A groove-type anode fast recovery diode with bipolar Schottky control and a manufacturing method thereof

A recovery diode, groove type technology, used in diodes, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of excessively high oscillating current and voltage, long reverse recovery time, increasing system circuit power consumption and limiting system operating frequency and other problems, to achieve the effect of easy passage and reduction of reverse recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in detail:

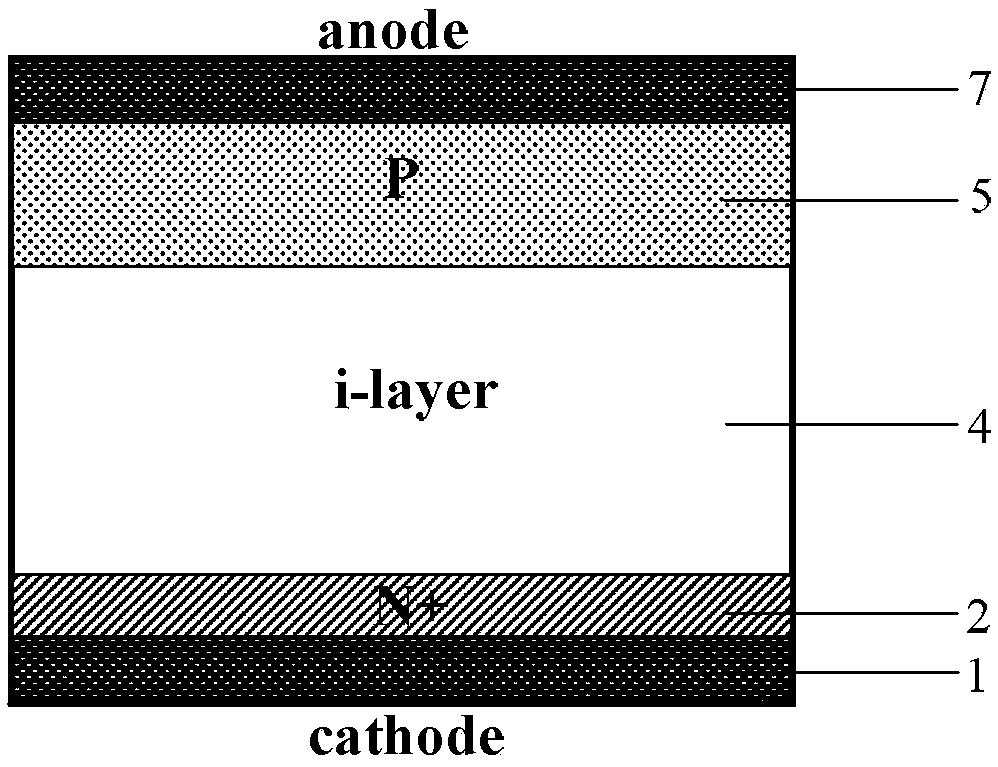

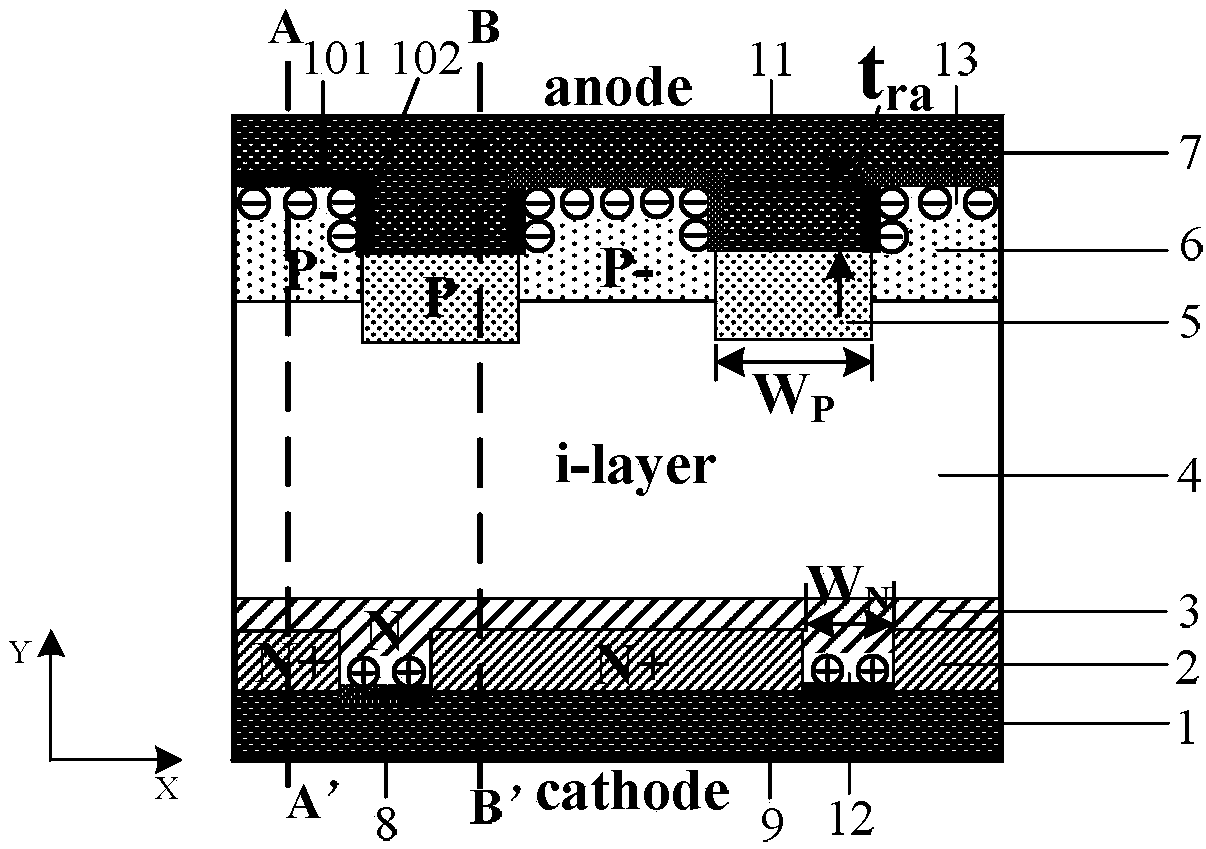

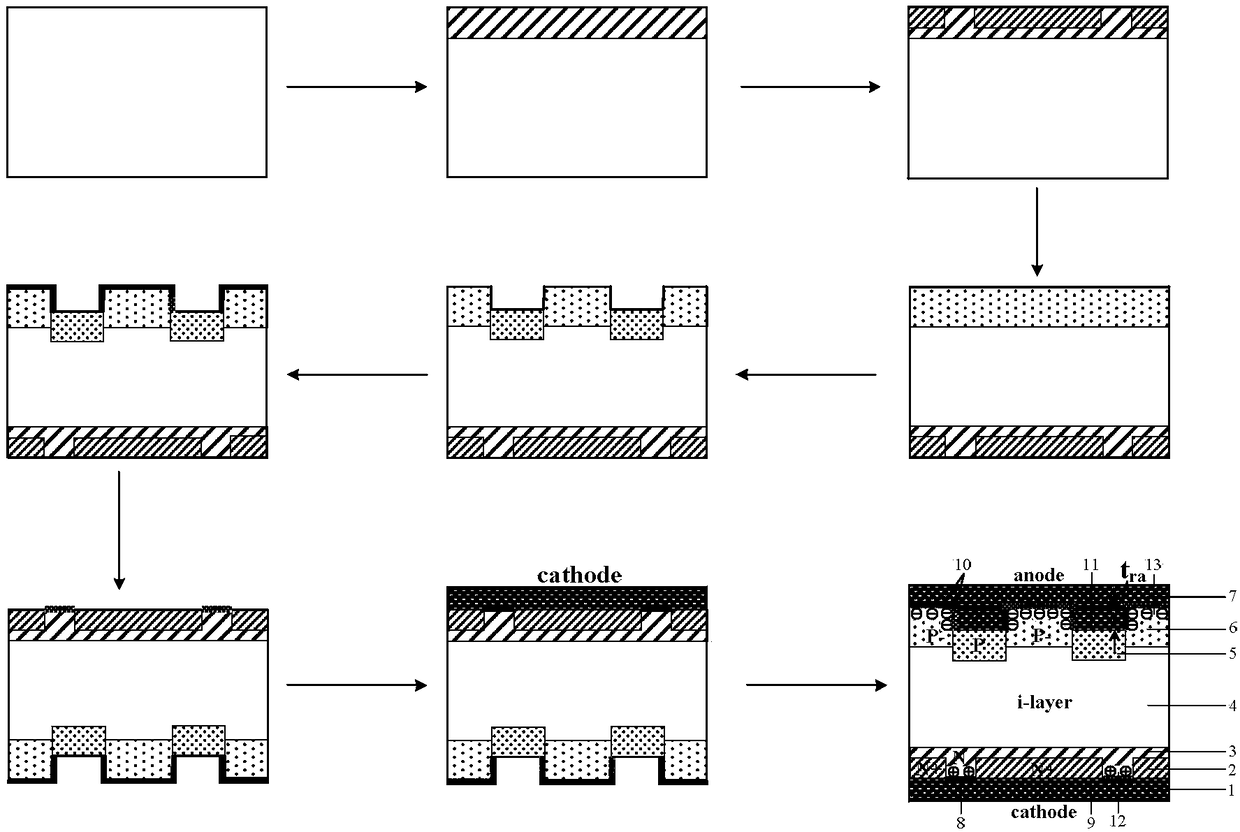

[0036] A notched anode fast recovery diode with bipolar Schottky control such as figure 2 As shown, it includes: a cathode metal 1 with an N-type intrinsic region 4 above the cathode metal 1 and an anode metal 7 above the N-type intrinsic region 4. It is characterized in that a lightly doped The hetero-doped N-type region 3 and the heavily doped N-type region 2, the lightly doped N-type region 3 and the heavily doped N-type region 2 are arranged at intervals, the bottom of the lightly doped N-type region 3 is connected to the cathode metal 1 It is a Schottky contact 8, and the lightly doped N-type region 3 extends toward the N-type intrinsic region 4 and makes the heavily doped N-type region 2 covered by the extension of the lightly doped N-type region 3 , the N-type intrinsic region 4 is located on the upper surface of the extension of the lightly doped N-type region 3; be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com