Method and device for reducing fuel consumption of diesel engine by catalytic decomposition of oxygen-containing fuel

An oxygen-containing fuel, catalytic decomposition technology, applied in exhaust devices, mufflers, combustion engines, etc., can solve problems affecting people's quality of life, and achieve the effect of reducing fuel consumption and pollutant emissions.

Inactive Publication Date: 2011-12-14

TSINGHUA UNIV

View PDF0 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At the same time, NOx and soot are easily formed during the combustion process of diesel engines, and these pollutants are discharged into the air together with exhaust gas, seriously affecting people's quality of life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0021] Carry out catalytic reaction with methanol as oxygen-containing fuel, with copper-based catalyst (with copper as active component, containing a small amount of zinc and aluminum); Experiments were carried out at 10% and 15% respectively, and the experimental results showed that, compared with ordinary diesel engine combustion, the comprehensive fuel saving rate was in the range of 10-15%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

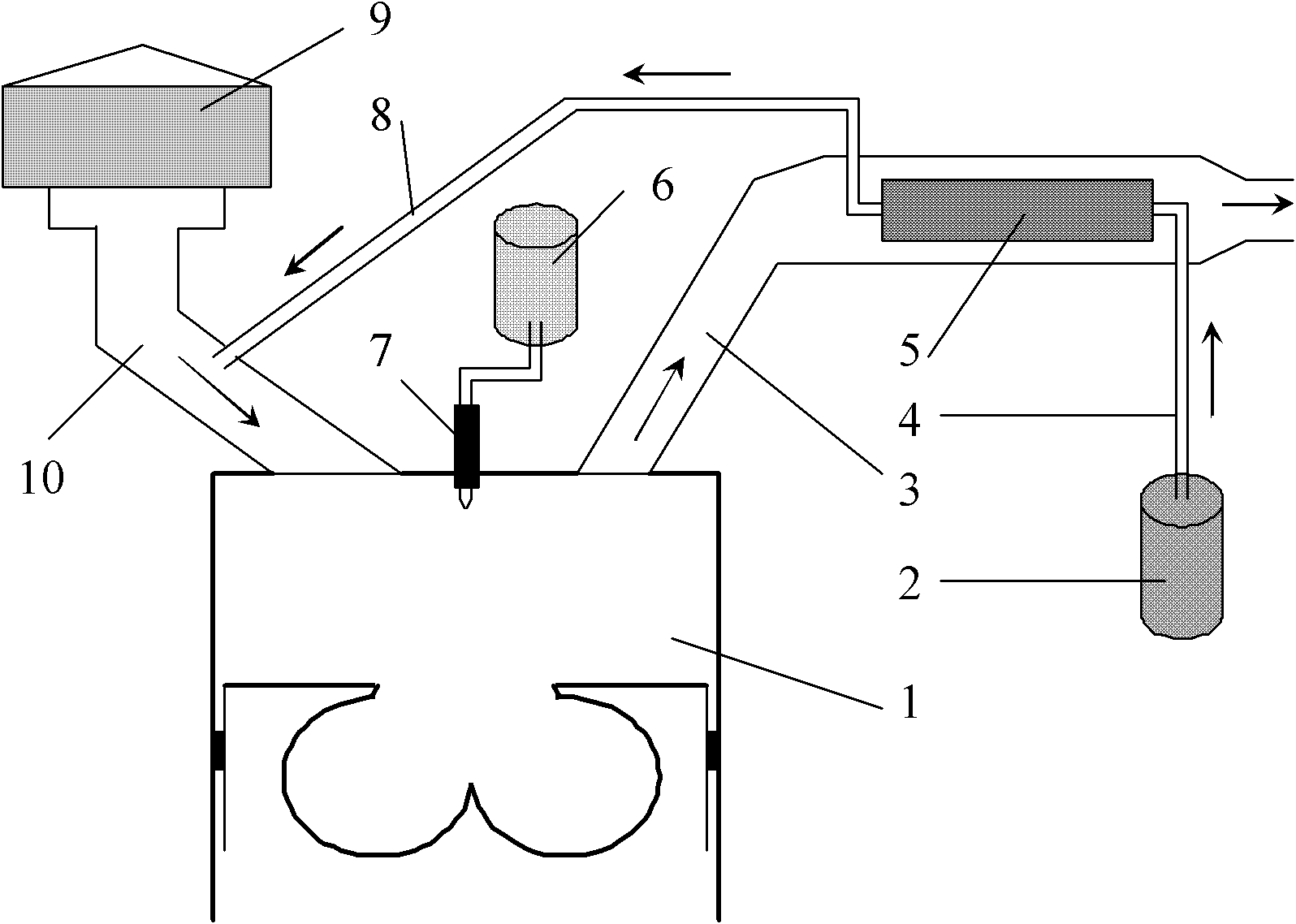

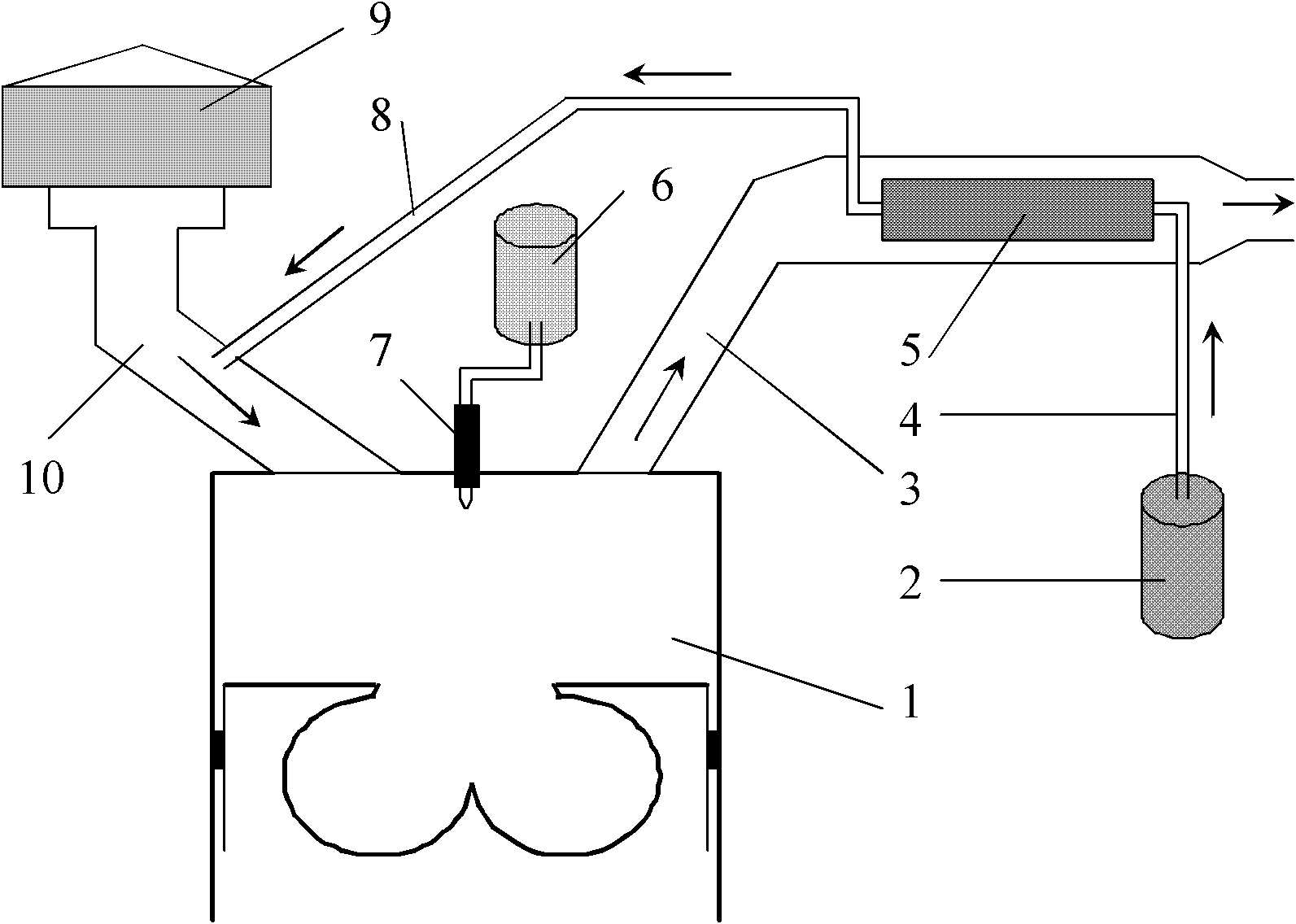

A method and device for reducing fuel consumption of a diesel engine by catalytic decomposition of oxygen-containing fuel belong to the technical field of diesel engine combustion energy saving and emission reduction. In the present invention, the oxygen-containing fuel is fed into the catalytic reactor installed in the exhaust channel of the diesel engine, and the catalytic reactor is heated by the waste heat of the tail gas discharged from the combustion chamber, so that the oxygen-containing fuel is catalytically decomposed, and the generated hydrogen-rich and carbon monoxide-rich The decomposed gas enters the intake port, mixes with air, and enters the combustion chamber. At the same time, the emulsified oil is sprayed from the nozzle. The atomized emulsified oil evaporates, mixes, ignites and burns in the combustion chamber, and pushes the piston to do work. The system of the present invention makes full use of the waste heat of the exhaust gas of the diesel engine, and can realize the catalytic decomposition of the oxygen-containing fuel without providing energy from the outside. At the same time, combined with the use of emulsified oil, the comprehensive fuel saving rate of the diesel engine can reach 10-15%, and can be greatly improved. Reduce the emission of pollutants such as nitrogen compounds and soot, so as to achieve the purpose of energy saving and emission reduction.

Description

technical field [0001] The invention belongs to the technical field of diesel engine combustion energy saving and emission reduction, and in particular relates to a method and a device for reducing fuel consumption of a diesel engine by combining catalytic decomposition of oxygen-containing fuel and emulsified oil. Background technique [0002] The exhaust gas temperature of medium and high-speed diesel engines currently used is relatively high, and the exhaust gas temperature reaches 500-550°C during high-load operation, carrying a large amount of heat energy, which is about 40-50% of the calorific value of fuel oil. The "heat island effect" of the exhaust gas causes thermal pollution, and this part of the high-temperature flue gas discharged with the tail gas has a high enthalpy value, resulting in a great waste of energy. How to utilize this part of waste heat is one of the important contents of current research. At the same time, NOx and soot are easily formed during th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F02M25/022F02M25/12F01N5/02

CPCY02T10/16Y02T10/121Y02T10/12

Inventor 龚景松钟北京党帅

Owner TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com