Water-oil separating system and method using centrifugation, gravitation, expansion composite principle

A technology for oil-water separation and oil-water separation, which can be used in immiscible liquid separation, earthwork drilling, and fluid production, etc., and can solve problems such as reduced processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

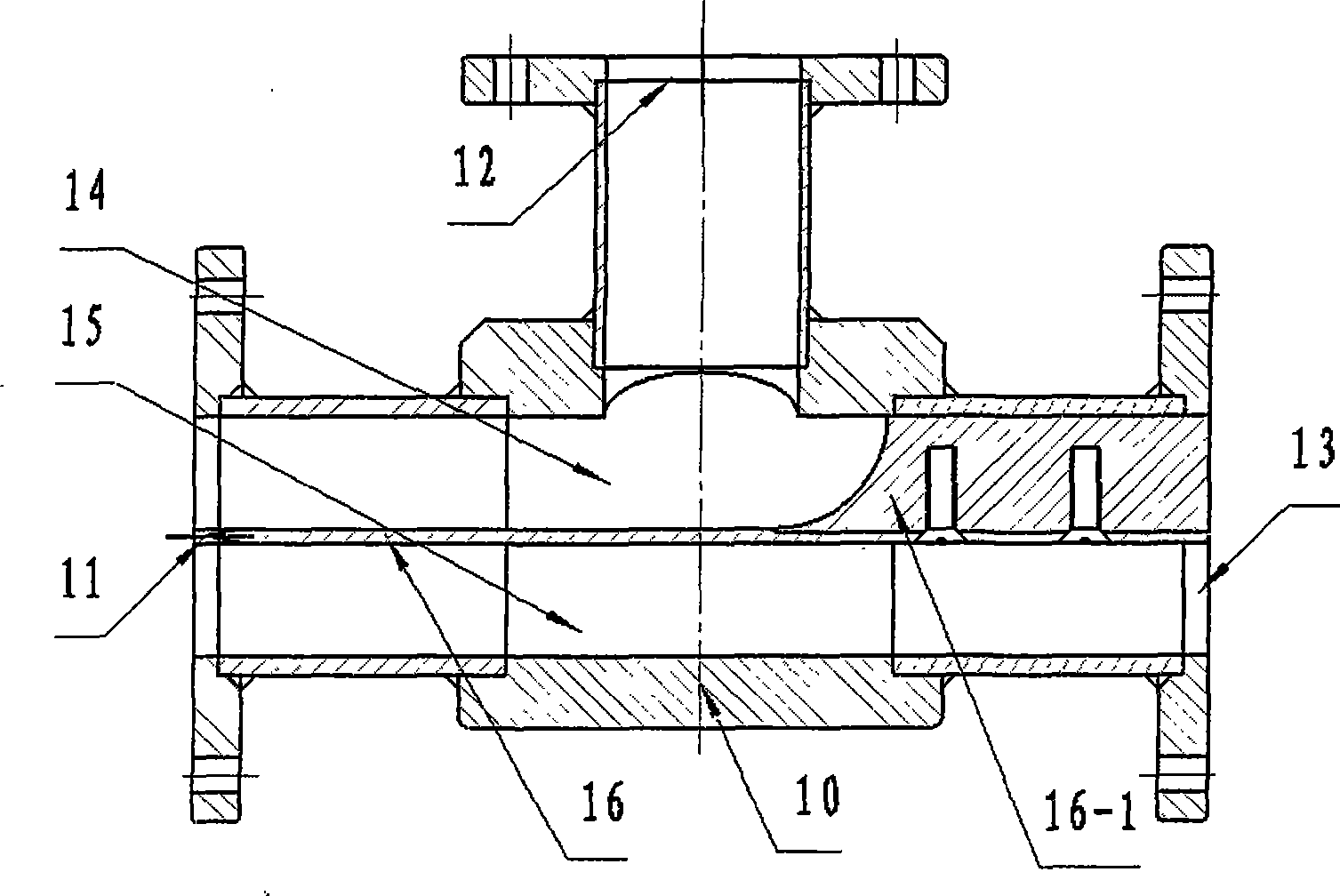

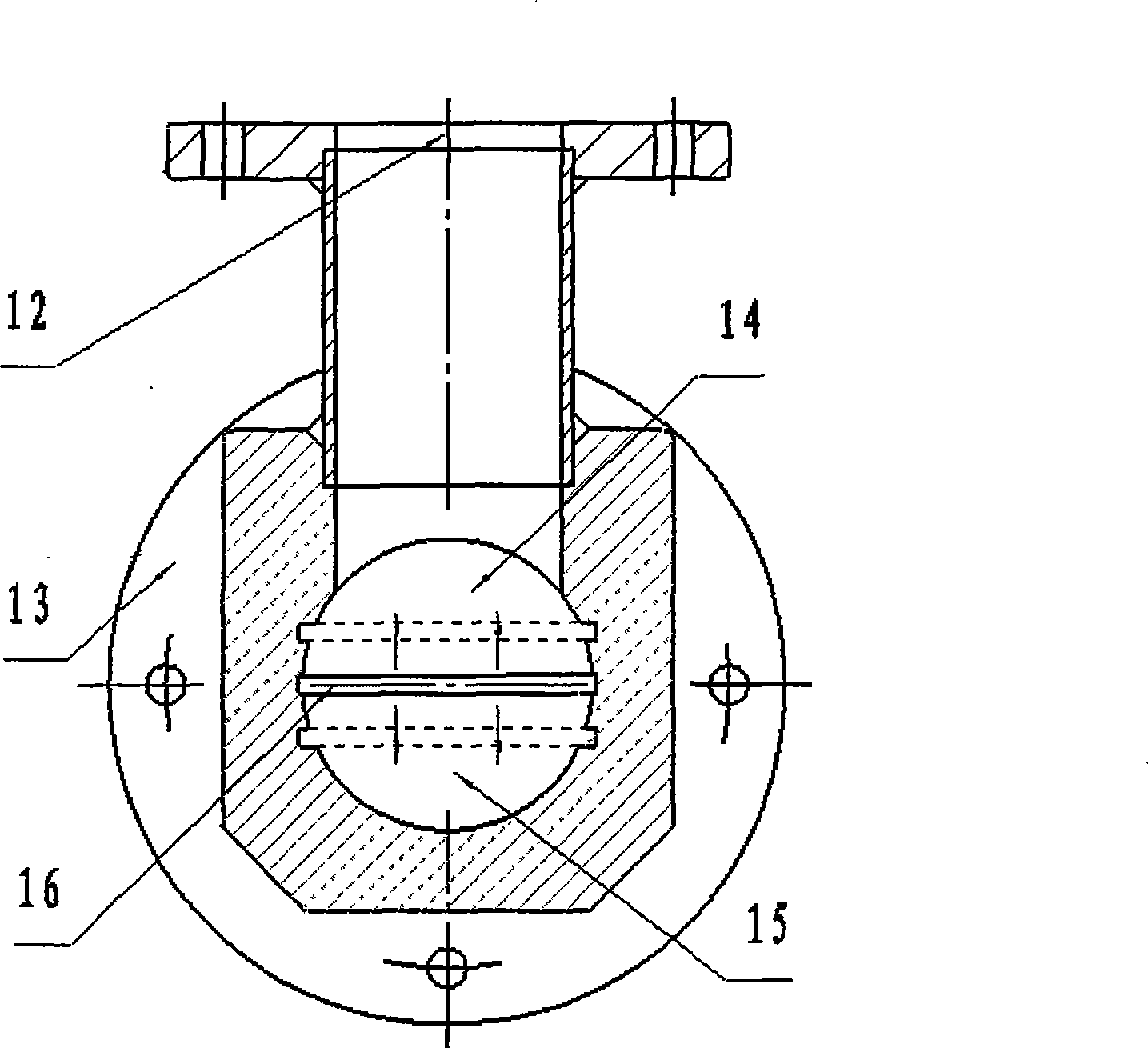

[0046] Referring to Fig. 1, make the first shunt 10 and the second shunt 20, the body of the shunt is a pressure-resistant vessel with a three-way tubular structure, and a liquid inlet 11 is provided on the pressure-resistant vessel, and the three-way pipe The nozzle on the left side is the liquid inlet 11, the nozzle on the right side of the three-way pipe is the lower liquid outlet 13, and the upper nozzle of the three-way pipe is the upper liquid outlet 12; Divider baffle 16 divides cavity into upper and lower two spaces, upper chamber 14 communicates with upper liquid outlet 12, lower chamber 15 communicates with lower liquid outlet (or horizontal liquid outlet) 13, and both layers of space are connected with inlet. The liquid port is connected. The end of the splitter is flush with the end of the liquid inlet. The splitter is located above one end of the nozzle on the right side of the tee pipe and has a plug 161 that closes the upper part of the nozzle. The longitudinal...

Embodiment 2

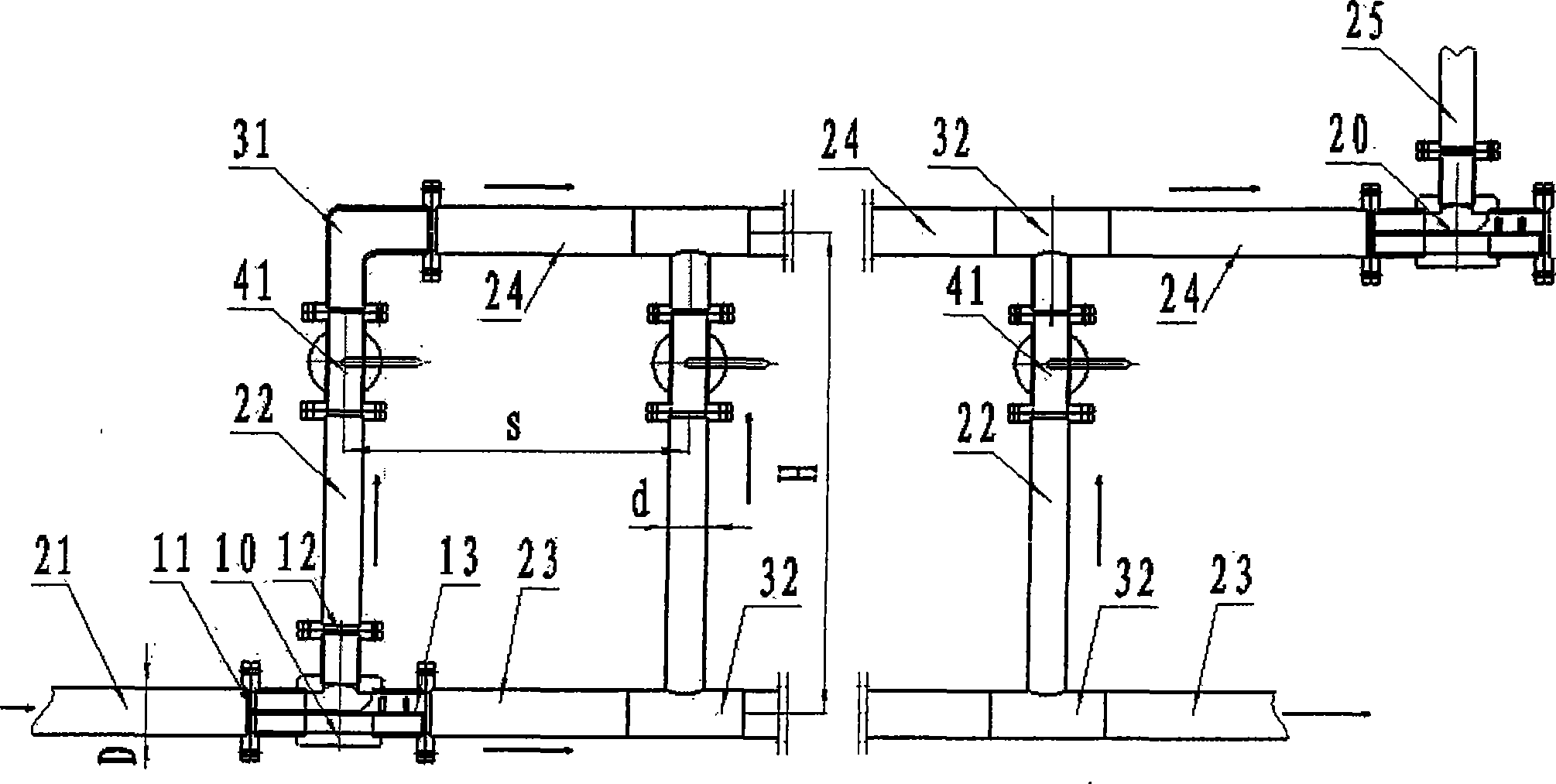

[0049] See Figure 1 and figure 2 , Make a T-shaped pipe separation device: T-shaped pipe 200 is made up of horizontal total liquid inlet pipe 21, upper horizontal pipe 24, lower horizontal pipe 23, vertical pipe 22, flow divider 10 (20) and valve 41. The horizontal main liquid inlet pipe 21 is connected to the incoming flow pipeline, the other end is connected to the inlet 11 of the flow divider 10, the upper outlet 12 of the flow divider is connected to the vertical pipe 22, the horizontal outlet 13 is connected to the lower horizontal pipe 23, and the upper end of the vertical pipe is connected to the valve 41. The other side of 41 is connected with the bottom opening 31 of the 90-degree elbow, and the elbow is connected with the upper horizontal pipe 24. N vertical tubes 22 are connected in parallel between the upper horizontal tube 24 and the lower horizontal tube 23 , thereby forming a T-shaped tube 200 . The T-shaped pipe is at least composed of a total liquid inlet pi...

Embodiment 3

[0051] refer to image 3 , make a helical tube separator: the helical tube main body 500 is a vertical structure, the helical tube main body 500 is fixed on the support 90 of the helical tube main body, the helical tube input pipe 51-port of the helical tube main body 500 is installed with an input pipe valve 42, Spiral pipe input pipe 55 one port installs output pipe valve 43; The total number of turns is 25, and the spiral pipe upper part of spiral pipe main body 500 has 4 circles to be band hole section 54, and the band hole section below is closed section 52; The number of small holes in the 3 circles from top to bottom is n 1 , n 2 , n 3 , the apertures are d 1 、d 2 、d 3 ;The number and diameter of circular holes should follow the following design criteria: n 1 ≤n 2 ≤n 3 , d 1 ≤d 2 ≤d 3 Have a circular hole 70 on each circle of the perforated section, the circular hole 70 begins to perforate from the outlet 1 / 4 circumference of the output pipe 55, and the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com