Method for preparing one dimension SiC Nano fiber

A nanowire and graphite powder technology, applied in the field of preparation of SiC nanomaterials, can solve the problems of difficult growth control, complex process, low conversion rate, etc., and achieve the effects of low raw material and preparation cost, simple process and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

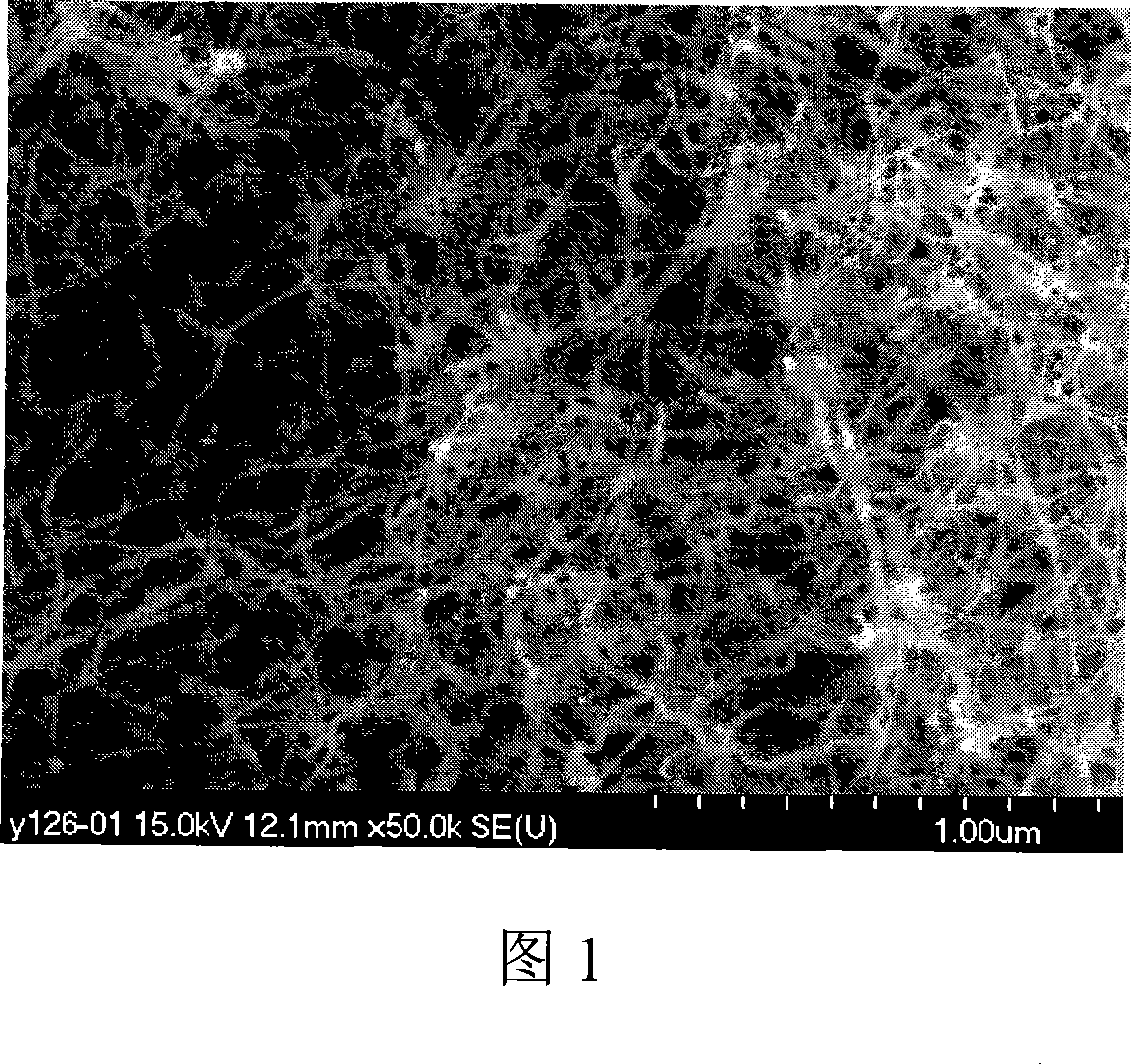

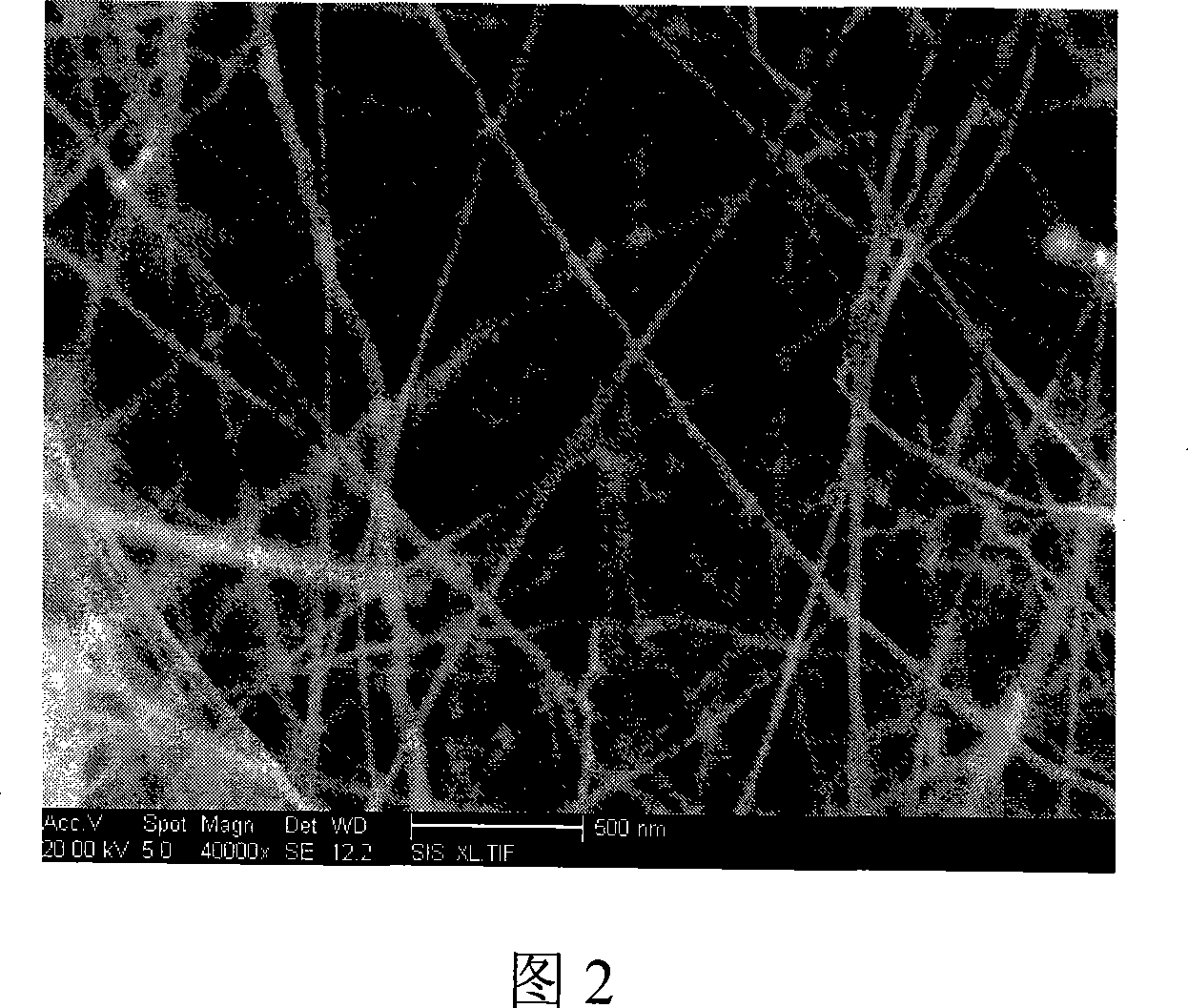

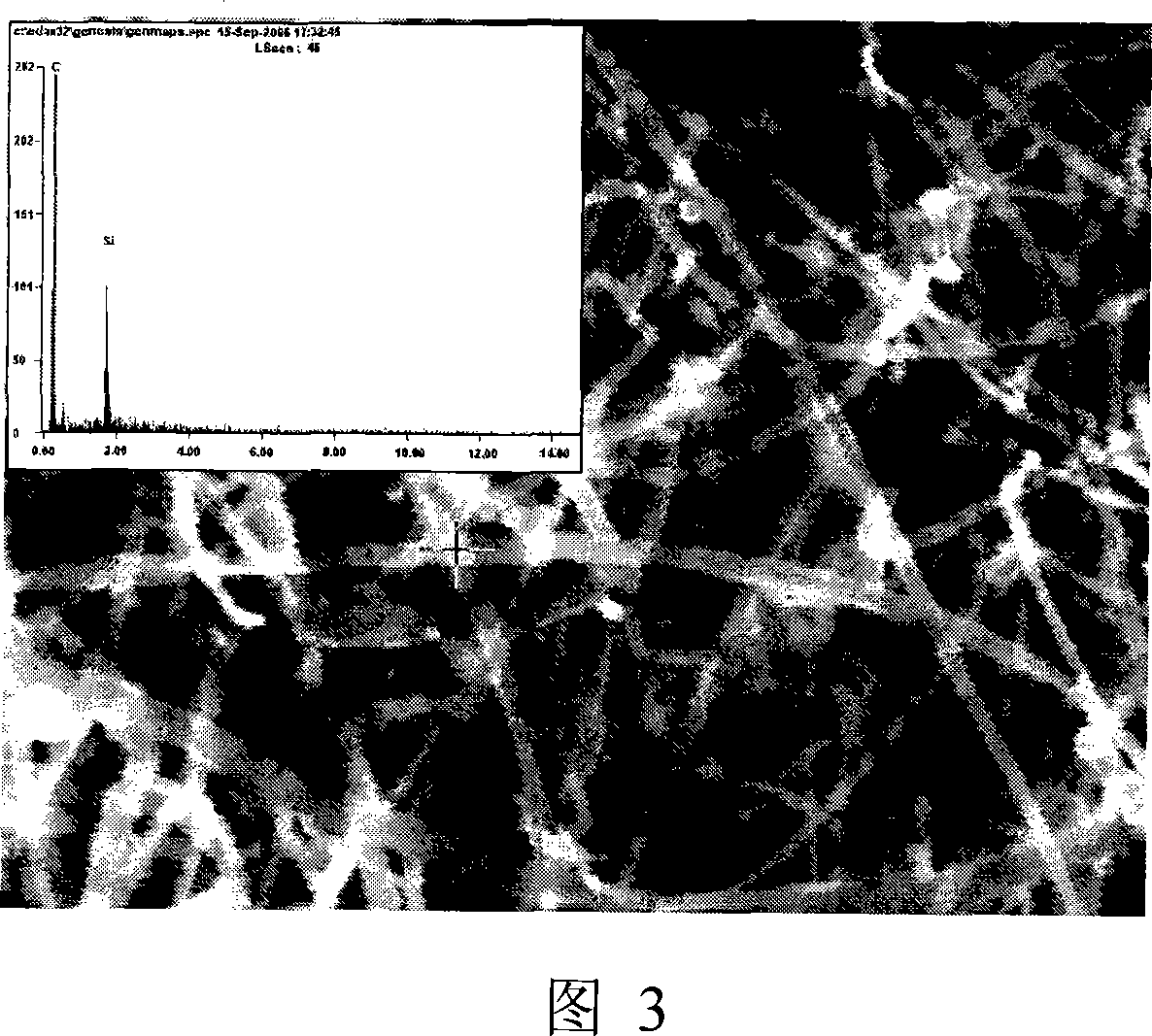

[0010] Specific embodiment one: the method for preparing silicon carbide nanowires in this embodiment adopts the method of in-situ reaction, realizes through the following steps: a, take by weighing Si powder that purity is 99.99% by the molar ratio of 0.8~1.2:1 and Graphite powder, after Si powder and graphite powder are mixed; b, the mixture is packed in the vacuum ball milling jar, selects the ball material ratio as 20~35: 1, fills the ball milling jar with a vacuum and the purity of 0.01~0.2 atmospheric pressure is 99.9999% argon, put the ball mill jar on a high-energy ball mill for 12-48 hours at a speed of 430-510 rpm, and the particle size reaches 5-50nm; 3 with H 2 The volume ratio of O is 0.8 ~ 1.2:1 nitric acid solution soaked for 20 ~ 36h, then pour off the nitric acid, and pickle again according to the above method; d, the powder after pickling is washed with distilled water; Add an organic solvent to the powder, and disperse ultrasonically for 10-15 minutes; f. L...

specific Embodiment approach 2

[0012] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step g, the suspended liquid after standing still is dropped onto the cleaned substrate surface or porcelain boat, and then baked at 60-80°C Dry. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: the difference between this embodiment and specific embodiments one and two is that the molar ratio of Si powder and graphite powder in step a is 1:1. Other steps are the same as those in Embodiments 1 and 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com