Preparation method for novel nano-silver wire

A nano-silver wire, a new type of technology, applied in the field of preparation of new nano-silver wires, can solve the problems of high cost, complicated process, and inability to realize effective control of nanostructures, and achieve the effects of convenient operation, simplified process, and cost-saving preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

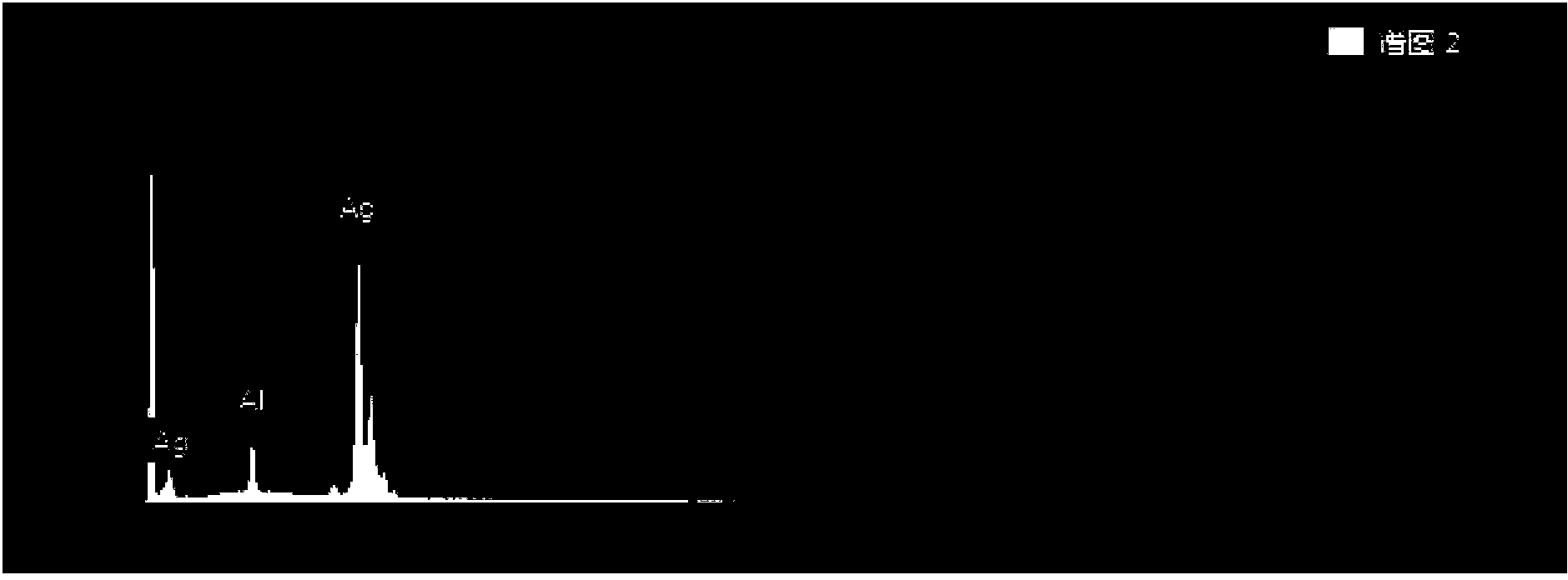

[0035] Embodiment 1 of the present invention: a kind of preparation method of novel nano-silver wire, comprises the following steps: take silver nitrate, dissolve in distilled water, obtain the A liquid that concentration is 0.5mol / L; Take dodecylamine, dissolve in ethanol In the solution, liquid B with a concentration of 0.5mol / L was obtained; liquid A and liquid B were transferred to the reactor through a syringe pump and mixed at a mixing rate of 1ml / min, and stirred with a glass rod until completely dissolved; Take 1mL of ammonia water and add it to 88mL of distilled water as a complexing agent, add the complexing agent into the mixed solution of A liquid and B liquid, stir evenly with a glass rod, let it stand for stratification, and obtain C liquid; take C liquid as the electrolytic solution Insert the anode into the water layer of the electrolyte, and insert the cathode into the oil layer of the electrolyte; slowly increase the voltage from 0V, when it increases to 31.5V...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of novel nano-silver wire, comprises the following steps: take by weighing 1.02g silver nitrate, be dissolved in the dehydrated alcohol of 10ml, obtain A liquid (concentration is 6mol / L); Take by weighing 5g twelve Alkylamine was dissolved in 30 mL of ethanol solution to obtain liquid B (concentration: 0.9 mol / L); liquid A and liquid B were transferred to the reactor through a burette and mixed at a mixing rate of 100 ml / min, and stirred with a glass rod until complete Dissolve; pipette 1mL of ethylenediamine into 80mL of distilled water as a complexing agent with a pipette gun, add the complexing agent into the mixed solution of liquid A and liquid B, stir evenly with a glass rod, let stand to separate layers, Obtain liquid C; take liquid C as the electrolyte, insert the anode into the water layer of the electrolyte, and insert the cathode into the oil layer of the electrolyte; perform an electrolytic reaction for 1 to 5 minute...

Embodiment 3

[0037] Embodiment 3: a kind of preparation method of novel nano silver wire, comprises the following steps: take by weighing 2.10g silver nitrate, be dissolved in the dehydrated alcohol of 30ml, obtain A liquid (concentration is 0.4mol / L); Weigh 10g ten Dialkylamine was dissolved in 50 mL of ethanol solution to obtain liquid B (concentration: 1.1 mol / L); liquid A and liquid B were transferred to the reactor through a needle and mixed at a mixing rate of 0.1 μl / min, and stirred with a glass rod until completely dissolved; pipette 1ml of salicylaldehyde into 20mL of distilled water as a complexing agent, add the complexing agent into the mixed solution of A liquid and B liquid, stir evenly with a glass rod, and let stand to separate layer to obtain liquid C; take liquid C as the electrolyte, insert the anode into the water layer of the electrolyte, and insert the cathode into the oil layer of the electrolyte; electrolyze for 5 minutes under the conditions of a voltage of 25V and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com