Fiber reinforcement and preparation method thereof

A fiber reinforcement and fiber weaving technology, which is applied in the field of fiber in-situ growth of multi-level SiC nanowire reinforcement and its preparation, can solve the problems of inability to microcrack branching, catastrophic failure of materials, and difficulty in size control. The effect of easy control of growth, simple preparation process and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

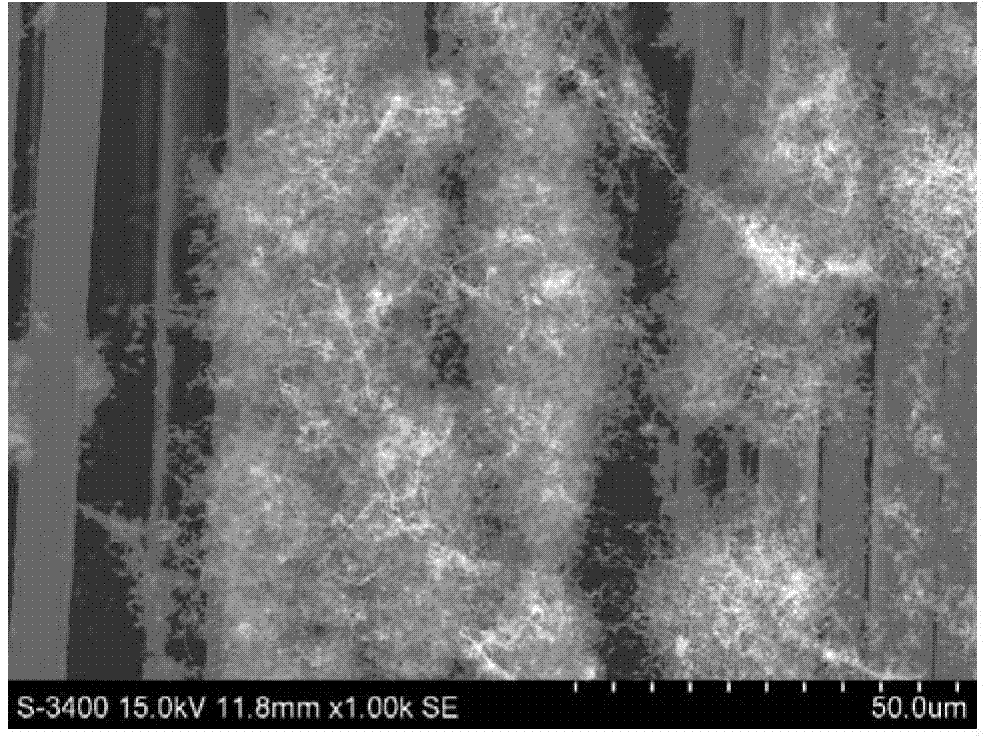

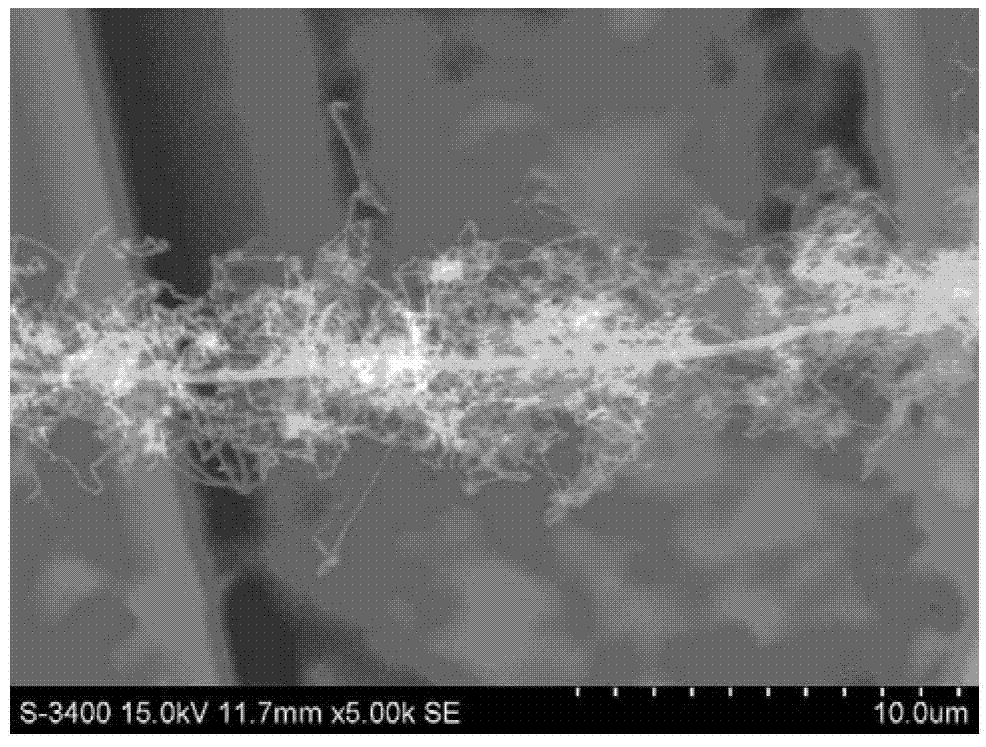

[0044] This example is to demonstrate the structure and morphology of the multi-level SiC nanowire reinforcement prepared by the "secondary catalyst method";

[0045] The carbon fiber braid was vacuum impregnated in 0.02 mol / L Ni(NO 3 ) 2 in acetone solution for 2h, remove and dry. Put the dry catalyst-loaded carbon fiber braid into the chemical vapor deposition equipment, raise the temperature to 700 ° C under the argon atmosphere, stop the argon, and pass in H 2 Ni(NO 3 ) 2 Reduced to Ni metal particles. stop h 2 Introduce, continue to heat up to 1100 ℃ by argon. Close the argon, pass through methyltrichlorosilane (MTS) and H 2 ,MTS / H 2 The mole fraction ratio is 0.1, the furnace pressure is 3KPa, and the reaction time is 0.5h. After the reaction, the gas was turned off and cooled to room temperature under an argon atmosphere to obtain a first-grade SiC nanowire reinforcement. The obtained reinforcement was washed with ethanol and dried, and the above steps were re...

Embodiment 2

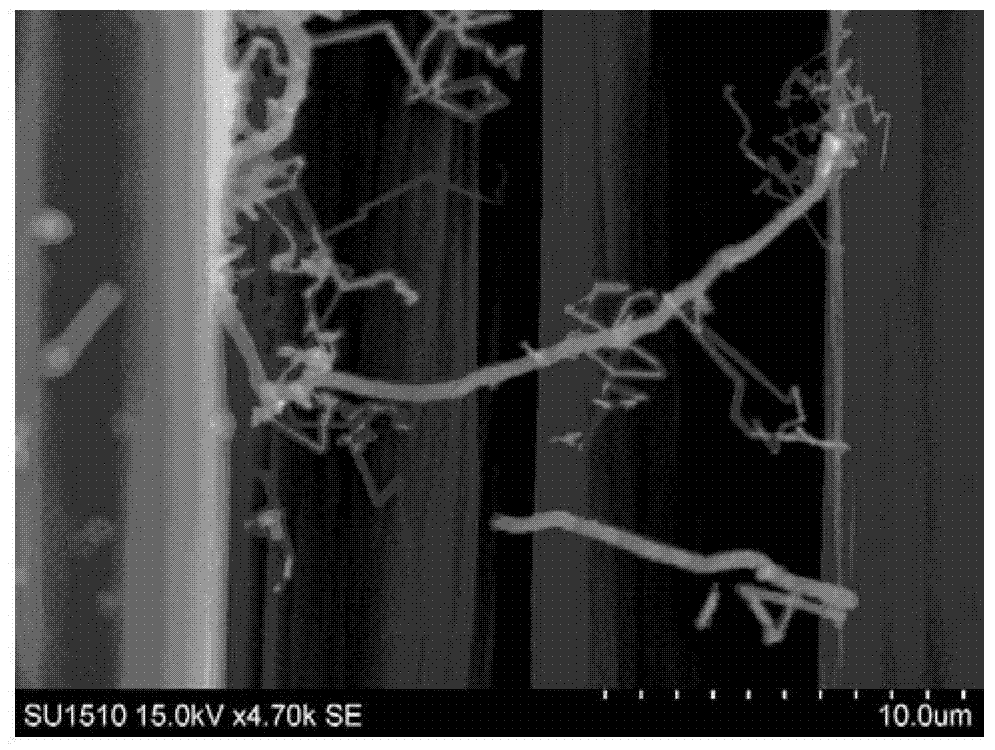

[0048] This example is to demonstrate the structure and morphology of the multi-level SiC nanowire reinforcement prepared by the "pressure adjustment method";

[0049] The SiC fiber braid was vacuum impregnated in a concentration of 0.01 Fe(NO 3 ) 3 in ethanol solution for 4h. Put the dry catalyst-loaded silicon carbide fiber braid into the chemical vapor deposition equipment, raise the temperature to 1000 ° C under nitrogen atmosphere, and pass H 2 Fe(NO 3 ) 3 Reduction to Fe metal particles. Stop aeration, pass into methyltrichlorosilane (MTS) and H 2 , and MTS / H 2 The mole fraction ratio is 0.2, the furnace pressure is 5KPa, the reaction is to be carried out for 40 minutes, the furnace pressure is changed to 100KPa, and the reaction is continued for 30 minutes. After the reaction, turn off the gas, and cool to room temperature under the protection of nitrogen atmosphere to obtain a multi-level SiC nanowire reinforcement, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com