Zero twist yarn feeding device

A yarn and feeding device technology, applied in textile and papermaking, thin material handling, looms, etc., can solve problems such as limiting the speed of looms, maintain yarn tension, and eliminate the risk of yarn twisting or entanglement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

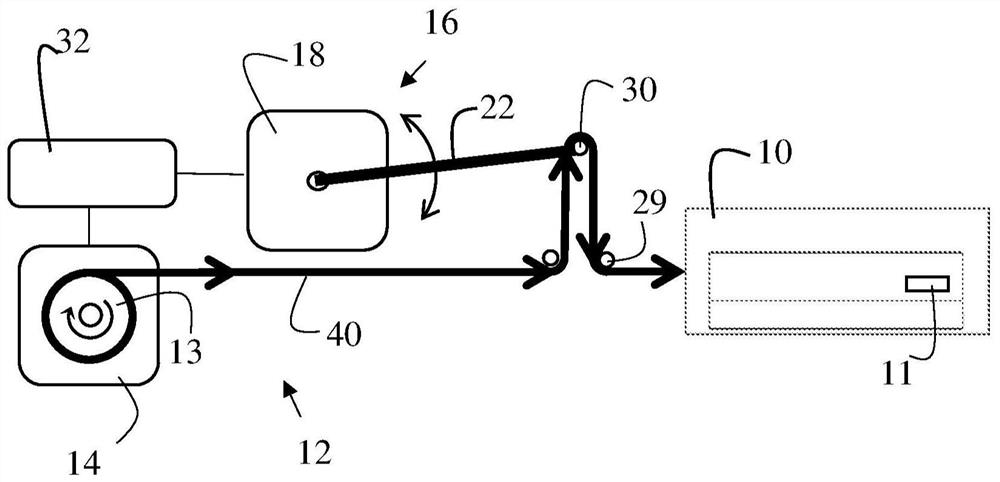

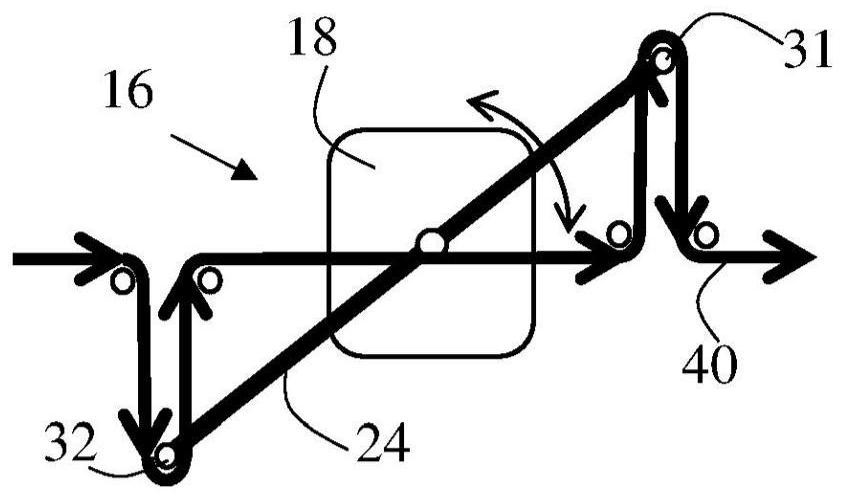

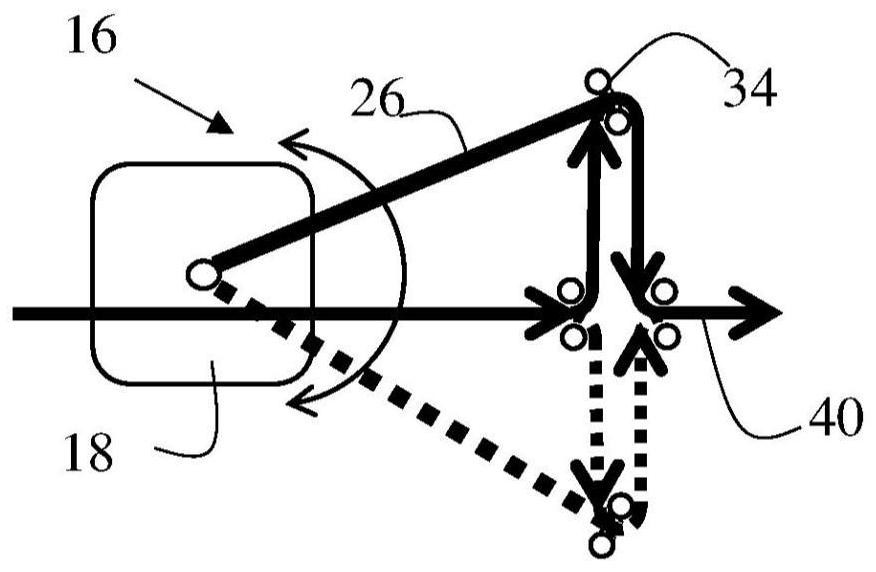

[0032] In the following, a weft feeding arrangement for a weaving machine will be described. In the figures, like reference numerals designate like or corresponding elements throughout the several figures. It should be understood that these drawings are for illustration only and are not intended to limit the scope of the invention in any way. Furthermore, features from different described embodiments may be combined to meet specific implementation needs.

[0033]For many types of yarn, no twist is allowed in the finished fabric. A known reliable way to achieve this is by providing a tangential spread of the spool. However, due to the inertia and limited stability of the spool and winding material, the maximum possible acceleration of the spool will be limited. Also, as has been recognized, the increased speed of the loom will require a weft buffer between the spool and the loom. Even with a buffer, if the speed of the loom increases, the demands on the weft buffer will be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com