Chemico-mechanical polishing liquid

A chemical mechanical and polishing liquid technology, which is applied in the fields of polishing compositions containing abrasives, electrical components, semiconductor/solid-state devices, etc., can solve the problems of reducing the removal rate of polysilicon, reduce surface depressions, and improve surface flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

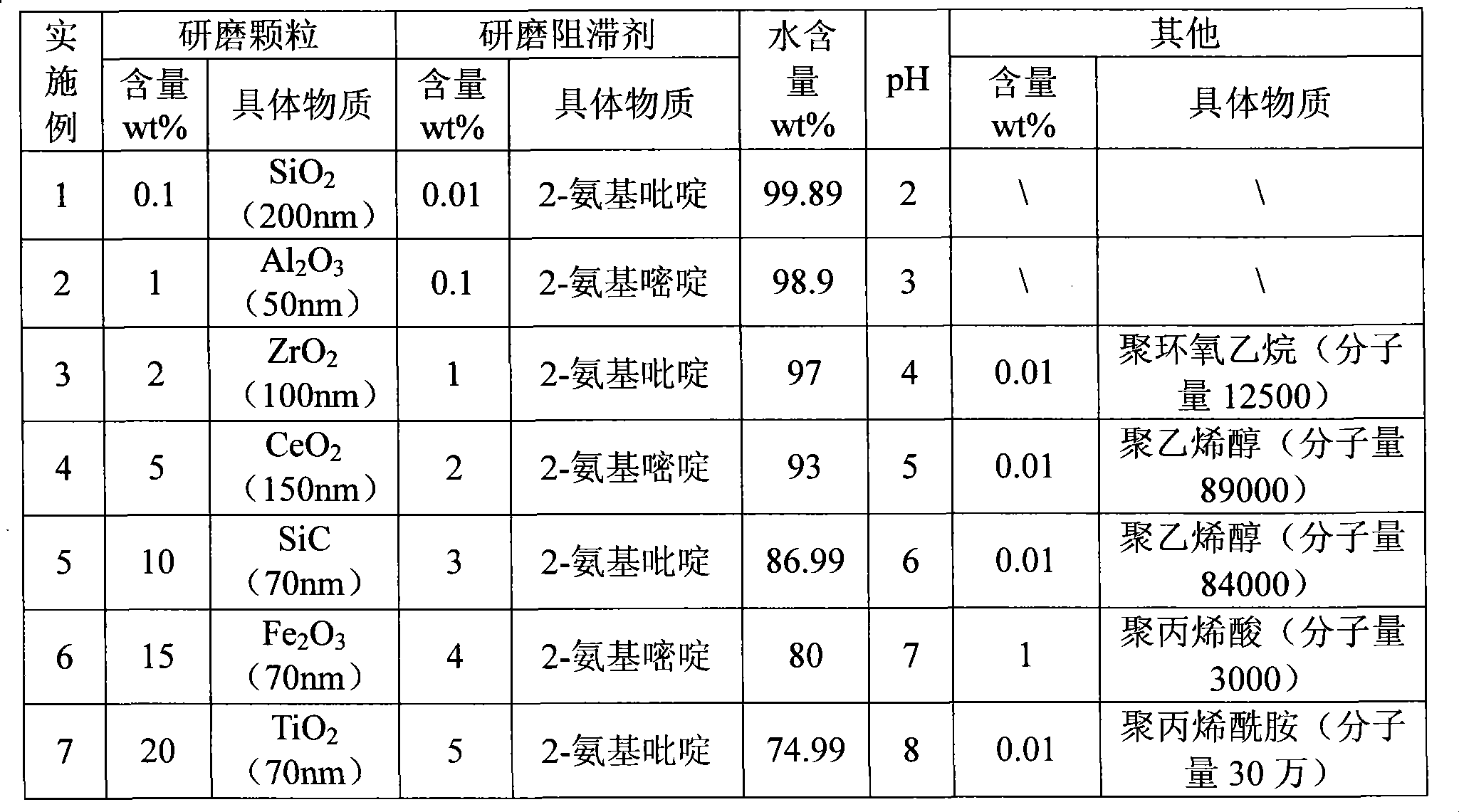

[0024] Table 1 shows Examples 1-12 of the chemical mechanical polishing liquid of the present invention. According to the formula in the table, the components are mixed evenly, and then adjusted to a suitable pH value with a pH regulator. In Examples 6-12, NaOH, KOH, ammonia water, primary amines, secondary amines, tertiary amines and quaternary amines were respectively used as pH regulators in sequence.

[0025] Table 1 Embodiments 1-12 of the chemical mechanical polishing fluid of the present invention

[0026]

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com