Piezoelectric transformer with arch structure

A piezoelectric transformer and arched structure technology, applied in the field of transformers, can solve the problems of inconvenient welding of side electrodes, large area of remaining tiles, increased power loss, etc., and achieve the effects of less heat generation, large output power, and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

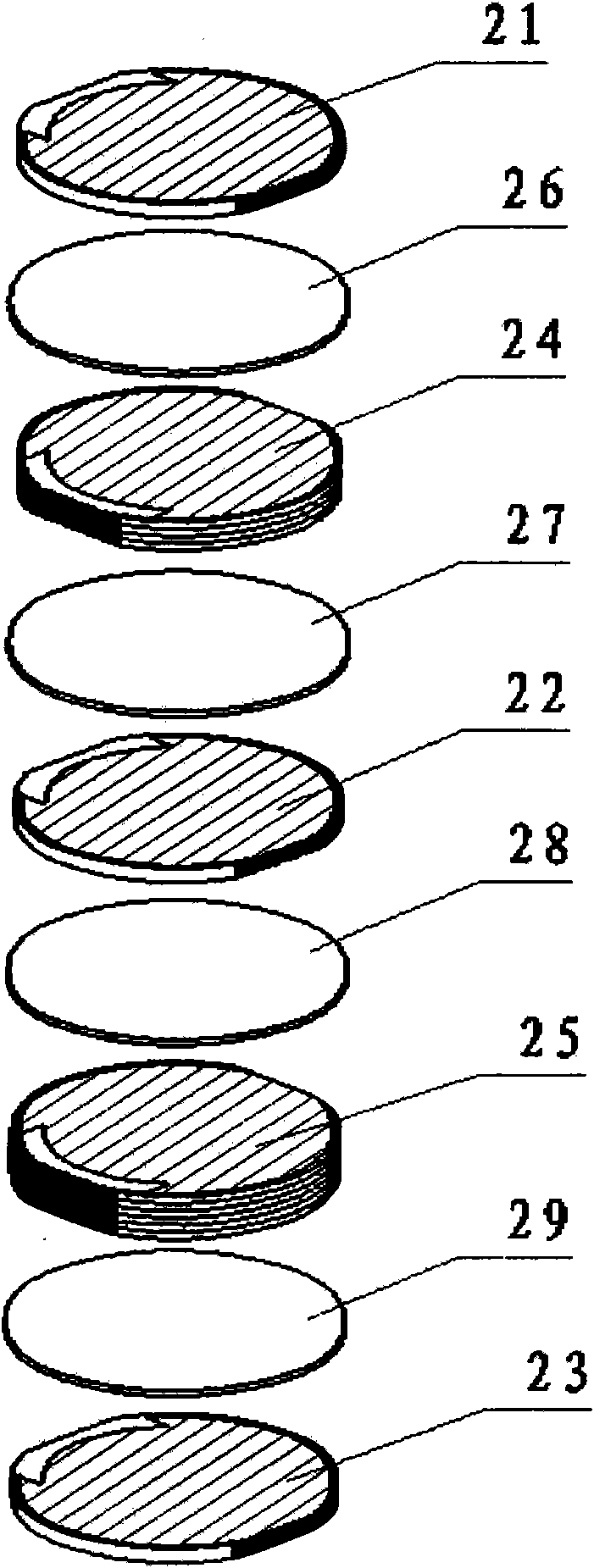

[0026] The main idea of the present invention is to form piezoelectric transformers of various structural forms by arranging the piezoelectric sheets in an arched structure, and then stacking the piezoelectric sheets of the arched structure layer by layer, so that a better surface of the piezoelectric transformer can be achieved. The electrode coverage can greatly reduce the loss caused by electrode extraction, improve the power density of the piezoelectric transformer, and facilitate the positioning of the side electrodes and piezoelectric sheets.

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

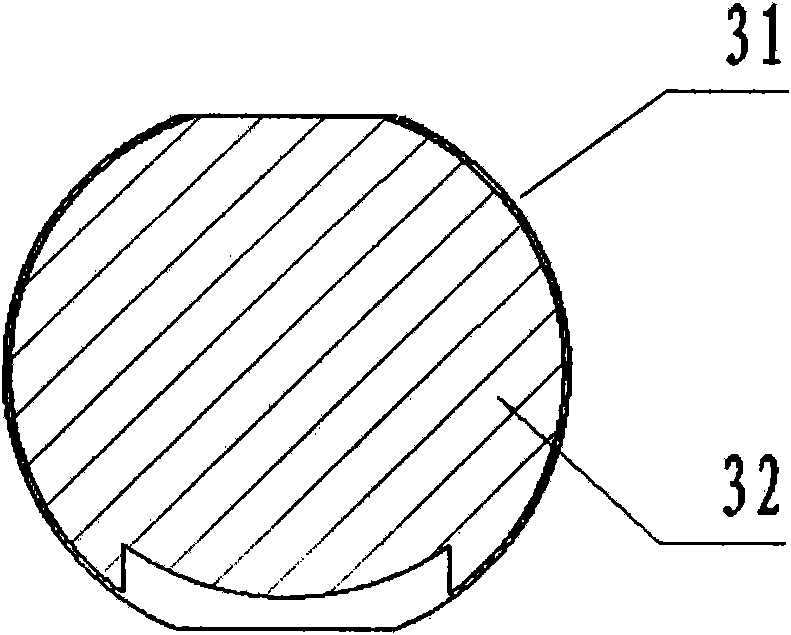

[0028] refer to figure 1 Shown is the front view of the piezoelectric sheet of the present invention. Surface electrodes 32 are arranged on the piezoelectric sheet 31 in this embodiment. The piezoelectric sheet 31 has an arched structure, and two arcs are symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com