Novel treatment device used for melting flying ash

A processing equipment and a new type of technology are applied in the field of new processing equipment for melting fly ash, which can solve the problems of difficulty in collecting fly ash and inconvenient processing, and achieve the effects of good heating effect, easy turning and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

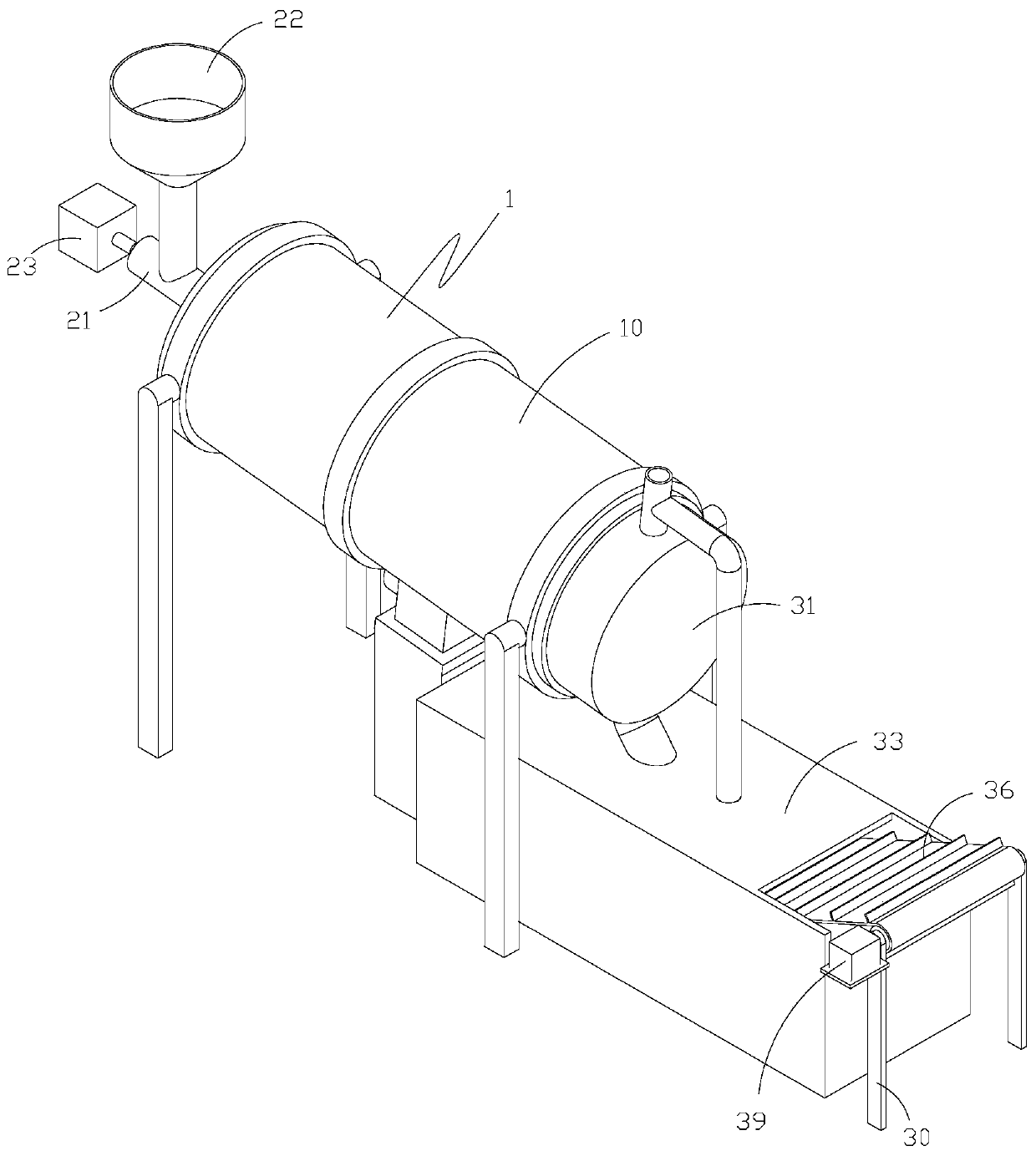

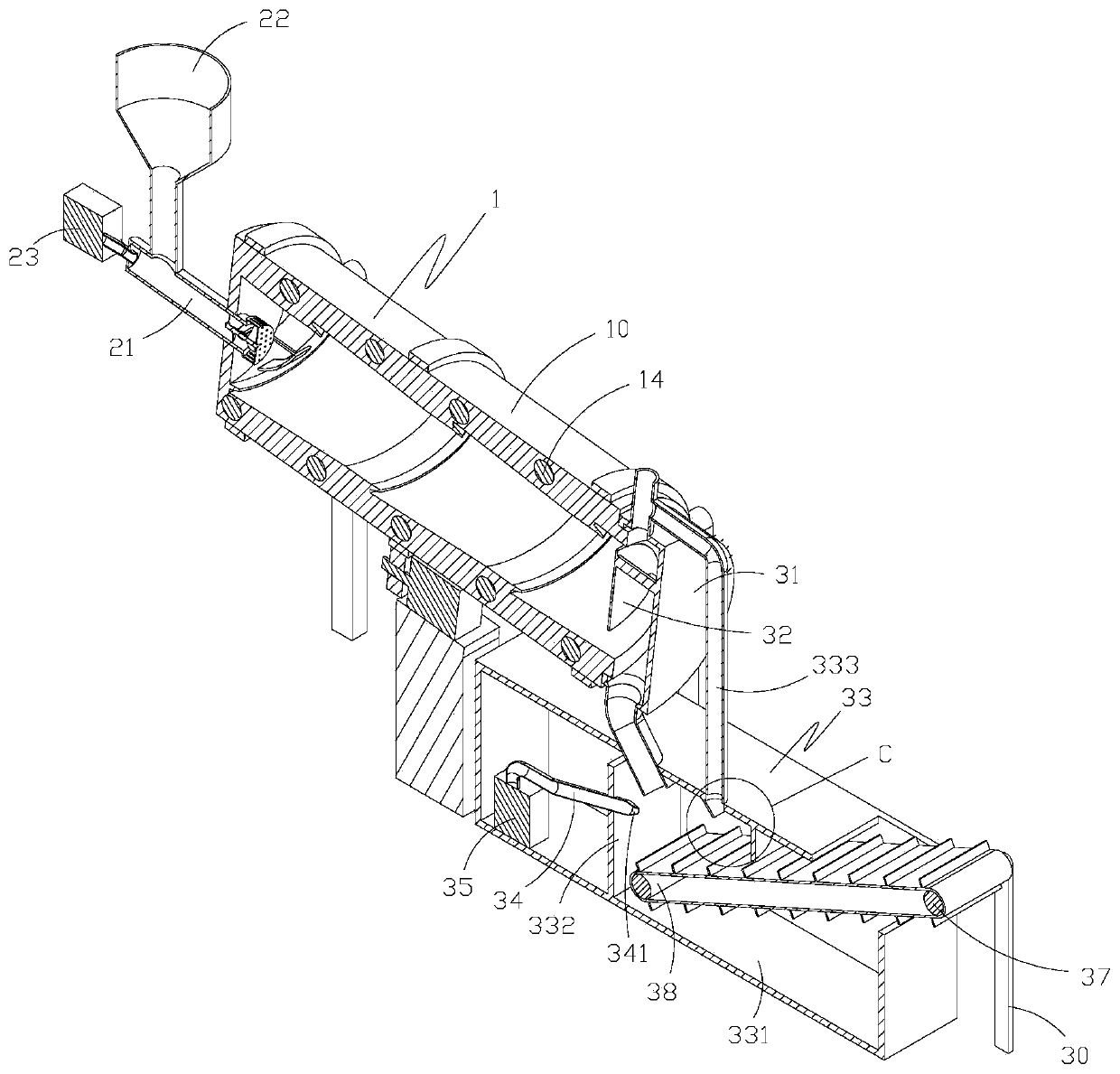

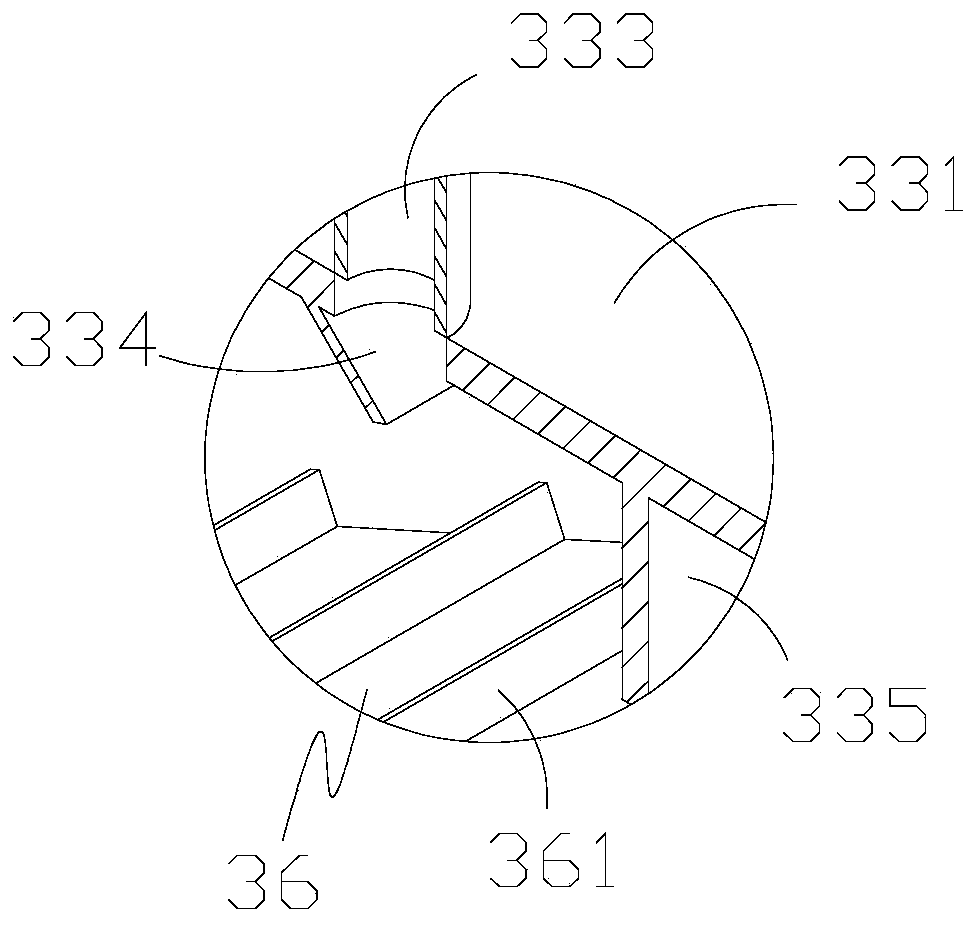

[0022] Such as Figure 4-8 As shown, a new type of processing equipment for molten fly ash includes an incineration device, a feeding device and a water quenching device; the incineration device includes a rotary kiln 1, a driving part 11 and a support 12; the rotary kiln is installed on the support and can be relatively Because the bracket rotates back and forth, the driving part is a motor purchased on the market. This is the prior art, so it will not be described here; the rotary kiln can rotate under the drive of the motor, and this driving method is also the prior art, so here No need to go into details; among them, the rotary kiln includes a kiln body 10, a heating element 13 and a stepped part 14. The kiln body is opened in a hollow cylindrical structure, and the kiln body is installed in an inclined state, so that the fly ash and slag in the kiln body are easier to flow smoothly. The heating element is installed in the side wall of the kiln body to heat the kiln body, ...

Embodiment 2

[0031] Such as Figure 1-3 As shown, the difference between the present embodiment and Embodiment 1 is: a spray device and a delivery device are installed on the water quenching pool 33; wherein, the spray device includes a spray pipe 34, a spray drive 35 and a nozzle 341; the spray drive is The water pump purchased on the market is an existing technology, so I won’t repeat it here; the jet driving part is bolted in the water quenching tank; one end of the jet pipe is connected with the jet driving part, and a nozzle is installed at the other end, and the nozzle is conical , so that the sprayed water flow has a certain water pressure and greater impact force. The spray pipe is installed in an inclined state, and the angle between the discharge pipe and the discharge pipe is an acute angle. At the same time, the plane where the spray pipe and the nozzle of the discharge pipe are located is an obtuse angle , so that when the slag is discharged from the discharge pipe, the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com