Temperature fuse and sliding electrode used in temperature fuse

一种温度熔断器、电极的技术,应用在电路、电开关、电气元件等方向,能够解决剥离、起不到温度熔断器、镀敷与母材料密接性差等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

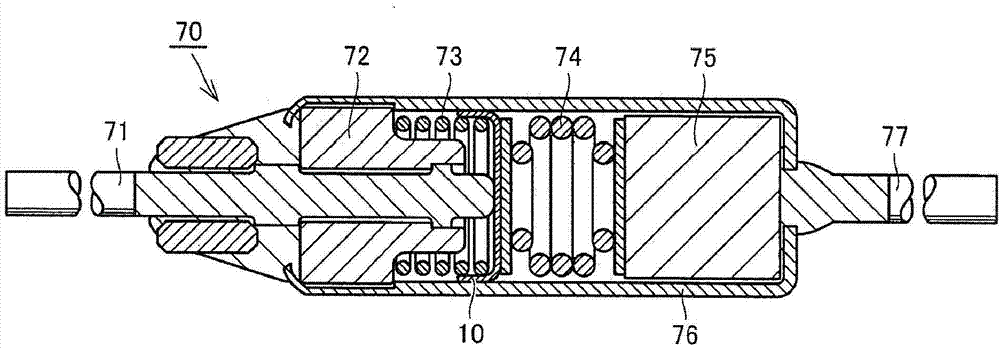

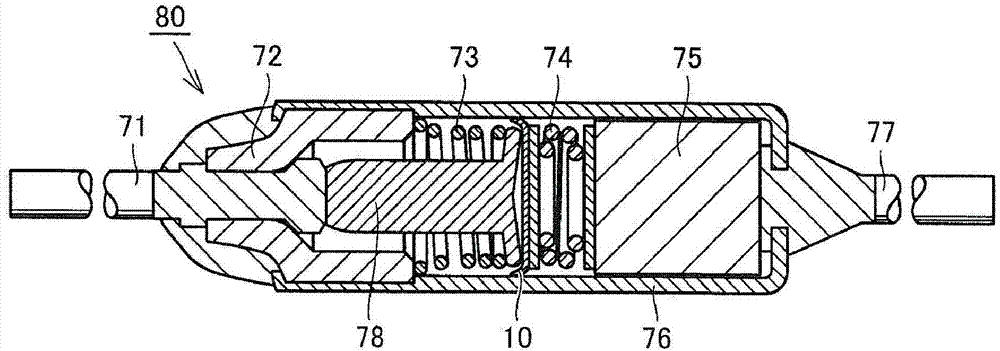

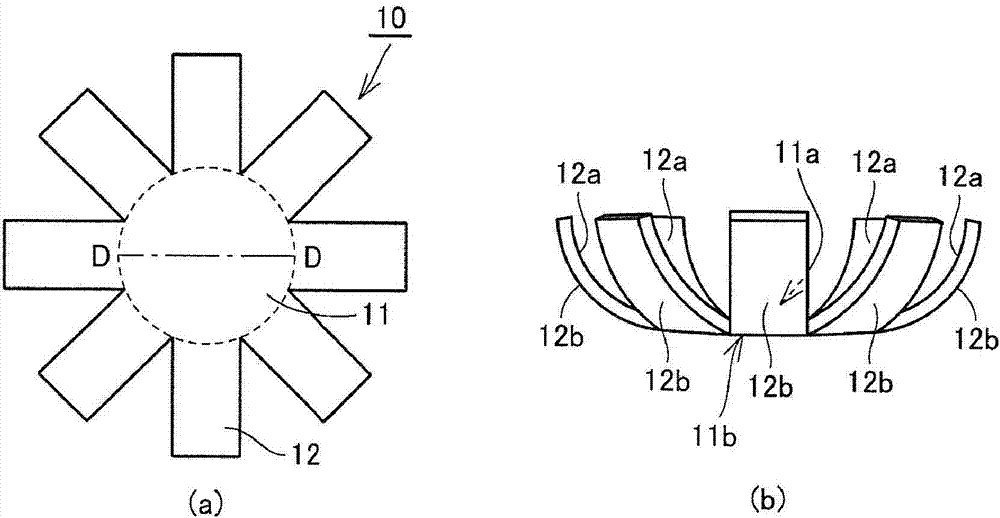

[0037] image 3 (a) is a plan view showing the sliding electrode 10 according to Embodiment 1, image 3 (b) is its side view. The slide electrode 10 has a circular central region 11 and a plurality of claws 12 extending outward from the central region 11 . The claws 12 have a shape in which a surface 12 a of the claw is curved inward. The sliding electrode 10 is arranged in the thermal fuse so that the outer surface 12b of the claw portion 12 is in contact with the inner surface of the metal case, and the inner surface 11a of the central region 91 is in contact with the terminal.

[0038] Sliding electrode 10 is formed by processing a thin metal plate. Sliding electrode 10 includes a base layer made of copper or copper alloy, and a first surface layer made of silver or silver alloy, and the contact portion with the terminal, that is, surface 11a inside central region 11 becomes the first surface layer. The processing method of the metal thin plate is not particularly limite...

Embodiment approach 2

[0045] The slide electrode according to Embodiment 2 has the same structure as the slide electrode according to Embodiment 1 except that the laminated structure is different. Figure 5 is a cross-sectional view showing the center region of the slide electrode according to the second embodiment. Figure 5 The laminated structure 30 shown has the base material layer 21 and the 1st surface layer 22 similarly to Embodiment 1, and also has the 2nd surface layer 31 laminated|stacked on the side opposite to the 1st surface layer 22 of the base material layer 21. The second surface layer 31 is preferably a layer composed of silver or a silver alloy. The second surface layer 31 also has the protection performance of the sliding electrode as the first surface layer 22 . As silver or a silver alloy, the same material as that exemplified for the first surface layer 22 can be used, but it is not necessarily the same as the material of the first surface layer 22 .

[0046] In addition, si...

Embodiment approach 3

[0048] The slide electrode according to Embodiment 3 has the same structure as the slide electrode according to Embodiment 2 except that the laminated structure is different. Figure 6 A cross-sectional view of a central region of a slide electrode according to Embodiment 3 is shown. Figure 6 The laminated structure 40 shown has a structure in which the first surface layer 22 and the second surface layer 31 are respectively laminated on both surfaces of the base material layer 21 as in the second embodiment, and the base layer 21 and the second surface layer are further laminated. Nickel layers 41 and 42 are provided between the first surface layer 22 and between the base material layer 21 and the second surface layer 31 . Diffusion of copper from the base material layer 31 can be prevented by the nickel layers 41 and 42 . The nickel layers 41 and 42 can be formed by methods such as electrolytic plating, electroless plating, and electroplating. The thickness of the nickel l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com