External wall fireproof reflective heat-insulation inorganic coating material and preparation method thereof

A technology for inorganic coatings and exterior walls, applied in fire-resistant coatings, reflective/signal coatings, anti-corrosion coatings, etc., can solve the problems of high combustion performance, difficult to meet fire resistance performance, improve and other problems, and achieve good film adhesion and excellent reflection. Thermal insulation, absorption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The invention relates to a fire-proof reflective and heat-insulating inorganic coating for exterior walls, which includes base material, filler, auxiliary agent and water.

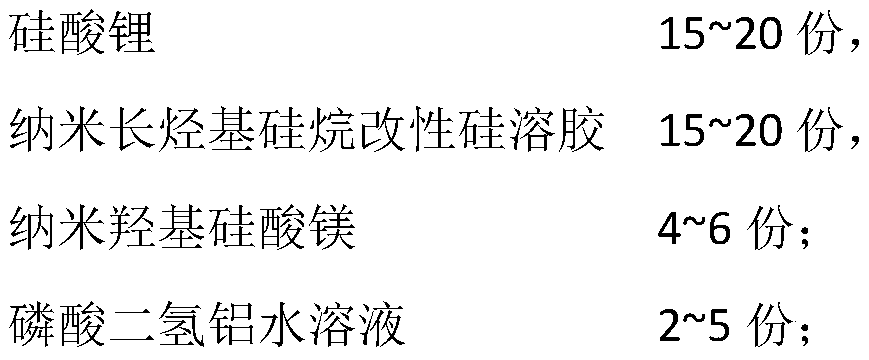

[0050] Calculated in parts by weight, the base material includes: 15 parts of lithium silicate, 15 parts of nano-long hydrocarbyl silane modified silica sol, 4 parts of nano-hydroxy magnesium silicate, and 2 parts of aluminum dihydrogen phosphate aqueous solution; the filler includes: 20 parts 10 parts of IR-1000 titanium dioxide, 10 parts of wollastonite powder, 10 parts of talc powder, and 1 part of nano titanium dioxide.

[0051] Among them, 0.6 parts of additives, 0.1 parts of wetting and dispersing agents, 0.1 parts of defoamers, 0.2 parts of stabilizers, 1 part of pH regulators, and 0.2 parts of leveling agents.

[0052] In this embodiment, the paint further includes 0.1 part of cellulose.

Embodiment 2

[0054] The invention relates to a fire-proof reflective and heat-insulating inorganic coating for exterior walls, which includes base material, filler, auxiliary agent and water.

[0055] Calculated in parts by weight, the base material includes: 17.5 parts of lithium silicate, 17.5 parts of nano-long hydrocarbyl silane modified silica sol, 5 parts of nano-hydroxymagnesium silicate, and 3.5 parts of aluminum dihydrogen phosphate aqueous solution; the filler includes: 22.5 parts Parts of IR-1000 titanium dioxide, 12.5 parts of wollastonite powder, 12.5 parts of talc, 3 parts of nano-titanium dioxide.

[0056] Among them, 4.8 parts of additives, 1.3 parts of wetting and dispersing agents, 0.3 parts of defoamers, 0.6 parts of stabilizers, 2.5 parts of pH regulators, and 1.0 parts of leveling agents.

[0057] In this embodiment, the paint also includes 0.2 parts of cellulose.

Embodiment 3

[0059] The invention relates to a fire-proof reflective and heat-insulating inorganic coating for exterior walls, which includes base material, filler, auxiliary agent and water.

[0060] Calculated in parts by weight, the base material includes: 20 parts of lithium silicate, 20 parts of nano-long hydrocarbyl silane modified silica sol, 6 parts of nano-hydroxymagnesium silicate, and 5 parts of aluminum dihydrogen phosphate aqueous solution; the filler includes: 25 parts 15 parts of IR-1000 titanium dioxide, 15 parts of wollastonite powder, 15 parts of talc, and 5 parts of nano-titanium dioxide.

[0061] Among them, 9 parts of auxiliary agent, 0.5 parts of wetting and dispersing agent, 0.5 parts of defoaming agent, 1 part of stabilizer, 5 parts of pH regulator, and 2.0 parts of leveling agent.

[0062] In this embodiment, the coating also includes 0.3 parts of cellulose.

[0063] The coating prepared in Example 1 is selected, and the conventional properties required by JG / T 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com