High-temperature-resistant high-strength low-density cement slurry system

A technology of high temperature resistance and cement slurry, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of low strength, high density of cement slurry system, small applicable temperature range, etc., and achieve fast strength, rapid development, The effect of shortening the waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

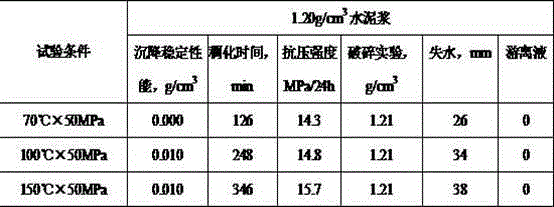

[0024] Example 1 The density is 1.20g / cm 3 high strength low density cement slurry system

[0025] G grade oil well cement is 100 parts by weight, 25 parts of domestic hollow glass microspheres, 12 parts of micro silicon, 2 parts of early strength agent AG204, 2 parts of early strength agent BTFA-18, 3 parts of fluid loss reducer AG33S (common type), 1 part of fluid loss reducer BG33S (special for low density), 2 parts of expansion agent G401, no retarder GH-9 at 70°C, 0.3 part of retarder GH-9 at 100°C, 150 1.2 parts of retarder GH-9 at ℃, the liquid-solid ratio is 0.67, and the ratio of fluid loss reducer A and B, early strength agent A and B is adjusted according to the cement slurry condition and the thickening time required for cementing.

[0026] Prepare cement slurry according to GB / T19139 standard, and carry out high-temperature settlement stability performance, high-pressure crushing test, thickening and compressive strength test, water loss and free liquid test. Th...

Embodiment 2

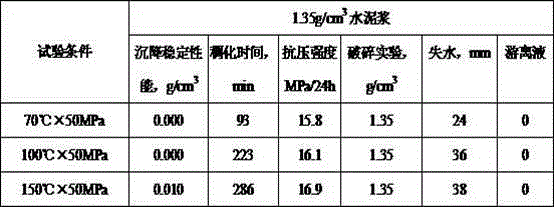

[0029] Example 2 The density is 1.35g / cm 3 high strength low density cement slurry system

[0030] G grade oil well cement is 100 parts by weight, 25 parts of domestic hollow glass microspheres, 12 parts of micro silicon, 2 parts of early strength agent AG204, 2 parts of early strength agent BTFA-18, 3 parts of fluid loss reducer AG33S (common type), 1 part of fluid loss reducer (special for low density), 2 parts of expansion agent G401, no retarder GH-9 at 70°C, 0.5 part of retarder GH-9 at 100°C, 150°C 1.5 parts of retarder GH-9, the liquid-solid ratio is 0.67, and the ratio of fluid loss reducer A and B, and early strength agent A and B should be adjusted according to the condition of cement slurry and the thickening time required for well cementing.

[0031] Prepare cement slurry according to GB / T19139 standard, and carry out high-temperature settlement stability performance, high-pressure crushing test, thickening and compressive strength test, water loss and free liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com