Device and method for microwave heating and concentratimg of tobacco extract

A technology of tobacco extract and microwave heating, applied in separation methods, chemical instruments and methods, evaporators heated by serpentine tubes, etc., can solve the problems of low concentration efficiency, high membrane price and maintenance cost, and improve heating efficiency. , The effect of inhibiting the growth of bacteria and avoiding scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

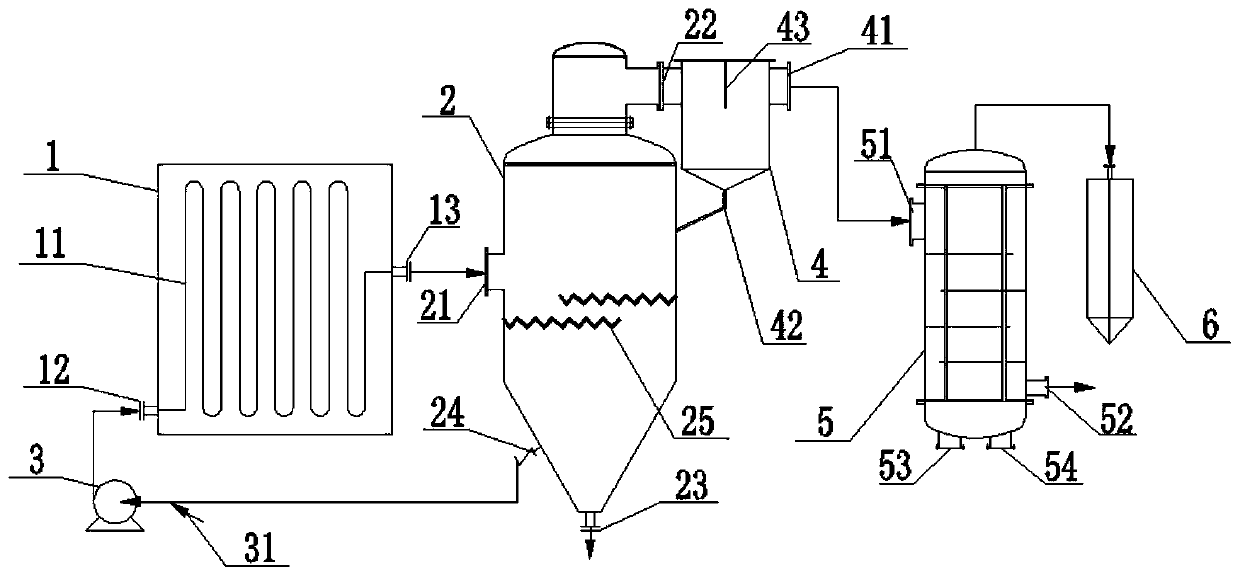

[0028] A method for concentrating tobacco extract by microwave heating:

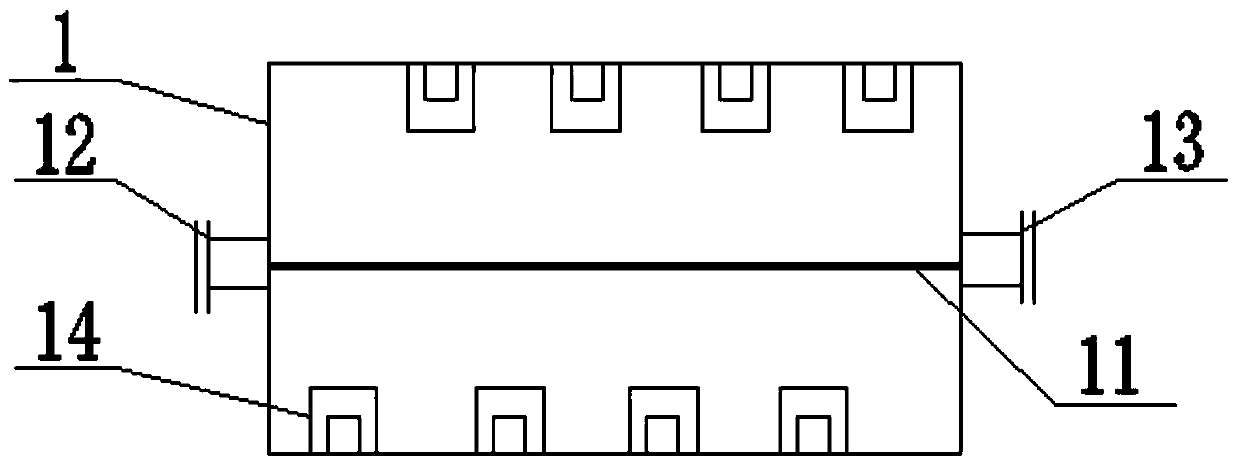

[0029] First start forced circulation pump 3, microwave heater 1, vacuum pump 6, tobacco extract (solid content is 8%, temperature is 45 ℃, flow is 500kg / h) enters the serpentine shape of microwave heater 1 by forced circulation pump 3 In the pipeline 11, after being heated to the set temperature of 58°C, it is sprayed into the evaporation tank 2 at a speed of 1.5m / s, falls on the upper baffle 25, and then continues to flow to the lower baffle 25 and then flows Extending to the evaporation chamber below it, the set negative pressure of the tobacco extract in the evaporation tank due to the control of the suction of the vacuum pump 6 is 0.185kgf / cm 2 Boiling at low temperature, the steam generated by boiling enters the gas-liquid separator 4 through the steam outlet 22, and the water droplets in the steam meet the water baffle 43 and flow to the bottom drain port 42 to return to the evaporation tank 2; th...

Embodiment 2

[0034] A method for concentrating tobacco extract by microwave heating:

[0035]First start forced circulation pump 3, microwave heater 1, vacuum pump 6, tobacco extract (solid content is 7.5%, temperature is 47 ℃, flow is 500kg / h) enters the serpentine shape of microwave heater 1 by forced circulation pump 3 In the pipeline 11, after being heated to a set temperature of 60°C, it sprays into the evaporation tank 2 at a speed of 1.3m / s, falls on the upper baffle 25, and then continues to flow to the lower baffle 25 and then flows Extending to the evaporation chamber below it, the set negative pressure generated by controlling the suction of the vacuum pump 6 in the evaporation tank of the tobacco extract is 0.203kgf / cm 2 Boiling at low temperature, the steam generated by boiling enters the gas-liquid separator 4 through the steam outlet 22, and the water droplets in the steam meet the water baffle 43 and flow to the bottom drain port 42 to return to the evaporation tank 2; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com