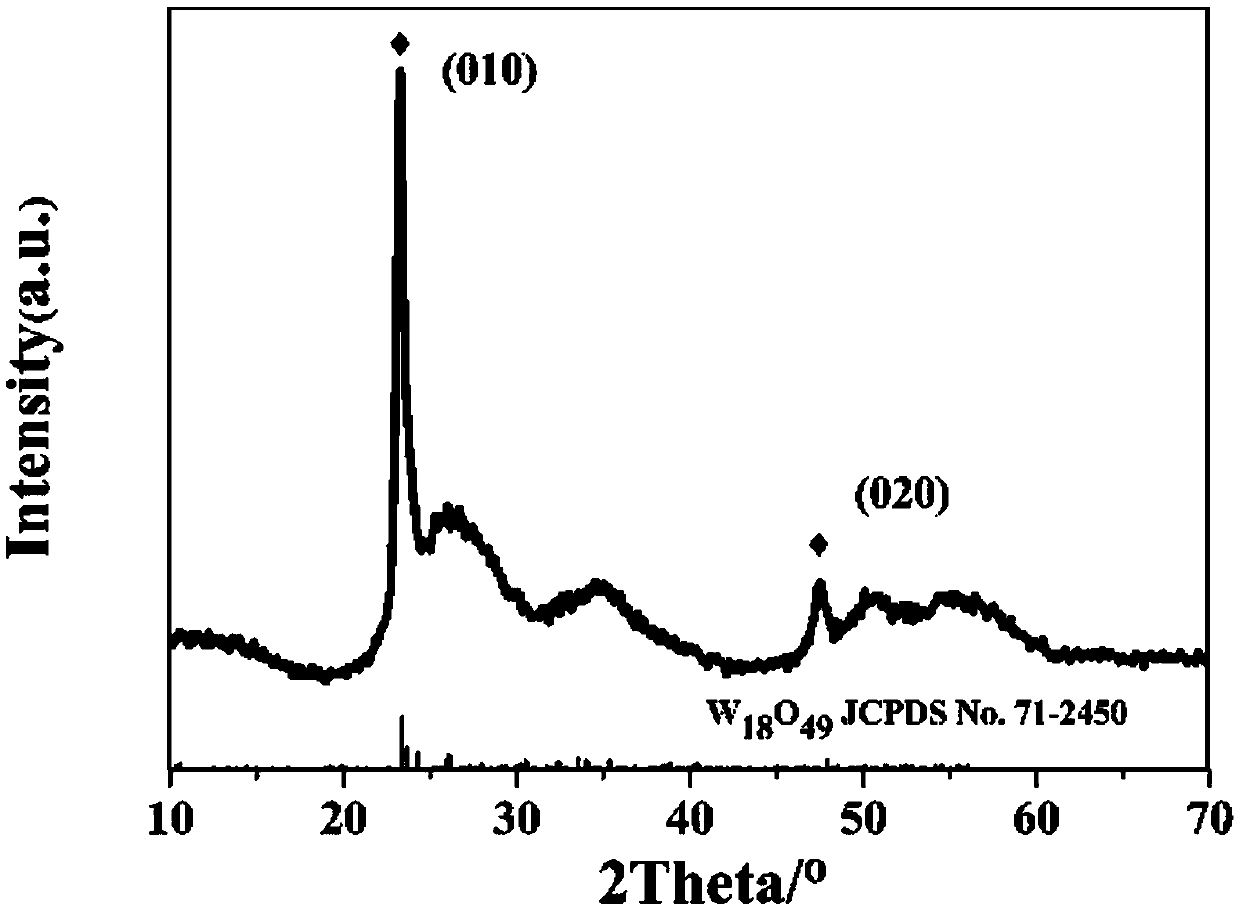

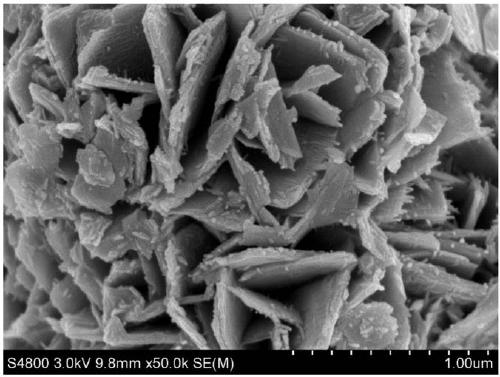

Method for synthesizing W18O49 nano material through microwave assistance

A nanomaterial and microwave-assisted technology, applied in nanotechnology, tungsten oxide/tungsten hydroxide, etc., can solve the problems of high sintering temperature, low product purity, long holding time, etc., to avoid grain growth and shorten the reaction time time, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Take analytically pure (NH 4 ) 10 W 12 o 41 ·5H 2 O is added in absolute ethanol and is mixed with the solution A of 0.05mol / L, and seals up with plastic wrap in time to avoid pollution;

[0026] 2) Sodium oleate and n-propylamine were added to solution A, and magnetically stirred until the solution gradually changed from yellow to blue to obtain a mixed solution B with a concentration of sodium oleate of 0.05mol / L and a concentration of n-propylamine of 0.05mol / L;

[0027] 3) Put the mixed solution B into the microwave hydrothermal reactor at a filling ratio of 40%, set the heating power to 300W with the MDS-8 microwave hydrothermal instrument, and raise the temperature in the reactor from The room temperature was raised to 150°C, and the reaction was carried out for 60 minutes;

[0028] 4) Naturally cool to room temperature after the reaction, and centrifuge and wash the final reactant with deionized water and absolute ethanol, and dry the centrifuged and wash...

Embodiment 2

[0032] 1) Take analytically pure (NH 4 ) 10 W 12 o 41 ·5H 2 O is added in isopropanol and is mixed with solution A of 0.01mol / L, and seals up with plastic wrap in time to avoid pollution;

[0033] 2) Sodium oleate and n-propylamine were added to solution A, and magnetically stirred until the solution gradually changed from yellow to blue to obtain a mixed solution B with a concentration of sodium oleate of 0.03mol / L and a concentration of n-propylamine of 0.03mol / L;

[0034] 3) Put the mixed solution B into the microwave hydrothermal reactor at a filling ratio of 30%, set the heating power to 400W with the MDS-8 microwave hydrothermal instrument, and raise the temperature in the reactor from The room temperature was raised to 160°C, and the reaction was carried out for 80 minutes;

[0035] 4) Cool down to room temperature naturally after the reaction, and centrifuge and wash the final reactant with deionized water and absolute ethanol, and dry the centrifuged and washed m...

Embodiment 3

[0038] 1) Take analytically pure (NH 4 ) 10 W 12 o 41 ·5H 2 O is added in n-butanol and is mixed with the solution A of 0.2mol / L, and seal up with fresh-keeping film in time to avoid pollution;

[0039] 2) adding sodium oleate and n-propylamine into solution A, and magnetically stirring until the solution gradually changes from yellow to blue to obtain a mixed solution B with a concentration of sodium oleate of 0.04mol / L and a concentration of n-propylamine of 0.02mol / L;

[0040] 3) Put the mixed solution B into the microwave hydrothermal reactor at a filling ratio of 40%, set the heating power to 400W with the MDS-8 microwave hydrothermal instrument, and raise the temperature in the reactor from The room temperature was raised to 140°C, and the reaction was carried out for 70 minutes;

[0041] 4) Naturally cool to room temperature after the reaction, and centrifuge and wash the final reactant with deionized water and absolute ethanol, and dry the centrifuged and washed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com