Chemi-mechanical polishing fluid for polishing semiconductor wafer

A chemical machinery and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, polishing compositions containing abrasives, electrical components, etc., can solve the problems of insufficient polishing precision, low polishing precision, scratches, etc., and achieve high polishing precision, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Table 1 has provided the formula of chemical mechanical polishing liquid 1~5 of the present invention, can get the polishing liquid of each embodiment by mixing each component and its content given in the table, water is surplus.

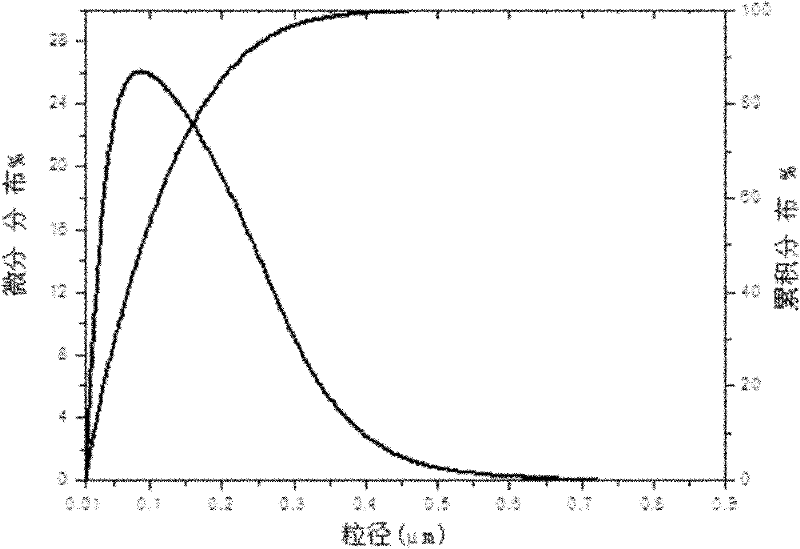

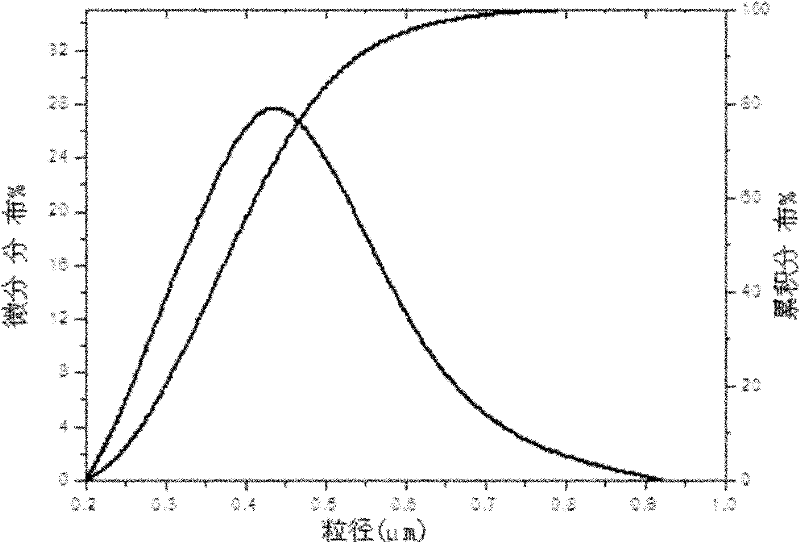

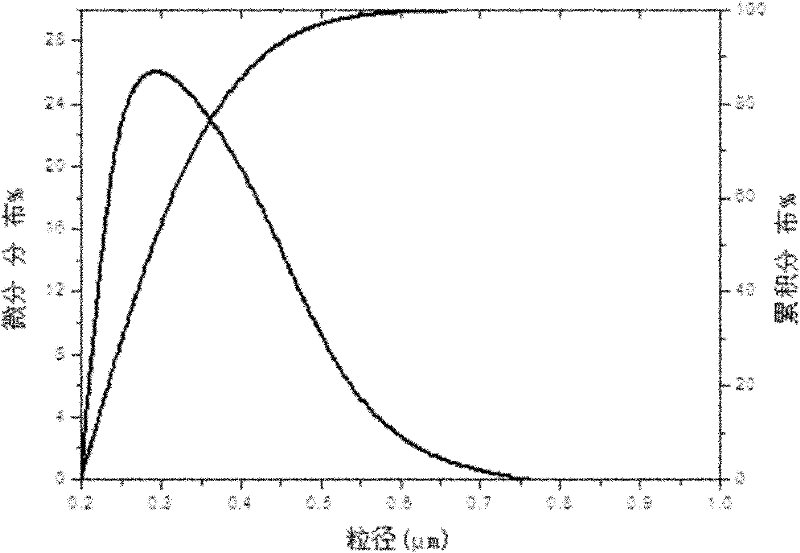

[0025] Use the LS-POP (VI) laser particle size analyzer of Zhuhai European and American Co., Ltd. to test the particle size of the abrasive particles in the polishing liquid 1 to 5 respectively. The obtained particle size distribution diagram is shown in Figure 1~5 , the result of the particle size test is that the CeO in the polishing solution 1 2 The median particle size of the particles is 103nm, and the CeO doped with aluminum in the polishing solution 2 2 The median particle size of the particles is 392nm, polished 3 SiO 2 The median particle size of the particles is 334nm, and the CeO in the polishing solution 4 2 The median particle size of the particles is 215nm, and SiO in polishing solution 5 2 The median diameter of the particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com