Preparation method of PS-Cl and application thereof

A polystyrene, chlorine-based technology, applied in the chemical industry, can solve problems such as the influence of slurry stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

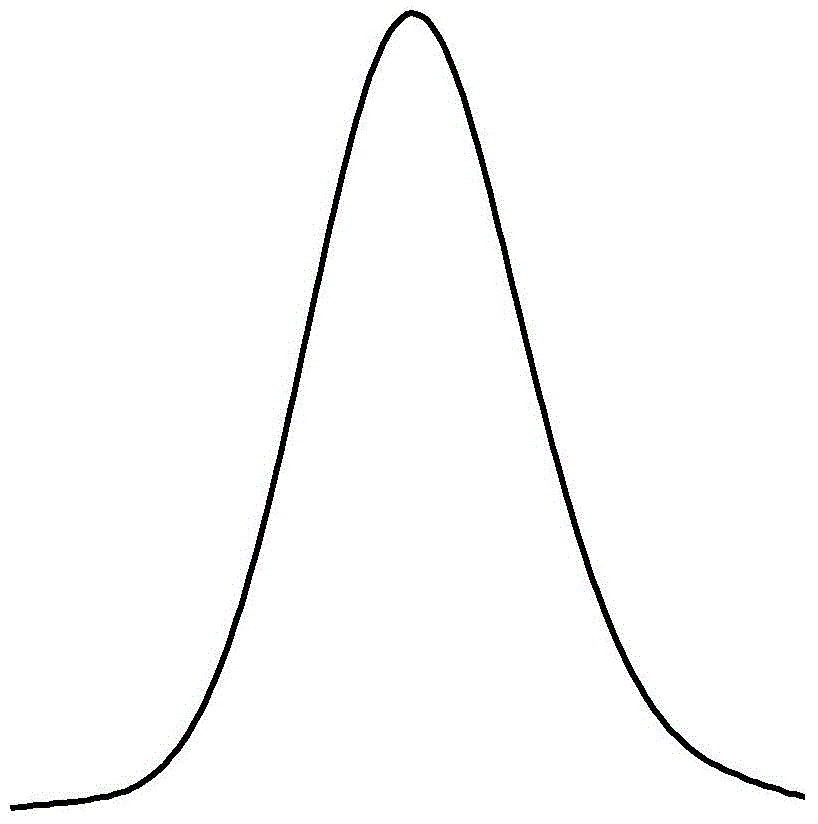

Image

Examples

Embodiment 1

[0020] Add 0.5ml of styrene and 1ml of hexane into an anhydrous and oxygen-free polymerization bottle, add 1ml of cumyl chloride hexane solution (concentration: 0.007mol / L), and co-initiator AlCl 3 0.009g, reacted at -50°C for 30min, added to -50°C for 30min at a constant temperature, the monomer concentration prepared in a mixed solvent of dichloromethane and hexane (volume ratio: 4:6) was 20% isobutene (85g) and isoprene (2g) solution, add AlCl to the system 3 (2.6g), after reacting for 50min, add 2ml of ethanol solution containing 1wt% NaOH to terminate the polymerization, the product is milky white, no obvious aggregation of glue blocks, and no wall hanging phenomenon. The product was dried in a vacuum drying oven to constant weight, the polymerization conversion rate was 72%, the relative number average molecular weight was 230000, and the molecular weight distribution was 2.1.

Embodiment 2

[0022] Add 4.5ml of styrene and 10ml of hexane into an anhydrous and oxygen-free polymerization bottle, add 9ml of cumyl chloride hexane solution (concentration: 0.007mol / L), and co-initiator FeCl 3 0.012g, reacted at -110°C for 30min, added to -110°C for 30min at a constant temperature, and the monomer concentration prepared in a mixed solvent of methyl chloride and hexane (5:5 by volume) was 30% isobutylene (90g) and In the solution of isoprene (2.72g), add AlCl to the system 3 (5g), after reacting for 50min, add 2ml of ethanol solution containing 1wt% NaOH to terminate the polymerization, the product is milky white, no obvious aggregation of glue blocks, and no wall hanging phenomenon. The product was dried in a vacuum drying oven to constant weight, the polymerization conversion rate was 69%, the relative number average molecular weight was 180000, and the molecular weight distribution was 1.9.

Embodiment 3

[0024] Add 3ml of styrene and 10ml of hexane into an anhydrous and oxygen-free polymerization bottle, add 8ml of cumyl chloride hexane solution (concentration is 0.007mol / L), and co-initiator FeCl 3 0.012g, reacted at -90°C for 30min, added to -90°C for 30min at a constant temperature, and the monomer concentration prepared in a mixed solvent of methyl chloride and methylcyclohexane (volume ratio: 5:5) was 40% isobutene ( 90g) and isoprene (2.6g) solution, add AlCl to the system 3 (3.5g), after 50min of reaction, 2ml of ethanol solution containing 1Wt% NaOH was added to terminate the polymerization, the product was milky white, no obvious aggregation of glue blocks was found, and there was no wall hanging phenomenon. The product was dried in a vacuum drying oven to constant weight, the polymerization conversion rate was 75%, the relative number average molecular weight was 250,000, and the molecular weight distribution was 2.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com