Electronic infinite variable speed parallel type mixed power driving device

A continuously variable speed and hybrid technology, applied in power plant, hybrid vehicle, pneumatic power plant, etc., can solve the problem of small power and speed ratio range, limited speed ratio range, ability to transmit torque and power and other problems. Low efficiency and other problems, to avoid fuel consumption and exhaust emissions, less power transmission components, and improve fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

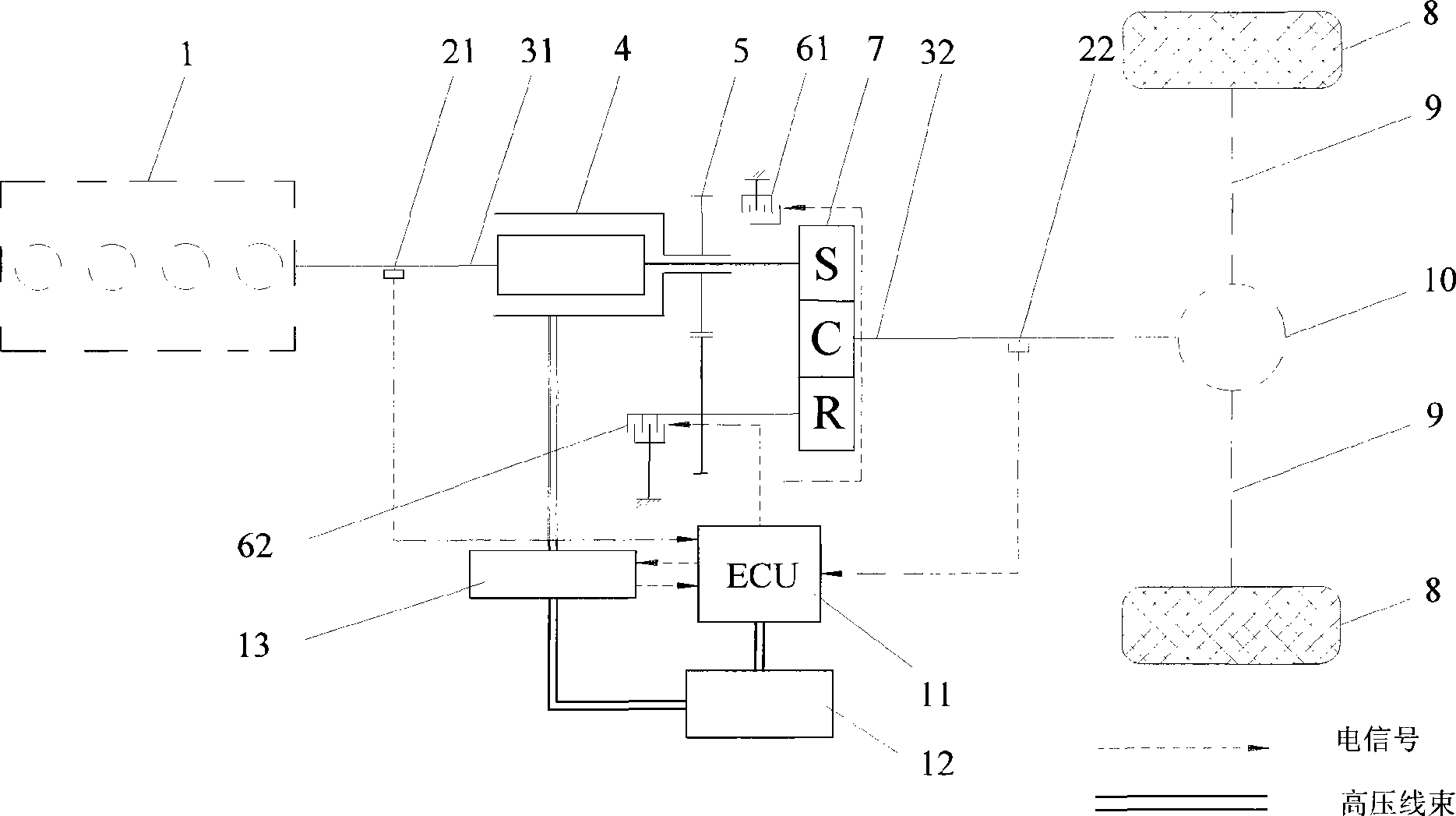

[0046] Such as figure 2 As shown, an electronic continuously variable speed parallel hybrid driving device includes an engine 1, a counter-rotating double-rotor motor 4, a planetary mechanism 7, a first brake 61, a second brake 62, a battery pack 13, a control unit ECU11, a pair of fixed shaft gear pair 5 and multiple rotational speed sensors. The engine 1 is connected with the sun gear of the planetary mechanism 7 through the input shaft 31 and the first brake 61; the input shaft 31 is also provided with a fixed shaft gear pair 5, and the fixed shaft gear pair 5 is connected with the inner rotor of the counter-rotating double rotor motor 4, The outer rotor of the dual-rotor motor 4 is connected with the second brake 62 and the ring gear of the planetary mechanism 7 through a shaft. The planet carrier of the planetary mechanism 7 is connected to the driving axle 10 through the output shaft 32 , and the driving axle 10 is connected to the driving wheel 8 through the two half ...

Embodiment 2

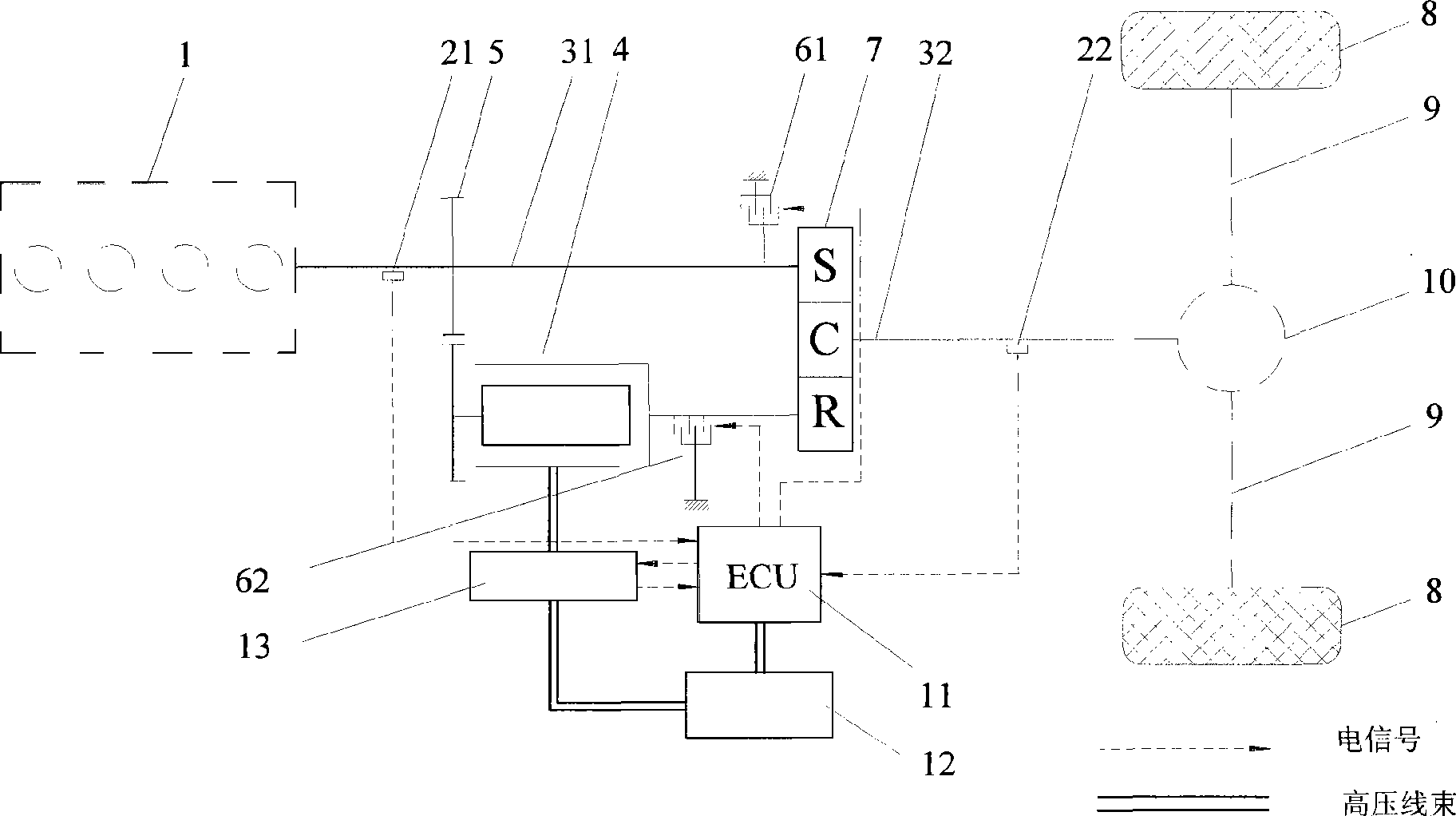

[0068] Such as image 3 As shown, an electronic continuously variable speed parallel hybrid driving device includes an engine 1, a counter-rotating double-rotor motor 4, a planetary mechanism 7, a first brake 61, a second brake 62, a battery pack 13, a control unit ECU11, a pair of fixed shaft gear pair 5 and multiple rotational speed sensors. The engine 1 is connected to the inner rotor of the counter-rotating dual-rotor motor 4 through the input shaft 31 and the automatic controllable clutch 14, and the inner rotor is connected to the sun gear of the planetary mechanism 7 through the shaft; the outer rotor of the dual-rotor motor 4 is connected to the fixed shaft gear pair 5 , The first brake 61 is connected with the ring gear of the planetary mechanism 7 . The planet carrier of the planetary mechanism 7 is connected to the driving axle 10 through the output shaft 32 , and the driving axle 10 is connected to the driving wheel 8 through the two half shafts 9 . The battery p...

Embodiment 3

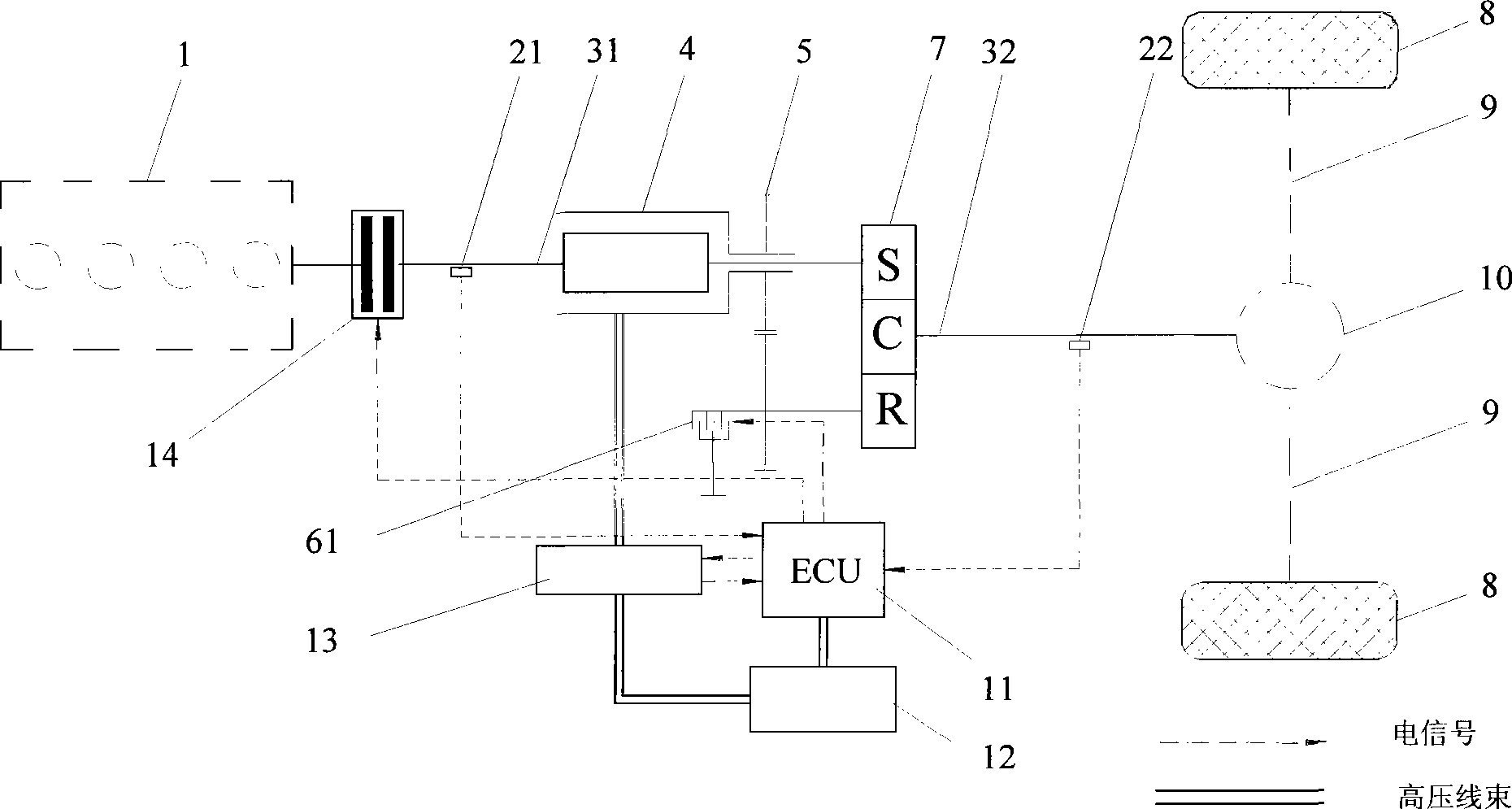

[0088] An electronic continuously variable speed parallel hybrid driving device includes an engine 1, a counter-rotating double-rotor motor 4, a planetary mechanism 7, a first brake 61, a second brake 62, a battery pack 13, a control unit ECU11, and a pair of fixed shaft gears Vice 5 and multiple speed sensors. The engine 1 is connected to the inner rotor of the counter-rotating dual-rotor motor 4 through the input shaft 31 and the automatic controllable clutch 14, and the inner rotor is connected to the sun gear of the planetary mechanism 7 through the shaft and the first brake 61; the outer rotor of the dual-rotor motor 4 passes through The fixed axis gear pair 5 and the second brake 61 are connected with the ring gear of the planetary mechanism 7 . The planet carrier of the planetary mechanism 7 is connected to the driving axle 10 through the output shaft 32 , and the driving axle 10 is connected to the driving wheel 8 through the two half shafts 9 . The battery pack 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com