technology, applied in lighting and heating equipment, furnaces, furnace types, etc., can solve the problems of dust pollution, easy wrinkling of hydrosols, poor curing effect, etc., to achieve good flatness and rapid heat transfer. , the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

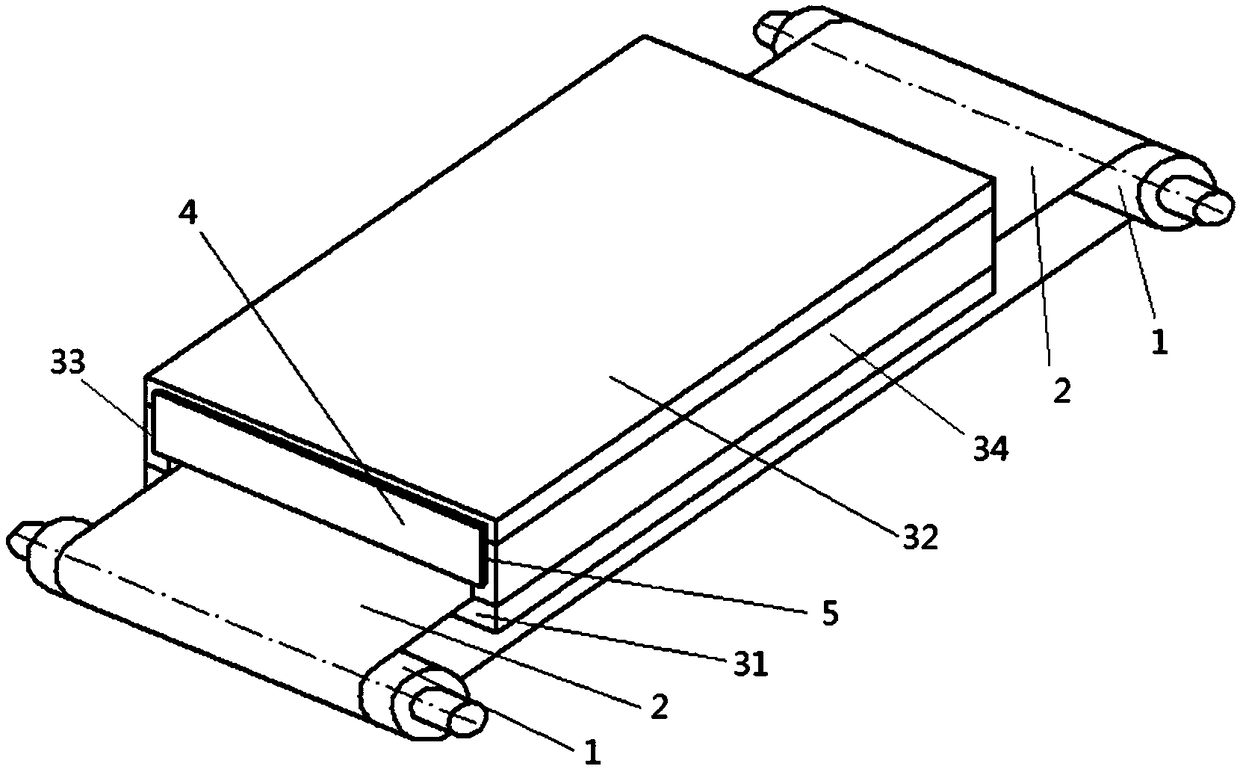

[0023] Such as figure 1 As shown, the tunnel-type constant-temperature heating furnace of the present invention includes two rollers 1 , a conveyor belt 2 , a lower heating plate 31 , an upper heating plate 32 , and two gates 4 .

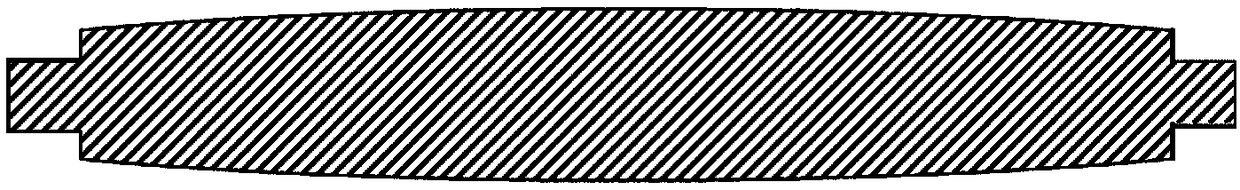

[0024] The upper heating plate 32, the lower heating plate 31, and the two side plates 33, 34 connecting the upper heating plate 32 and the lower heating plate 31 form a constant temperature tunnel with openings at both ends, and two gates 4 are respectively installed at the front and rear of the constant temperature tunnel. At the openings at both ends; the two heat shields 5 are attached to the inner surfaces of the two gates 4 facing the constant temperature tunnel respectively, and their heat insulation effect; or the two gates 4 are directly made of materials with good heat insulation performance. The two rollers 1 are located at the front and rear of the constant temperature tunnel; the conveyor belt 2 is made of Teflon with wide width and tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com