Barrier polishing solution

一种抛光溶液、阻挡层的技术,应用在含研磨剂的抛光组合物、其他化学过程、研磨机床等方向,能够解决低钽去除速率等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

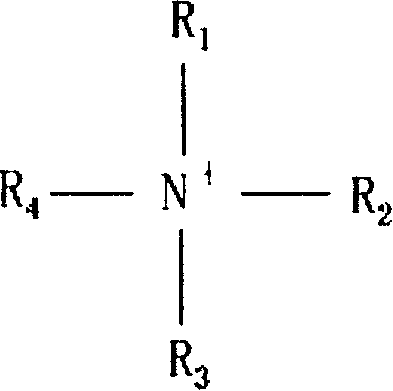

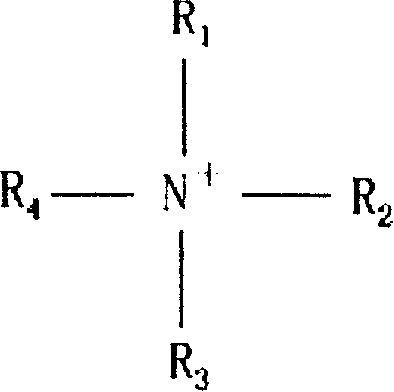

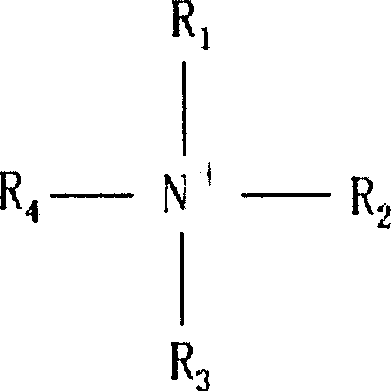

Image

Examples

Embodiment 1

[0039] A series of solution compositions shown in Table 1 were prepared in order to evaluate the performance of two anti-yellowing additives (EDTA and citric acid) at different concentration levels. In preparing this composition, all necessary chemicals shown in Table 1 (except hydrogen peroxide and abrasives) were added in required amounts to deionized water in a container. Stir the solution in the container until all ingredients are dissolved in water. The abrasive is then added to the container. The pH of the solution was then adjusted to the target pH by adding nitric acid. Subsequently, hydrogen peroxide was added to the container for use as a polishing composition.

[0040] The yellowing test was performed at room temperature and without disturbance. The slurries with different amounts of anti-yellowing additives were filled into plastic bottles. Keep these bottles in one location and avoid disturbance for 18 days. The colors of these slurries were determined by vis...

Embodiment 2

[0046] Slurries A, 2, 3 and 10 were selected from Example 1 for polishing tests to determine whether the presence of additives would affect the removal rate of the wafers. In the test slurry, slightly increase the pH and H 2 o 2 concentration. In addition, the sodium salt of EDTA was replaced with the acid form of EDTA in order to reduce the total alkali ion concentration in the slurry. Similar to Example 1, slurries 12, 13 had the same effective molar concentration of EDTA as slurries 2 and 3.

[0047] Polishing experiments were performed using a Mirra(R) type polishing tool manufactured by Applied Materials. The polishing pad was IC1010 from Rohm and Haas Electronic Materials CMP Technologies TM Porous polyurethane pad. Before each run, the pads were conditioned with diamond lapping plates produced by Kinik with 180 μm diamonds. The polishing process was performed at a membrane pressure of 10.33 kPa (1.5 psi), a table speed of 93 revolutions per minute (rpm) and a carr...

Embodiment 3

[0052] This example examines the effect of anti-yellowing additives on wafer defects.

[0053] The experiment was performed on a Mirra(R) type polishing tool manufactured by Applied Materials. The polishing pad was IC1010 from Rohm and Haas Electronic Materials CMP Technologies TM Cellular polyurethane backing. The pads were conditioned before each operation using a diamond lapping plate made by Kinik containing 180 μm diamonds. The polishing process was performed at a pressure of 10.33 kPa (1.5 psi), a table speed of 93 revolutions per minute (rpm) and a carriage speed of 87 rpm. The feed rate (slurry flow rate) of the CMP composition was 200 milliliters per minute (ml / min). By commercially available slurry EPL2362 (produced by Eternal Chemical Co., Ltd), using a CUP4410 pad (provided by Rohm and Haas Electronic Materials CMP Technologies) and 21.7kPa (3psi), 93rpm table rotation speed, 87rpm carriage rotation speed and 200ml / min slurry Process Parameters for Flow Rate A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| composition ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com