Oxidation strengthening technique and device for processing organic poison waste water

A technology of organic poison and oxidation process, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high equipment requirements, unstable operation, long reaction time, etc., and achieve the effect of high reaction efficiency, wide application range and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

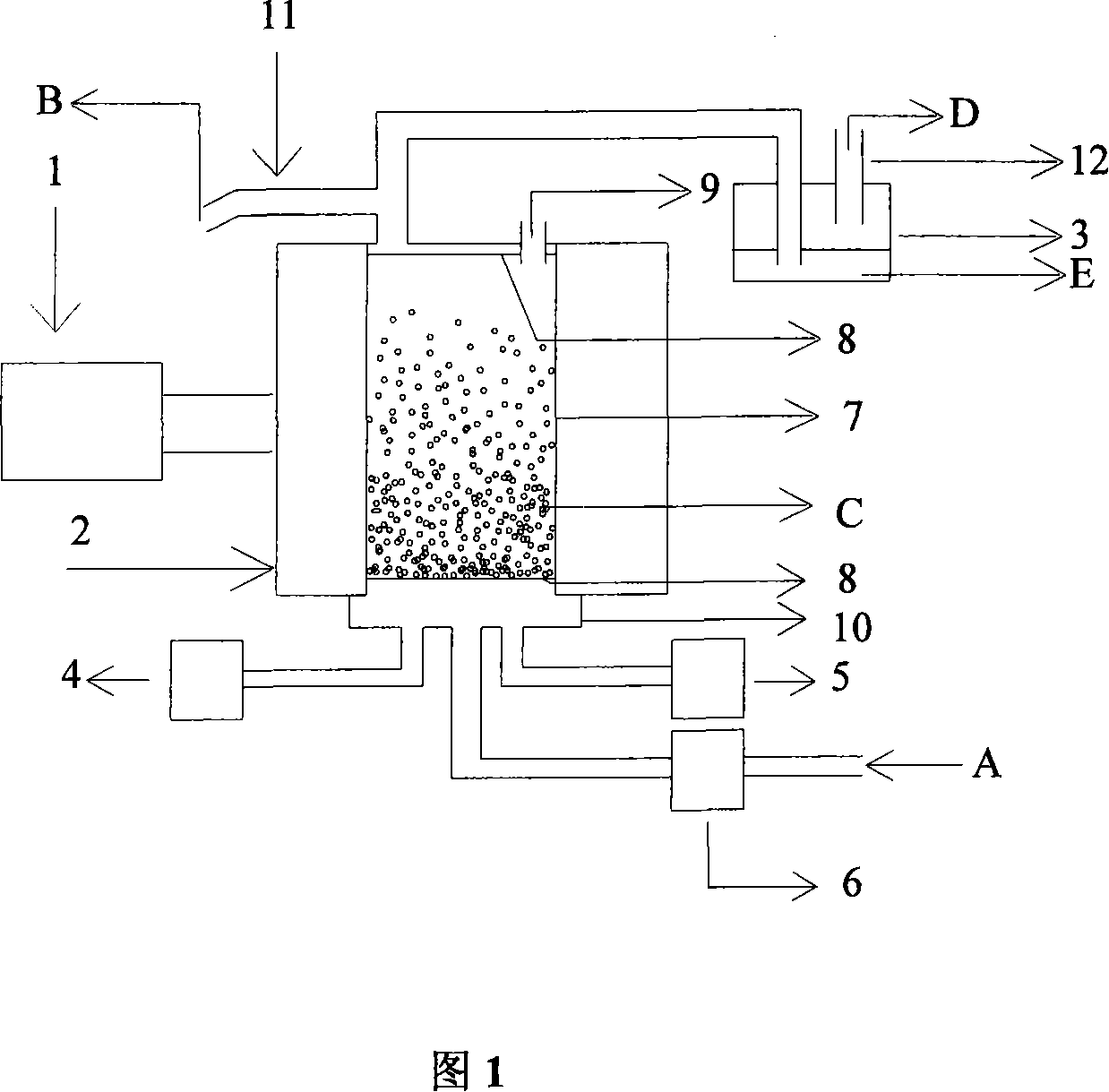

[0029] The water treatment device is composed of an energy generator 1, a reaction chamber 2, an exhaust gas collection device 3, and inflow pumps 4, 5, and 6. The reaction column 7 is built in the reaction chamber 2. The reaction column 7 has a diaphragm 8 above and below, and the catalyst C is filled in the column. , the catalyst C is added from the catalyst dosing port 9 on the upper part of the reaction column 3, and the inlets 4, 5, and 6 below the reaction column are respectively used for inflow air, organic poisons and oxidants, and enter the reaction column 7 through the water distributor 10, and the treated effluent Exhausted from the branch port 11 on the pipeline of the exhaust gas collection device 3, the exhaust gas enters the exhaust gas collection device 3, and the exhaust gas is discharged from the exhaust gas outlet 12. The energy source 1 is external, and the power of the energy source is continuously adjustable. The energy is introduced into the reaction cham...

Embodiment 2

[0031] The water treatment device is composed of an energy generator 1, a reaction chamber 2, an exhaust gas collection device 3, and inflow pumps 4, 5, and 6. The reaction column 7 is built in the reaction chamber 2. The reaction column 7 has a diaphragm 8 above and below, and the catalyst C is filled in the column. , the catalyst C is added from the catalyst dosing port 9 on the upper part of the reaction column 3, and the inlets 4, 5, and 6 below the reaction column are respectively used for inflow air, organic poisons and oxidants, and enter the reaction column 7 through the water distributor 10, and the treated effluent Exhausted from the branch port 11 on the pipeline of the exhaust gas collection device 3, the exhaust gas enters the exhaust gas collection device 3, and the exhaust gas is discharged from the exhaust gas outlet 12. The energy source 1 is external, the power of the energy source is continuously adjustable, and the energy is introduced into the reaction cham...

Embodiment 3

[0034] The water treatment device is composed of an energy generator 1, a reaction chamber 2, an exhaust gas collection device 3, and inflow pumps 4, 5, and 6. The reaction column 7 is built in the reaction chamber 2. The reaction column 7 has a diaphragm 8 above and below, and the catalyst C is filled in the column. , the catalyst C is added from the catalyst dosing port 9 on the upper part of the reaction column 3, and the inlets 4, 5, and 6 below the reaction column are respectively used for inflow air, organic poisons and oxidants, and enter the reaction column 7 through the water distributor 10, and the treated effluent Exhausted from the branch port 11 on the pipeline of the exhaust gas collection device 3, the exhaust gas enters the exhaust gas collection device 3, and the exhaust gas is discharged from the exhaust gas outlet 12. The energy source 1 is external, the power of the energy source is continuously adjustable, and the energy is introduced into the reaction cham...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com