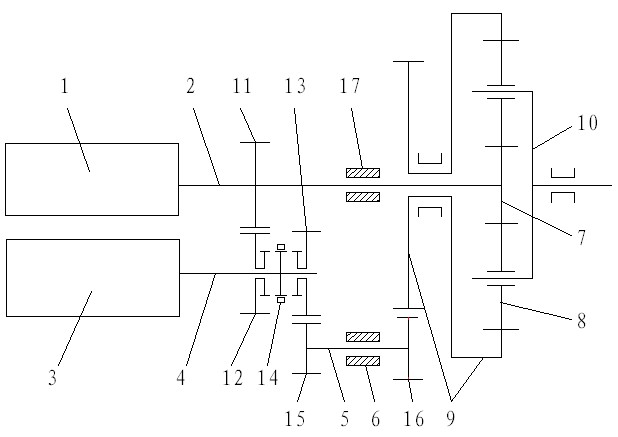

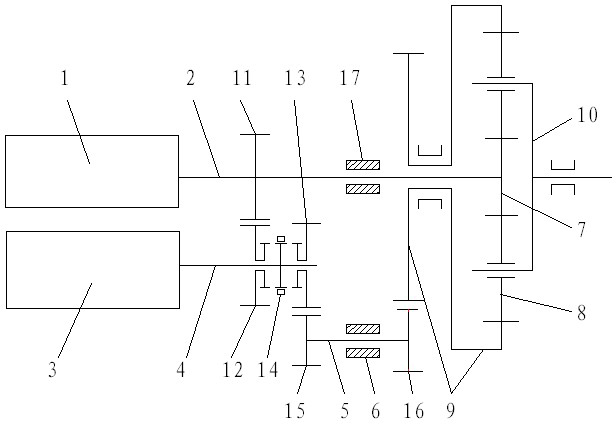

Multi-power-source multi-mode coupling drive system

A technology of coupled drive and power source, which is applied to the arrangement of multiple different prime movers of multi-gear ratio transmissions, general power units, power units, etc. and low reliability of work, to achieve the effect of high integration, high transmission efficiency, and few transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] Embodiment 2: The difference between the implementation of this embodiment and Embodiment 1 is that the first power source 1 and the second power source 3 are both electric motors; this embodiment has the following working modes:

[0044] 1. The first power source works alone:

[0045] When the second power source 3 is not working and the synchronizer 14 is in an idle state, it is driven solely by the first power source 1 , and the first brake 6 brakes the third transmission shaft 5 to realize pure electric operation. When the first power source 1 and the second power source 3 are both electric motors, the first power source 1 can be used as the main power source, and the second power source 3 can be used as the auxiliary power source, then the main power source will be in a normal working state, which means The second brake 17 may not be provided during this time.

[0046] 2. Idle start-stop mode:

[0047] When the first power source 1 is not working, the synchronize...

Embodiment 3

[0054] Embodiment 3: The difference between the implementation of this embodiment and Embodiment 1 is that the first power source 1 and the second power source 3 are both engines; this embodiment has the following working modes:

[0055] 1. The driving mode of the first power source alone:

[0056] When the second power source 3 is not working, the synchronizer 14 is in an idle state, driven solely by the first power source 1 , and the first brake 6 brakes the third transmission shaft 5 .

[0057] 2. Idle start-stop mode:

[0058] When the first power source 1 is not working, the synchronizer 14 is in an empty state, the second power source 3 is working, and the drive system is in an idle start-stop state.

[0059] 3. Driving assistance mode:

[0060] When the first power source 1 and the second power source 3 work at the same time, and the synchronizer 14 is in the state of combining with the second gear 12 or the third gear 13, the second power source 3 can provide auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com