Duel-clutch stepless speed change series parallel hybrid power system

A technology of hybrid power system and continuously variable transmission, which is applied in the system field of automobile technology field, and can solve the problems of difficult electric drive efficiency, large motor torque, and high system cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

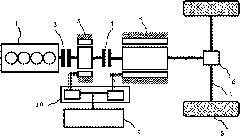

[0030] like figure 1 As shown, the hybrid power system of this embodiment includes an engine 1, a first clutch 2, a first motor 3, a second clutch 4, a second motor 5, a reduction differential device 6, a drive axle 7, wheels 8, and an energy storage device 9. Motor control device 10. Wherein: the crankshaft output end of engine 1 is connected with the input end of first clutch 2, and the output end of first clutch 2 is connected with the rotor of first motor 3, and the rotor of first motor 3 is connected with the input of second clutch 4 again. The output end of the second clutch 4 is connected with the rotor of the second motor 5, and the rotor of the second motor 5 is connected with the reduction differential device 6, and the reduction differential device 6 is connected to the wheel through the drive axle 7. 8, the energy storage device 9 is connected to the motor control device 10 through a high-voltage circuit, and the motor control device 10 is connected to the first m...

Embodiment 2

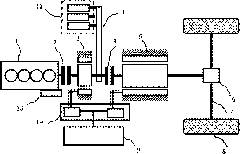

[0070] Such as figure 2 As shown, this embodiment is an optimized solution of the present invention. On the basis of Embodiment 1, it also includes an accessory drive transmission 11 connected to the rotor of the first motor 3, through which the accessory drive transmission 11 is used for air conditioning, braking, etc. It also includes a starter motor 13, which is connected to the output end of the crankshaft of the engine 1 through the output end driving disc of the first clutch 2. The connection of other components, working process, system operation mode and basic control strategy are the same as those in Embodiment 1, and will not be repeated here.

[0071] Due to the existence of the accessory drive transmission device 11, this embodiment provides a very flexible hybrid drive mode for devices 12 such as air conditioning, braking, and steering: in the case of pure electric drive, idling shutdown, etc., the first clutch 2, The second clutch 4 is in a disengaged state, and...

Embodiment 3

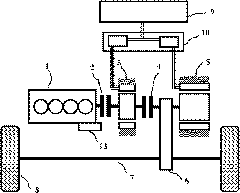

[0075] Such as image 3 As shown, the present embodiment is another optimized solution of the present invention. On the basis of Embodiment 1, the deceleration differential device 6 is arranged between the second clutch 4 and the second motor 5, and the input end of the deceleration differential device 6 At the same time, it is connected with the output end of the second clutch 4 and the rotor of the second electric machine 5 . The connection of other components, working process, system operation mode and basic control strategy are the same as those in Embodiment 1, and will not be repeated here.

[0076] This embodiment shortens the length of the system and is especially suitable for front-drive vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com