Polishing solution for chemically and mechanically polishing cobalt barrier layer structure and applications thereof

A structural chemical and mechanical polishing technology, applied in the field of materials, can solve problems such as poor surface quality, cobalt and copper are easy to corrode, and achieve the effects of reducing removal rate, preventing over-corrosion, and reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0044] Polishing fluid formula: 2wt% colloidal silicon dioxide, 1wt% hydrogen peroxide, 0.5wt% glycine, 0.0266wt% methyl-1H-benzotriazole, 0.02wt% polyethylene glycol octane Base phenyl ether and the remaining water, using nitric acid and potassium hydroxide to adjust the pH value to 2.0-12.0;

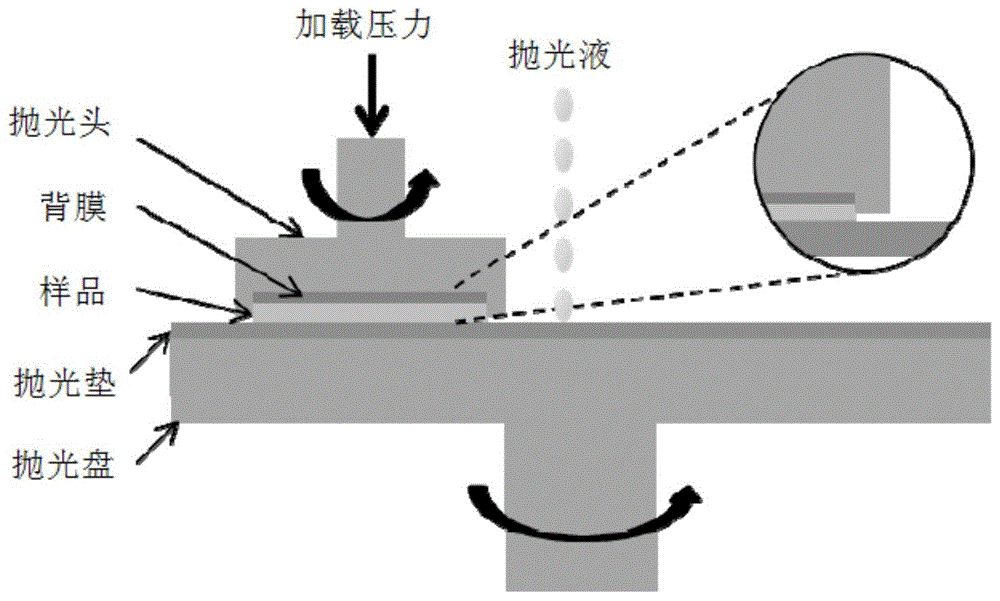

[0045] Polishing step: During chemical mechanical polishing, such as figure 1 As shown, the polishing liquid is continuously added to the polishing pad at a certain flow rate, and the sample on the polishing head is in contact with the polishing pad under the applied pressure, and the polishing pad and the sample rotate in the same direction to continuously replenish the polishing liquid to the contact area. The surface material is planarized and removed under the synergistic action of the chemical reaction of the polishing fluid and mechanical grinding, thereby achieving local and global planarization. It is worth noting that the above usage method is based on the traditional polishi...

experiment example 2

[0048] Polishing fluid formula: 2wt% colloidal silicon dioxide, 1wt% hydrogen peroxide, 0.5wt% glycine, 0.02wt% polyethylene glycol octylphenyl ether, no metal corrosion inhibitor or 0.0138wt% 1,2,4-triazole or 0.0238wt% benzotriazole or 0.0266wt% methyl-1H-benzotriazole, the balance being water, using nitric acid and potassium hydroxide to adjust the pH value to 8.0;

[0049] Polishing steps: the same as Experimental Example 1.

[0050] The test results show that the removal rate of cobalt and copper materials is significantly reduced after the metal corrosion inhibitor is added, indicating that during the polishing process, the metal corrosion inhibitor can react with the cobalt and copper surface products to form a passivation layer with protective effect. film, prevents over-corrosion during polishing, and reduces cobalt and copper material removal rates. By comparison, it was found that after the addition of methyl-1H-benzotriazole, the removal rate of cobalt and copper ...

experiment example 3

[0052] Polishing fluid formula: 2wt% colloidal silicon dioxide, 1wt% hydrogen peroxide, 0.5wt% glycine, 0.0266wt% methyl-1H-benzotriazole, no surfactant or 0.02wt% non- Ionic surfactant or 0.05wt% nonionic surfactant, the balance is water, and nitric acid and potassium hydroxide are used to adjust the pH value to 8.0. Three different types of nonionic surfactants were tested: polyethylene glycol (molecular weight about 6000), P123 (CAS number: 9003-11-6, produced by BASF, Germany) and polyethylene glycol octylphenyl ether.

[0053] Polishing step: with embodiment 1, test result is shown in table 1 below:

[0054] Table 1

[0055]

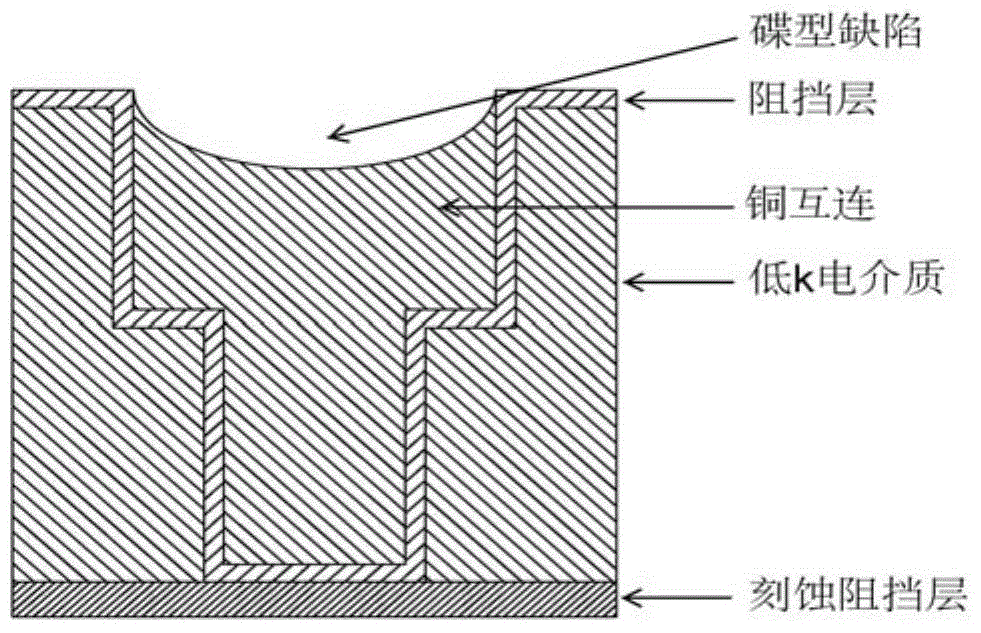

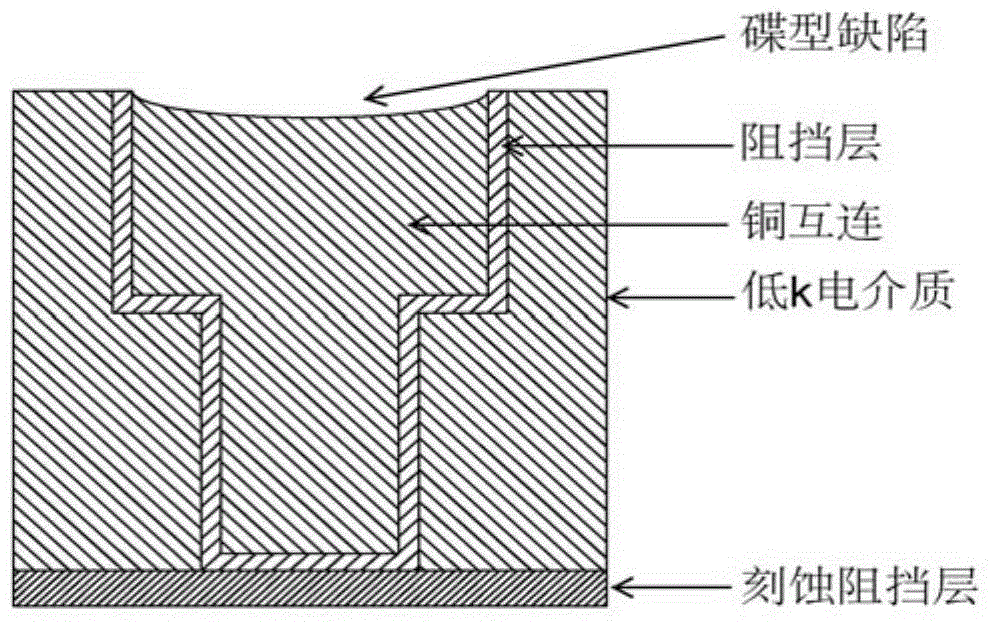

[0056] It can be seen that the co-action of metal corrosion inhibitor methyl-1H-benzotriazole and non-ionic surfactant can further reduce the removal rate of cobalt and copper materials, and obtain adjustable cobalt / copper material removal rate selectivity. figure 2 is a schematic cross-sectional view of the cobalt barrier layer structure b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com