Rotary cantilever porcelain insulator and preparation method thereof

A technology of porcelain insulators and rotating wrist arms, applied in the field of porcelain insulators, can solve the problems of low strength of porcelain blanks, affecting the quality of finished products, and limited installation space for catenary suspension systems, and achieve high strength, ensure stability, and improve density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

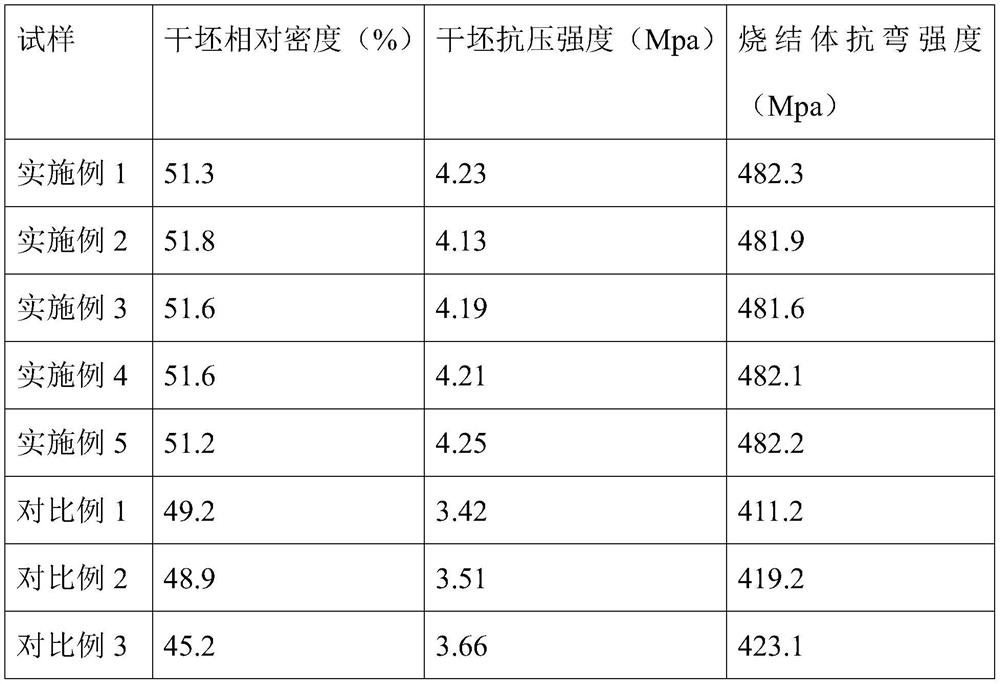

Examples

Embodiment 1

[0021] A method for preparing a rotating wrist-arm porcelain insulator. The raw material of the porcelain body is mixed with an aqueous solution containing polysaccharide, a dispersant is added, and ball milling is performed at 90°C to obtain a slurry. The proportion of the solid phase of the slurry is controlled to be 50wt%. Adjust the pH value of the slurry to 9, add 0.5wt% oxygen inhibitor to the slurry, mix well and inject into the mold, cool down to 30°C to form a porcelain body, and then dry the porcelain body in sequence (dried for 4 hours at a temperature of 35°C and a relative humidity of 95%), firing (in a sintering furnace: heat preservation at 200°C for 1 hour, heat preservation at 450°C for 2 hours, heat preservation at 900°C for 1.5 hours, heat preservation at 1430°C for 2 hours, and heating The speed is 0.5°C / min), and the porcelain sintered body is made with the furnace cooling, and then the porcelain sintered body and metal accessories are assembled to make a p...

Embodiment 2

[0024] A preparation method of a rotary wrist-arm porcelain insulator, mixing the raw material of the porcelain blank with an aqueous solution containing polysaccharide, adding a dispersant, and ball milling at 85°C to obtain a slurry, controlling the solid-containing phase of the slurry to a ratio of 55wt%. Adjust the pH value of the material to 9.2, add an oxygen inhibitor accounting for 0.5wt% of the slurry mass to the slurry, mix it and inject it into the mold, cool it down to 25°C and mold it to make a porcelain body, and then dry the porcelain body in sequence ( Drying for 4 hours at a temperature of 35°C and a relative humidity of 95%, firing (in a sintering furnace: heat preservation at 200°C for 1 hour, heat preservation at 450°C for 2 hours, heat preservation at 900°C for 1.5 hours, heat preservation at 1430°C for 2 hours, heating rate 0.5°C / min), the porcelain sintered body is made with furnace cooling, and then the porcelain sintered body and metal accessories are a...

Embodiment 3

[0027] A preparation method of a rotary wrist-arm porcelain insulator, mixing the raw material of the porcelain blank with an aqueous solution containing polysaccharide, adding a dispersant, and ball milling at 75°C to obtain a slurry, controlling the solid phase of the slurry to a ratio of 58wt%, and the slurry Adjust the pH value of the material to 8.3, add an oxygen inhibitor accounting for 0.5wt% of the slurry quality to the slurry, mix it and inject it into the mold, cool it down to 15°C and mold it to make a porcelain body, and then dry the porcelain body in sequence ( Drying for 4 hours at a temperature of 35°C and a relative humidity of 95%, firing (in a sintering furnace: heat preservation at 200°C for 1 hour, heat preservation at 450°C for 2 hours, heat preservation at 900°C for 1.5 hours, heat preservation at 1430°C for 2 hours, heating rate 0.5°C / min), the porcelain sintered body is made with furnace cooling, and then the porcelain sintered body and metal accessorie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com