Method for treating bisphenol A-containing wastewater

A treatment method, wastewater technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of incomplete degradation of bisphenol A, insufficient effect, complicated process, etc. Achieve the effect of good treatment effect, obvious removal effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

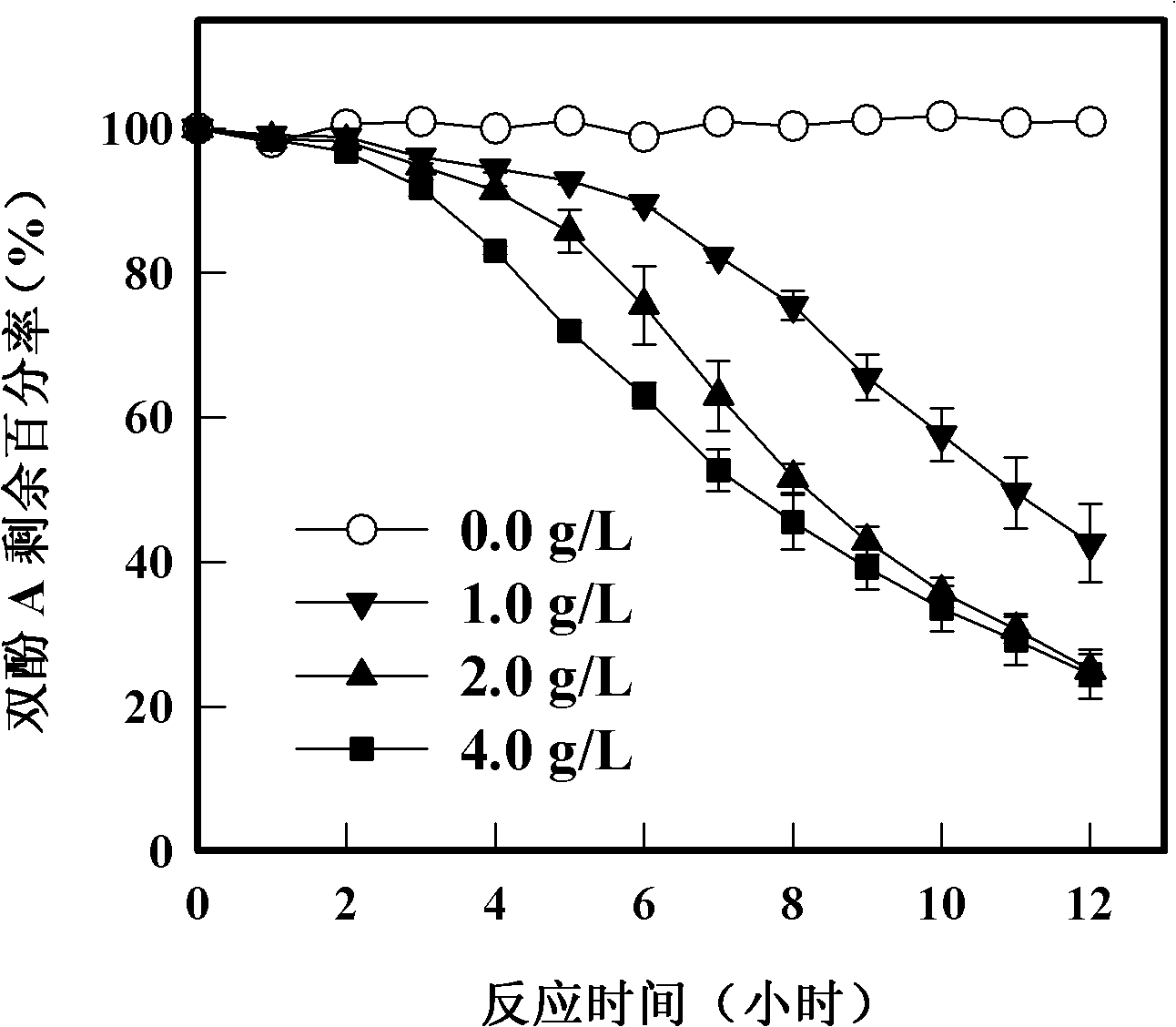

[0018] Embodiment 1: The influence of the dosage of aluminum powder on the degradation rate of bisphenol A

[0019] The treatment object is wastewater containing bisphenol A concentration of 2.0mg / L, firstly use HNO 3 Adjust the pH to 2.5, then add aluminum powder according to different dosages, carry out the treatment at 25°C under constant stirring, measure the remaining percentage of bisphenol A in the wastewater every 2 hours, the results are shown in figure 1 .

[0020] It can be seen from the figure that the degradation efficiency of bisphenol A increases with the increase of the dosage of aluminum powder. With the dosage of 4g / L aluminum powder, the degradation rate of bisphenol A can reach more than 75% after 12 hours of treatment.

Embodiment 2

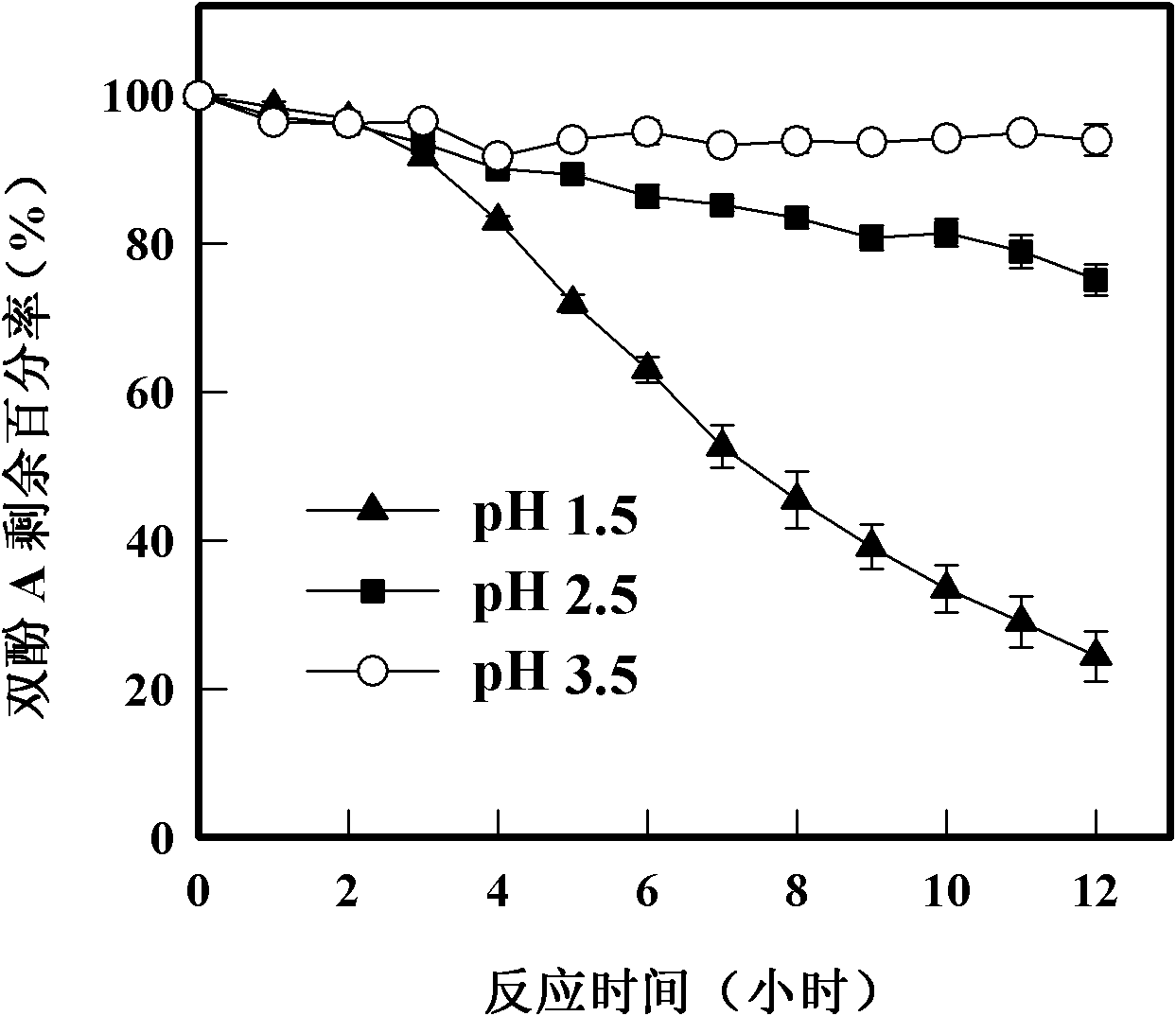

[0021] Embodiment 2: The influence of initial pH value on bisphenol A degradation rate

[0022] The treatment object is wastewater containing bisphenol A concentration of 2.0mg / L, firstly use HNO 3 Adjust the pH to different initial pH values, then add aluminum powder according to the dosage of 4g / L wastewater, and process it at 25°C under constant stirring, and measure the remaining percentage of bisphenol A in the wastewater every 2 hours. The results are shown in figure 2 .

[0023] It can be seen from the figure that the lower the initial pH, the better the degradation effect of bisphenol A. When the initial pH is 1.5, the degradation rate of bisphenol A can reach about 80% after 12 hours of treatment.

Embodiment 3

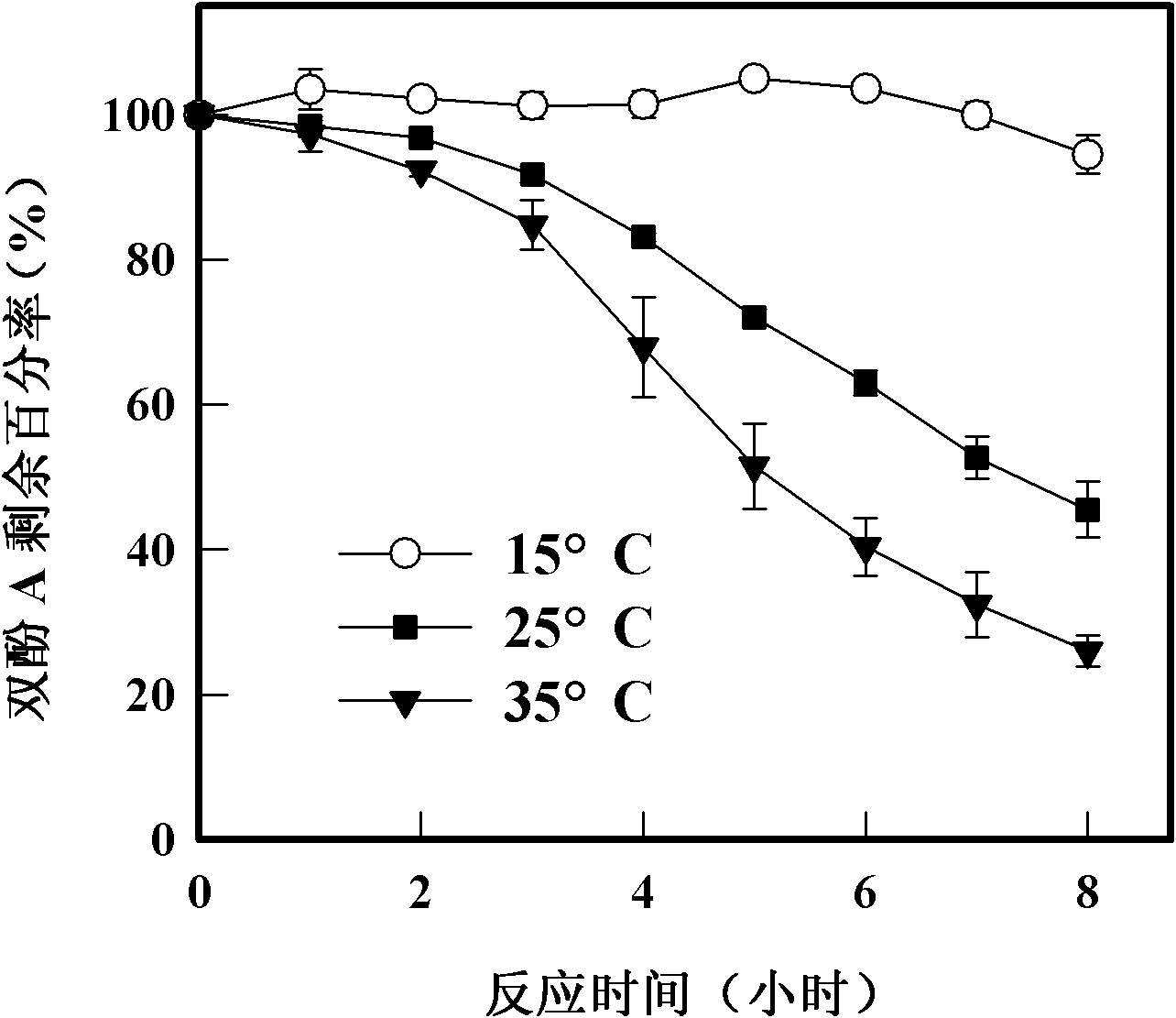

[0024] Embodiment 3: the influence of temperature on bisphenol A degradation rate

[0025] The treatment object is wastewater containing bisphenol A concentration of 2.0mg / L, firstly use HNO 3 Adjust the pH to 2.5, then add aluminum powder according to the dosage of 4g / L waste water, carry out treatment at different temperatures under constant stirring, measure the remaining percentage of bisphenol A in the waste water every 2 hours, the results are shown in image 3 .

[0026] It can be seen from the figure that the higher the treatment temperature, the better the degradation effect of bisphenol A. When the treatment temperature is 35°C, the degradation rate of bisphenol A can reach more than 75% after 12 hours of treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com