Transducer, propeller, output device, power transmission mechanism, vehicle and ship

A technology of power transmission mechanism and transducer, applied in vehicle parts, transportation and packaging, non-mechanical gear transmission, etc., can solve the problems of insufficient output power, high technical difficulty, small external size, etc., and achieve less energy loss , Improve the economy, the effect of light weight structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

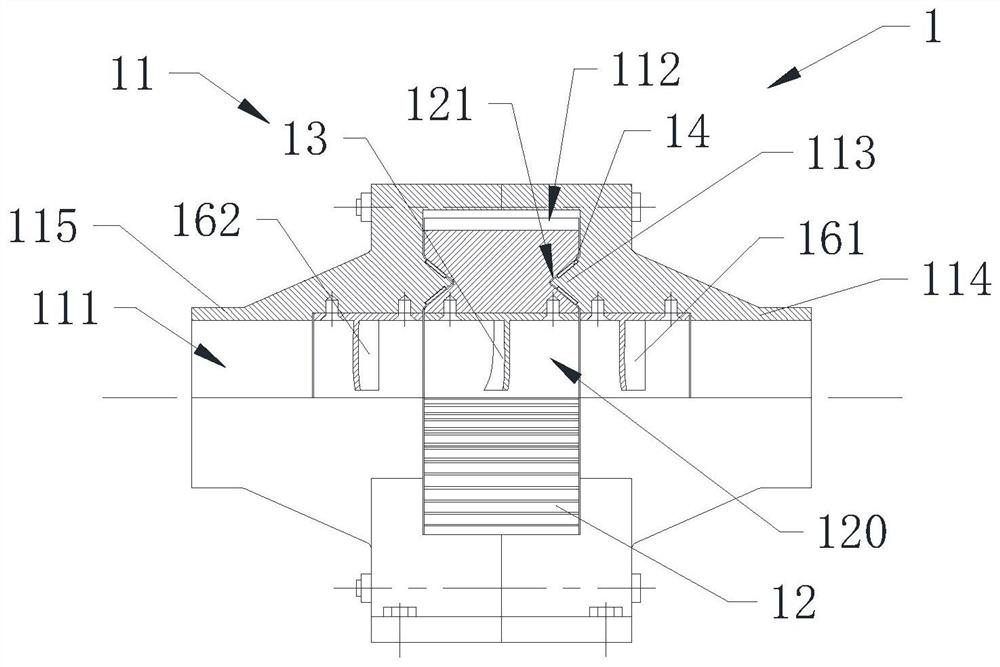

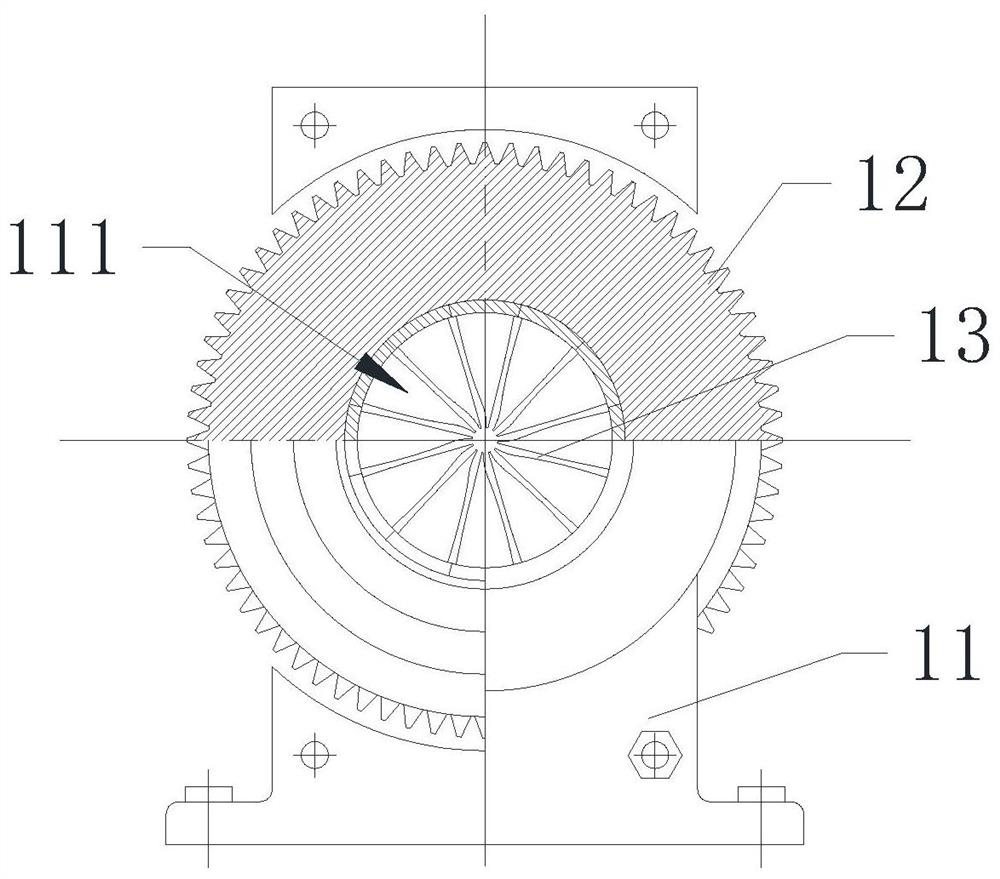

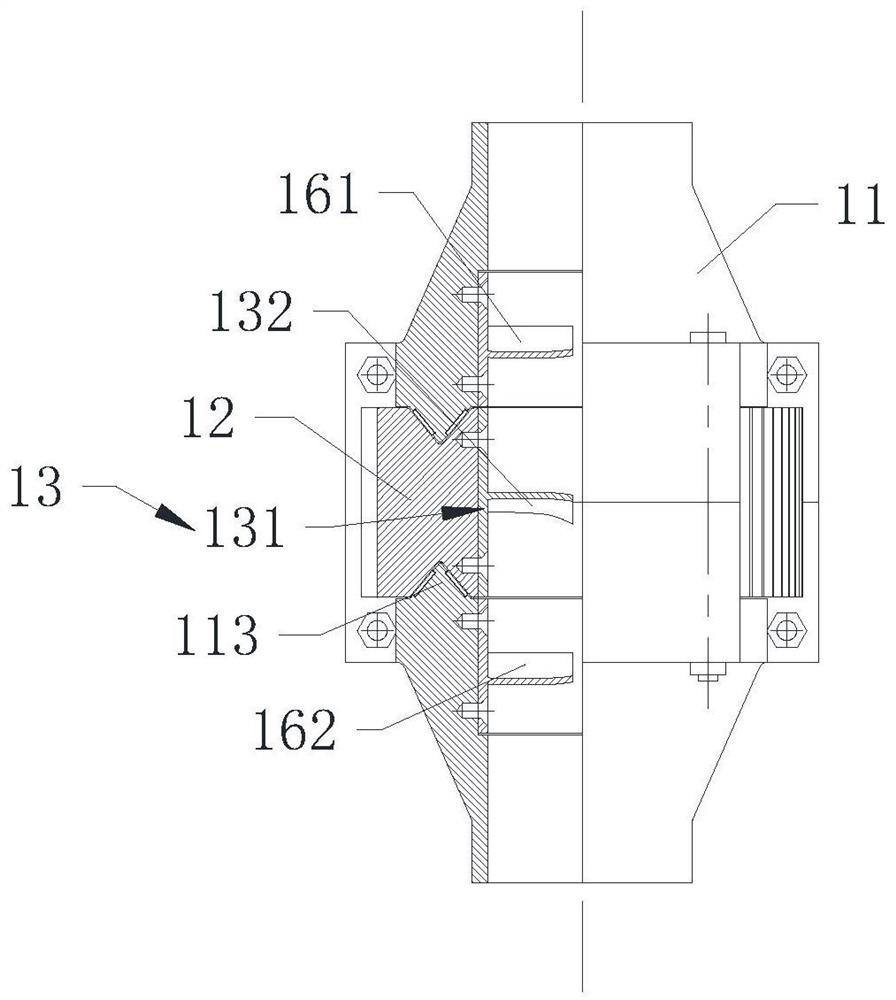

[0094] Reference manual attached Figure 1 to Figure 3B, the present invention provides a transducer 1, which can be bidirectionally driven. On the one hand, the shaftless blade can be driven to rotate through the gear, and the fluid in the fluid chamber can be driven by the shaftless blade; on the other hand, when the When the fluid in the fluid cavity flows, the fluid can drive the shaftless blade to rotate, and the rotating shaftless blade can drive the gear to rotate. The so-called transducer 1 in the present invention refers to a mechanical device that converts fluid kinetic energy into mechanical energy or converts mechanical energy into kinetic energy.

[0095] Reference manual attached figure 1 , specifically, the transducer 1 includes a base 11 , a gear 12 and blades 13 . The base 11 has a fluid channel 111 and a gear cavity 112 . The gear 12 is ring-shaped, and the gear 12 has a hollow cavity 120; the gear 12 is rotatably installed in the gear cavity 112 of the ba...

Embodiment 2

[0130] Reference manual attached Figure 4 to Figure 6 , the present invention provides a shaftless paddle propeller 2, and the shaftless paddle propeller 2 includes the transducer 1 and the driving mechanism 21 described in the above embodiments. The driving mechanism 21 includes a driving member 211 and a driving gear 212 , the driving member 211 is drivably connected to the driving gear 212 , and the driving gear 212 meshes with the gear 12 of the transducer 1 .

[0131] The shaftless propeller 2 further includes a housing 22 , and the driving mechanism 21 and the transducer 1 are respectively mounted on the housing 22 .

[0132] It should be pointed out that, in this preferred embodiment, the driving gear 212 can be driven to rotate by the driving member 211, and the rotating driving gear 212 can drive the gear 12 of the transducer 1 to rotate, so The gear 12 drives the vane 13 in the transducer 1 to rotate, and the vane 13 drives the fluid in the fluid channel 110 of the...

Embodiment 3

[0136] The present invention further provides a shaftless paddle output device, the shaftless paddle output device includes the transducer 1 described in Embodiment 1 above, an output shaft and an output gear. The output gear is fixedly installed on the output shaft, and the output gear is also meshed with the gear 12 of the transducer 1 . When the fluid in the fluid channel 111 of the continuously variable transmission 1 flows, the fluid flowing in the fluid channel 111 pushes the blade 13 to rotate, and the rotating blade 13 drives the gear 12 to rotate, and the gear 12 drives the The output gear rotates, and the rotating output gear drives the output shaft to rotate. It can be understood that the output shaft of the shaftless paddle output device can be drivably connected to the final drive shaft or the wheel shaft of the vehicle, so as to transmit the power of the engine power to the final drive shaft or the wheel shaft of the vehicle. axle.

[0137] This shaftless paddl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com