Extrusion mechanism of plastic injection molding machine

An extrusion mechanism and injection molding machine technology, applied in the field of plastic injection molding machines, can solve problems such as the troublesome cleaning of waste barrels, the influence of internal temperature control, and the rise, so as to improve energy consumption and the surrounding working environment, improve energy consumption, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the invention is described in detail below in conjunction with accompanying drawing:

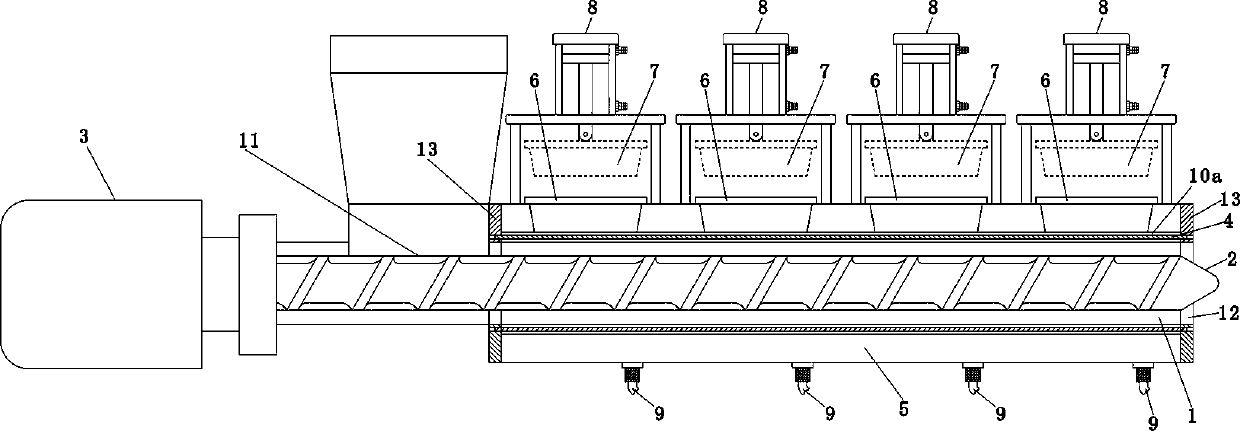

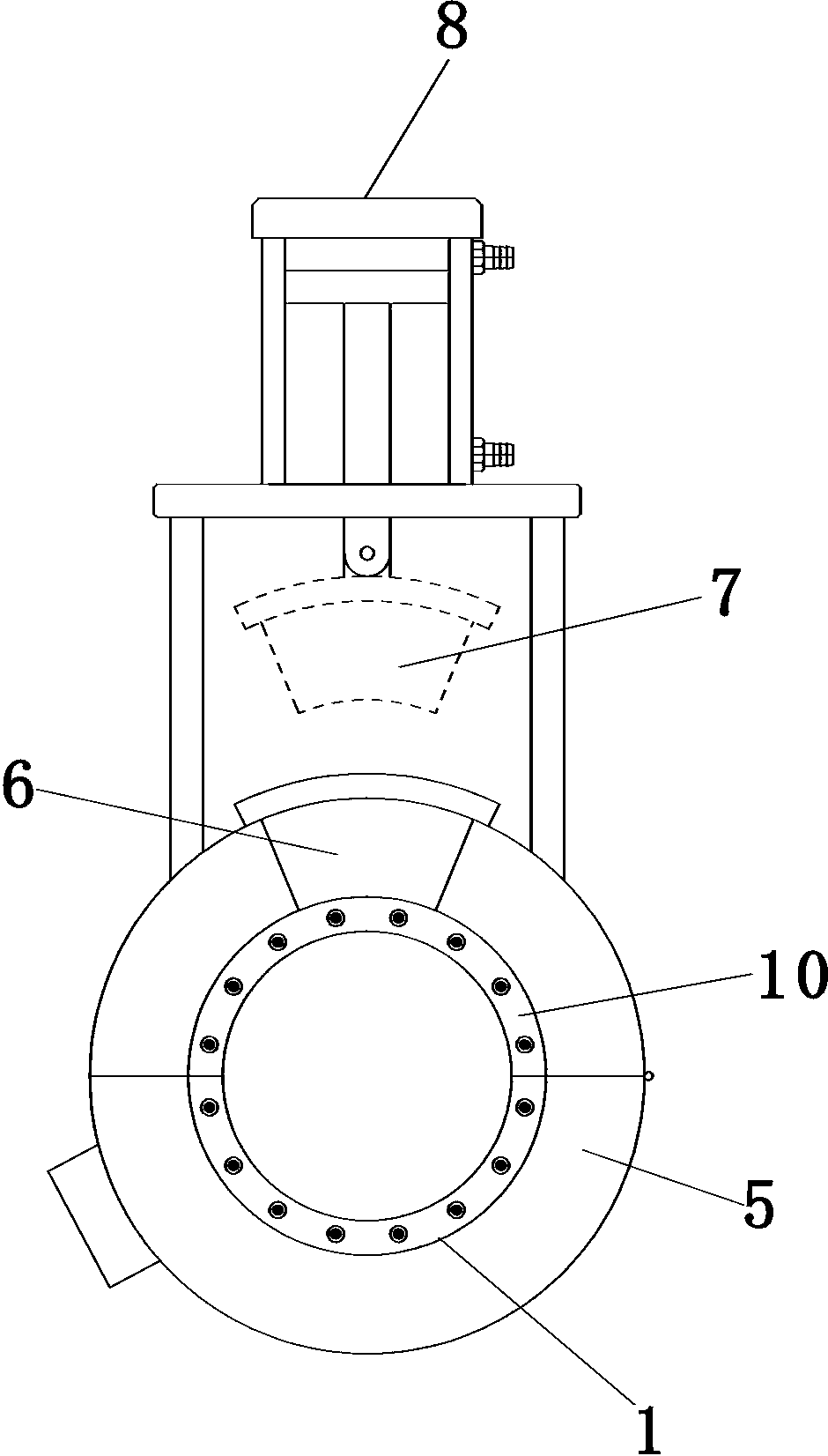

[0020] refer to figure 1 and figure 2 , the extruding mechanism of the plastic injection molding machine of this specific embodiment comprises a barrel 1, a screw 2 and a motor 3, a feed port 11 and a discharge port 12 are arranged on the barrel 1, and the screw 2 is arranged in the barrel 1 , the motor 3 drives the screw 2 to rotate in the barrel 1, the barrel 1 evenly distributes several chambers 10a on the circular barrel wall 10, each chamber 10a is cylindrical, and each chamber 10a is cylindrical The axis of each is parallel to the axial direction of the barrel 1, the two ends of the barrel 1 are respectively provided with brackets 13, each chamber 10a is equipped with a quartz glass heating tube 4, each quartz glass heating tube 4 is located in the corresponding chamber 10a, And the two ends of each quartz glass heating tube 4 protrude from the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com