Patents

Literature

30results about How to "Slurry stabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-polymeric organic particles for chemical mechanical planarization

InactiveUS20050005525A1Reduce defectsHigh selectivityPigmenting treatmentOther chemical processesSoft waterSURFACTANT BLEND

An abrasive composition comprising non-polymeric organic particles that is useful for chemical mechanical planarization (CMP), and which can widely be used in the semiconductor industry. The inventive compositions preferably comprise soft water in combination with 0.001-20 w / w % of non-polymeric organic particles, 0.1-10 w / w % of an oxidizing agent, 0.05-10 w / w % of a chelating agent, 0.01-10 w / w % of a surfactant, and 0-10 w / w % of a passivation agent at a pH in the range of 2-12, wherein said percentages are w / w (weight / weight) percentages, based on the total weight of said compositions. The abrasive compositions provide an efficient polishing rate, excellent selectivity and good surface quality when utilized as a new abrasive composition in CMP applications.

Owner:DYNEA AUSTRIA

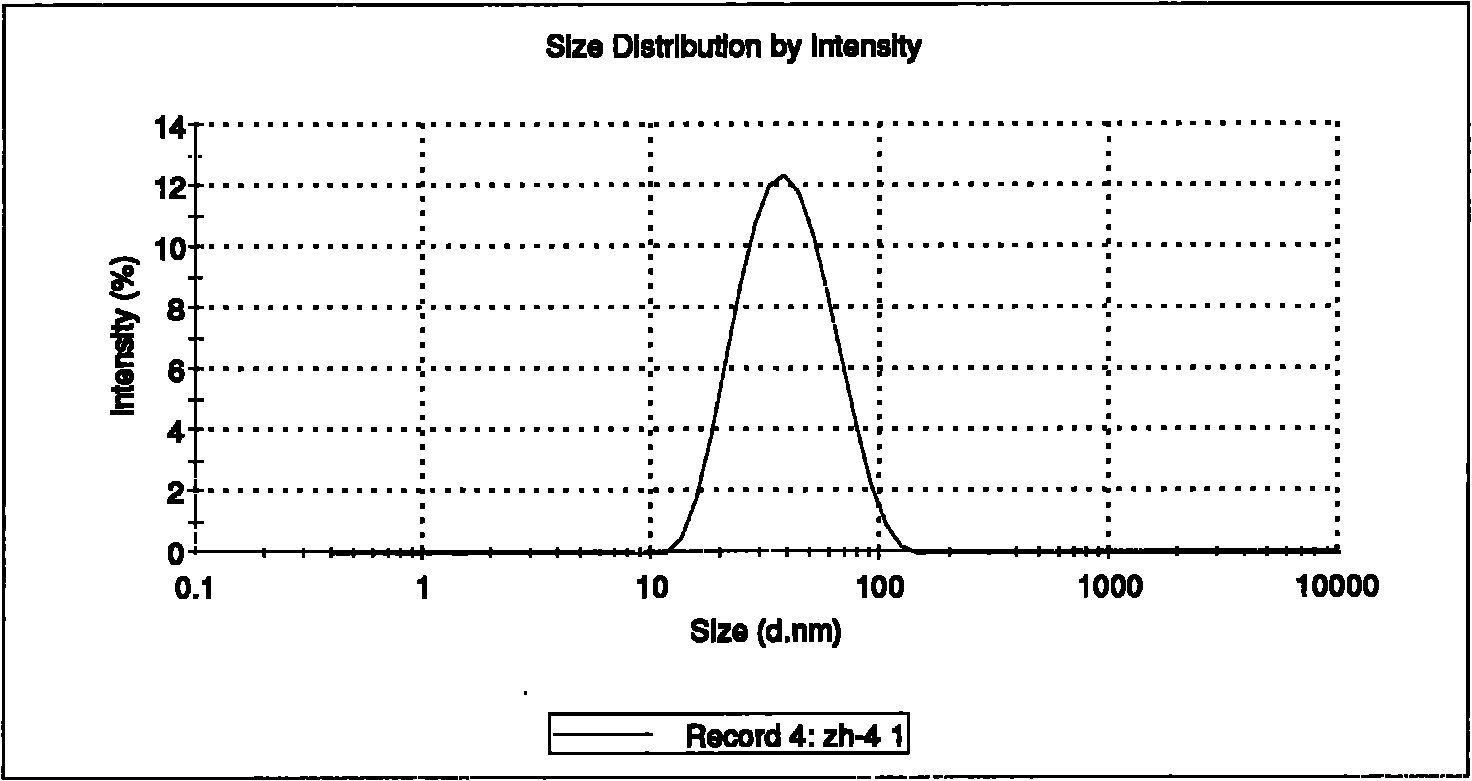

Graphene/UHMWPE composite fiber and preparation method and application thereof

ActiveCN106222780AGood dispersionEasy secondary dispersionMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberCvd graphene

The invention discloses a graphene / UHMWPE composite fiber and a preparation method thereof. In the composite fiber, the content of graphene is 0.05-5 wt% of that of UHMWPE. The preparation method comprises: pre-dispersing graphene in a solvent to form a uniform graphene dispersion liquid, fully dissolving UHMWPE powder in a solvent in a heating condition, fully mixing the obtained solution with the obtained graphene dispersion liquid, spinning the fully-mixed UHMWPE / graphene mixed solution through a gel-spinning method, and performing solvent extraction and drawing to obtain the graphene / UHMWPE composite fiber. The prepared graphene / UHMWPE composite fiber is obviously improved in the mechanical strength. The tensile strength can reach 29 cN / dtex, and the tensile modulus can reach 1300 cN / dtex. Through changing the addition ratio of graphene and UHMWPE powder, the size of graphene and different dispersion processes, the mechanical property of the composite fiber can be regulated.

Owner:南通恒尚新材料科技有限公司 +1

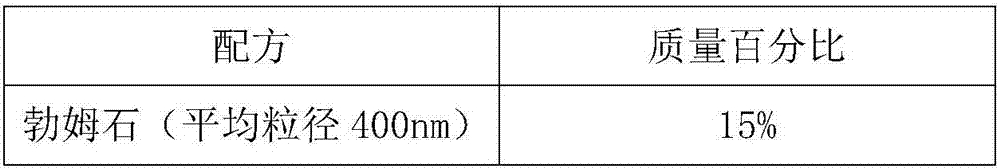

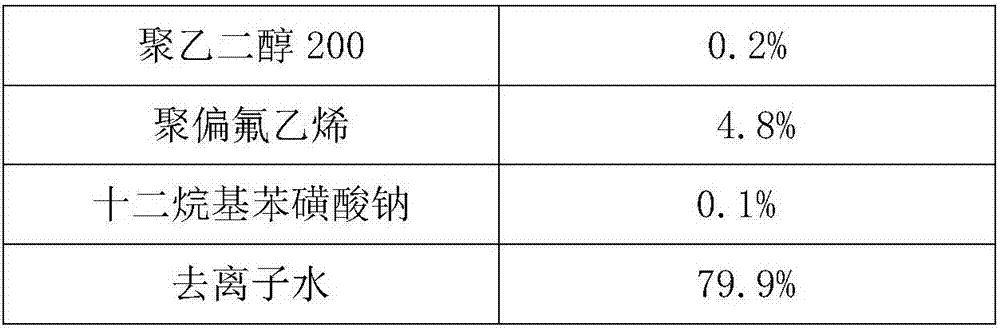

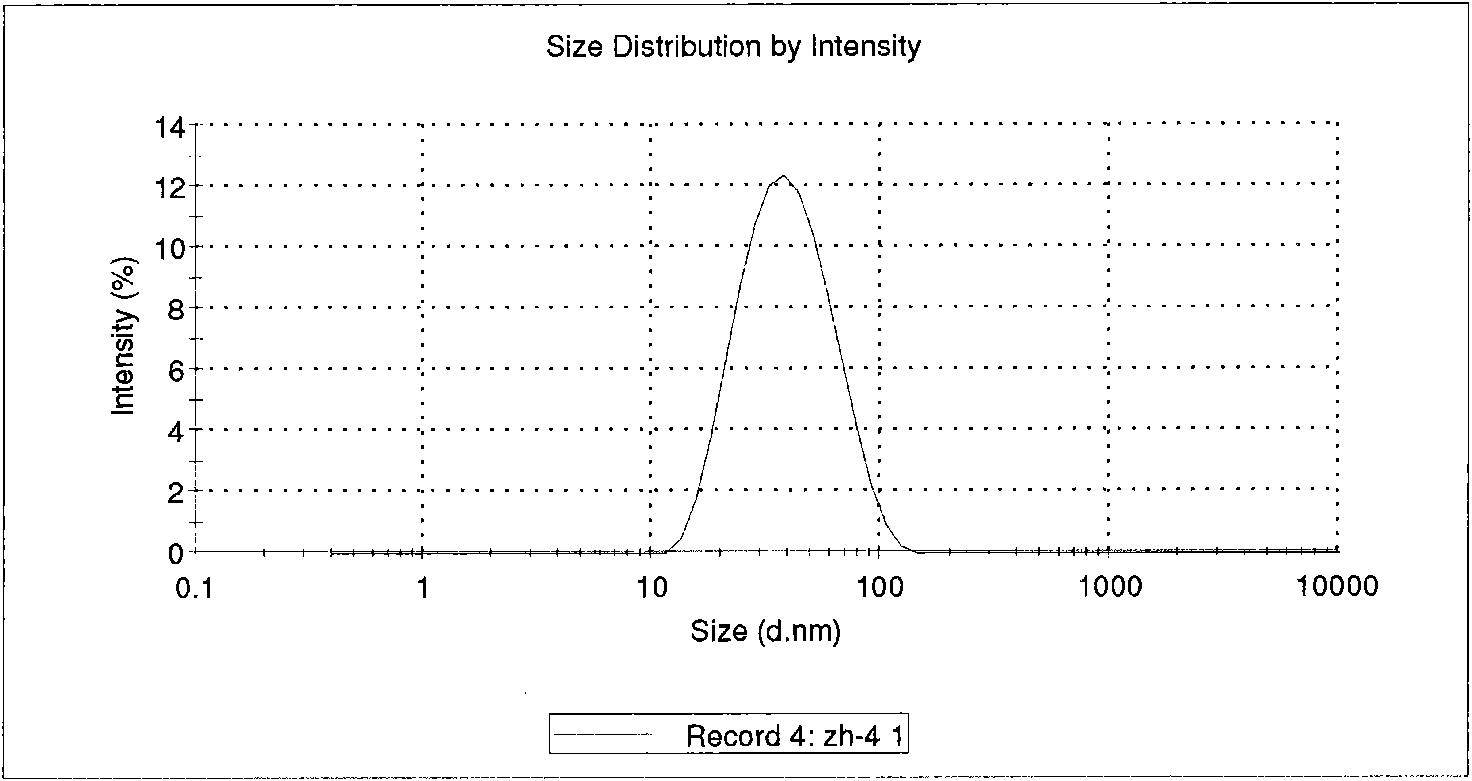

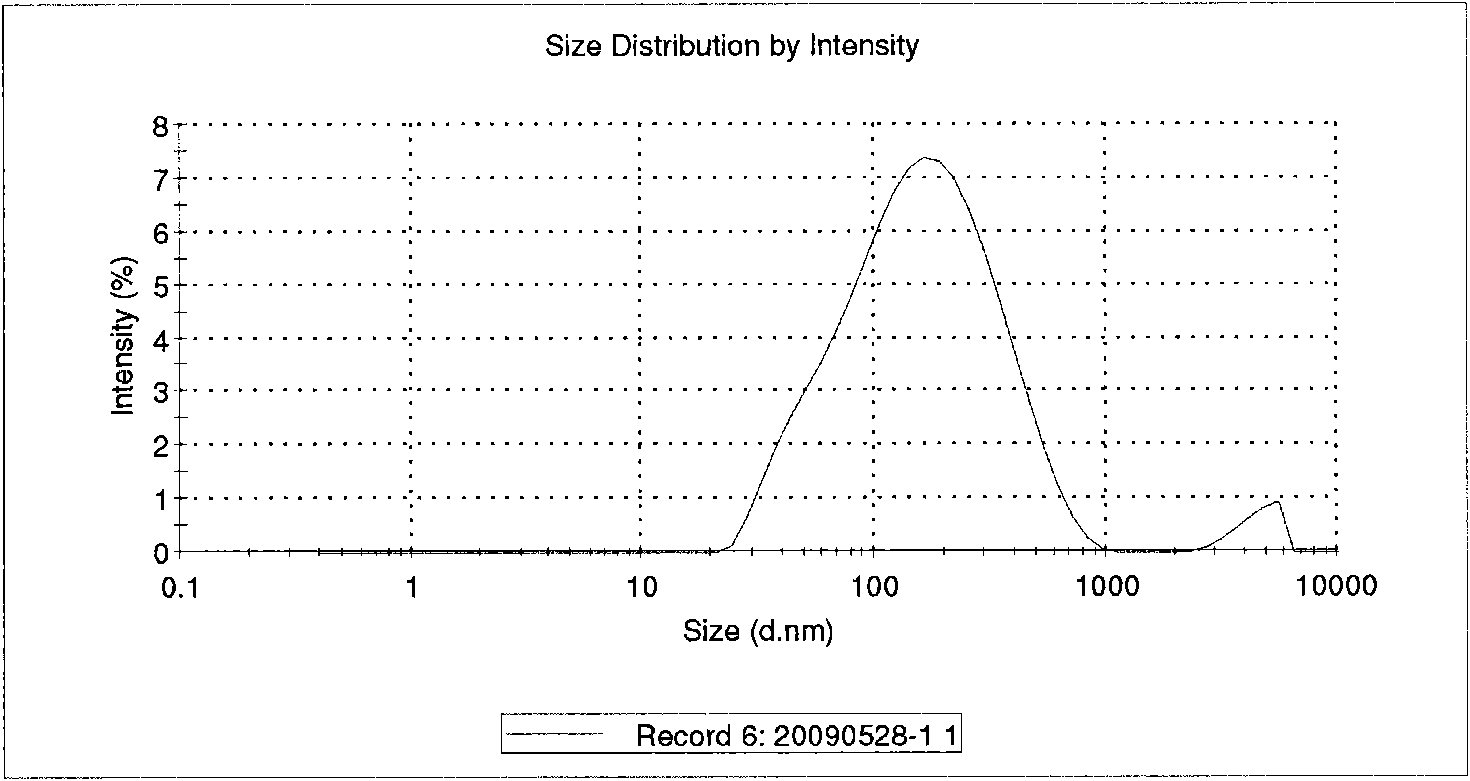

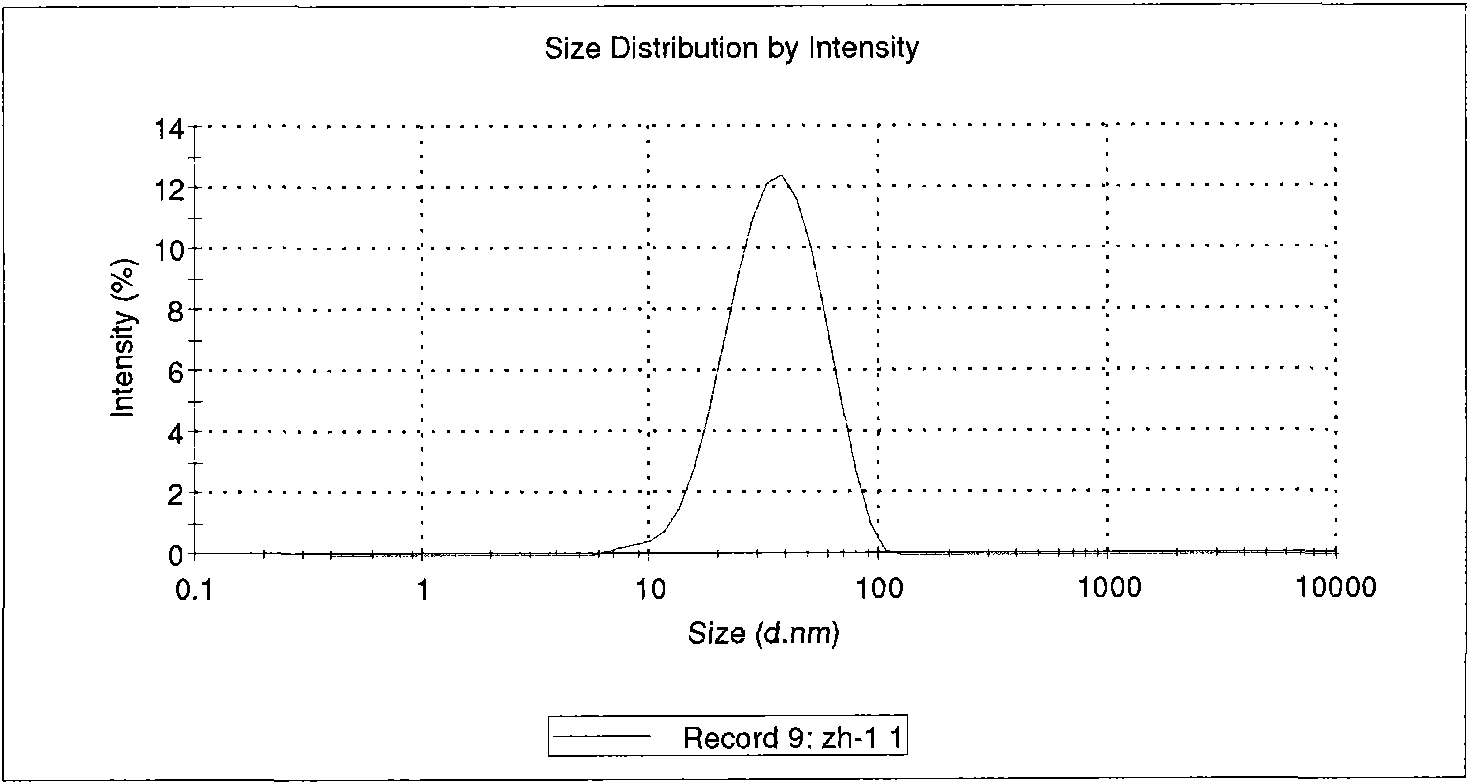

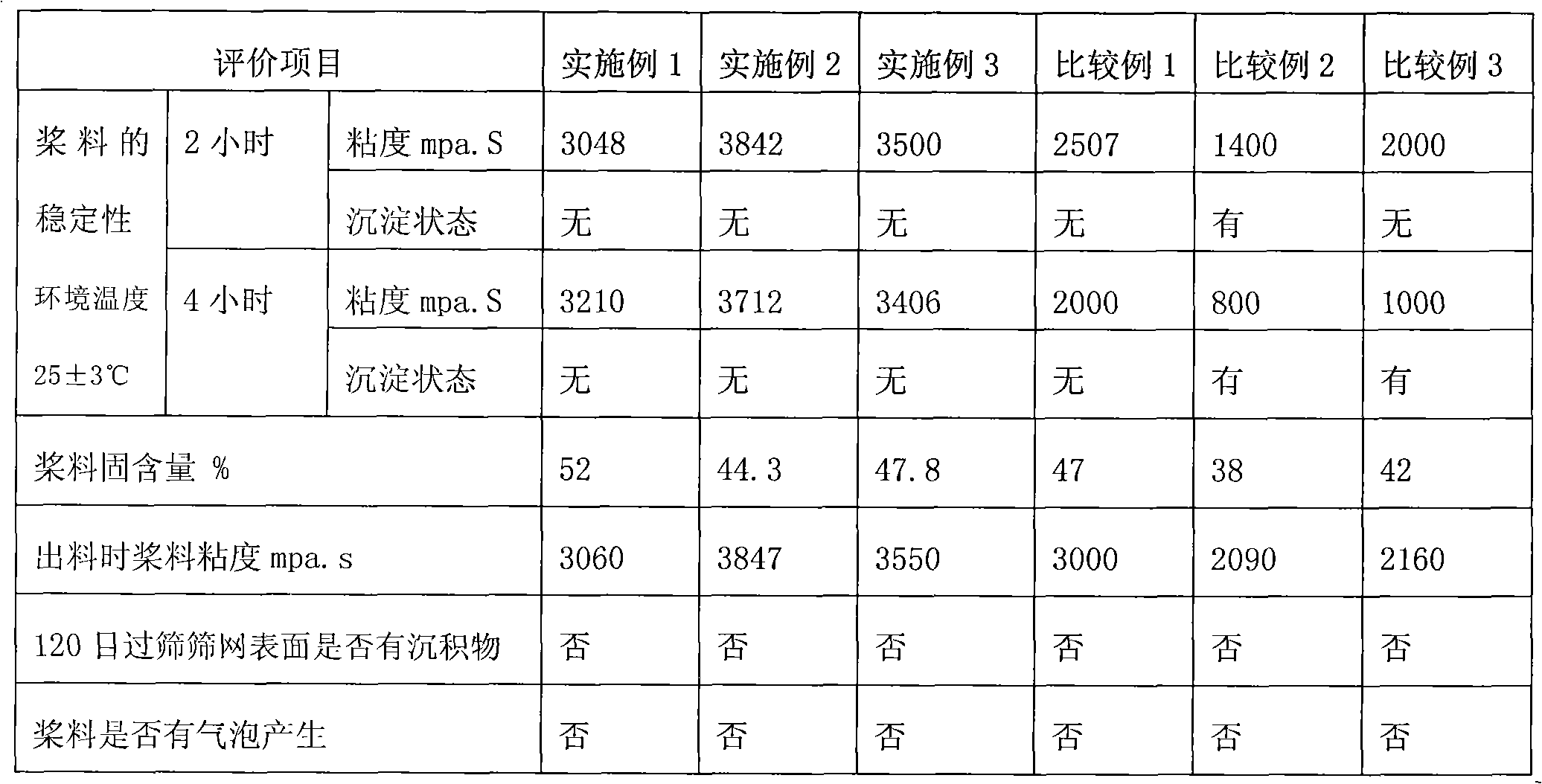

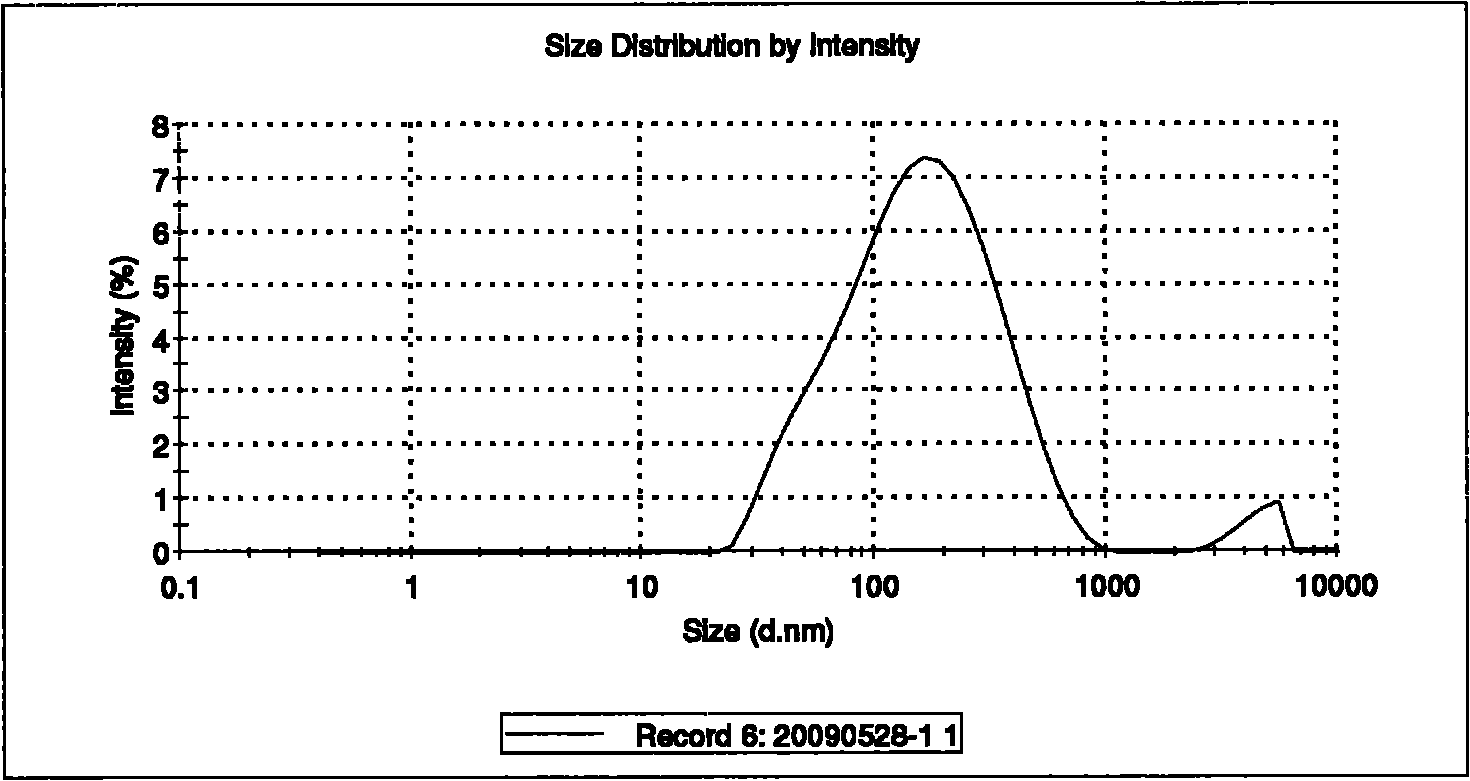

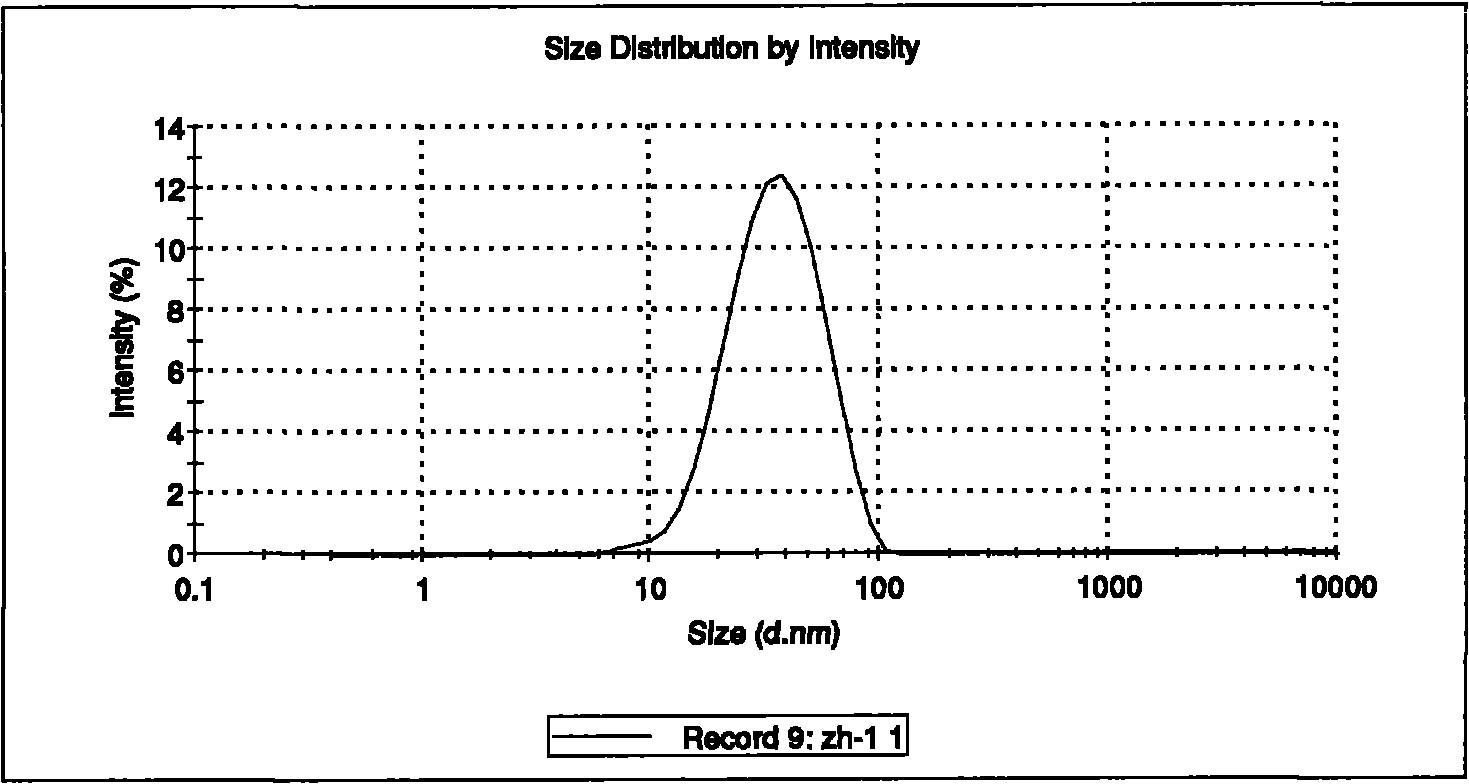

Waterborne ceramic slurry for lithium ion battery and preparation method of composite separator from waterborne ceramic slurry

InactiveCN107403898ASlurry stabilizationNot easy to settleCell component detailsCeramic compositeHeat resistance

The invention provides waterborne ceramic slurry for a lithium ion battery and a preparation method of a composite separator from the waterborne ceramic slurry. The waterborne ceramic slurry is prepared from inorganic powder, an adhesive, a dispersant, an aid and deionized water. The invention further provides a preparation method of the waterborne ceramic composite separator. Compared with oily ceramic coated lithium ion battery separators, the composite separator has good wettability, heat resistance and adhesion performance, a coating contains inorganic powder with uniform particle sizes, the safety performance of the battery is effectively improved, and the composite separator cannot cause pollution to the environment and has a good application prospect.

Owner:VONTRON MEMBRANE TECH CO LTD

Preparation method and coating method of molecular sieve coating

ActiveCN104525242AIncrease loadUniform coatingMolecular sieve catalystsCatalyst activation/preparationNitric oxideMolecular sieve

The invention discloses a preparation method of a molecular sieve type monolithic catalyst. The preparation method of the molecular sieve type monolithic catalyst has the advantage that the purposes of improving the activity of the catalyst and widening the temperature window of the catalyst are achieved by combining a plurality of molecular sieve active coatings on a catalyst due to the adoption of different activities of different molecular sieve type catalysts in NOx selective catalytic reduction reaction. The preparation method of the molecular sieve type monolithic catalyst comprises the following steps: preparing Fe modification ZSM-5 molecular sieves and NH4-ZSM-5 molecular sieves into corresponding slurries, then respectively coating the slurries on one end of a cordierite honeycomb ceramic carrier to prepare a molecular sieve type monolithic catalyst applied to selective catalytic reduction of nitric oxides. The catalyst prepared by the method has high activity of selective catalytic reduction of nitric oxides; the performance of the catalyst is superior to that of the molecular sieve type monolithic catalyst which only takes the Fe modification ZSM-5 molecular sieves and the NH4-ZSM-5 molecular sieves as active coatings; the conversation rate of NOx in a temperature zone of 190-490 DEG C can reach over 80%; and the catalyst is simple in preparation method and relatively low in production cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing composite textile pulp by nanometer polymer emulsion

InactiveCN101597861AEasy to useNanoscale effects are evidentFibre treatmentPolymer scienceParaffin oils

The invention relates to a method for preparing sizing agent for sizing textile chaine in textile industry. The method for preparing composite textile pulp by nanometer polymer emulsion is characterized by comprising the following steps: 1) preparation of polymer emulsion: according to the mixture ratio of 10 milliliters: 0.3 to 0.8g:0.2 to 0.5 g:60 to 100 milliliters of alkene monomer to emulsifying agent to initiating agent to water, the components are selected and mixed and then are stirred for 6 to 10 hours at the temperature from 75 to 85 DEG C so as to obtain the polymer emulsion; 2) according to the mixture ratio of 10 milliliters: 0.2 to 0.8 g: 0.3 to 0.9g:1.0 to 3.0 g:25 to 80 g of alkene monomer to paraffin to sodium hexametaphosphate to nanometer silicon dioxide to modified starch, the paraffin, the sodium hexametaphosphate, the nanometer silicon dioxide and the modified starch are selected for standby use; and the polymer emulsion, the paraffin, the sodium hexametaphosphate, the nanometer silicon dioxide and the modified starch are mixed and then react for 2 to 4 hours at the temperature from 75 to 85 DEG C, thereby obtaining the composite textile pulp by nanometer polymer emulsion. The method has the advantages of low cost and environmental protection.

Owner:HUAZHONG NORMAL UNIV

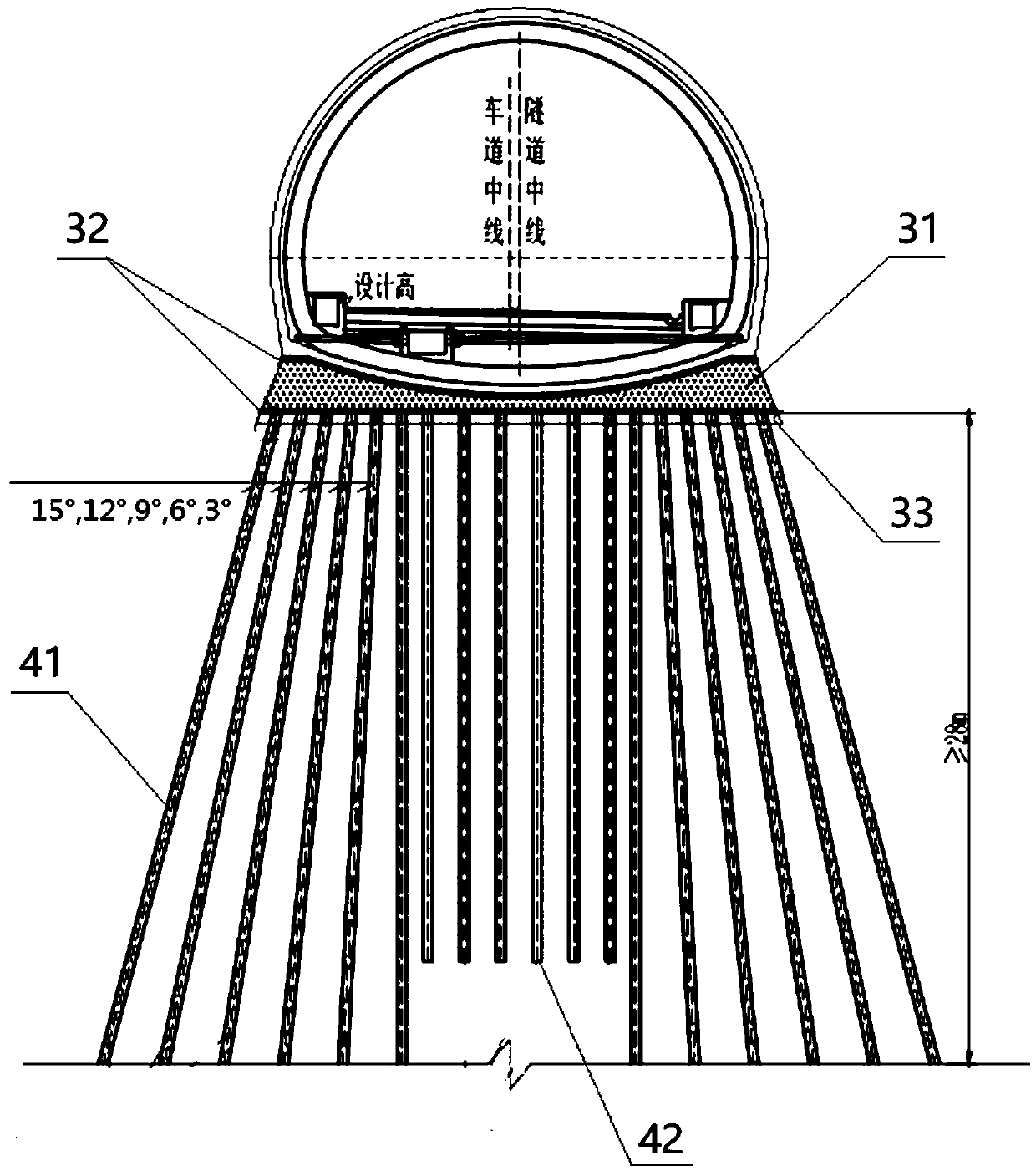

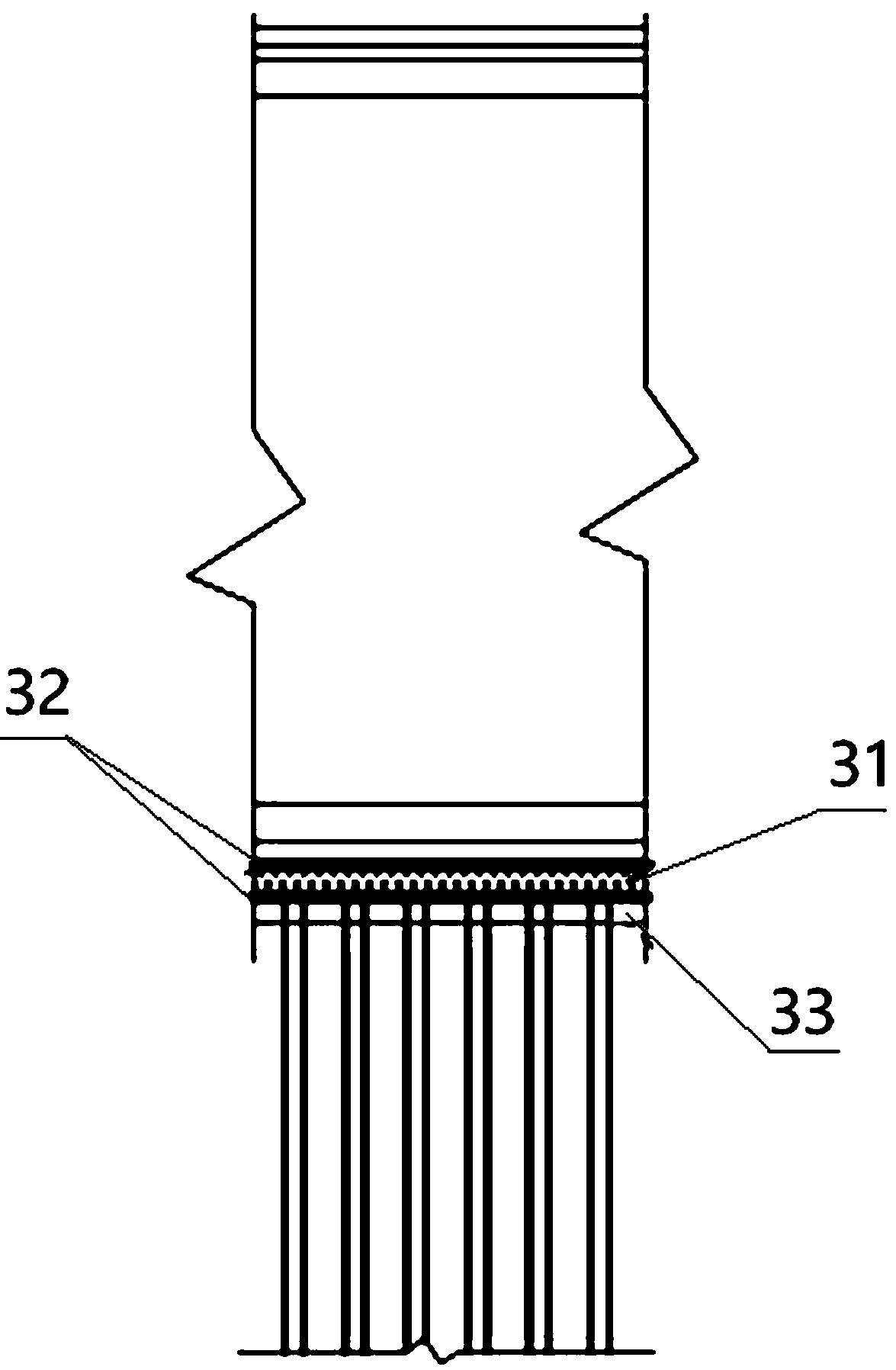

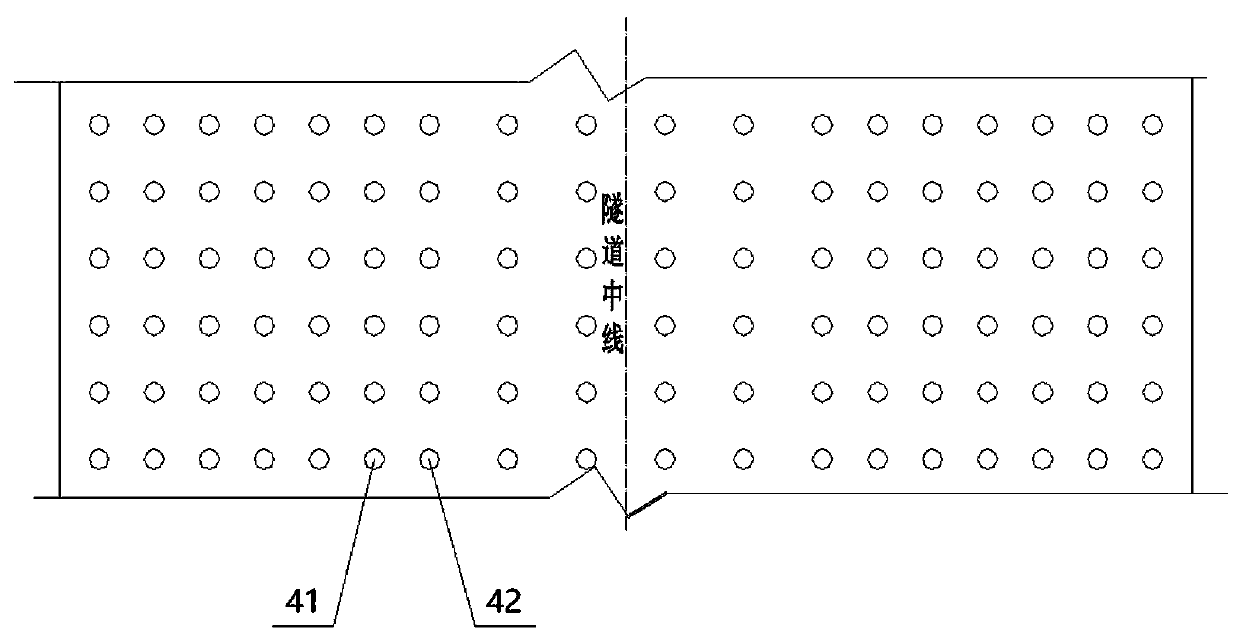

Large filling type karst cave geological tunnel foundation reinforcing structure and construction method thereof

PendingCN111594232ATightly boundIncrease static frictionUnderground chambersTunnel liningBedrockKarst

The invention discloses a large filling type karst cave geological tunnel foundation reinforcing structure. A plurality of rows of grouting steel pipe piles are arranged at the bottom of a tunnel inverted arch in the length direction of a tunnel and go deep into underground bedrock or a soil body with a certain depth, a graded broken stone hardcore is laid above the steel pipe piles at the bottomof the tunnel, and a concrete bearing platform is poured above the graded broken stone hardcore. The construction method comprises the following steps of on-site surveying and setting out, drilling, hole cleaning and hole inspection, steel floral tube installation, primary grouting, secondary grouting and tunnel inverted arch bottom concrete bearing platform construction. The requirements for theconstruction quality and the service life of a karst cave geological tunnel foundation can be met, the bearing capacity is high, subsidence of the karst cave geological tunnel foundation is effectively controlled, the mechanical property of the cast-in-place pile is good, the piles are not prone to breakage, and hole collapse and blockage are effectively controlled in the hole forming process of the cast-in-place pile; and the whole foundation reinforcing structure is beneficial to maintaining water and soil stability in a tunnel mountain, and the natural water system environment is not affected.

Owner:GUANGXI ROAD CONSTR ENG GRP CO LTD

Thickener and super high-density cement paste based on thickener

ActiveCN103773341ADensity meetsImprove performanceDrilling compositionMicrofine cementMining engineering

The invention discloses a thickener and a super high-density cement paste based on the thickener. The thickener comprises the following components in parts by weight: 80-90 parts of iron ore powder, 5-10 parts of manganese mineral powder, 5-10 parts of G-grade superfine cement and 5-10 parts of silica fume. The super high-density cement paste provided by the invention is stable in performance, and low in water loss, has certain anti-gas channeling ability and ideal thickening transition time, and can form strong set cement. A high-pressure hydrocarbon reservoir can be effectively controlled, jump-out of an oil gas is avoided, and the cementing quality can be better improved.

Owner:四川川庆井下科技有限公司

Graphite water-base cathode formula and preparation method thereof

InactiveCN101604742AFix stability issuesSolving Dispersion ProblemsElectrode manufacturing processesActive material electrodesWater basedLithium

The invention discloses a graphite water-base cathode formula and a preparation method thereof, aiming to provide a graphite water-base cathode formula with stable slurry, low production cost and little environmental pollution and a preparation method thereof. The invention comprises the following components according to the parts by weight: 100 parts of graphite, 40-60 parts of water-base binder, 60-80 parts of deionized water and 4-6 parts of ethanol. The invention can be widely used in the field of the cathode blending of the lithium ion secondary battery and the battery producing and processing field.

Owner:ZHUHAI LIYUAN NEW ENERGY TECH

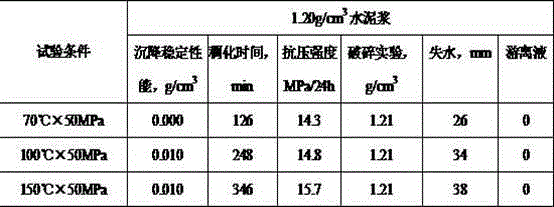

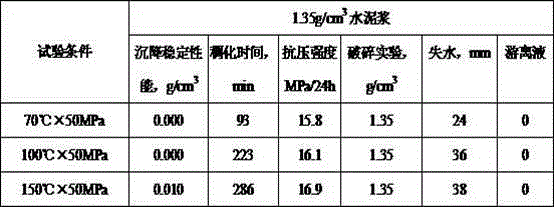

High-temperature-resistant high-strength low-density cement slurry system

InactiveCN105130292ASlurry stabilizationRapid development of strengthDrilling compositionPhysical chemistryCement slurry

The invention relates to a high-temperature-resistant high-strength low-density cement slurry system, which is composed of following components, by weight, 100 parts of oil well cement, 10-35 parts of high-strength hollow glass beads, 1-4 parts of an high-temperature-resistant salt-resistant fluid loss agent A, 1-4 parts of an high-temperature-resistant salt-resistant fluid loss agent B, 1-2 parts of an early strength agent A, 1-2 parts of an early strength agent B, 8-15 parts of micro-silicon, 1-4 parts of an expansion agent, 0-2 parts of a retarder, and 90-150 parts of water. The invention achieves the high-temperature-resistant high-strength low-density cement slurry system.

Owner:SINOPEC EAST CHINA PETROLEUM ENG CO LTD

Rice steamed sponge cake production process

The invention mainly relates to the technical field of rice steamed sponge cake production and discloses a rice steamed sponge cake production process. The process comprises the steps as follows: (1)material selection for primary fermentation; (2) powder mixing; (3) pulp mixing; (4) primary resting; (5) material selection for secondary fermentation; (6) secondary resting; and (7) steaming. The secondary resting process is adopted, through secondary resting of the primarily rested rice steamed sponge cake, the surface of the rice steamed sponge cake is flatter, the uniformity of pores in the rice steamed sponge cake is improved, starch is added during material selection for secondary fermentation, so that the elasticity of the rice steamed sponge cake can be guaranteed, the taste of the rice steamed sponge cake can be improved, besides, the rice steamed sponge cake pulp is more stable, has long fermentation time, cannot become thin easily and is not prone to aging cracking during storage, a mechanical mechanism is used for uniformly stirring raw materials of the rice steamed sponge cake, and the fermentation time of the raw materials of the rice steamed sponge cake can be saved.

Owner:杭州普罗星淀粉有限公司

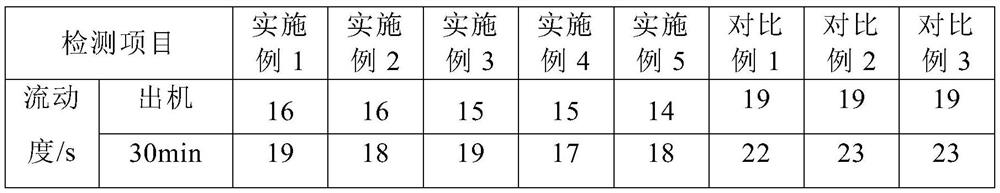

Ultrafine inorganic grouting material for tunnel inverted arches, and preparation method thereof

ActiveCN109020419AGuaranteed mechanical propertiesImprove early strengthWater reducerMaterials science

The invention discloses an ultrafine inorganic grouting material for tunnel inverted arches. The grouting material comprises, by mass, 75-90% of an ultrafine cementing material, 5-20% of a mineral filler, 2.5-7.5% of a composite expansion agent, 0.04-0.08% of a fluid volume stabilizer, 0.5-1.5% of a film forming modifier, 0.4-0.8% of a water reducer, 0.02-0.05% of a defoamer, 0.1-0.4% of a dispersant, 0.05-0.1% of an anti-seepage water repellent and 1-5% of a nano-reinforcing component. Above components are uniformly mixed, water is added according to a water-cement ratio of 0.25-0.30, and stirring is performed to obtain the grouting material which can be used for grouting reinforcement portions and defect parts of the tunnel inverted arches. The inorganic grouting material obtained in theinvention is suitable for repairing and stabilizing defects and dangerous rock bodies of tunnel inverted arches at 5-35 DEG C, has the advantages of high fluidity, high bonding strength, no shrinkage, good impermeability and good durability, and is suitable for being promoted and applied.

Owner:HUBEI UNIV

Cement permeation promoter for oil and gas well

The cement permeation promoter for oil and gas well is compounded with gum resin 25í½35 wt%, modified aluminum powder 8í½12 wt%, asphalt 35í½45 wt% and chrysotile fiber 16í½24 wt%. It is re-compounded through treating the aluminum powder with water solution of potassium permanganate to deactivate and stoving to obtain modified aluminum powder, and mixing the modified aluminum powder with other components in the said weight proportion to obtain the cement permeation promoter. The cement permeation promoter may be re-compounded with other admixtures to form a new type of permeating cement slurry system, which is cured in the stratum condition to form oil and gas passage with certain permeation rate, high strength, high heat and salt tolerance, oil phase permeation rate higher than water phase permeation rate, stable chemical performance and for cementing well, preventing sand, blocking water, etc.

Owner:SOUTHWEST PETROLEUM UNIV

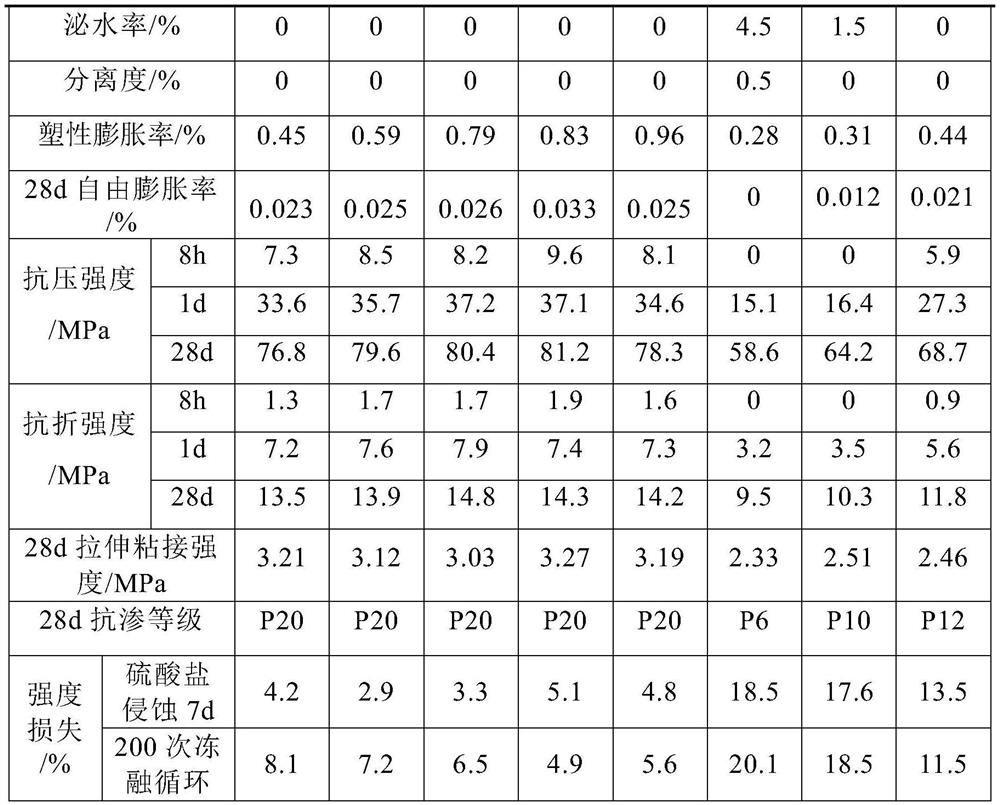

Physical foam cementing concrete

InactiveCN101417868AHigh compressive strengthMeet the return requirementsCeramicwareFoaming agentCement slurry

The invention discloses a physical foam cementing cement comprising foam medias and cement slurries and the weight mixing ratio of the foam medias and the cement slurries is 1:10 to 30, wherein, the components of the foam medias comprise a foaming agent stock solution and clear water, and the weight mixing ratio of the foaming agent stock solution and the clear water is 1:10 to 30. The invention forms air chambers of the internal structure of cement stones, which are spherically, independently and uniformly distributed, and the physical foam cementing cement has the advantages of excellent light quality, small density difference, stable slurry and good environmental protection performance.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

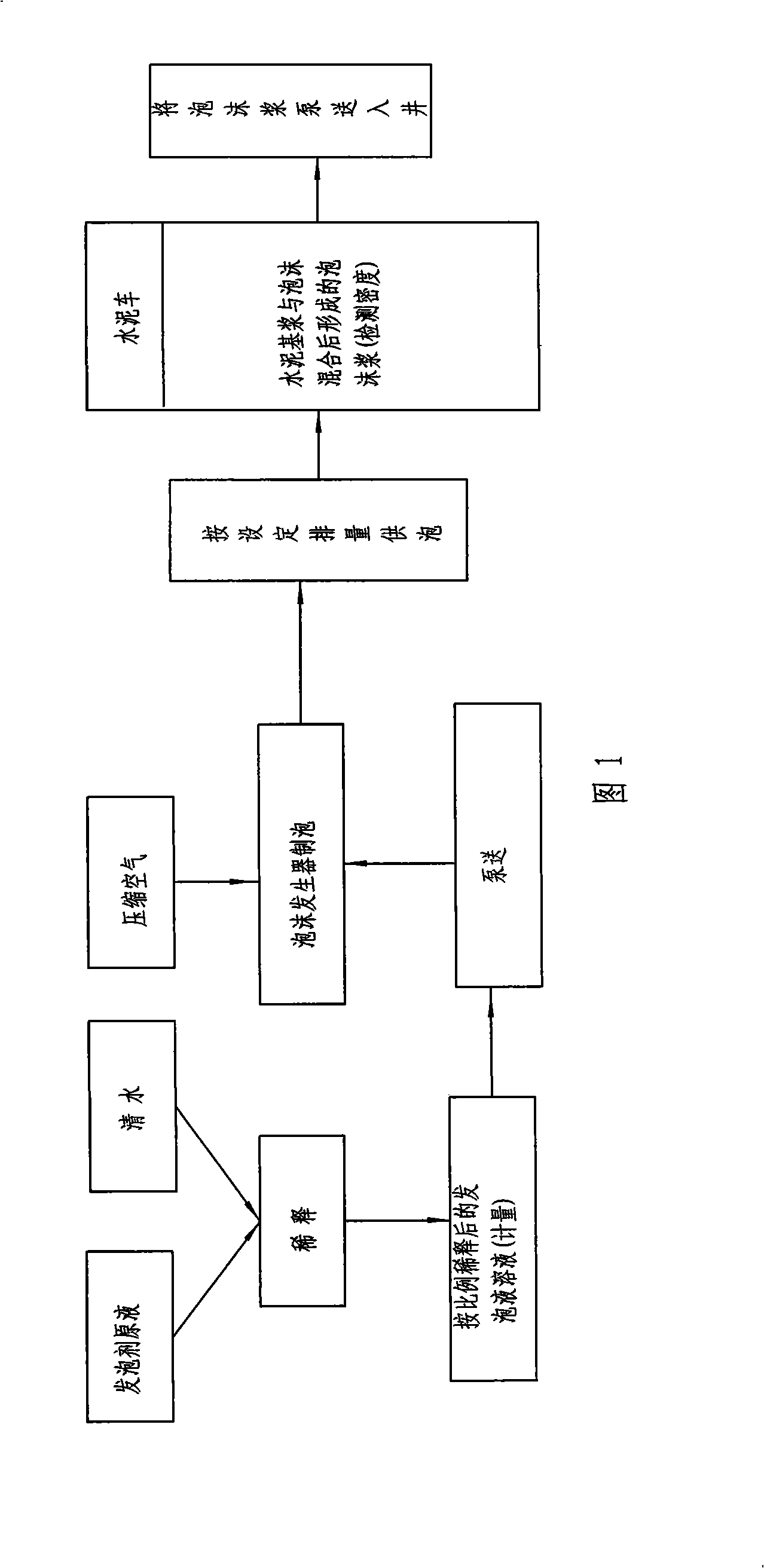

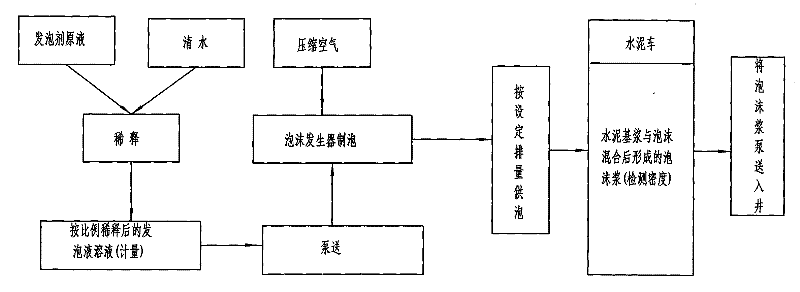

Physical foam cementing method

ActiveCN101403285AFast constructionImprove homogeneityDrilling compositionSealing/packingFoaming agentGas compressor

The invention discloses a cementing method with physical foamed cement, which comprises the steps: the stock solution of a foaming agent and clear water are diluted according to the weight proportion of 1: 10 to 30, stirred evenly, and provided with compressed air with the pressure of 0.2 to 0.6MPa through an air compressor; the pumping rate of a metering pump is set, diluted stock solution of the foaming agent and the compressed air are simultaneously provided for a foam generator in unit time of 20 to 45min so as to cause the stock solution of the foaming agent and the compressed air to form foamed media in the foam generator, the foamed media is input into a cement pump by the driving of the compressed air, and mixed with cement slurry according to the weight proportion of 1: 10 to 30, and finally pumped into a well. The invention changes the technique for preparing cement by the existing chemical foaming method, the foaming process changes into ground foaming from the original well foaming, thus leading the foaming media and the cement mud to be more evenly, the slurry to be stable and the density to be small; and the cementing method is easy to adjust, control and detect.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

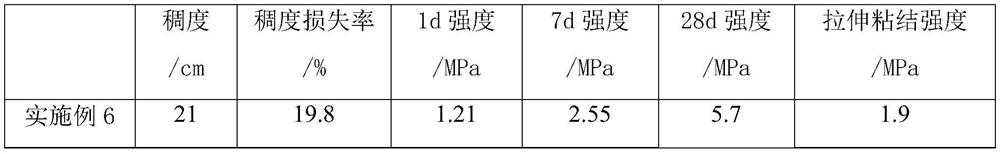

Cementing material, historic building repair mortar and preparation method of historic building repair mortar

ActiveCN114105502AWell mixedImprove adhesionSolid waste managementCement productionCompressive resistanceArchitectural engineering

The invention relates to the technical field of building materials, in particular to a cementing material, historic building repair mortar prepared from the cementing material and a preparation method of the historic building repair mortar, the historic building repair mortar is composed of the cementing material, aggregate, an additive and water, and the cementing material comprises the following components in parts by weight: 20-150 parts of slag and 250-500 parts of active iron tailings; a preparation method of the active iron tailings comprises the steps that iron tailings are dried and then subjected to first-time grinding, quicklime powder and water are added for second-time grinding, then high-temperature activation is conducted at the temperature of 700-800 DEG C, and the active iron tailings are obtained. According to the preparation method of the historic building repair mortar, provided by the invention, the active iron tailings and the slag are used for preparing the gel material for the historic building repair mortar, so that the bonding performance and the compressive strength of each age of the historic building repair mortar can be improved; the early strength is high, the cohesiveness is good, the erosion resistance is strong, and the durability is good.

Owner:UNIV OF SCI & TECH BEIJING +1

A kind of graphene/uhmwpe composite fiber and its preparation method and application

ActiveCN106222780BGood dispersionEasy secondary dispersionMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberSolvent

The invention discloses a graphene / UHMWPE composite fiber and a preparation method thereof. In the composite fiber, the content of graphene is 0.05-5 wt% of that of UHMWPE. The preparation method comprises: pre-dispersing graphene in a solvent to form a uniform graphene dispersion liquid, fully dissolving UHMWPE powder in a solvent in a heating condition, fully mixing the obtained solution with the obtained graphene dispersion liquid, spinning the fully-mixed UHMWPE / graphene mixed solution through a gel-spinning method, and performing solvent extraction and drawing to obtain the graphene / UHMWPE composite fiber. The prepared graphene / UHMWPE composite fiber is obviously improved in the mechanical strength. The tensile strength can reach 29 cN / dtex, and the tensile modulus can reach 1300 cN / dtex. Through changing the addition ratio of graphene and UHMWPE powder, the size of graphene and different dispersion processes, the mechanical property of the composite fiber can be regulated.

Owner:南通恒尚新材料科技有限公司 +1

Preparation method of PS-Cl and application thereof

The invention provides a preparation method of PS-Cl and the application thereof, wherein PS-Cl is used as a slurry stabilizer of IIR. The preparation method comprises the following steps that monomer styrene prepared by mixing solvents is placed in an oxygen-free water-free polymerization bottle, an inifer and coinitiator Lewis acid which are prepared through a hexane solution are placed in the polymerization bottle, a reaction is conducted for 30 min under the condition of -110 DEG C to -60 DEG C, a reaction product is added to an isobutene and isoprene solution prepared by mixing solvents at a constant temperature for 30 min, the Lewis acid is added to the system, after reaction is conducted for 50 min, 2 ml of an ethanol solution containing 1Wt% of NaOH is added to the system, and then polymerization is ended. A product is milky white, an obvious rubber block clustering phenomenon is not found, and a wall attachment phenomenon is avoided. A slurry stabilizing solution prepared through the method can directly achieve the slurry stabilizing function on IIR without after-treatment.

Owner:商巧玲

Method for preparing composite textile pulp by nanometer polymer emulsion

InactiveCN101597861BEasy to useNanoscale effects are evidentFibre treatmentPolymer scienceParaffin oils

The invention relates to a method for preparing sizing agent for sizing textile chaine in textile industry. The method for preparing composite textile pulp by nanometer polymer emulsion is characterized by comprising the following steps: 1) preparation of polymer emulsion: according to the mixture ratio of 10 milliliters: 0.3 to 0.8g:0.2 to 0.5 g:60 to 100 milliliters of alkene monomer to emulsifying agent to initiating agent to water, the components are selected and mixed and then are stirred for 6 to 10 hours at the temperature from 75 to 85 DEG C so as to obtain the polymer emulsion; 2) according to the mixture ratio of 10 milliliters: 0.2 to 0.8 g: 0.3 to 0.9g:1.0 to 3.0 g:25 to 80 g of alkene monomer to paraffin to sodium hexametaphosphate to nanometer silicon dioxide to modified starch, the paraffin, the sodium hexametaphosphate, the nanometer silicon dioxide and the modified starch are selected for standby use; and the polymer emulsion, the paraffin, the sodium hexametaphosphate, the nanometer silicon dioxide and the modified starch are mixed and then react for 2 to 4 hours at the temperature from 75 to 85 DEG C, thereby obtaining the composite textile pulp by nanometer polymer emulsion. The method has the advantages of low cost and environmental protection.

Owner:HUAZHONG NORMAL UNIV

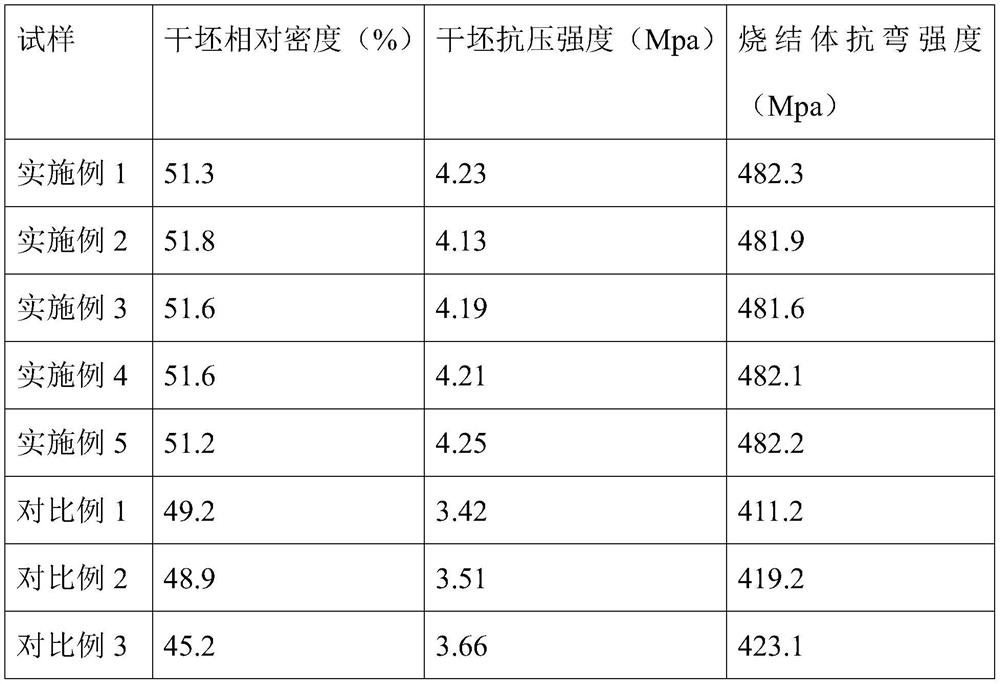

A kind of high thermal conductivity aluminum nitride ceramic and preparation method thereof

ActiveCN112939607BLower sintering temperatureImprove thermal conductivityFlexural strengthUltimate tensile strength

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

A kind of densifier and ultra-high density cement slurry based on the densifier

ActiveCN103773341BImprove void fill rateDensity meetsDrilling compositionMicrofine cementHigh density

The invention discloses a densifier and an ultra-high-density cement slurry based on the densifier. The weight composition of the densifier is: 80-90 parts of iron ore powder, 5-10 parts of manganese ore powder, and 5 parts of G-grade superfine cement. -10 parts, microsilica fume 5-10 parts. The ultra-high-density cement slurry provided by the invention has stable performance, low water loss, certain anti-air channeling ability, relatively ideal thickening transition time and can form cement stone with strong strength. It can effectively control high-pressure oil and gas layers, avoid oil and gas escape, and better improve the quality of cementing.

Owner:四川川庆井下科技有限公司

Binder Composition for Secondary Battery, and Electrode Slurry Composition, Electrode and Secondary Battery Including Same

PendingUS20200194792A1Slurry stabilizationAvoid contaminationElectrode manufacturing processesConjugated diene hydrocarbon coatingsConjugated dieneSaturated carboxylic acid

The present invention relates to a binder composition for a secondary battery, an electrode slurry composition including the same, and an electrode and a secondary battery manufactured by using the same, the binder composition including: a latex particle (A) which is a polymer of a monomer mixture including (a1) a conjugated diene monomer, (a2) an ethylenically unsaturated carboxylic acid monomer, and (a3) an aromatic vinyl monomer; and an emulsifier (B), wherein the (a2) ethylenically unsaturated carboxylic acid monomer is included in an amount of 3 parts by weight or more based on 100 parts by weight of the monomer mixture and the emulsifier (B) is included in an amount of less than 3000 ppm based on 100 parts by weight of the latex particles.

Owner:LG CHEM LTD

Oil field well cementation filtration-reducing agent and preparation method thereof

The invention relates to an oil field well cementation filtration-reducing agent and a preparation method thereof, which is characterized in that alcoholysis reaction is carried out on a copolymer raw material formed by polyvinyl acetate with certain degree of polymerization and at least one carboxylic vinyl ester polymer with another degree of polymerization in a certain weight ratio, and then drying and crushing are carried out to obtain the filtration-reducing agent. The filtration-reducing agent has the characteristics of uniformity, stability, good flowability and good dispersibility and has the advantages of good filtration reducing action and high safety, is convenient to use and is easy to control. The invention has simple process operation, and the production can be carried out only by using a simple production device; as the filtration-reducing agent, the product has good filtration reducing capacity. Moreover, the product has small influence on the thickening time, has high compression strength and certain high temperature resistance and can meet the well drilling and well cementation construction demands under different geological conditions.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of superfine inorganic grouting material for tunnel inverted arch and preparation method thereof

Owner:HUBEI UNIV

A method for preparing and coating molecular sieve coating

ActiveCN104525242BIncrease loadUniform coatingMolecular sieve catalystsCatalyst activation/preparationCordieriteNitric oxide

The invention discloses a preparation method of a molecular sieve type monolithic catalyst. The preparation method of the molecular sieve type monolithic catalyst has the advantage that the purposes of improving the activity of the catalyst and widening the temperature window of the catalyst are achieved by combining a plurality of molecular sieve active coatings on a catalyst due to the adoption of different activities of different molecular sieve type catalysts in NOx selective catalytic reduction reaction. The preparation method of the molecular sieve type monolithic catalyst comprises the following steps: preparing Fe modification ZSM-5 molecular sieves and NH4-ZSM-5 molecular sieves into corresponding slurries, then respectively coating the slurries on one end of a cordierite honeycomb ceramic carrier to prepare a molecular sieve type monolithic catalyst applied to selective catalytic reduction of nitric oxides. The catalyst prepared by the method has high activity of selective catalytic reduction of nitric oxides; the performance of the catalyst is superior to that of the molecular sieve type monolithic catalyst which only takes the Fe modification ZSM-5 molecular sieves and the NH4-ZSM-5 molecular sieves as active coatings; the conversation rate of NOx in a temperature zone of 190-490 DEG C can reach over 80%; and the catalyst is simple in preparation method and relatively low in production cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Cement permeation promoter for oil and gas well

The cement permeation promoter for oil and gas well is compounded with gum resin 25~35 wt%, modified aluminum powder 8~12 wt%, asphalt 35~45 wt% and chrysotile fiber 16~24 wt%. It is re-compounded through treating the aluminum powder with water solution of potassium permanganate to deactivate and stoving to obtain modified aluminum powder, and mixing the modified aluminum powder with other components in the said weight proportion to obtain the cement permeation promoter. The cement permeation promoter may be re-compounded with other admixtures to form a new type of permeating cement slurry system, which is cured in the stratum condition to form oil and gas passage with certain permeation rate, high strength, high heat and salt tolerance, oil phase permeation rate higher than water phase permeation rate, stable chemical performance and for cementing well, preventing sand, blocking water, etc.

Owner:SOUTHWEST PETROLEUM UNIV

Physical foam cementing method

ActiveCN101403285BFast constructionImprove homogeneityDrilling compositionSealing/packingFoaming agentGas compressor

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Process for preparing ceramic sheet from emulsoid system by water-base doctor blading method

A process for preparing ceramic sheet (or film) by water-base doctor, blading method includes such steps as proportionally mixing water, ceramic powder, acrylate emulsoid, plasticizer, and filming assistant, stirring, ball grinding, and doctor blading. Its advantages are high drying speed, strength and toughness, and wide application range.

Owner:TSINGHUA UNIV

High-strength casting gypsum powder

The invention relates to the technical field of gypsum, and discloses high-strength casting gypsum powder. The high-strength casting gypsum powder comprises, by weight, 20-30 parts of raw gypsum powder, 25-34 parts of beta-type semi-hydrated gypsum powder, 8-13 parts of white carbon black, 18-28 parts of high-aluminum powder, 0.3-0.8 part of calcium carbonate powder, 0.2-0.6 part of calcium sulfate powder, 0.01-0.1 part of retarders, 0.2-0.7 part of milk-white glue, 0.5-1.3 parts of sodium carbonate, 1.3-2.4 parts of water glass, 0.2-0.4 part of defoaming agents and 0.1-0.6 part of inorganic fibers. Preferably, the high-strength casting gypsum powder comprises, by weight, 10-18 parts of raw gypsum powder, 21-31 parts of beta-type semi-hydrated gypsum powder, 7-15 parts of white carbon black, 16-25 parts of high-aluminum powder, 0.2-0.7 part of calcium carbonate powder and 0.1-0.5 part of calcium sulfate powder. The high-strength casting gypsum powder has the advantages that technologies for the high-strength casting gypsum powder are simple, crystals can be stably, completely and thoroughly converted, and the stability and the high quality of product indexes further can be guaranteed; safe discharge can be carried out after processing is completed, accordingly, environments can be protected, energy can be saved, the high-strength casting gypsum powder is environmentally friendly and effectively conforms to technological standards, slurry is stable and is long in storage time, and prepared finished product powder is stable.

Owner:应城市嘉鸿技术服务科技有限公司

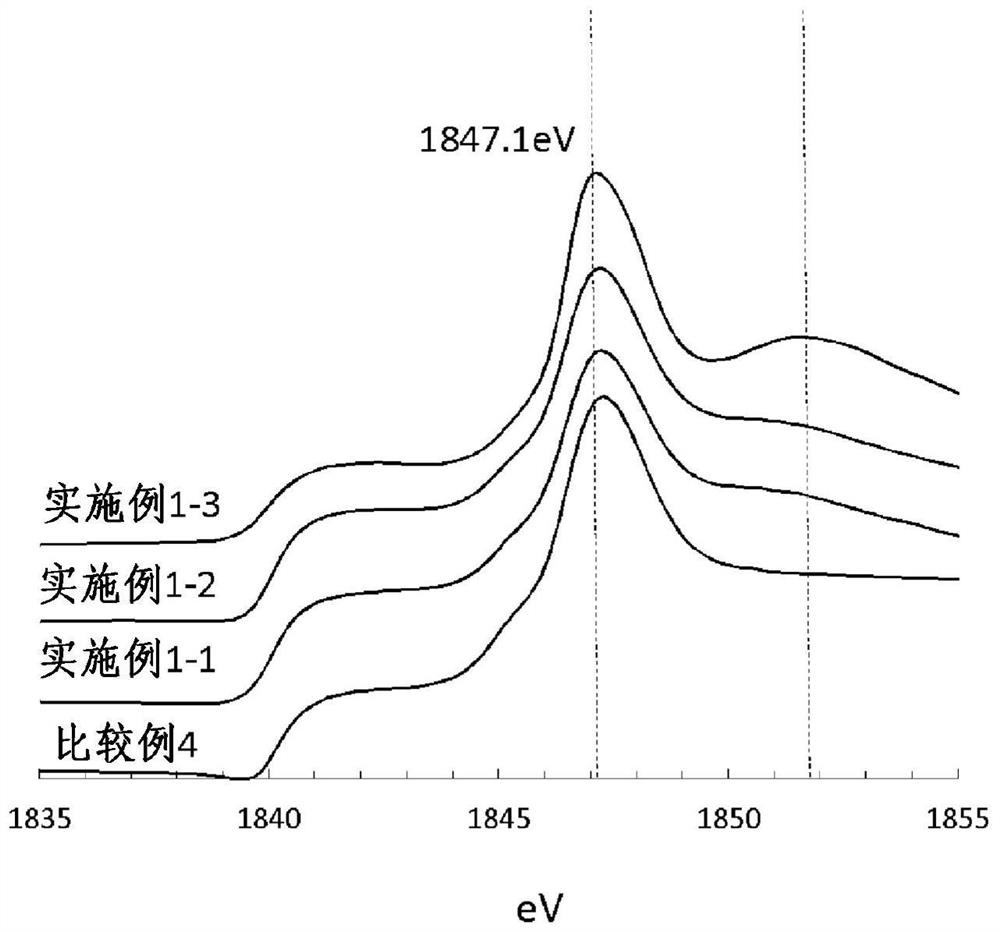

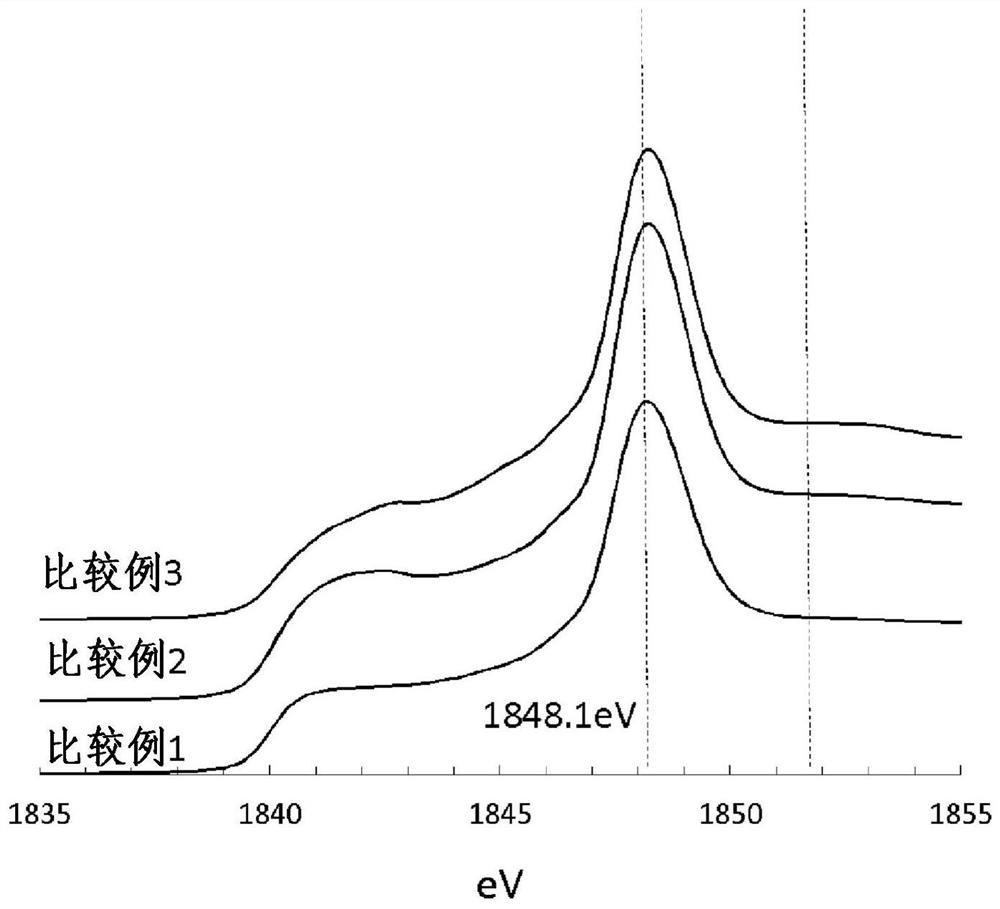

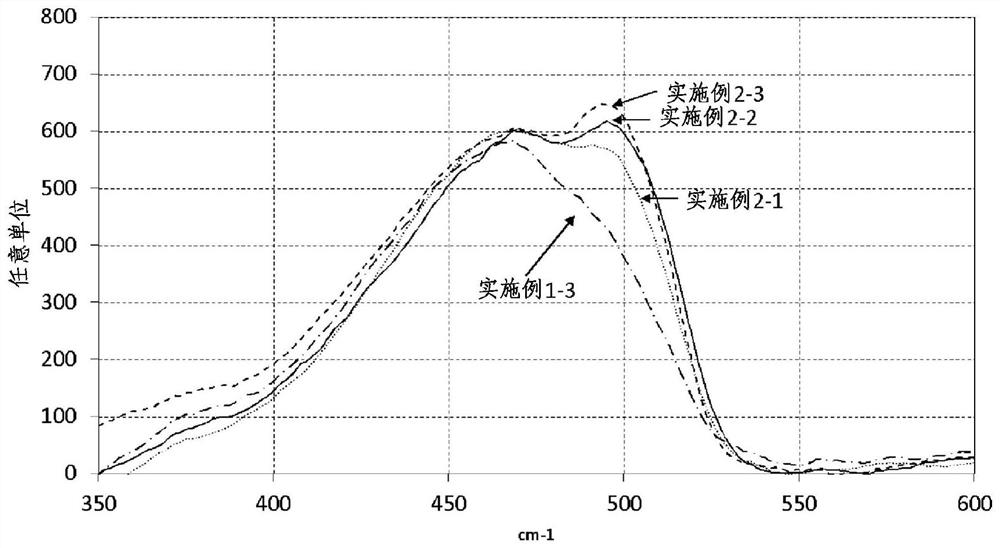

Negative-electrode active material and method for producing same

PendingCN113165889AImprove first-time efficiencyAdvantage productionNegative electrodesAlkali metal silicatesElectrical batterySlurry

The present invention is a negative-electrode active material comprising negative-electrode active material particles, the negative-electrode active material being characterized in that the negative-electrode active material particles comprise silicon compound particles each containing an oxygen-containing silicon compound, each of the silicon compound particles contains at least one component selected from Li2SiO3 and Li2Si2O5, and each of the silicon compound particles has a peak P attributed to a Li silicate at a position around 1847 eV and also has a peak Q that is gentler than the peak P at a position around 1851 to 1852 eV in an Si K-edge spectrum obtained from an XANES spectrum. It is possible to provide a negative-electrode active material which enables the increase in a battery capacity associated with the improvement in initial efficiency while stabilizing a slurry when used as a negative-electrode active material for a secondary battery.

Owner:SHIN ETSU CHEM CO LTD

Rotary cantilever porcelain insulator and preparation method thereof

The invention discloses a preparation method of a rotary cantilever porcelain insulator, and relates to the field of porcelain insulators. The preparation method comprises the following steps: mixing a porcelain billet raw material and a premixed solution containing polysaccharide, adding a dispersant, carrying out ball milling at 70-90 DEG C to obtain slurry, adjusting the pH value of the slurry to 8-10, adding an oxygen inhibitor into the slurry, uniformly mixing, injecting into a mold, cooling to 10-30 DEG C, molding to obtain a porcelain billet, sequentially drying and firing the porcelain billet to obtain a porcelain sintered body, and assembling the porcelain sintered body and a metal accessory to obtain the porcelain insulator. According to the invention, natural polysaccharide gel which can be dissolved at a high temperature is adopted, and can be formed after cooling, and ceramic particles are bonded together to dramatically increase the viscosity of a suspension, so that in-situ solidification forming is achieved, the shape stability after forming is guaranteed, water occupies the positions of pores between the particles before drying, water is discharged in the drying process, and the particles are connected by the residual organic glue so as to ensure the high strength of the billet body.

Owner:萍乡市长岭电瓷制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com