A hydraulic transformer with a swinging swash plate and a rotating distribution plate

A technology of hydraulic transformer and distribution plate, applied in the field of hydraulic transformer, can solve the problems of large coupling degree of pressure and flow control, increase the difficulty of system control, poor flow adjustment ability, etc., so as to reduce the instantaneous output flow pulsation and improve the operation stability. , The effect of preventing the speed from changing too much

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

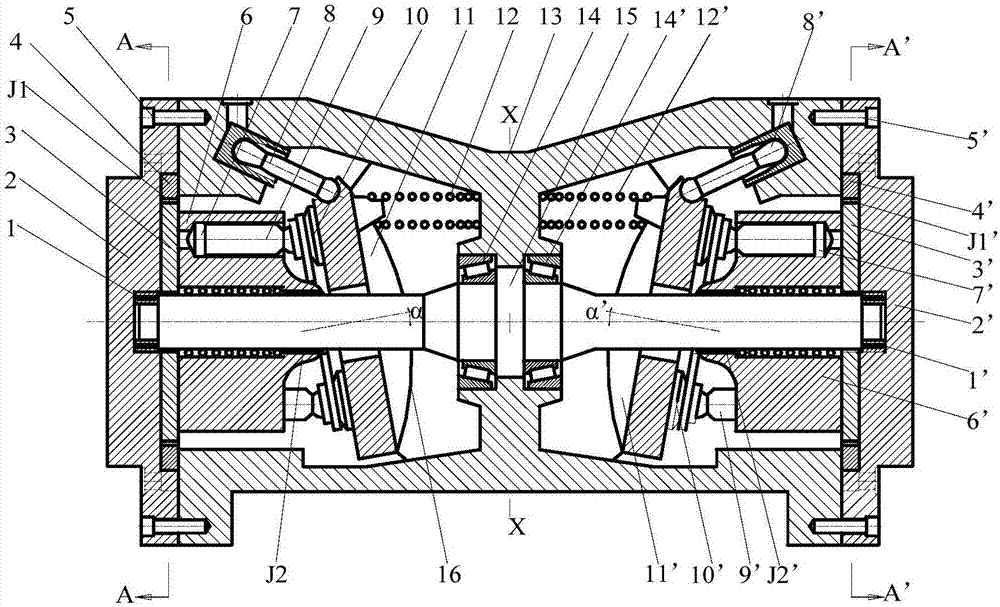

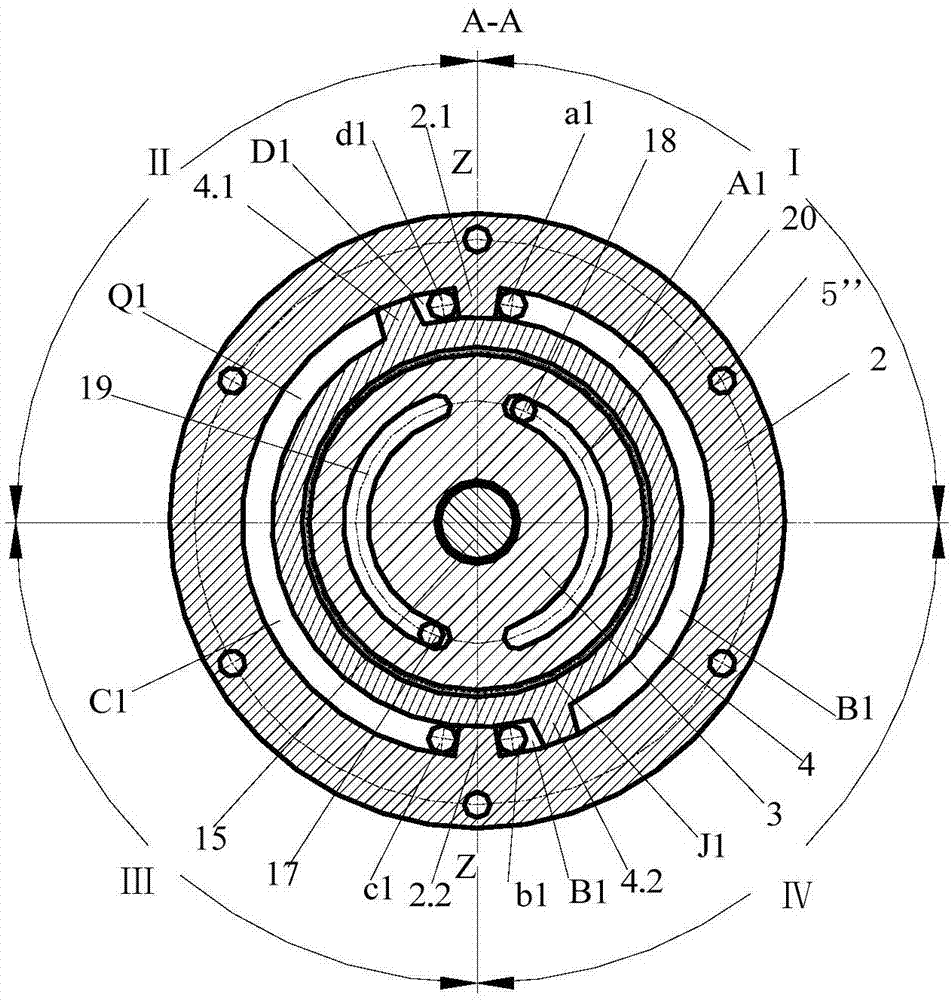

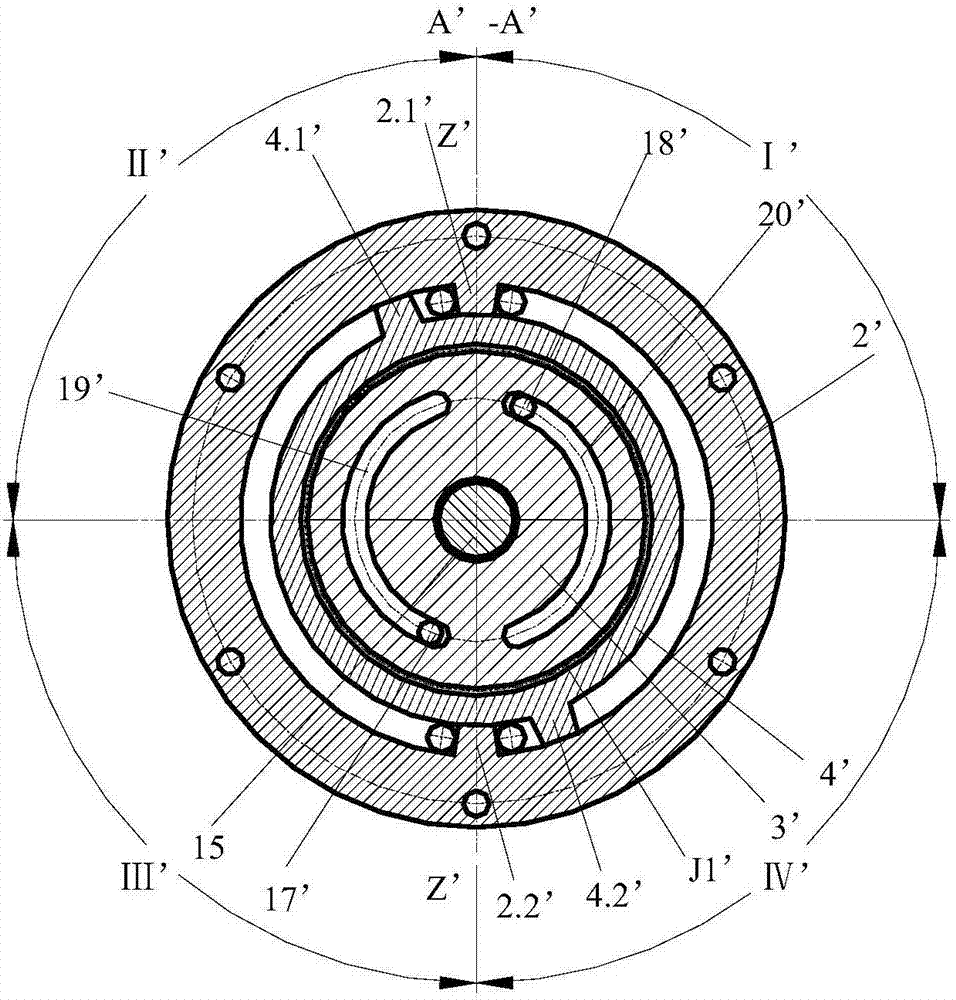

[0019] Such as figure 1 As shown, the left housing 2, the right housing 2' and the middle housing 13 form a closed cavity of the hydraulic transformer; 2 and the bearing cavity of the right housing 2', the middle part of the rotating shaft 15 is installed in the left and right concave cavity of the middle housing 13 through the left and right second bearings 14 and 14' respectively, and the rotating shaft 15 passes through the left and right respectively The second right spline J2, J2' is connected with the left and right plunger cylinders 6, 6', and the left and right plunger cylinders 6, 6' are respectively connected with the left and right plungers 9, 9' to form 9 left plungers Cavities 8 and 9 right plunger chambers 8', the axes of the rotating shaft 15 intersect the axes of the left and right plunger cylinders 6 and 6' at acute angles α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com