Chemico-mechanical polishing liquid

A chemical machinery, polishing liquid technology, applied in polishing compositions, chemical instruments and methods, polishing compositions containing abrasives, etc., to achieve the effect of good surface morphology

Inactive Publication Date: 2009-04-29

ANJI MICROELECTRONICS (SHANGHAI) CO LTD

View PDF0 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

So far, there have been no relevant literature reports

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~7

[0022] Table 1 shows examples 1 to 7 of the polishing solution of the present invention. According to the formula in the table, the components are simply and uniformly mixed, and the balance is water, and potassium hydroxide or nitric acid is used to adjust to a suitable pH, and each example can be prepared. of polishing fluid.

[0023] Table 1 Polishing liquid embodiment 1~7 of the present invention

[0024]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

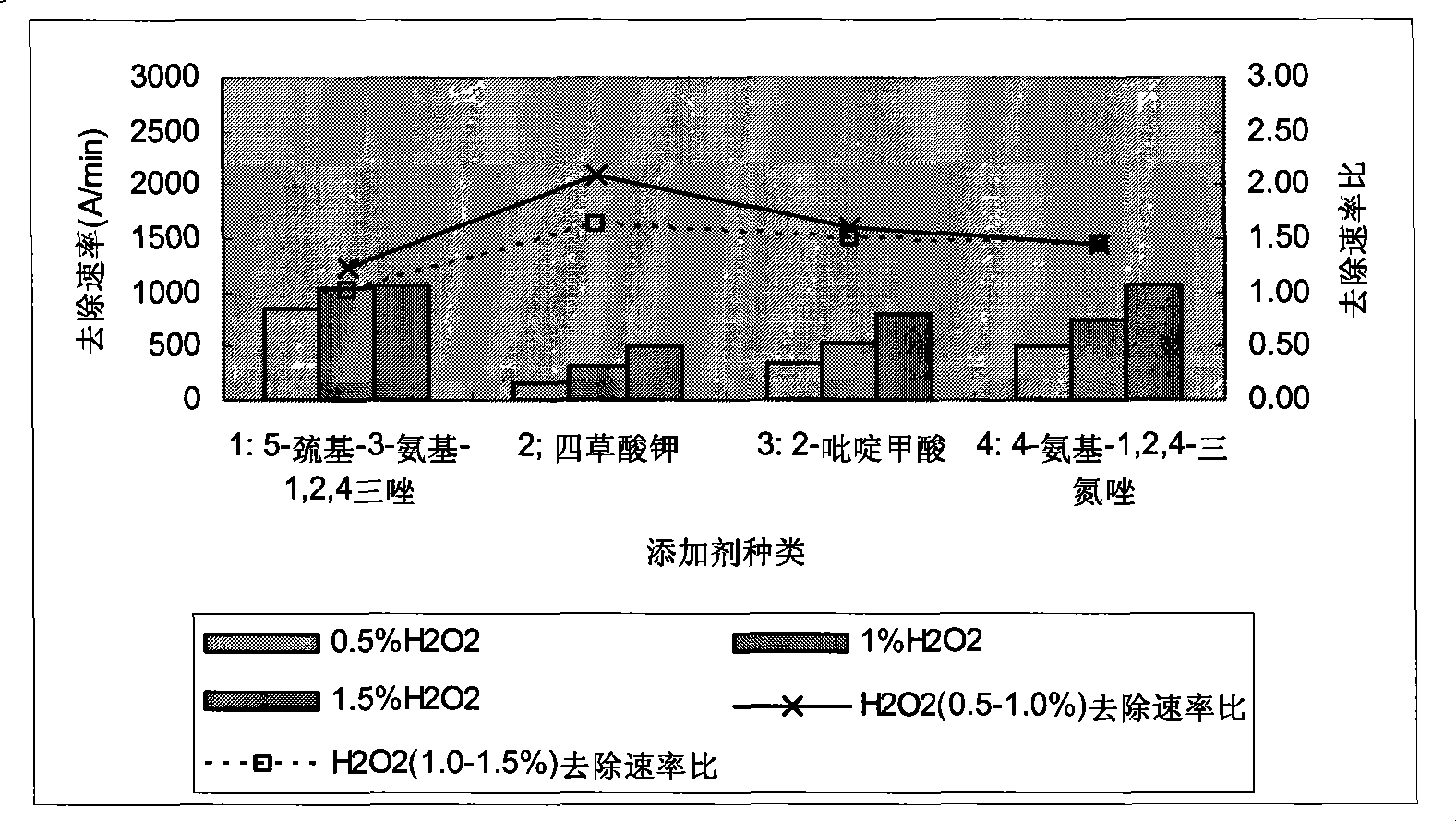

The invention discloses a chemical-mechanical polishing solution, which is characterized by comprising an abrading agent, an oxidizer, water and the following one or more complexing agents: triazole ring containing sulfydryl, triazoles compound the active nitrogen atom of which contains donative electron substituent, pyridine ring containing carboxyl and oxalate. Cu removing rate of the polishingsolution has low sensitivity to concentration change of oxyful contained in the polishing solution. After the polishing solution is adopted for polishing, the copper has smooth surface and good surface topography.

Description

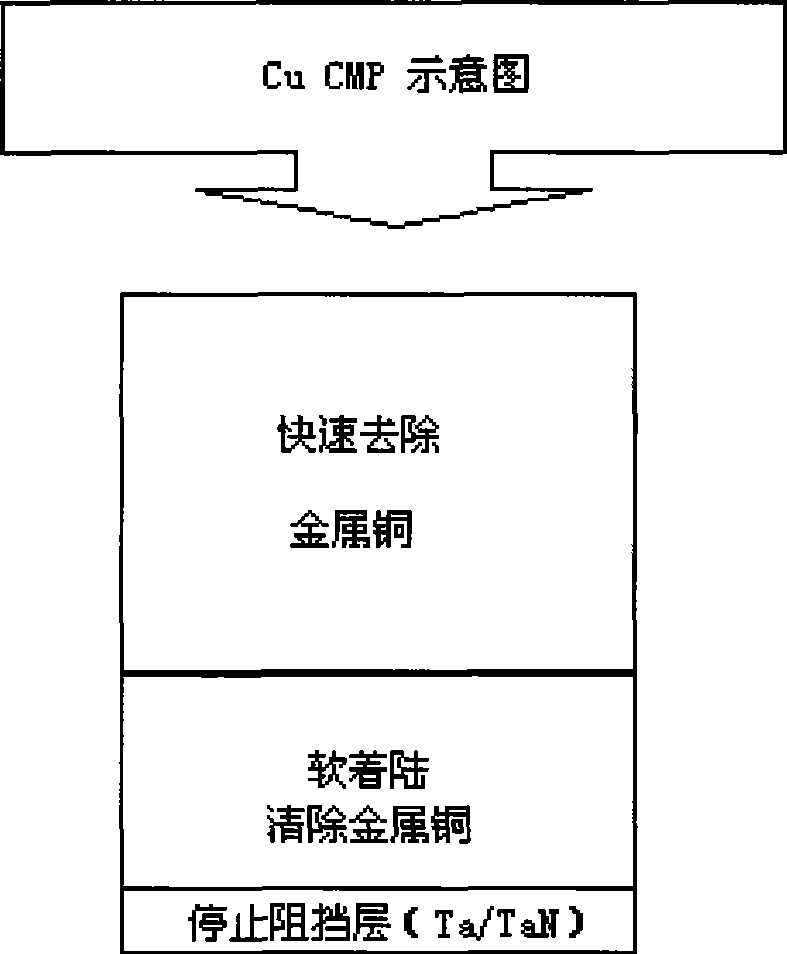

technical field [0001] The invention relates to a chemical mechanical polishing liquid. Background technique [0002] In the semiconductor process below 130nm, metal copper has been widely used as an interconnection material. Chemical mechanical polishing (CMP) of Cu interconnects is a widely used technique in today's global planarization process. Different processes have different technical requirements for copper polishing rate. It is a common method in the industry to adjust the copper removal rate by optimizing the process conditions. Many literatures have reported different polishing fluid formulations to achieve different selectivity ratios to adjust the surface morphology and removal rate of Cu. [0003] In the chemical mechanical polishing process of Cu, there are two stages: fast removal stage and soft landing stage (such as figure 1 shown). Polishing in the soft landing stage requires a relatively low copper removal rate and a very high Cu / Ta polishing selecti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09G1/02C09G1/18H01L21/304

Inventor 宋伟红姚颖陈国栋包建鑫

Owner ANJI MICROELECTRONICS (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com