Preparation method of manganese oxide yttrium semiconductor photocatalytic powder

A semiconductor and photocatalytic technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of fast speed, short reaction cycle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

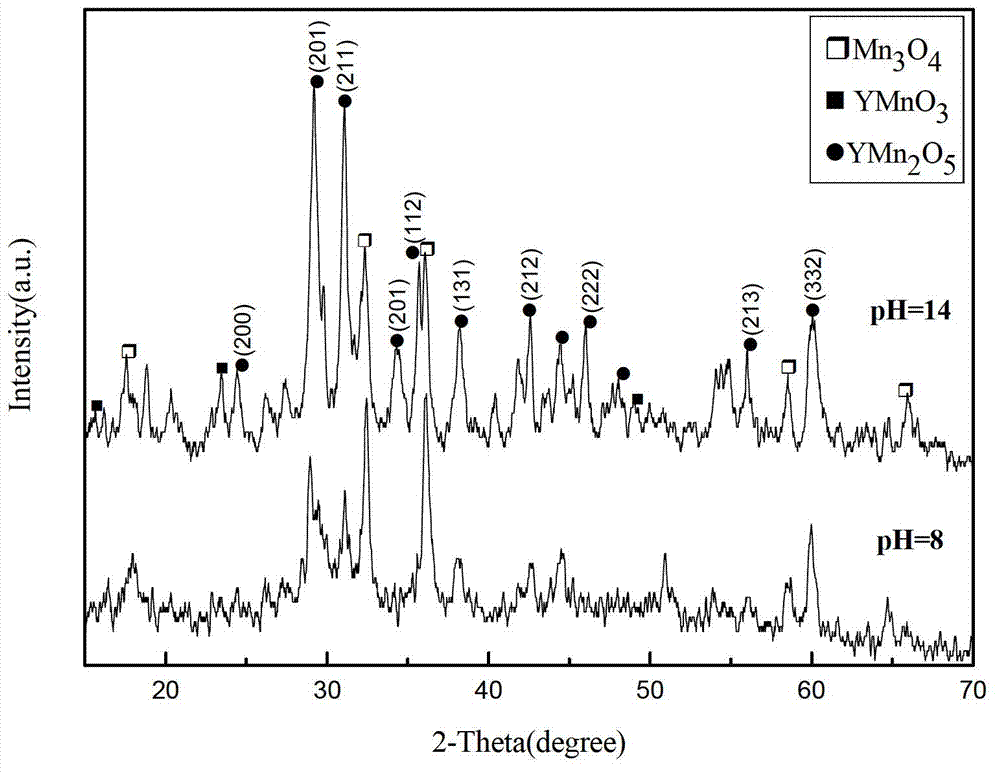

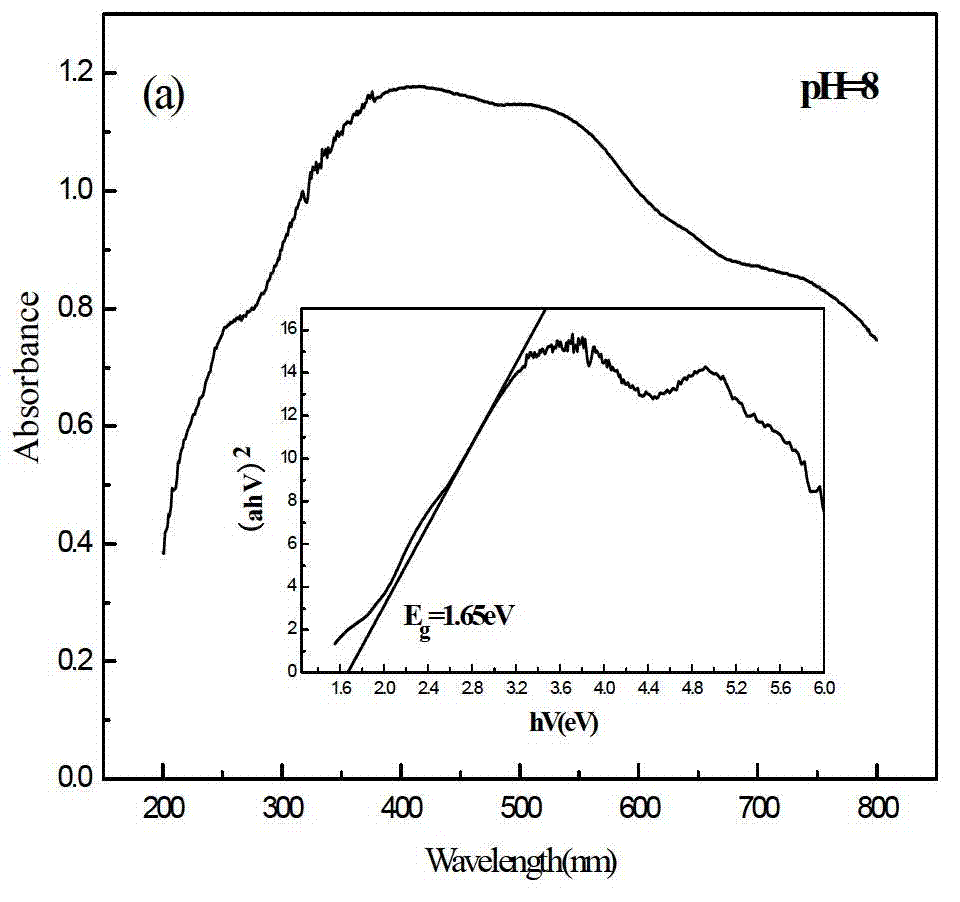

[0026] The pH of the precursor solution of the yttrium manganate semiconductor photocatalytic powder prepared in this example is 8.

[0027] Step 1: getting concentration is the uniform solution A of yttrium nitrate of 0.1mol / L, and concentration is the uniform solution B of potassium permanganate and 50% manganese nitrate solution C of 0.1mol / L;

[0028] Step 2: According to the molar ratio of Y / Mn: 1:1.5, Mn 7+ :Mn 2+ The molar ratio is: 1:4 Add solutions B and C to solution A, add deionized water and stir evenly, so that the concentration of yttrium nitrate is 0.0625mol / L; adjust to pH 8 to form a uniform co-precipitation precursor D ;

[0029] Step 3: Pour the co-precipitation precursor D into the microwave hydrothermal reaction kettle, control the filling degree to 40%, seal the reaction, first keep it at 100°C for 5 minutes, then keep it at 125°C for 5 minutes, then keep it at 150°C for 10 minutes, and then Incubate at 175°C for 15 minutes, and finally at 200°C for 30...

Embodiment 2

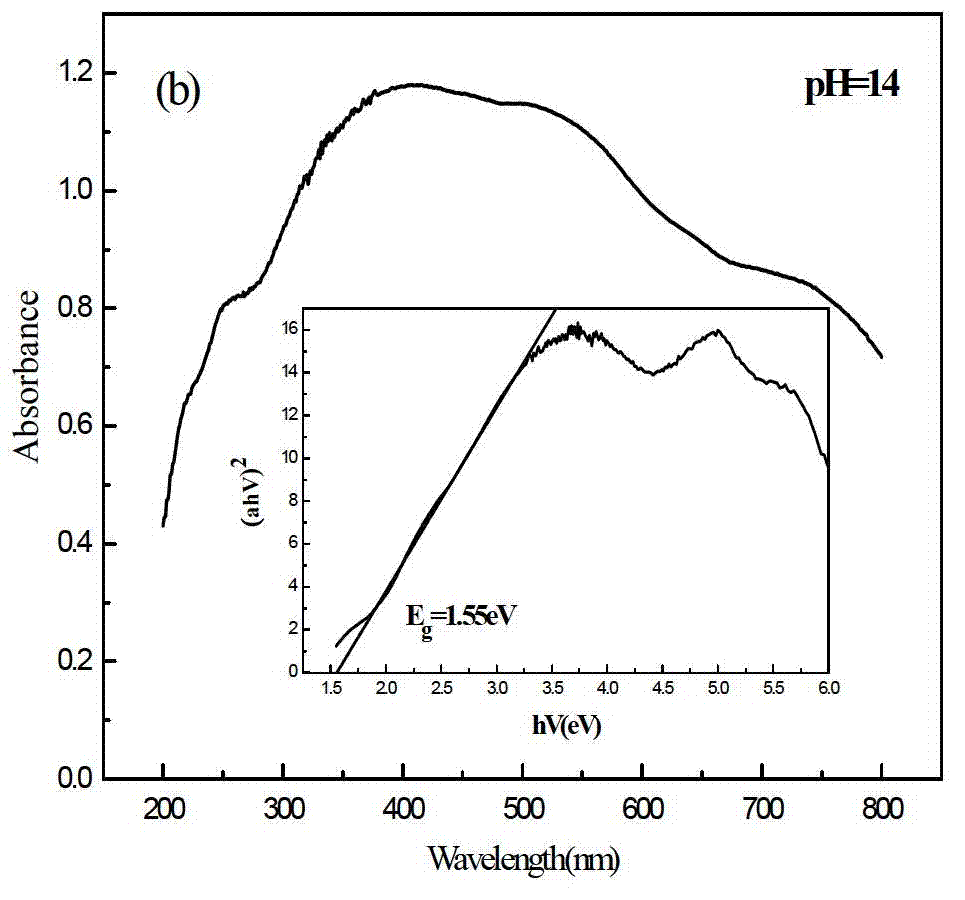

[0032] The pH of the precursor solution of the yttrium manganate nanopowder prepared in this example is 14.

[0033] Step 1: getting concentration is the uniform solution A of yttrium nitrate of 0.1mol / L, and concentration is the uniform solution B of potassium permanganate and 50% manganese nitrate solution C of 0.1mol / L;

[0034] Step 2: According to the molar ratio of Y / Mn: 1:1.5, Mn 7+ :Mn 2+ The molar ratio is: 1:4 Add solutions B and C to solution A, add deionized water and stir evenly, so that the concentration of yttrium nitrate is 0.0625mol / L; adjust to pH 14 to form a uniform co-precipitation precursor D ;

[0035] Step 3: Pour the co-precipitation precursor D into the microwave hydrothermal reaction kettle, control the filling degree to 40%, seal the reaction, first keep it at 100°C for 5 minutes, then keep it at 125°C for 5 minutes, then keep it at 150°C for 10 minutes, and then Incubate at 175°C for 15 minutes, and finally at 200°C for 30 minutes. After the re...

Embodiment 3

[0038] Step 1: getting concentration is the uniform solution A of yttrium nitrate of 0.1mol / L, and concentration is the uniform solution B of potassium permanganate and 50% manganese nitrate solution C of 0.1mol / L;

[0039] Step 2: According to the molar ratio of Y / Mn: 1:1.5, Mn 7+ :Mn 2+ The molar ratio is: 1:4 Add solutions B and C to solution A, add deionized water and stir evenly, so that the concentration of yttrium nitrate is 0.0625mol / L; adjust to pH 10 to form a uniform co-precipitation precursor D ;

[0040] Step 3: Pour the co-precipitation precursor D into the microwave hydrothermal reaction kettle, control the filling degree to 40%, seal the reaction, first keep it at 100°C for 5 minutes, then keep it at 125°C for 5 minutes, then keep it at 150°C for 10 minutes, and then Incubate at 175°C for 15 minutes, and finally at 200°C for 30 minutes. After the reaction is completed, cool to room temperature;

[0041] Step 4: Take out the material in the reaction kettle a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com