Core-through type pillar base slate, drum step stone, reinforced concrete upright column structure and construction method thereof

A reinforced concrete column and reinforced concrete technology, which is applied to the structure and construction of reinforced concrete columns of drums, and the field of core-piercing slates, can solve the problems of inability to guarantee the integrity of the columns and drums, and achieve good verticality. , Increase the adhesion, the effect of smooth inner wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

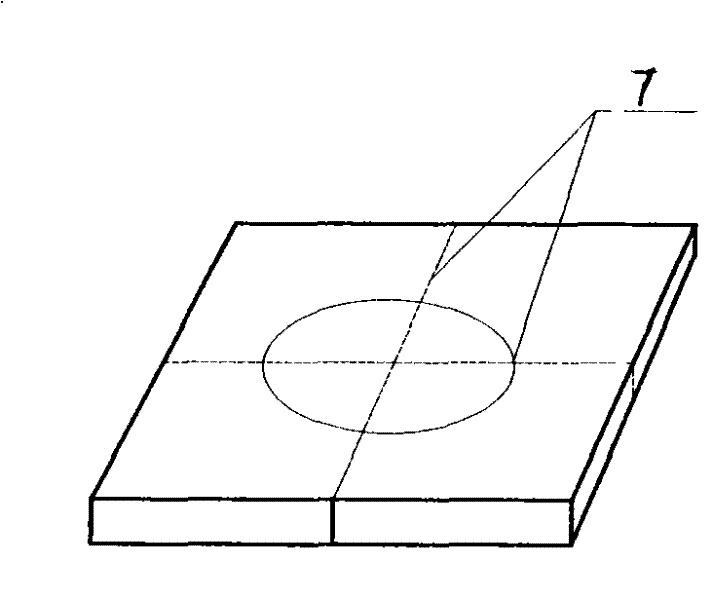

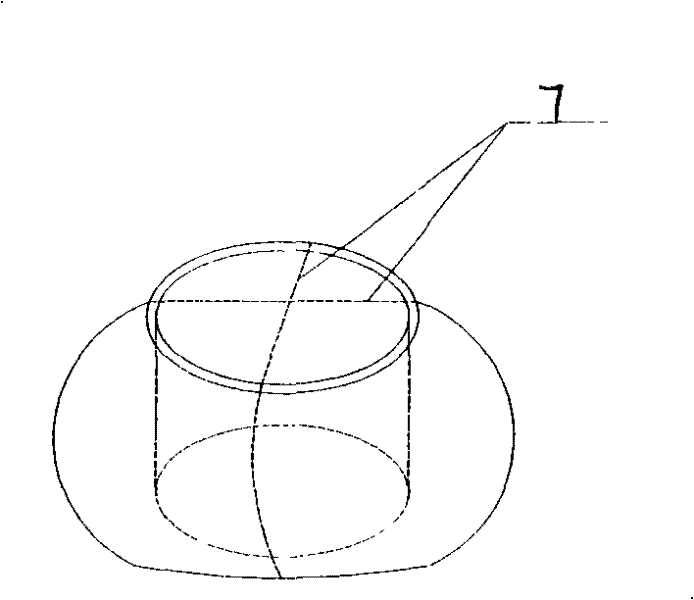

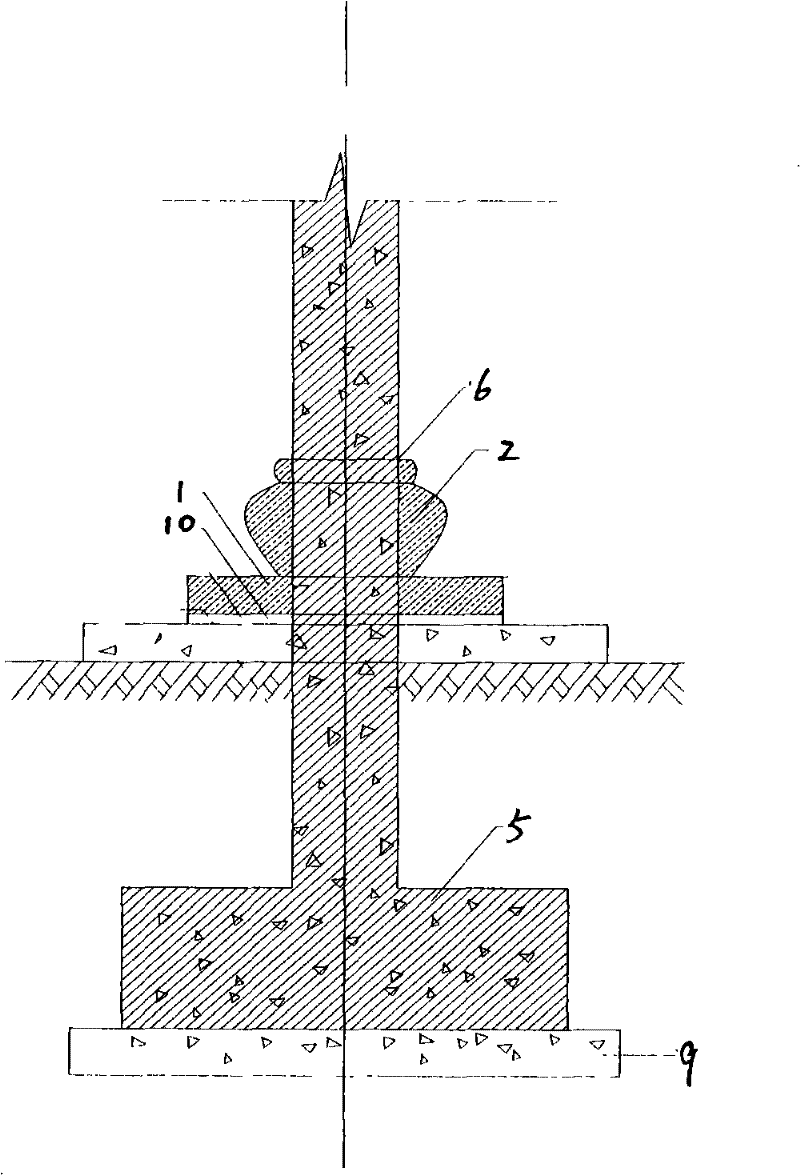

[0032] The core-piercing slate stone and drum stone reinforced concrete column structure described in this embodiment includes a slat stone 1, a drum stone 2 and a reinforced concrete column 3, and is characterized in that the slat stone 1, the drum A core through hole 4 is opened on the dang stone 2, and the reinforced concrete column 3 penetrates through the core through hole 4, and is integrated with the column base 5 to form an integral structure connecting the column body and the column base. A layer of adhesive material 6 is provided on the inner wall of the through-hole 4 of the string core of the drum stone 2 .

[0033] The present invention provides a construction method for a core-pierced slate stone and a reinforced concrete column of a slatted slate. Laying out, digging the core of the slate stone, the slate stone and the stiletto column in place and fixing, the column steel bar binding, the formwork, the pouring of the column concrete, the removal of the formwork,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com