Fatigue life test stand for angular contact ball bearing

A technology of angular contact ball bearings and fatigue life, applied in the field of mechanical engineering, can solve problems such as inconvenient operation, poor coaxiality of the shaft system, high cost, etc., and achieve the effects of convenient installation and disassembly, large adjustment range, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

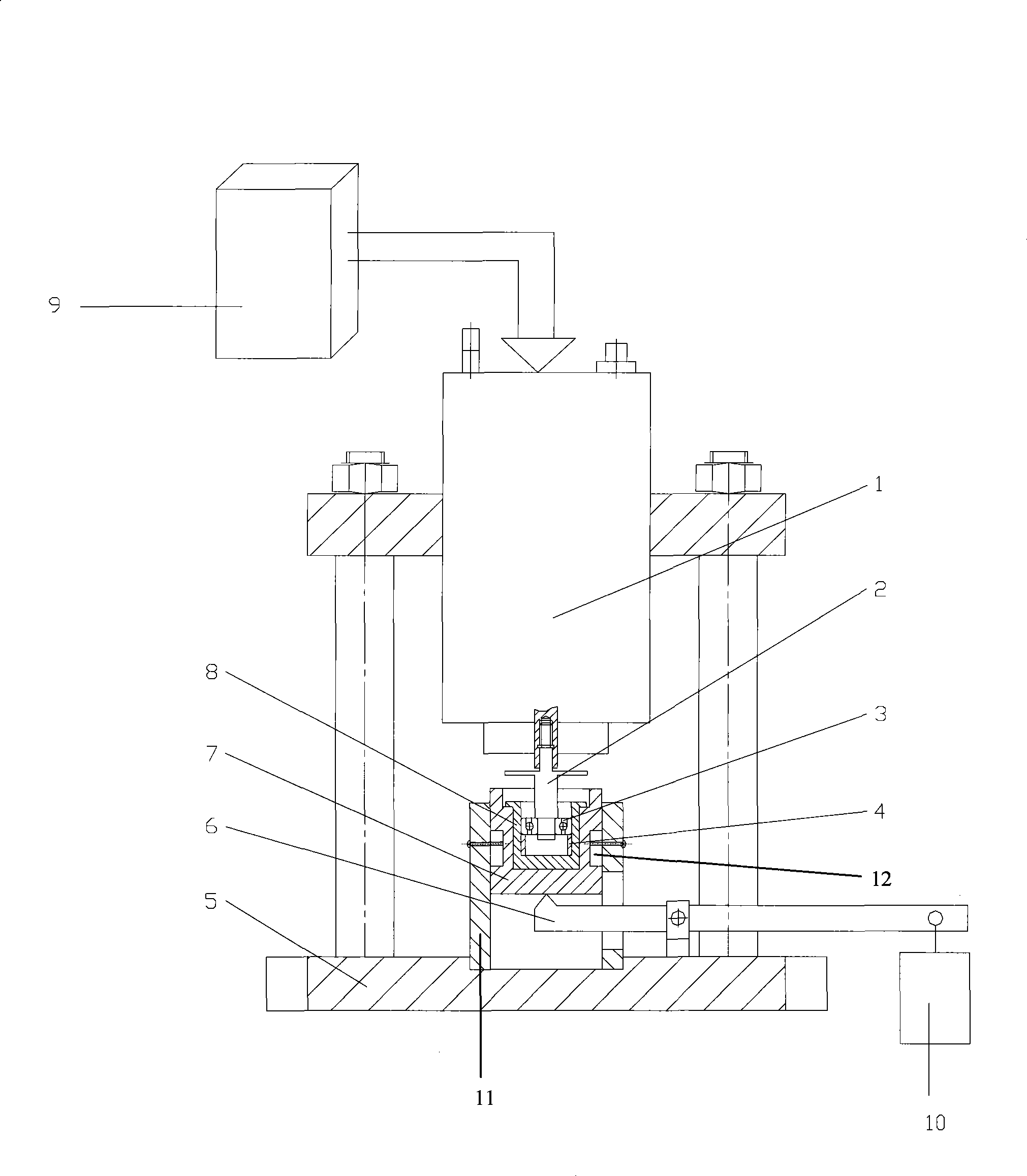

[0025] Angular contact ball bearing fatigue life test bench structure of the present invention is:

[0026] An angular contact ball bearing fatigue life test rig, the test rig includes a driving device, a tested bearing assembly, a loading device and a vertical test rig 5:

[0027] The driving device is arranged on the top of the test bench 5, and the driving device is composed of a frequency converter 9 and a high-frequency motor 1, and the transmission shaft 2 of the high-frequency motor 1 is provided with an angular contact ball bearing 3 to be tested;

[0028] The bearing assembly to be tested is coaxially arranged below the high-frequency motor 1. The assembly includes a loading sleeve 7, a bearing seat 8, a retaining ring 4 and a fixed part 11: the loading sleeve 7 is arranged on the fixed part 11 on the base of the test bench 5 Inside, a limiting device 12 is provided between the outer wall of the loading sleeve 7 and the fixed part 11, so that the loading sleeve 7 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com