Manganese dioxide-magnetic biochar composite catalyst as well as preparation method and application thereof

A technology of composite catalyst and manganese dioxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve the problem of difficult recovery of manganese dioxide and pollutant adsorption capacity Weakness and other problems, to achieve the effect of shortening the migration path, improving the effective utilization rate, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

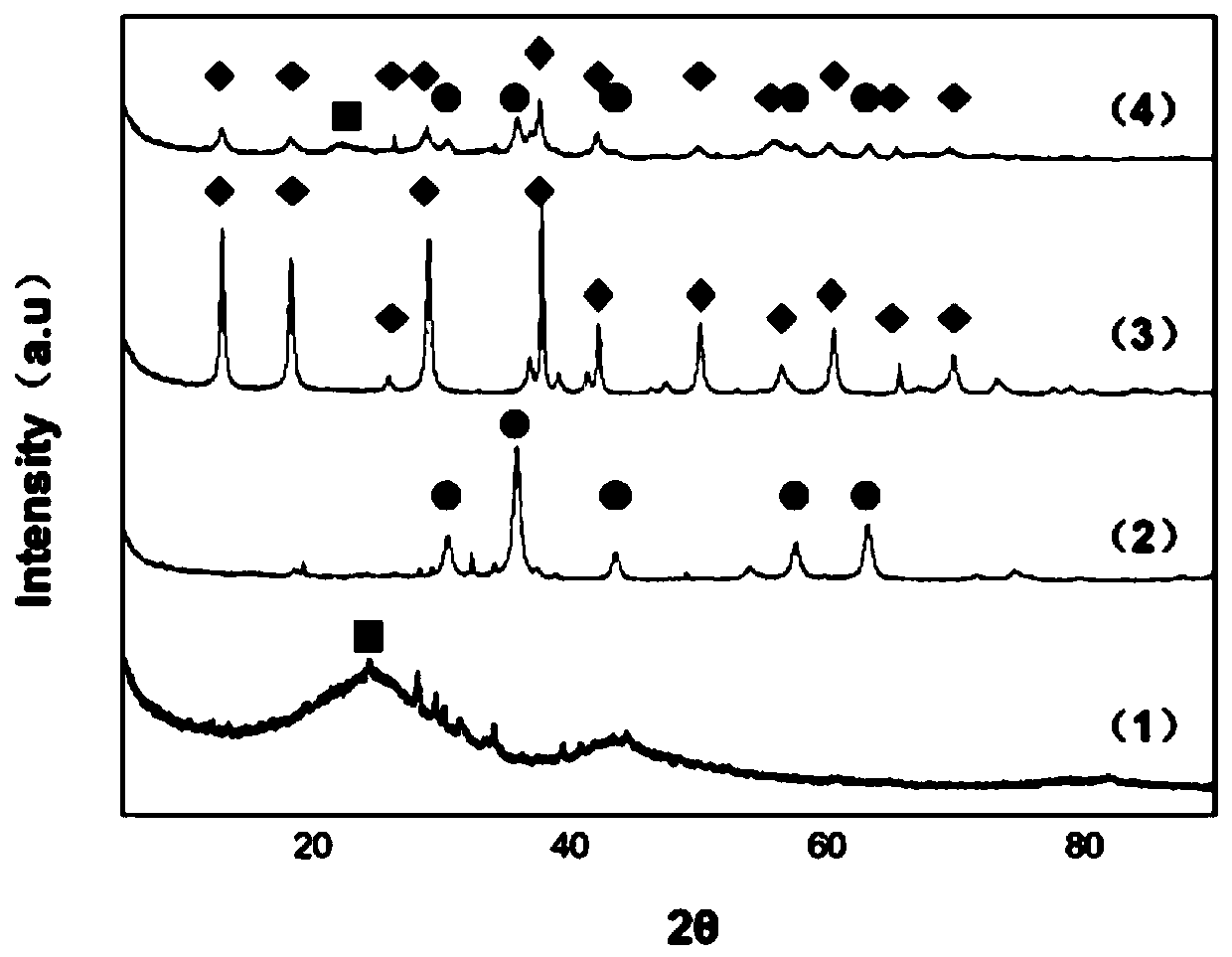

[0043] In this embodiment, the steps of the preparation method of the manganese dioxide-magnetic biochar catalyst are as follows:

[0044] 1) Put the grapefruit peel as biomass in a crucible, cover it and put it in a muffle furnace, pyrolyze it for 2 hours under oxygen-limited conditions at 800°C to generate biochar, wash it with deionized water and absolute ethanol, respectively After washing three times, dry, grind and sieve to obtain biochar A;

[0045] 2) Add 5.56g of ferrous sulfate heptahydrate and 3.244g of ferric chloride to 500ml of deionized water and mix uniformly to prepare an iron salt solution. Add 3g of biochar A to the iron salt solution and mix evenly (at this time, the biochar A The mass concentration is 2 mg / mL, the mass concentration of ferrous ions in the ferrous salt is 0.48 mg / mL, and the mass concentration of ferrous ions in the ferric salt is 0.96 mg / mL), so that the ferrous ions and ferrous ions are uniformly dispersed on the surface of the biochar; Add 1...

Embodiment 2

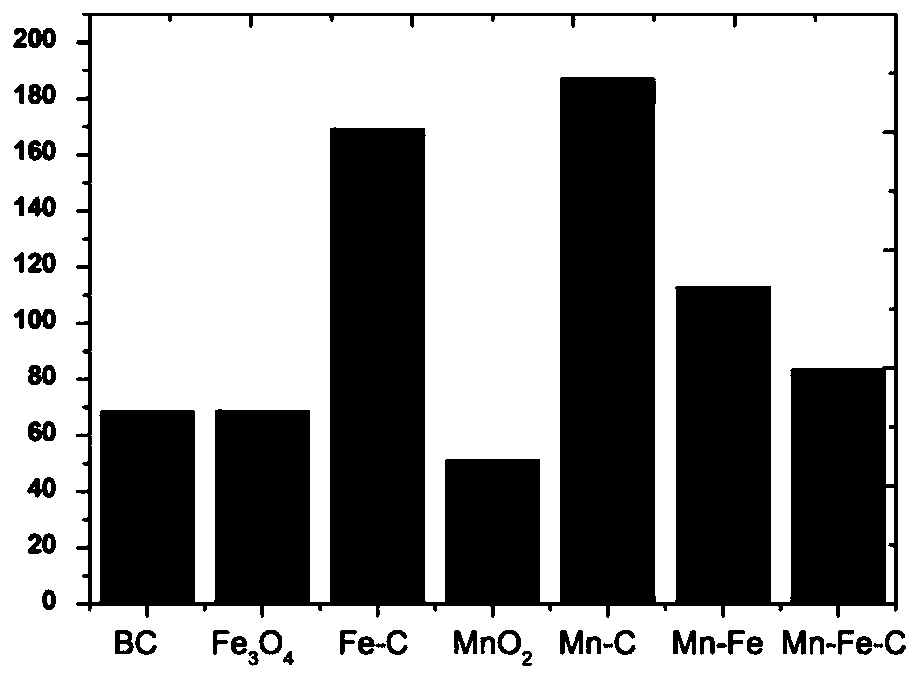

[0055] The manganese dioxide-magnetic biochar prepared in Example 1 and each control material were added to the solution containing potassium persulfate and 4-chlorophenol, and the concentration of each material added was 0.2g / L, 4-chlorophenol The concentration is 10mg / L, the potassium persulfate concentration is 10mmol / L, react for 180 minutes, take samples at 0, 5, 10, 20, 30, 45, 60, 90, 120, and 180 minutes to determine the concentration of 4-chlorophenol . The experimental results are as Figure 5 As shown, it can be seen that the manganese dioxide-magnetic biochar can still effectively activate potassium persulfate and has a better removal rate for 4-chlorophenol. However, the activity of manganese dioxide-biochar and manganese dioxide-ferric oxide is much lower than that of manganese dioxide-magnetic biochar. This is because the magnetic biochar can still retain the α-manganese dioxide structure, while the ferroferric oxide and biochar destroy its structure. In additi...

Embodiment 3

[0057] The manganese dioxide-magnetic biochar prepared in Example 1 and the control materials were added to the 4-chlorophenol solution, the concentration of each material added was 0.2g / L, and the concentration of 4-chlorophenol was 10mg / L. Reaction for 180 minutes, samples were taken at 0, 5, 10, 20, 30, 45, 60, 90, 120, and 180 minutes to determine the concentration of 4-chlorophenol. The experimental results are as Figure 7 As shown, it can be seen that both manganese dioxide-biochar and manganese dioxide-magnetic biochar have a certain adsorption capacity for 4-chlorophenol, while manganese dioxide and manganese dioxide-ferric tetroxide have a certain adsorption capacity for 4-chlorophenol. The adsorption capacity of chlorophenol is very weak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com