Crystal form transformation method for suspension roasting of natural spodumene

A technology of suspension roasting and conversion method, which is applied in the field of lithium extraction from ores, can solve the problems of difficult control of fluidized bed fluidization distribution, large and complex equipment, difficult temperature control, etc., and achieves easy comprehensive recycling, low equipment investment, and difficult material melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

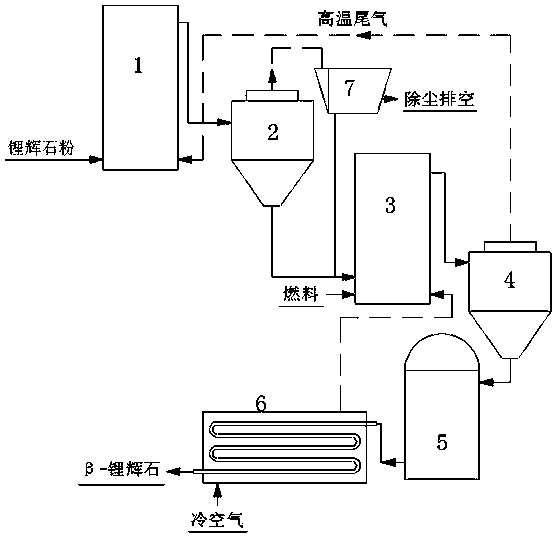

Embodiment 1

[0023] Grind natural α-spodumene (lithium oxide content 1.5%) into spodumene powder with an average diameter of 0.15 mm; then put it into the secondary suspension roaster, and use the 950 ℃ high-temperature tail gas for fluidized drying and preheating, so that the temperature of the spodumene powder reaches 150°C and the water content is less than 2%, and then the dried and preheated spodumene powder and high-temperature tail gas are passed into the secondary cyclone dust collector for degassing Solid separation, after the tail gas obtained from the separation is separated from the gas and solid by the dust collector, the collected preheated stone powder and the preheated stone powder separated in the secondary cyclone dust collector are introduced into the first-stage suspension roaster together, and are separated from the bottom of the first-stage suspension roaster. The 1000°C high-temperature gas obtained from the combustion chamber is rapidly mixed (the flow direction of t...

Embodiment 2

[0025] Grind natural α-spodumene (2.4% lithium oxide content) into spodumene powder with an average diameter of 0.1mm; then put it into the secondary suspension roaster, and use the 1100 ℃ high-temperature tail gas for fluidized drying and preheating, so that the temperature of the spodumene powder reaches 400 °C and the water content is less than 2%, and then the dried and preheated spodumene powder and high-temperature tail gas are passed into the secondary cyclone dust collector for degassing Solid separation, after the tail gas obtained from the separation is separated from the gas and solid by the dust collector, the collected preheated stone powder and the preheated stone powder separated in the secondary cyclone dust collector are introduced into the first-stage suspension roaster together, and are separated from the bottom of the first-stage suspension roaster. The high-temperature gas at 1100°C obtained from the combustion chamber is rapidly mixed (the flow direction o...

Embodiment 3

[0027]Grind natural α-spodumene (4.3% lithium oxide content) into spodumene powder with an average diameter of 0.06mm; then put it into the secondary suspension roaster, and use the 1000 ℃ high-temperature tail gas for fluidized drying and preheating, so that the temperature of the spodumene powder reaches 200°C and the water content is less than 2%, and then the dried and preheated spodumene powder and high-temperature tail gas are passed into the secondary cyclone dust collector for degassing Solid separation, after the tail gas obtained from the separation is separated from the gas and solid by the dust collector, the collected preheated stone powder and the preheated stone powder separated in the secondary cyclone dust collector are introduced into the first-stage suspension roaster together, and are separated from the bottom of the first-stage suspension roaster. The high-temperature gas at 1150°C obtained by the combustion chamber is rapidly mixed (the flow direction of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com