Chemically mechanical polishing solution

A chemical machinery and polishing liquid technology, applied in polishing compositions containing abrasives, etc., can solve the problems of difficult polysilicon removal, high polysilicon/silicon dioxide selection ratio, and achieve no polysilicon residue, increased productivity, and high flatness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

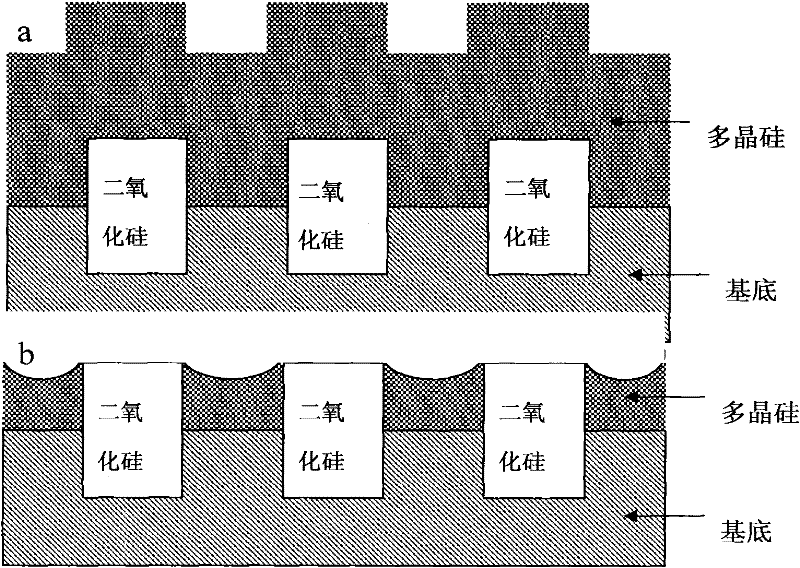

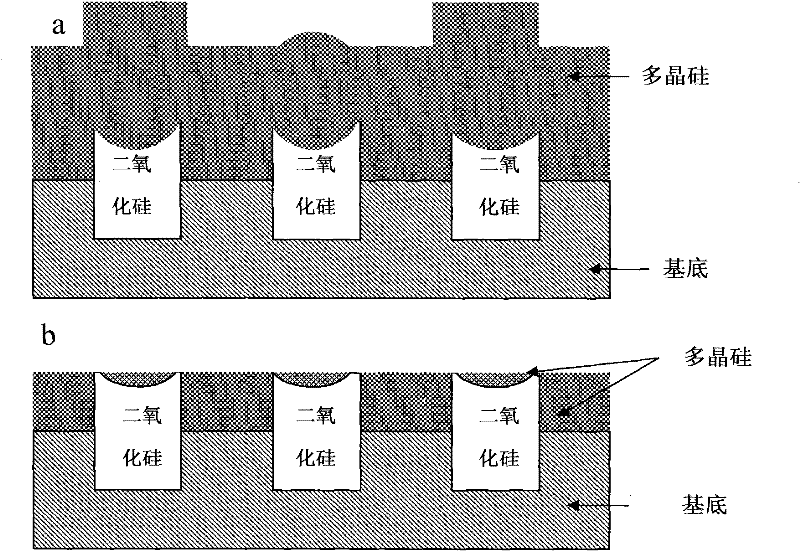

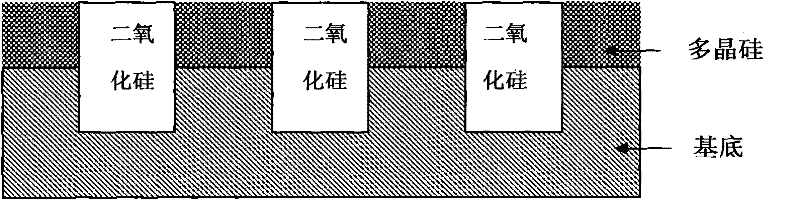

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The chemical mechanical polishing fluid of embodiment 1 polysilicon

[0027] Table 1 has provided the formula of polysilicon chemical mechanical polishing liquid 1~35 of the present invention, mixes uniformly by each component and content thereof given in the table, water makes up the percentage by weight to 100%, adopts potassium hydroxide and nitric acid etc. to adjust to The polishing liquid of each embodiment can be prepared at a suitable pH value, and water is the balance.

[0028] Table 1 Chemical Mechanical Polishing Fluids for Polysilicon 1-35

[0029]

[0030]

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com