Tester for thrust bearing

A test device and thrust bearing technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of high installation accuracy, difficult processing of test pieces, and low degree of automation, so as to achieve easy maintenance and adjustment without gaps, and a high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

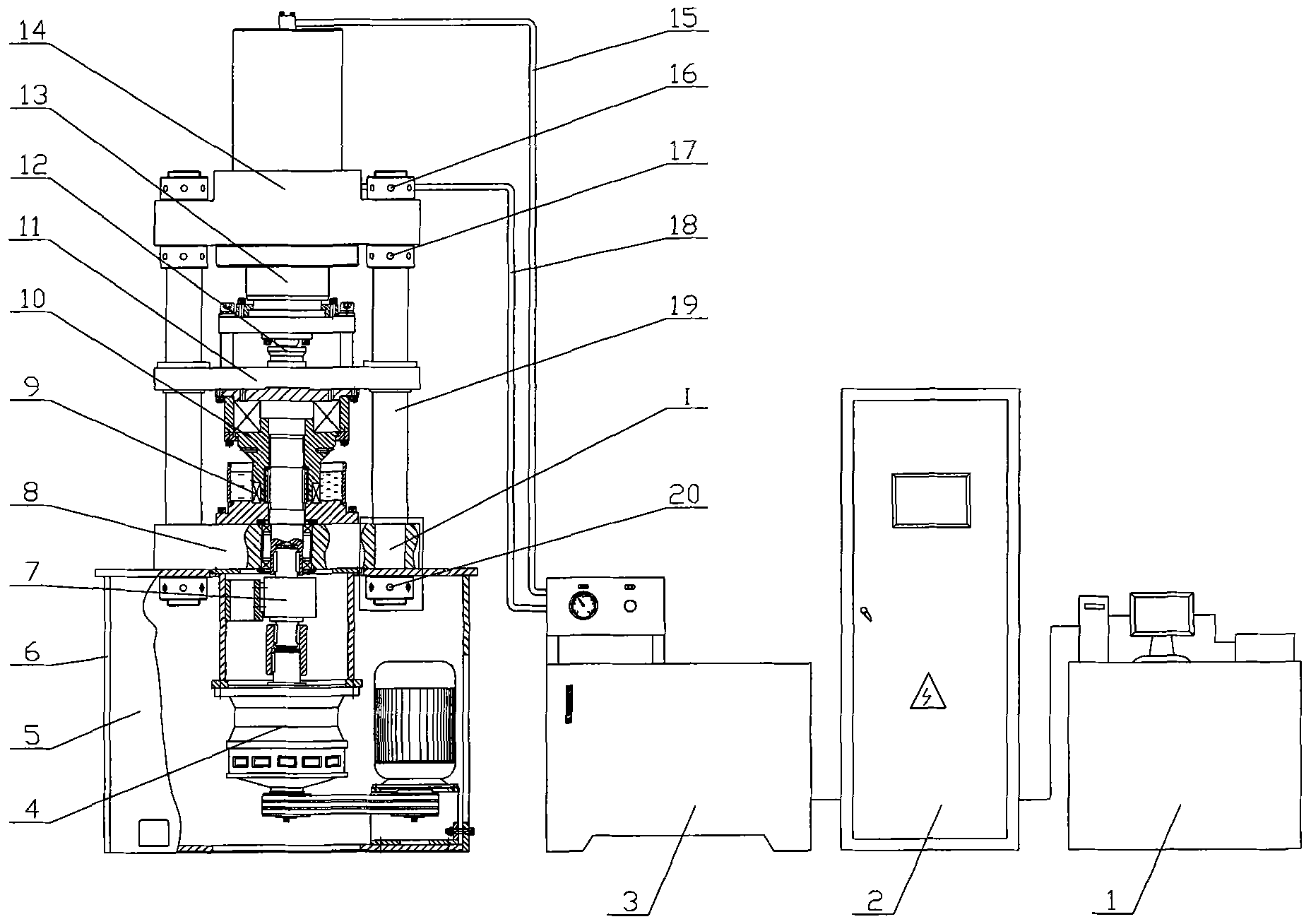

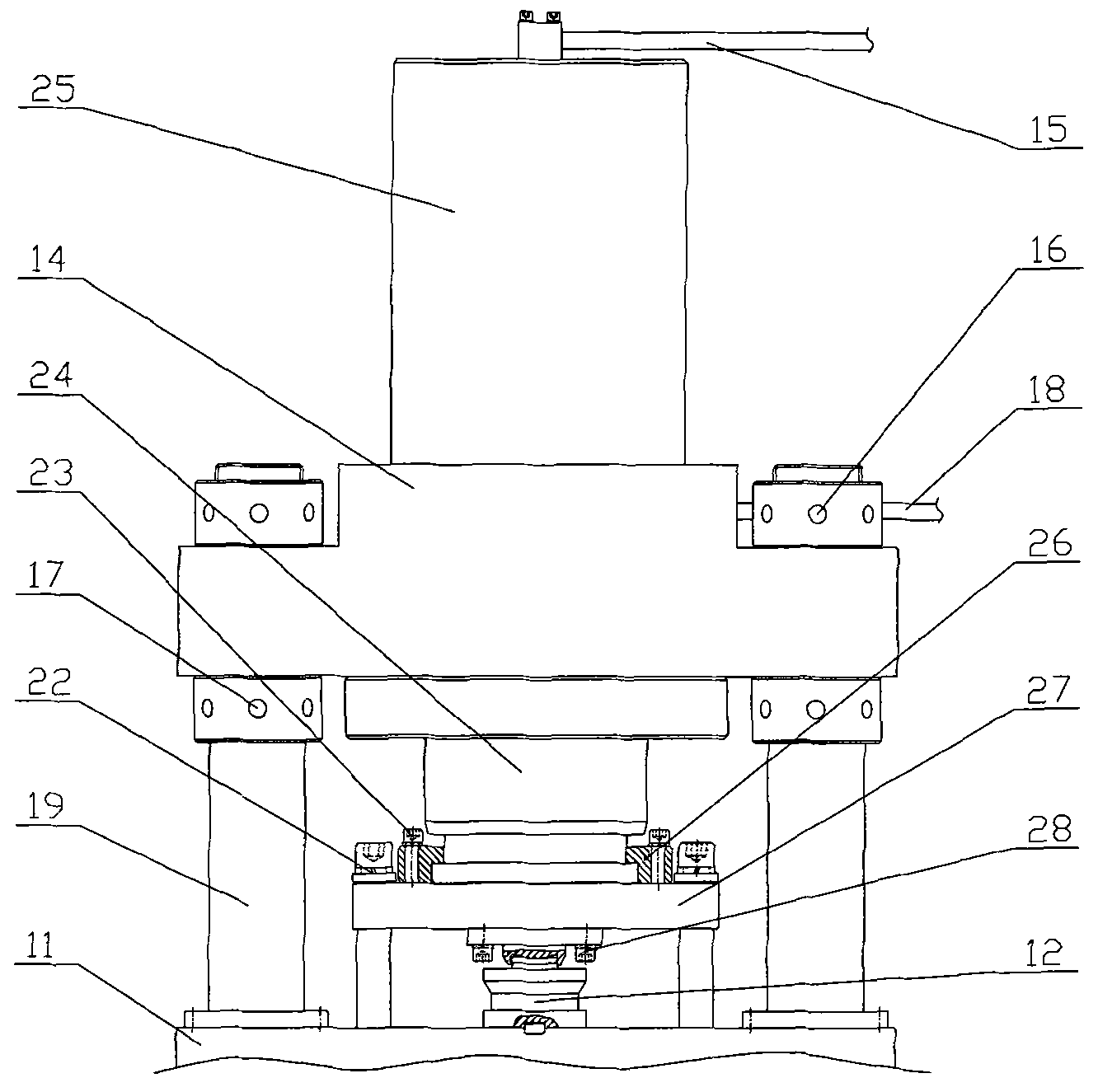

[0040] like figure 1 As shown, a thrust bearing test device includes a loading system 13 , a test bench component 10 , a rotary transmission system 4 and a frame component 5 .

[0041] The loading system 13, the test bench part 10 and the rotary transmission system 4 are based on the frame part 5, and are installed on it in a vertical order: the loading system 13 is installed above the test bench part 10, rotates The transmission part 4 is installed under the test bench part 10 . The loading system 13 , the test bench part 10 and the rotation transmission part 4 are installed on the frame part 5 . The loading system 13 is connected to the test bench part 10 which is connected to the rotary transmission part 4 . The loading system 13 provides the load required for the test, and the rotating transmission part 4 provides the power and speed of the test.

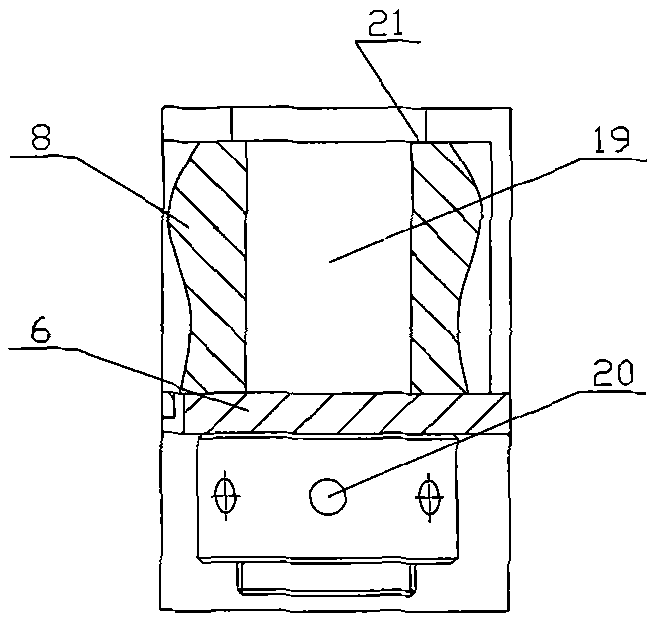

[0042] The frame component 5 includes a frame platform 6 , a frame bottom plate 8 , a frame drag plate 11 , a frame top pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com