Foaming furnace with monitoring and alarming functions and foaming process

A monitoring and alarming and foaming furnace technology is applied in the foaming furnace and foaming process field with monitoring and alarming function, which can solve the problems of sheet foaming deviating from market requirements, difficult to make qualified products, etc., and achieve automatic adjustment. , avoid errors, reduce the effect of less air exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

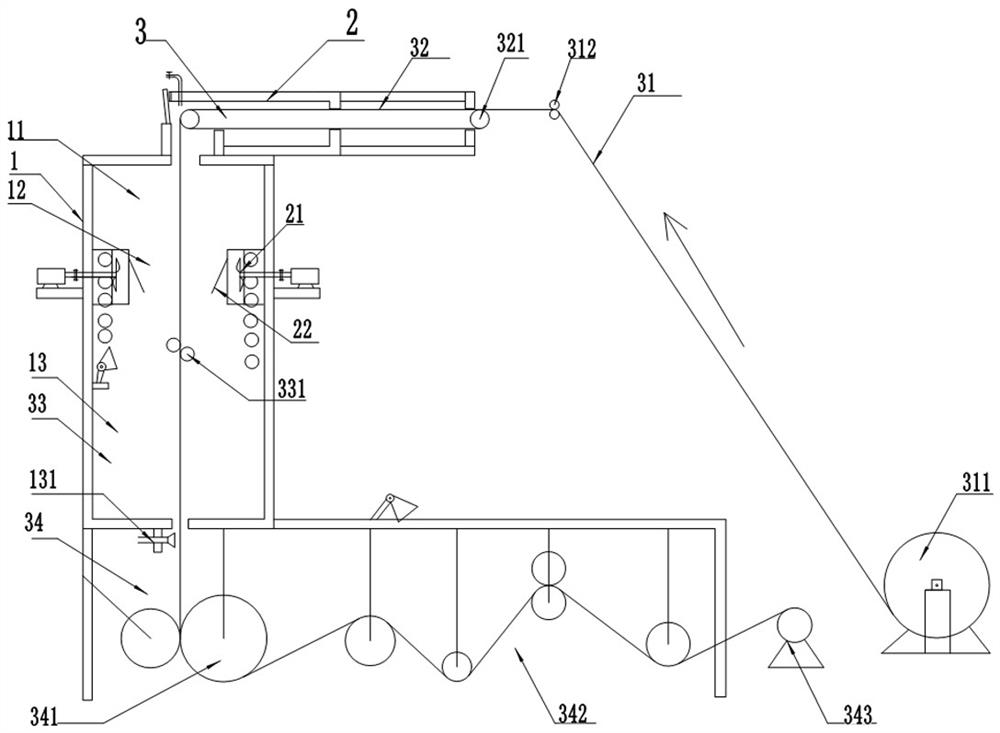

[0035] A foaming furnace with a monitoring and alarm function, comprising a vertical foaming furnace 1, a horizontal preheating furnace 2 arranged on the top of the vertical foaming furnace, and a horizontal preheating furnace 2 for transporting sheet-shaped continuous workpieces into and out of the horizontal preheating furnace 2 And the conveying device 3 of the vertical foaming furnace 1, the furnace space of the vertical foaming furnace 1 includes the first heating zone 11, the second heating zone 12 and the cooling zone 13 arranged in sequence from top to bottom, the described Conveyor 3 comprises incoming section 31, horizontal conveying section 32 in the furnace, vertical conveying section 33 and outgoing section 34 in the furnace, and incoming section 31 comprises unwinding roller 311 and guide roller 312, and horizontal conveying section 32 in the furnace comprises The horizontal conveying mechanism 321 arranged in the horizontal preheating furnace 2, the vertical conv...

Embodiment 2

[0046] A foaming furnace with a monitoring and alarm function, comprising a vertical foaming furnace 1, a horizontal preheating furnace 2 arranged on the top of the vertical foaming furnace, and a horizontal preheating furnace 2 for transporting sheet-shaped continuous workpieces into and out of the horizontal preheating furnace 2 And the conveying device 3 of the vertical foaming furnace 1, the furnace space of the vertical foaming furnace 1 includes the first heating zone 11, the second heating zone 12 and the cooling zone 13 arranged in sequence from top to bottom, the described Conveyor 3 comprises incoming section 31, horizontal conveying section 32 in the furnace, vertical conveying section 33 and outgoing section 34 in the furnace, and incoming section 31 comprises unwinding roller 311 and guide roller 312, and horizontal conveying section 32 in the furnace comprises The horizontal conveying mechanism 321 arranged in the horizontal preheating furnace 2, the vertical conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com