Method for preparing microcrystalline glass from kaolin-type coal gangue or fly ash and carbide slag

A technology of glass-ceramic and coal gangue, which is applied in the field of glass-ceramic preparation, can solve the problems of high cost, energy waste, complicated process, etc., and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Coal gangue and calcium carbide slag are selected as main raw materials, and a calendering method is used to produce a glass-ceramic plate. The steps of the preparation method are as follows:

[0032] 1. Pretreatment of coal gangue:

[0033] (1) Crushing the gangue into fine particles with a diameter less than 30 mm;

[0034] (2) The coal gangue fine particles are burned in a fluidized fluidized furnace (the heat released is used for other purposes) to obtain furnace ash;

[0035] (3) Crushing the furnace ash into a fine powder less than 40 mesh;

[0036] (4) Carry out deironing to fine powder with deironing machine;

[0037] (5) Sampling and testing, as one of the main raw materials for preparing glass-ceramic.

[0038] 2. Pretreatment of carbide slag:

[0039] Pass the calcium carbide slag through a 40-mesh sieve to remove the graphite electrode debris mixed in it, and use it as another main raw material for preparing glass-ceramics.

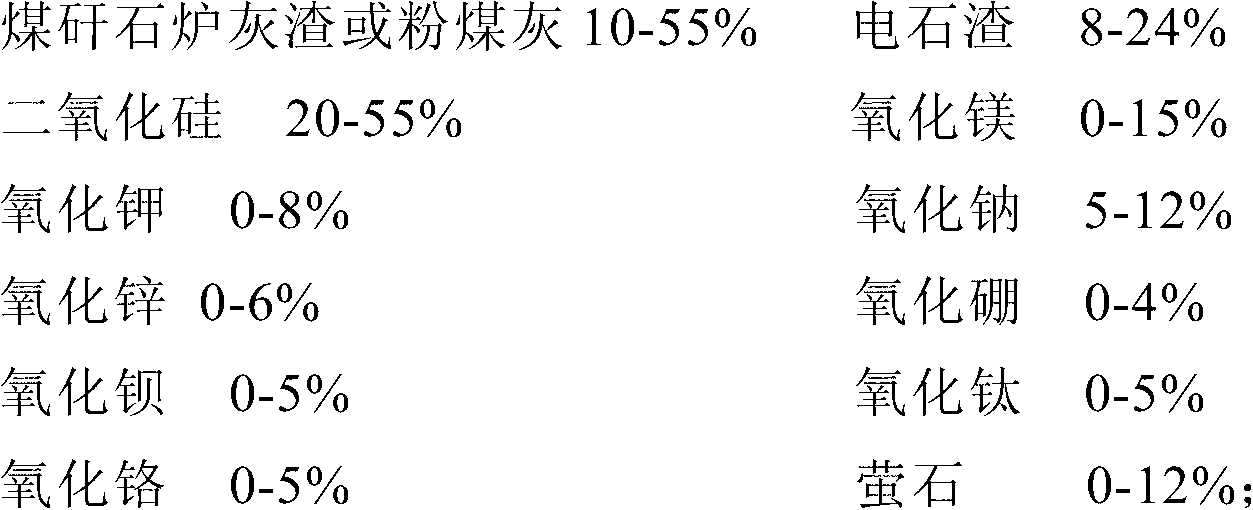

[0040] 3. Design the basic ...

Embodiment 2

[0059] Fly ash and carbide slag were selected as the main raw materials, and the glass-ceramic Buddha statue was prepared by casting method.

[0060] 1. Pretreatment of fly ash:

[0061] (1) Iron remover removes iron from fly ash.

[0062] (2) Sampling and testing, as the main raw material for preparing glass-ceramic pipes.

[0063] 2. Carbide slag is pretreated: Pass the carbide slag through a 40-mesh sieve to remove the graphite electrode debris mixed in it, and use it as another main raw material for preparing glass-ceramics.

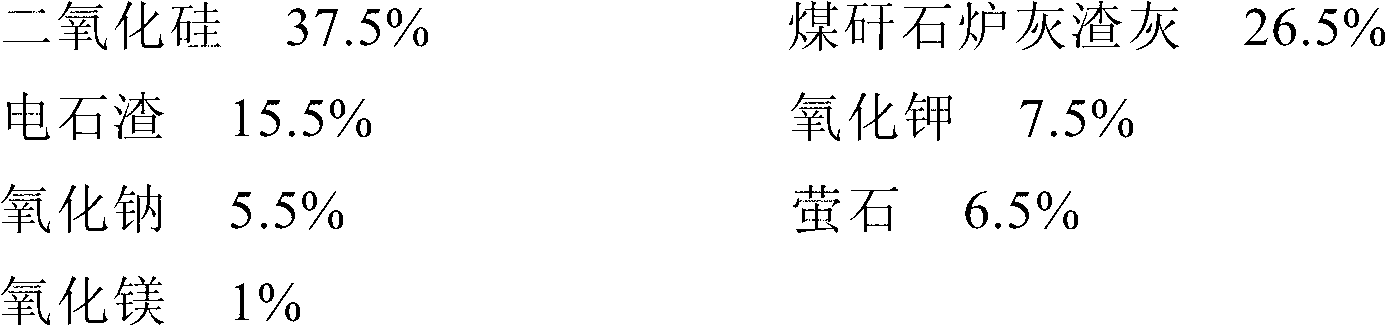

[0064] 3. Design the basic formula of the glass-ceramic Buddha statue:

[0065]

[0066] Note: Potassium oxide, sodium oxide, and barium oxide can be replaced by corresponding potassium carbonate, sodium carbonate, and barium carbonate, and boron oxide can be replaced by boric acid.

[0067] 4. Add 10-20 mesh 3% coal gangue furnace ash to the basic formula.

[0068] 5. Mix all kinds of raw materials evenly in proportion.

[0069] 6. Melting: ...

Embodiment 3

[0083] Coal gangue and carbide slag are selected as main raw materials, and patterned glass-ceramic decorative panels are prepared by sintering.

[0084] 1. Pretreatment of coal gangue:

[0085] (1) Crushing the gangue into fine particles with a diameter less than 30 mm;

[0086] (2) The coal gangue fine particles are burned in a fluidized fluidized furnace (the heat released is used for other purposes) to obtain furnace ash;

[0087] (3) Crushing the furnace ash into a fine powder less than 40 mesh;

[0088] (4) Carry out deironing to fine powder with deironing machine;

[0089] (5) Sampling and testing, as one of the main raw materials for preparing glass-ceramic.

[0090] 2. Carbide slag is pretreated: Pass the carbide slag through a 40-mesh sieve to remove the graphite electrode debris mixed in it, and use it as another main raw material for preparing glass-ceramics.

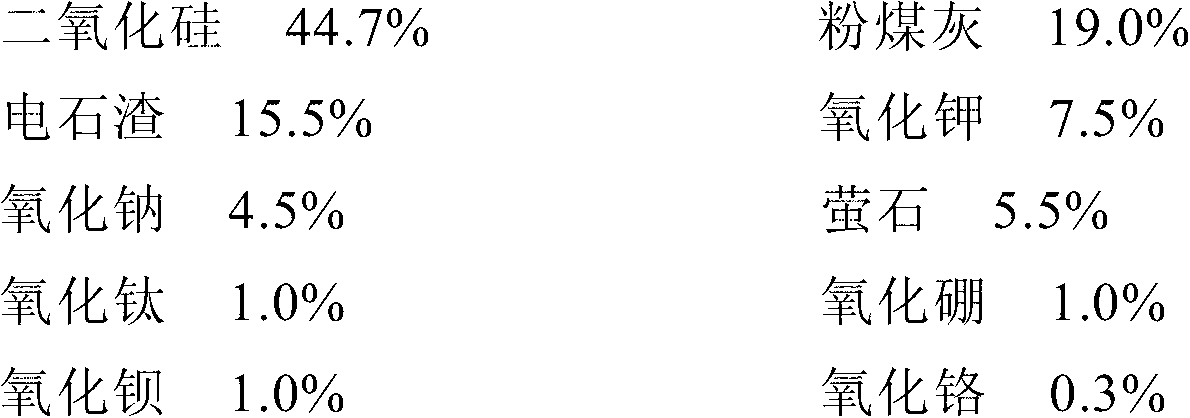

[0091] 3. Determine the basic formula of glass-ceramics:

[0092] Silica 25.5% Coal gangue furnace a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com