Dust separation cup of suction cleaner

A technology of dust separation and vacuum cleaner, applied in the direction of suction filter, etc., to achieve the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

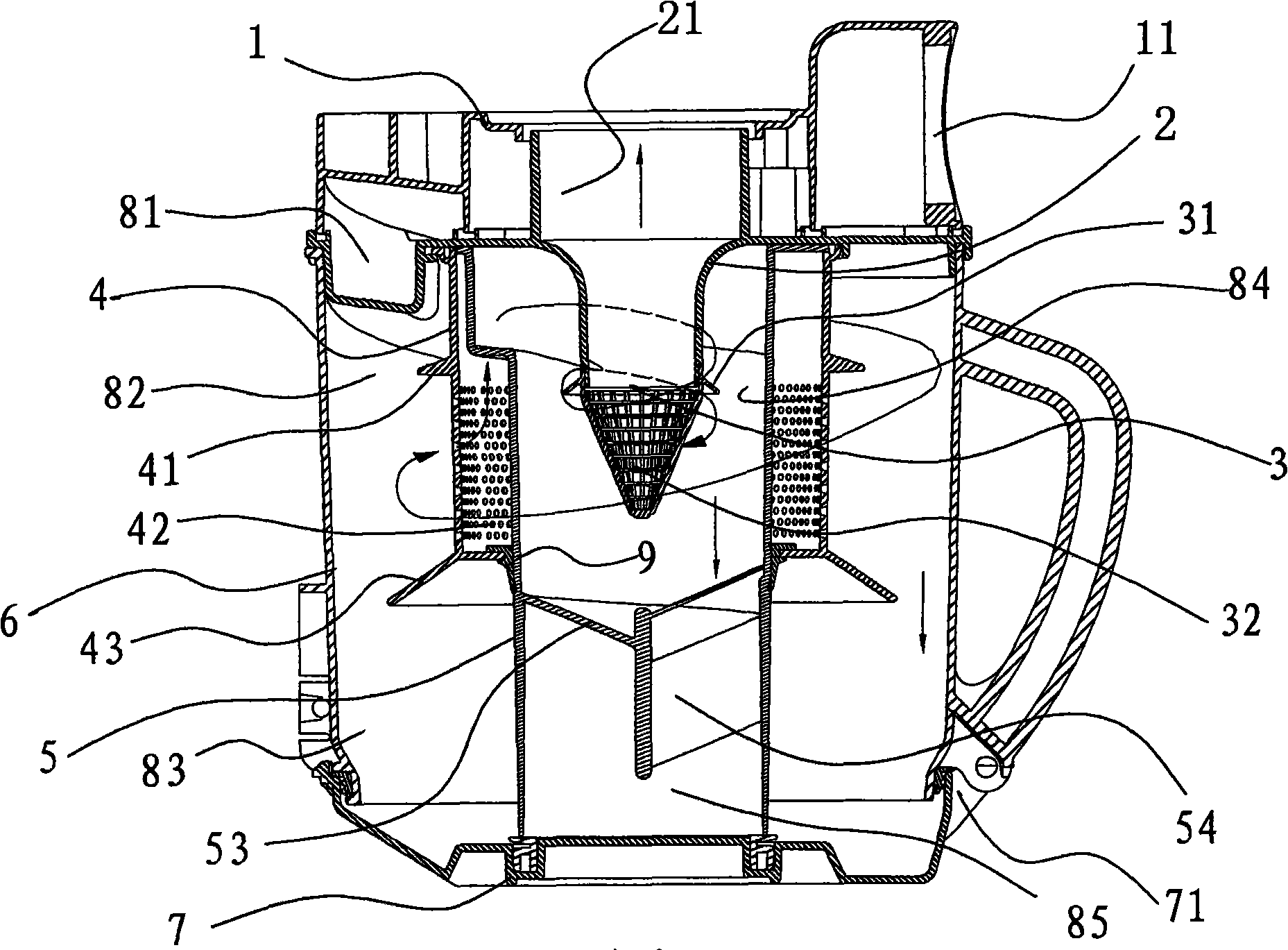

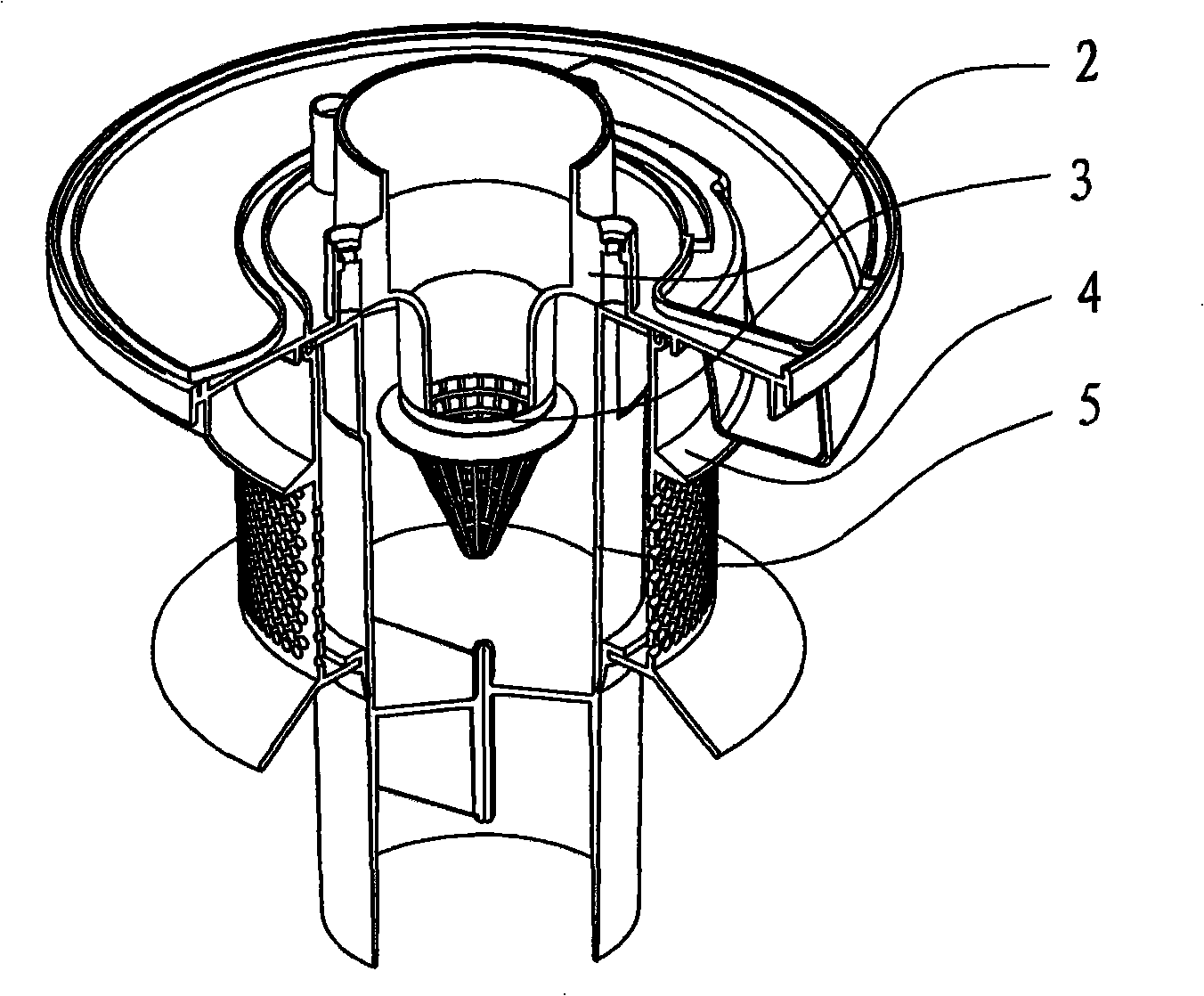

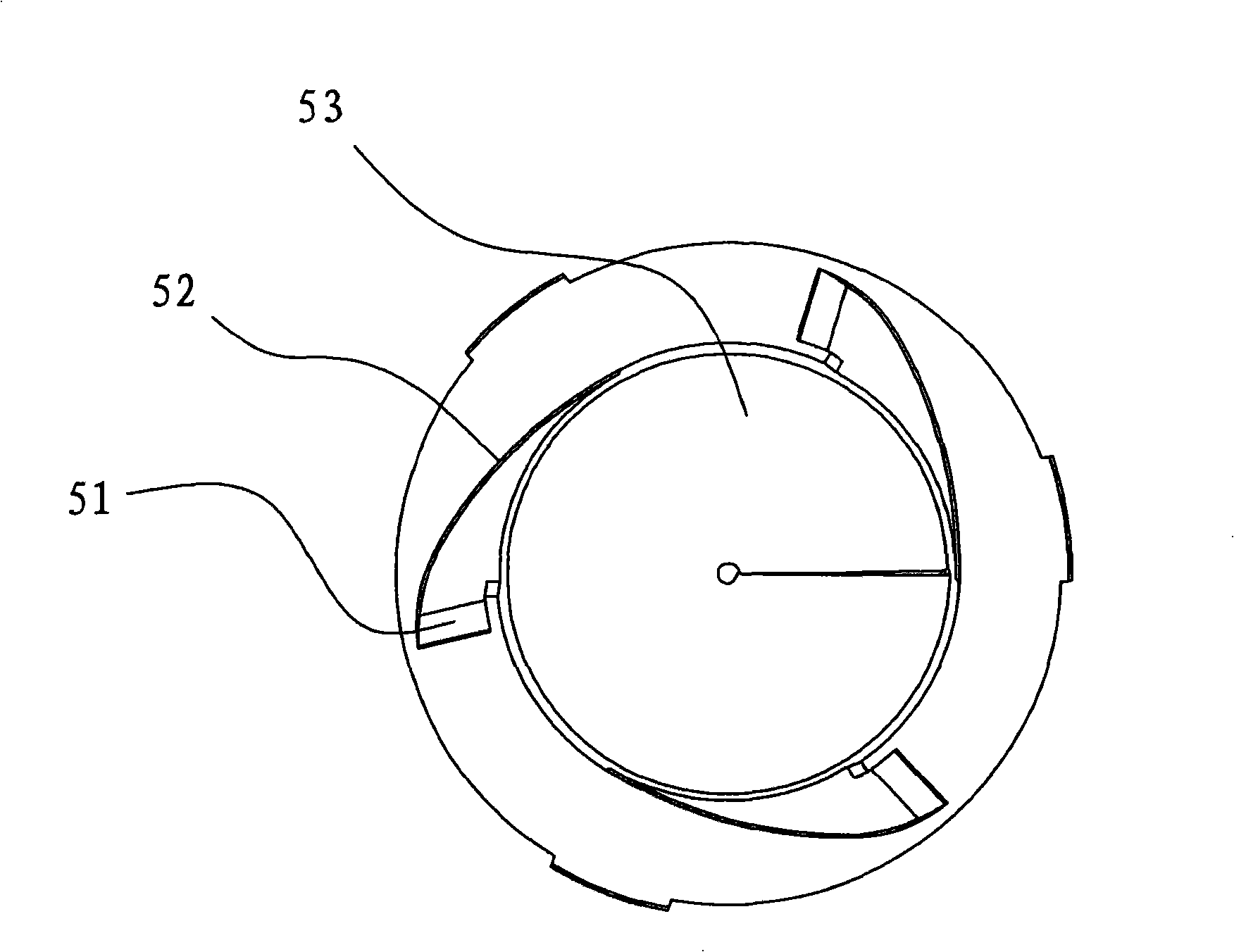

[0023] Example: refer to Figure 1 to Figure 5 , a dust separation cup for a vacuum cleaner, comprising a cup body 6 shaped like a cup, a cup bottom 7 matched with the bottom end of the cup body 6 along the mouth, a cup cover seat 2 connected with the top end of the cup body 6 along the mouth, and connected to the cup cover seat 2 The cup lid 1 on the upper side, and the air outlet 21 formed by the cup lid seat 2 and the center of the cup lid, is equipped with a first-stage dust separator 4 with a vent on the lower side of the cup lid seat 2, and the first-stage dust separator 4 The lower side of the device 4 is provided with a dust shield ring 43 extending outward, and the upper end installed through the inside of the first-stage dust separator 4 is provided with three cyclone tubes 5 with spiral air inlet passages. The upper part of the inner cavity of the cyclone is provided with an upper opening with a secondary filter screen 32, and a secondary dust separator 3 with no op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com