Patents

Literature

36results about How to "Controlled combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Free-piston type internal combustion engine power generating system

InactiveCN1888402AAvoid lostControlled combustionElectrical controlInternal combustion piston enginesCombustion chamberReciprocating motion

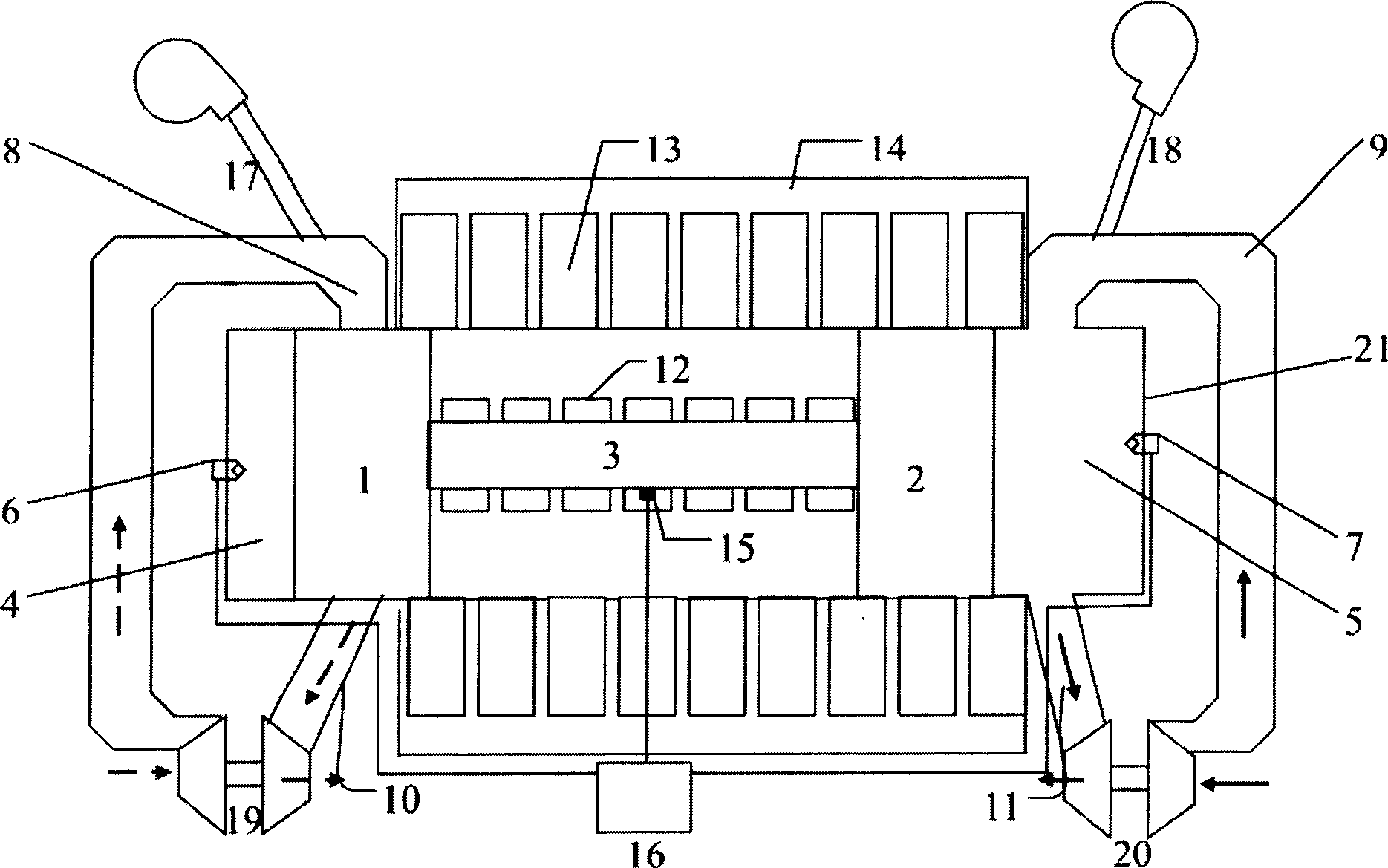

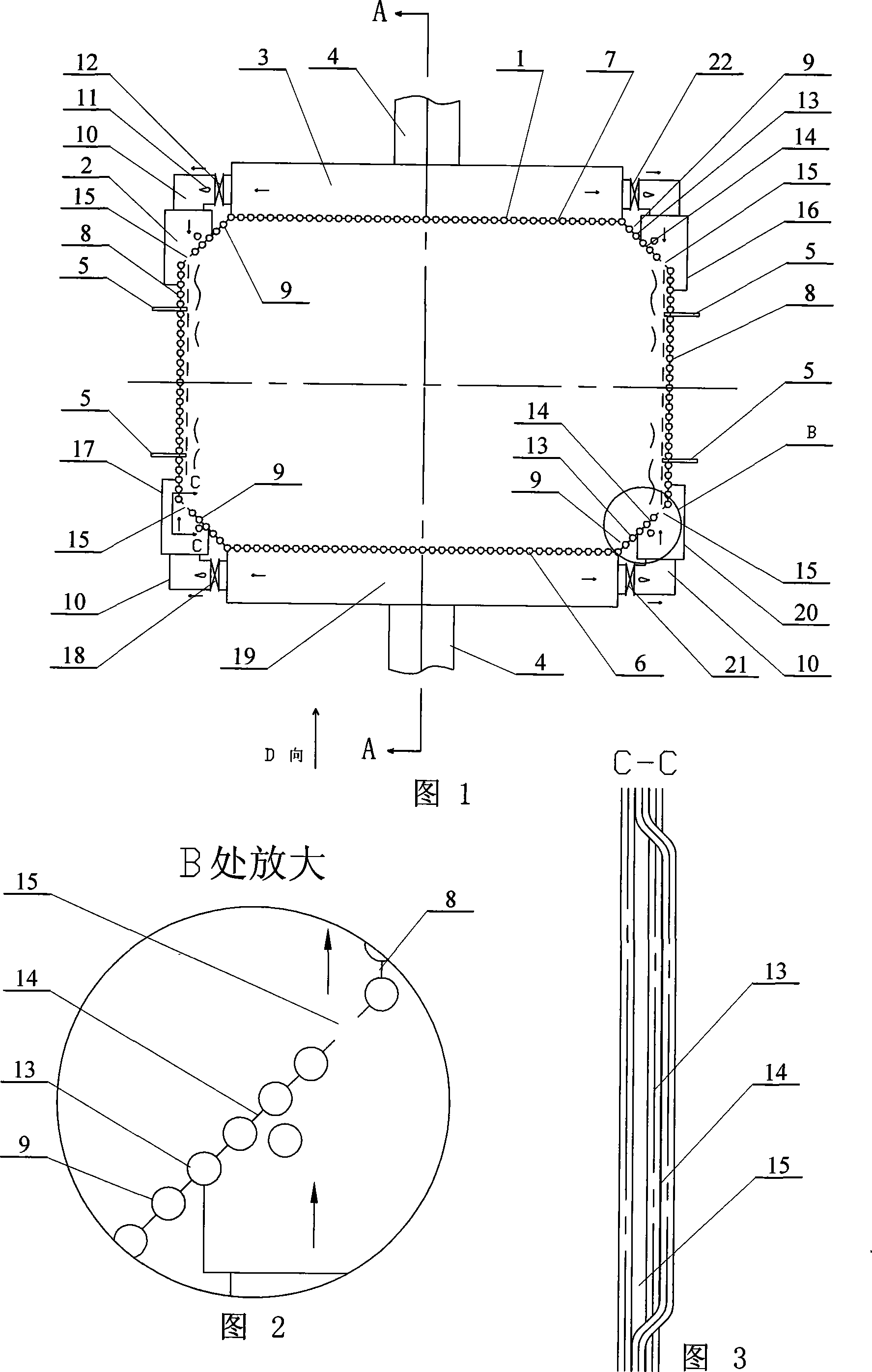

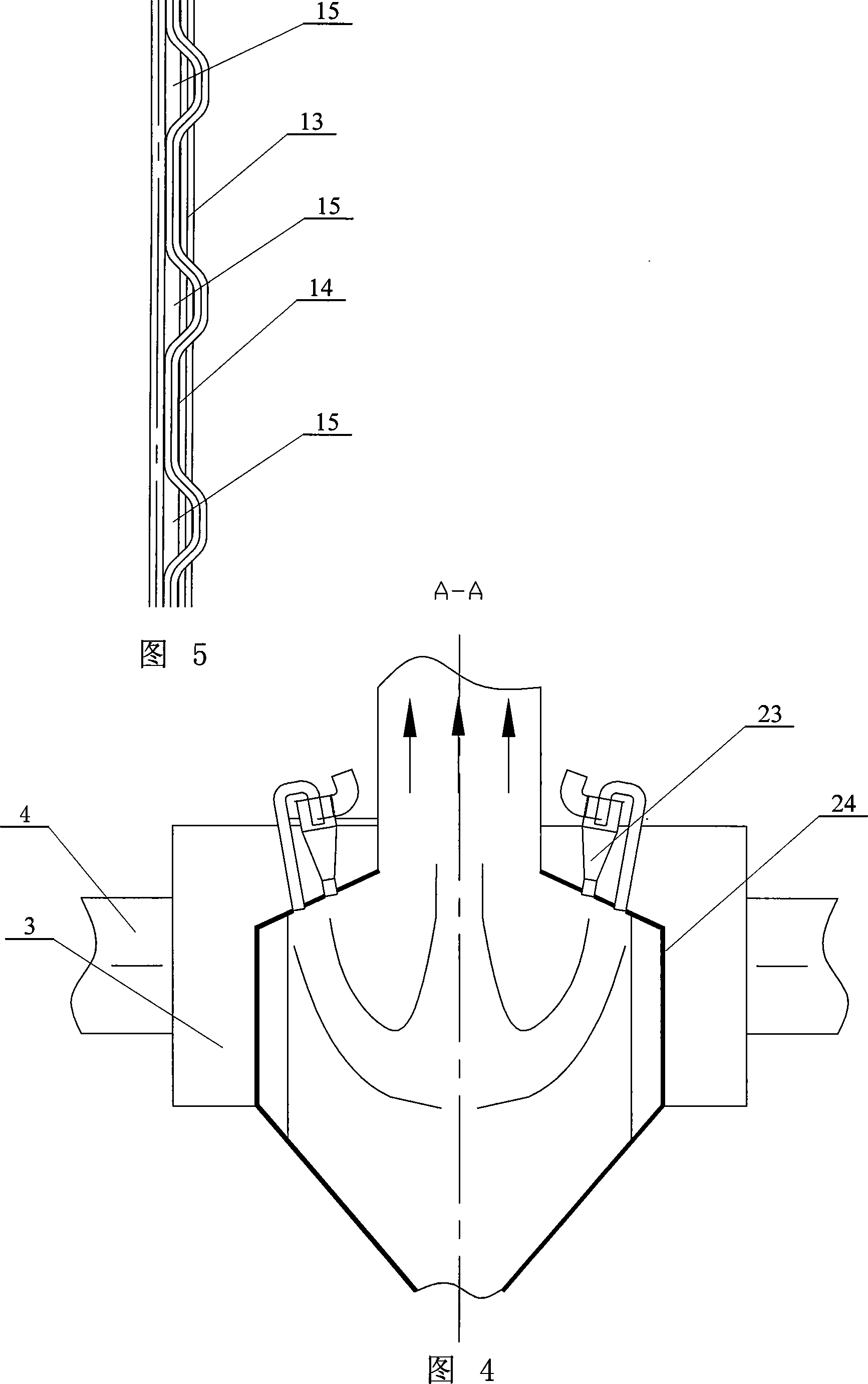

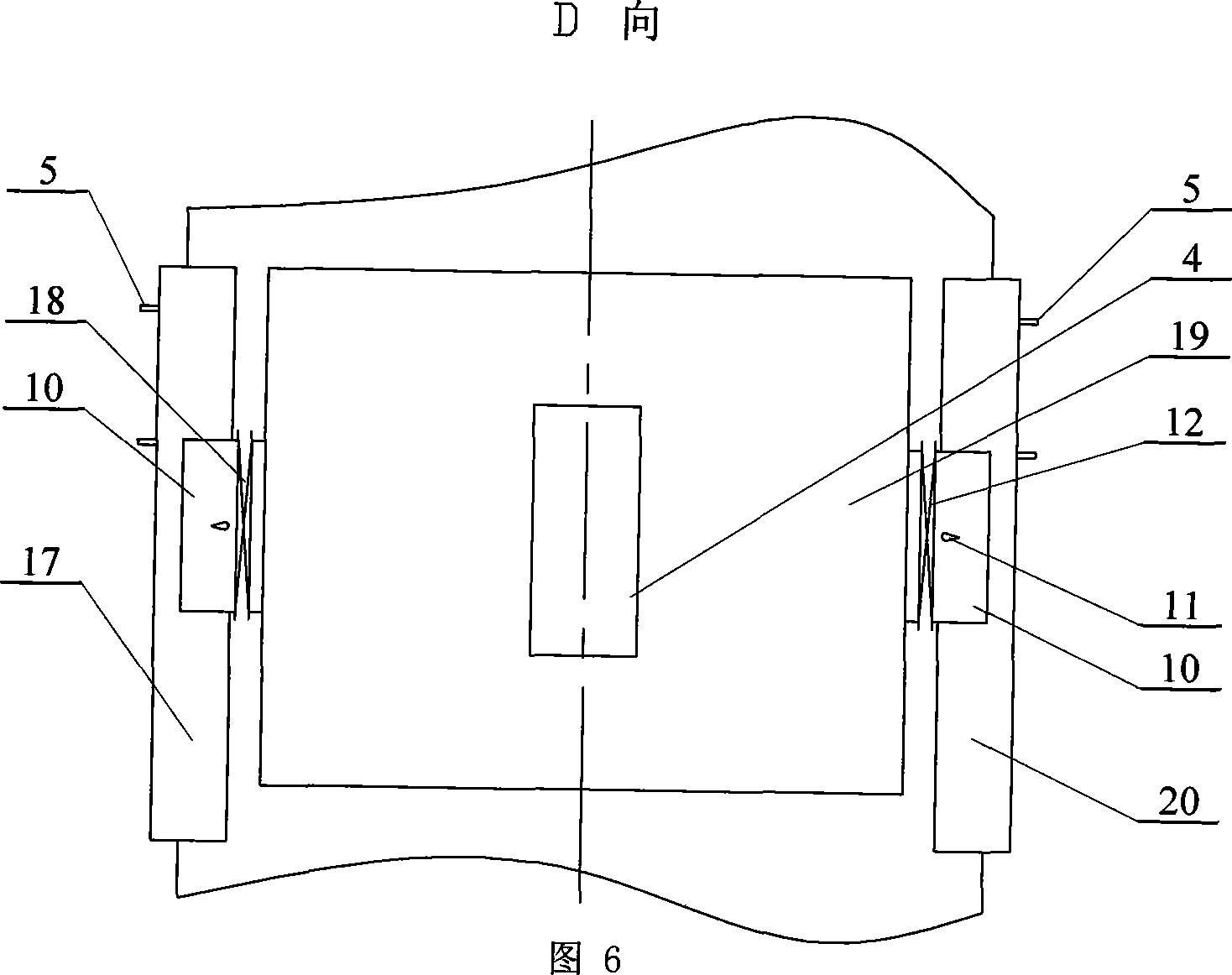

The present invention relates to a free piston type internal combustion engine power generation system, belonging to the field of internal combustion engine technology. Said invention includes left and right two pistons, connecting rod, cylinder, left and right oppositely-arranged two combustion chambers, fuel oil nozzle, air inlet, air outlet, permanent magnet placed on the connecting rod, coil outside of cylinder, iron core, piston position sensor, electronic control unit, two external high-pressure starting pumps and turbo supercharger. The power generation system is set between two combustion chambers. Besides, said invention also provides the concrete connection mode of all the above-mentioned portions and the working principle of said power generation system.

Owner:SHANGHAI JIAO TONG UNIV

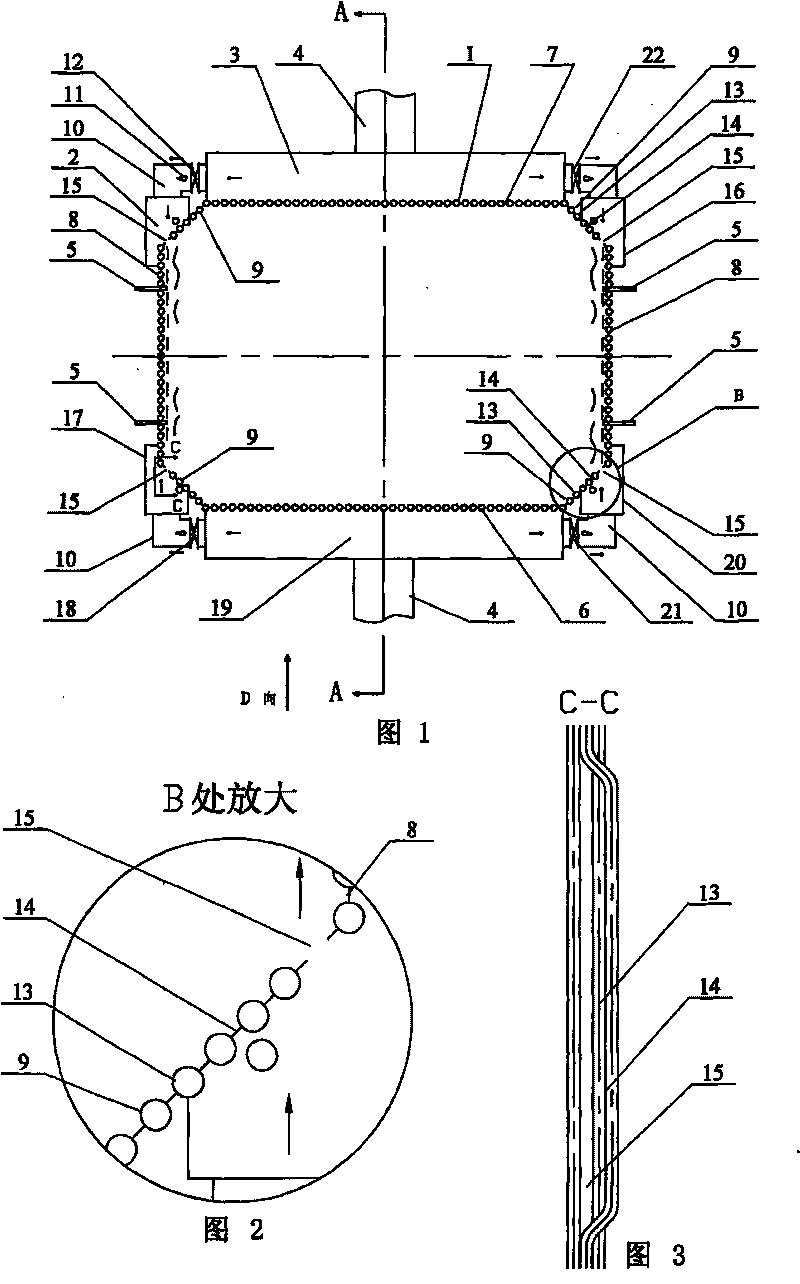

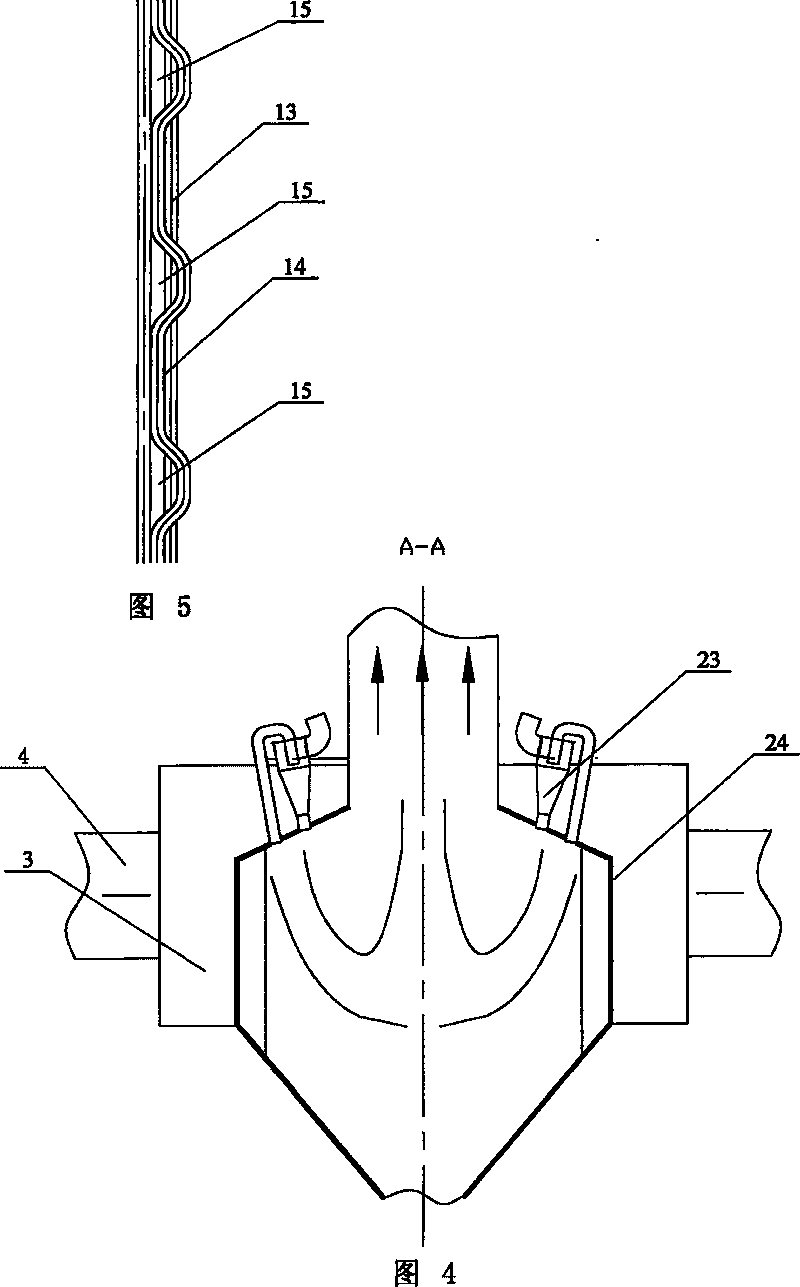

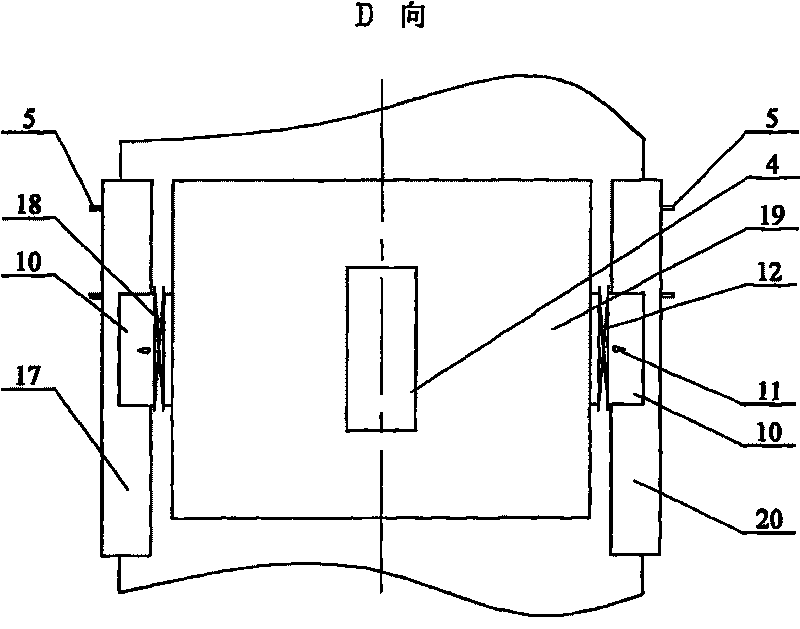

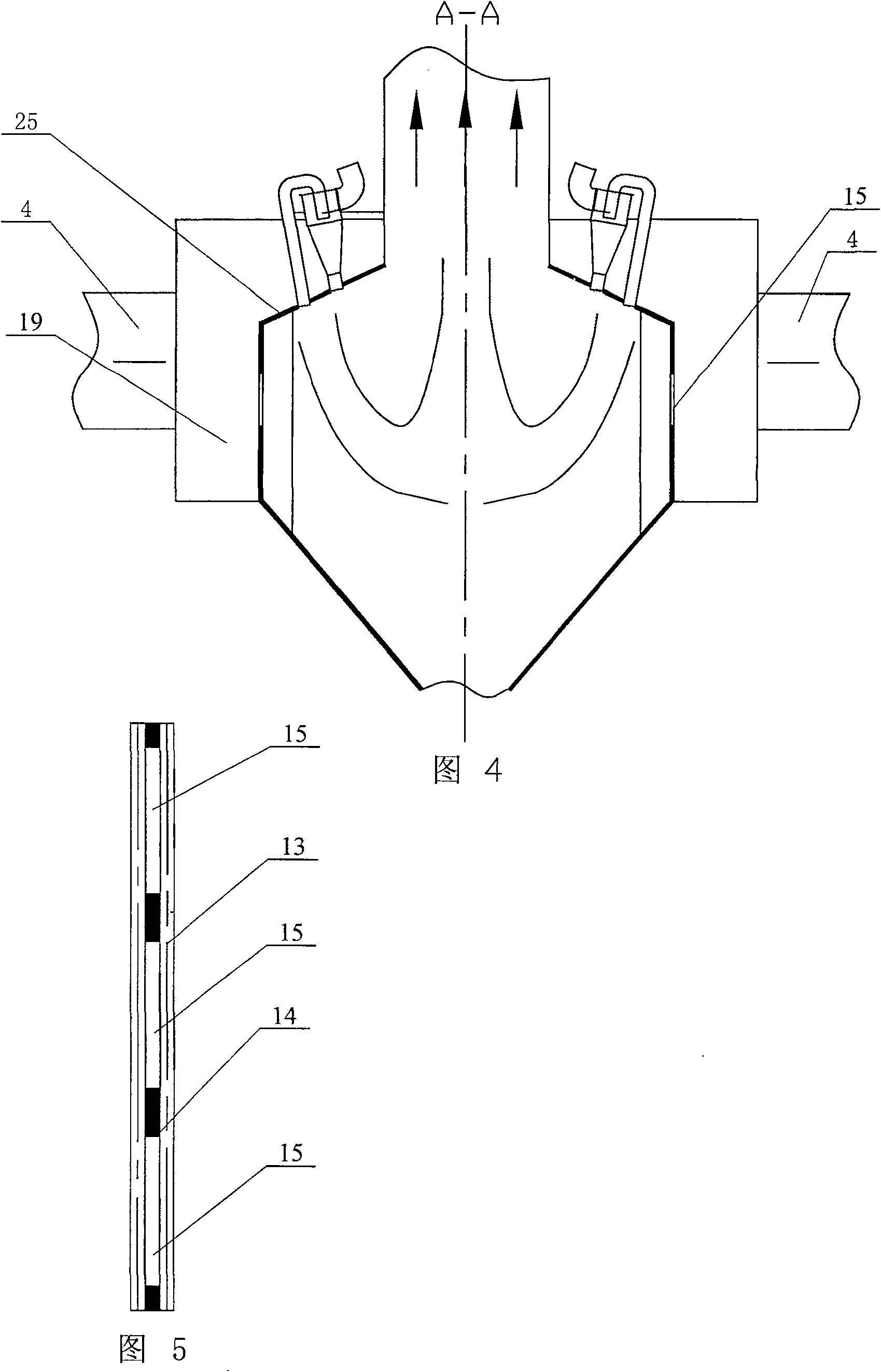

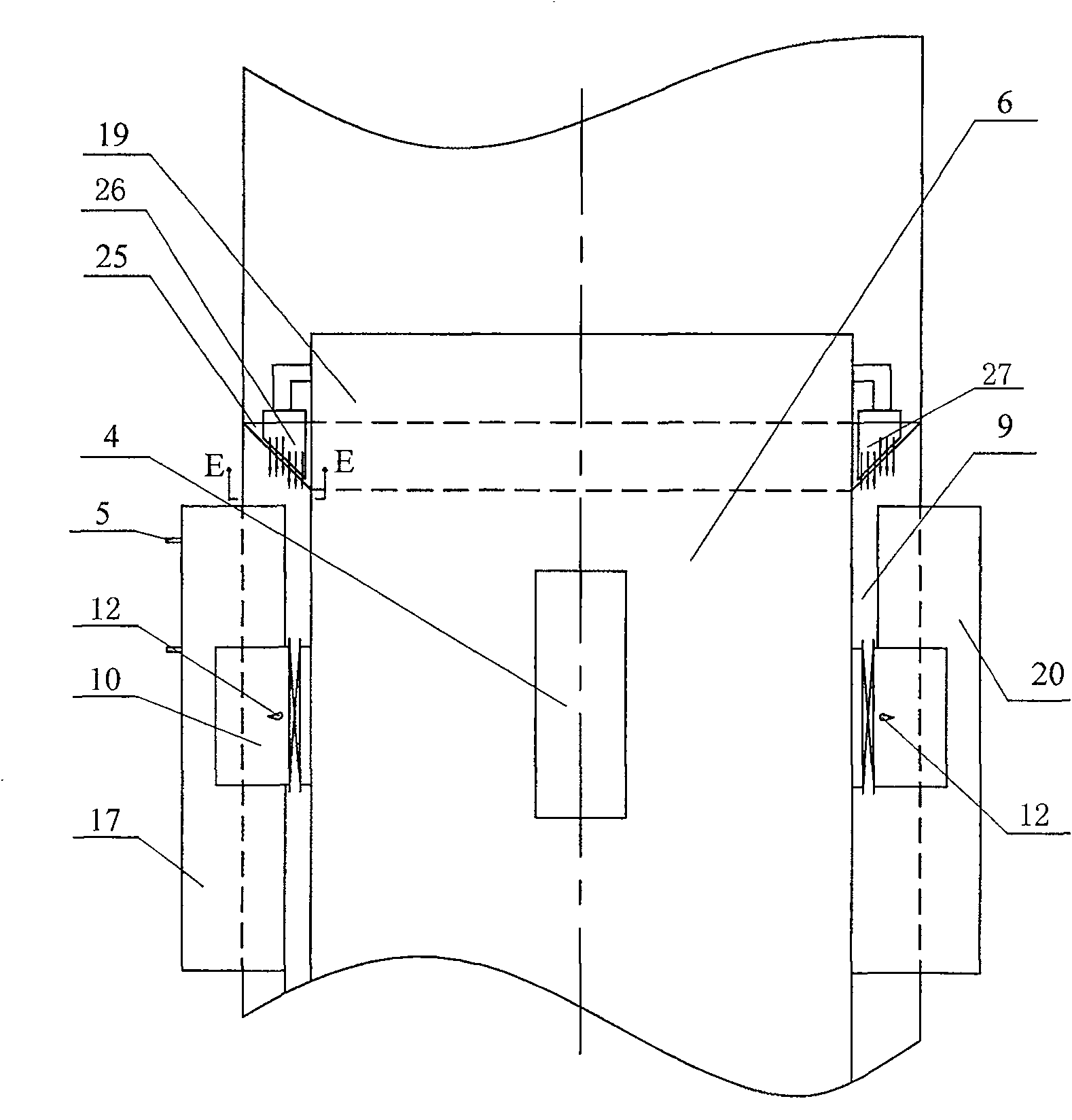

W-shape flame boiler for preventing side wall water cooling wall slagging scorification

ActiveCN101050854AAccelerated slagging problemReduce the temperatureSteam boilersCombustion chambersScarificationWing wall

A W type of flame boiler enabling to prevent water-cooled wall of wing walls from slagging scarification is prepared for setting four wall-wind fans separately on external sides of four wing walls and arranging ventilation gap on each of four wing walls.

Owner:HARBIN INST OF TECH

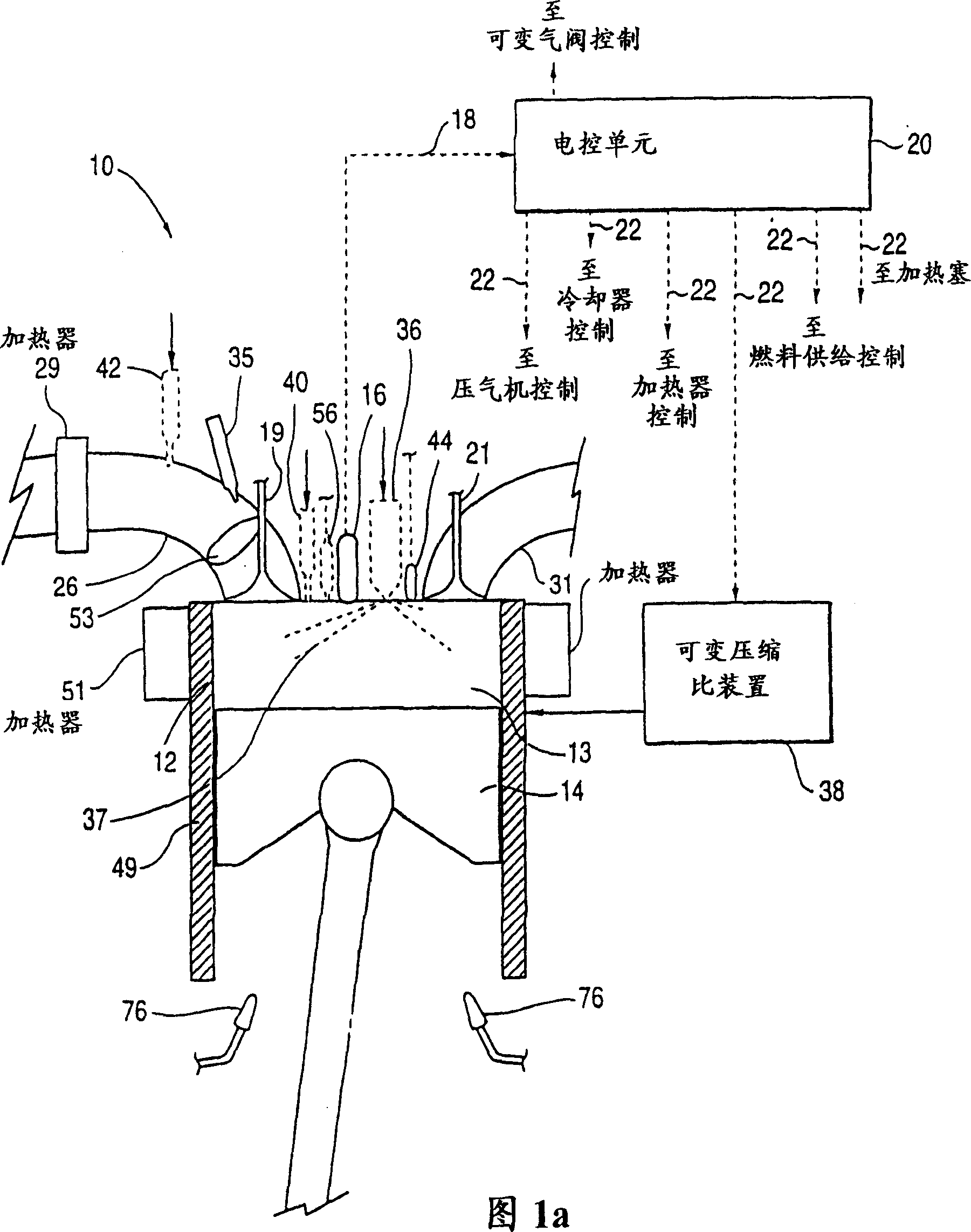

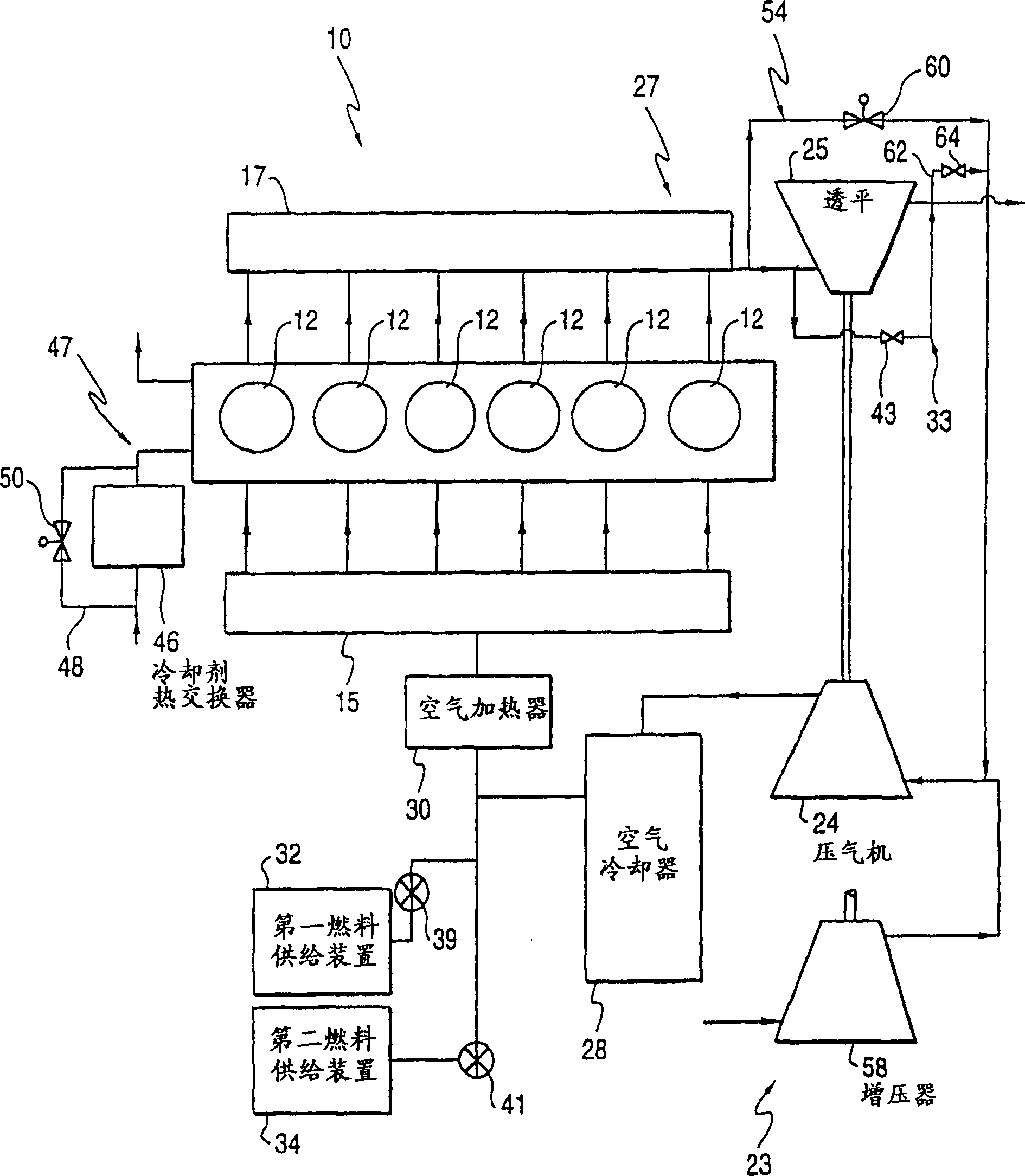

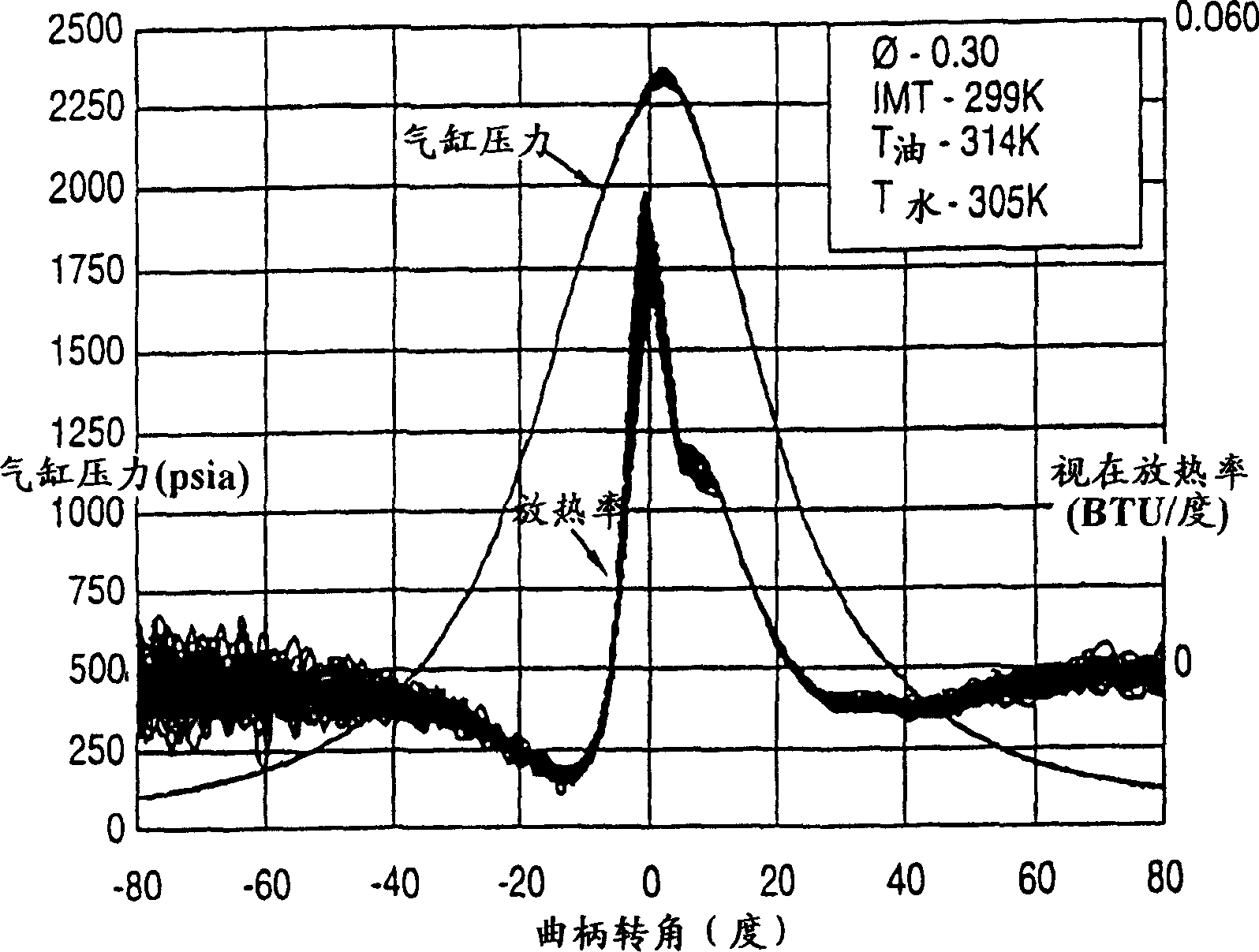

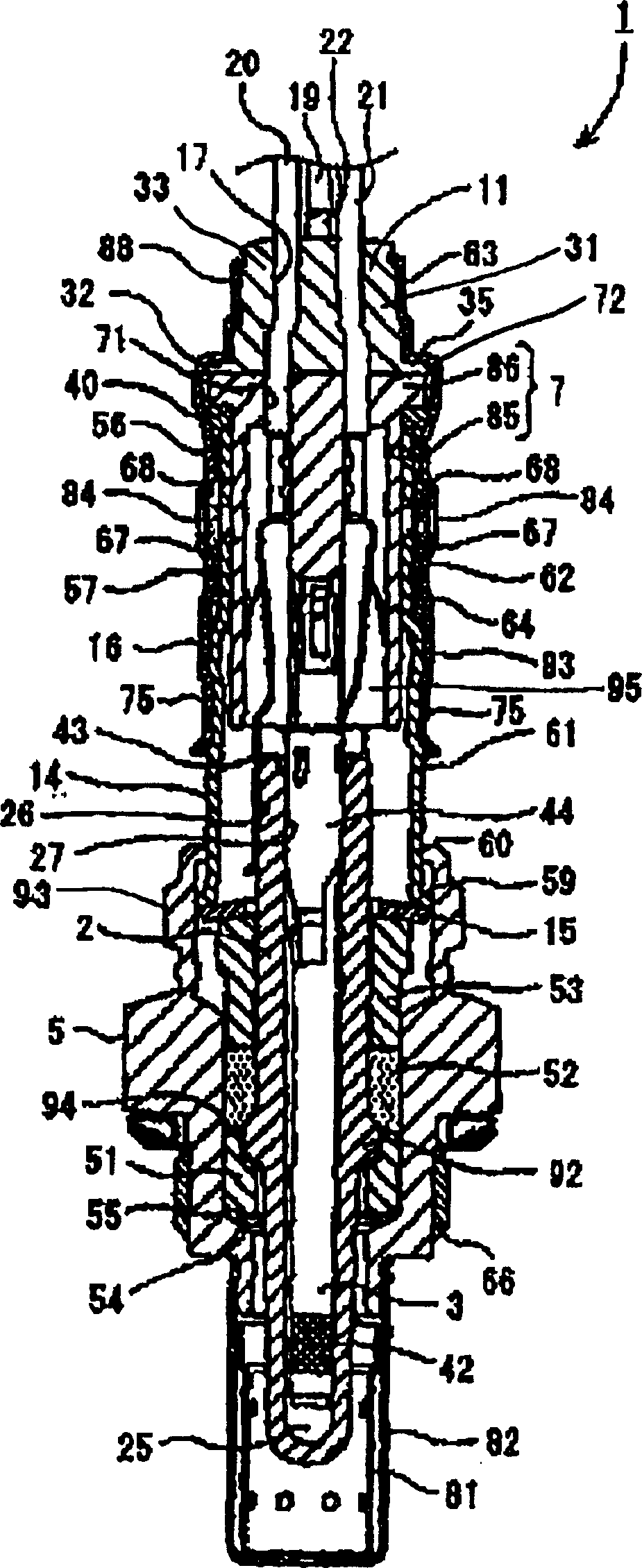

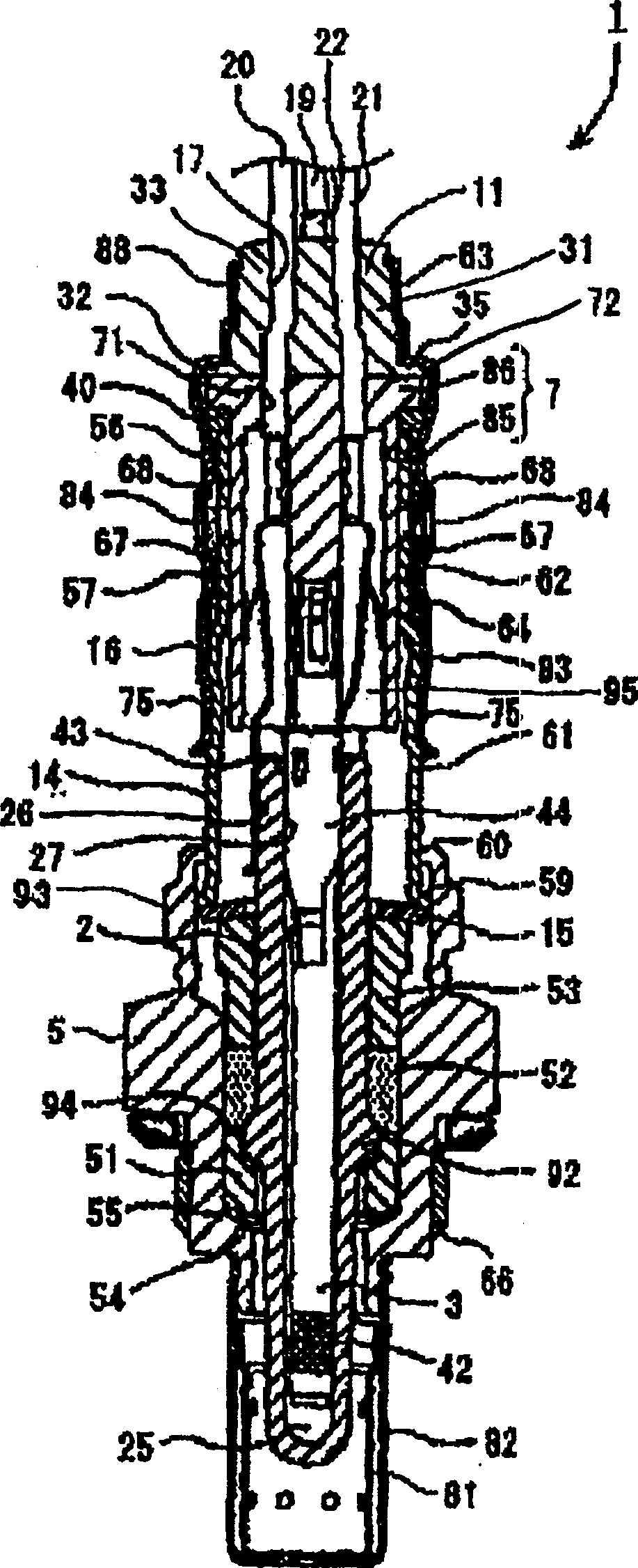

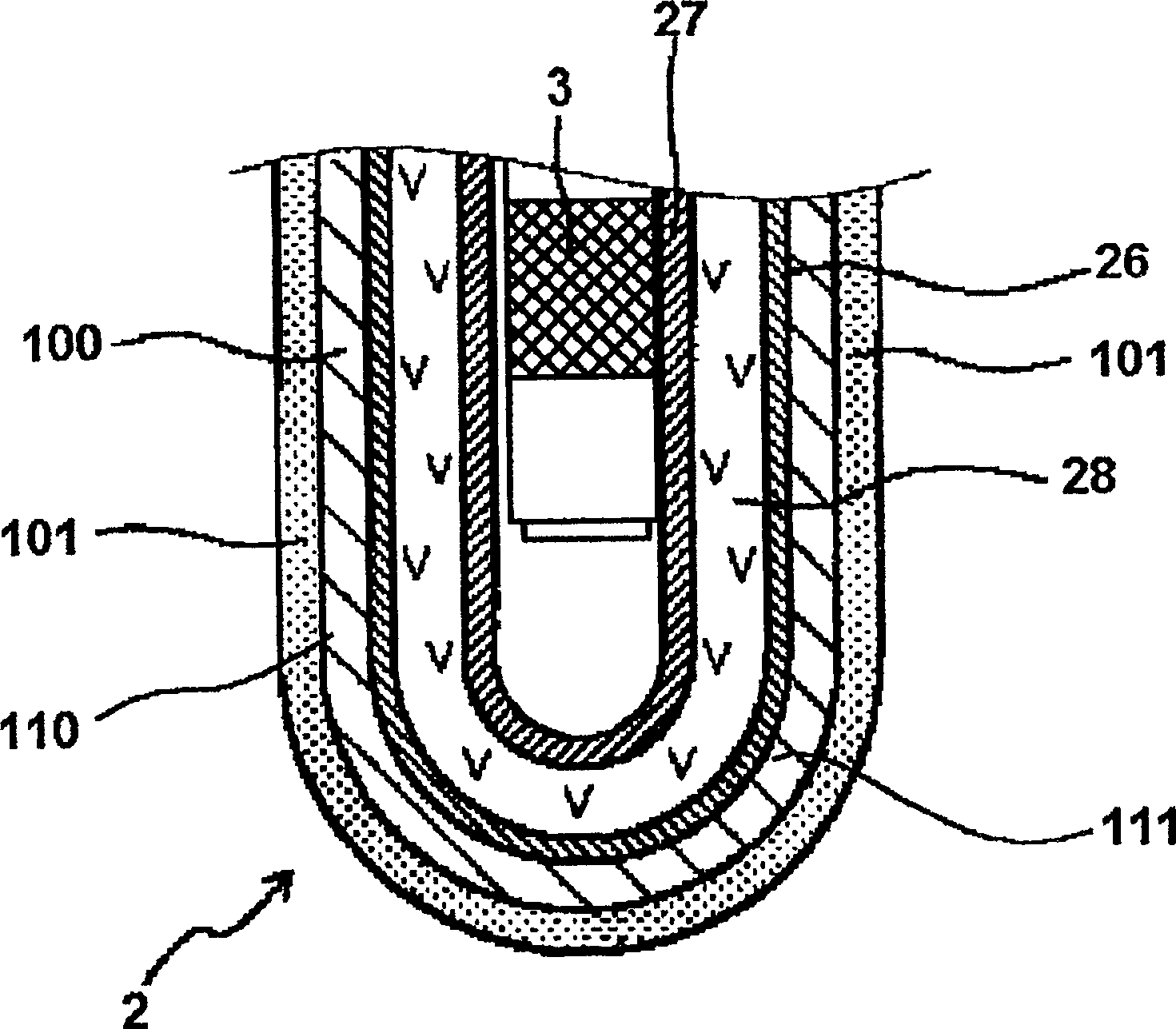

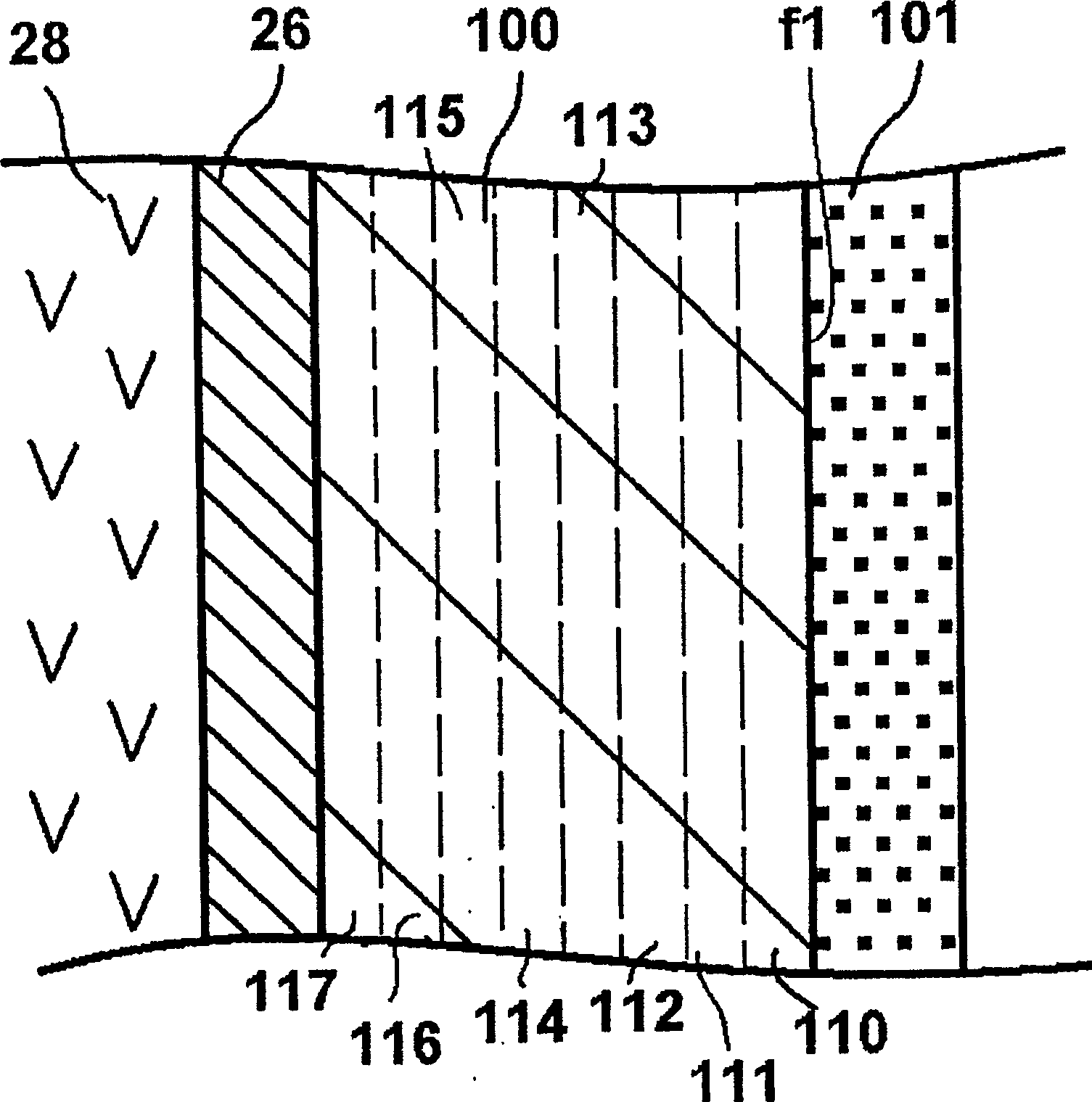

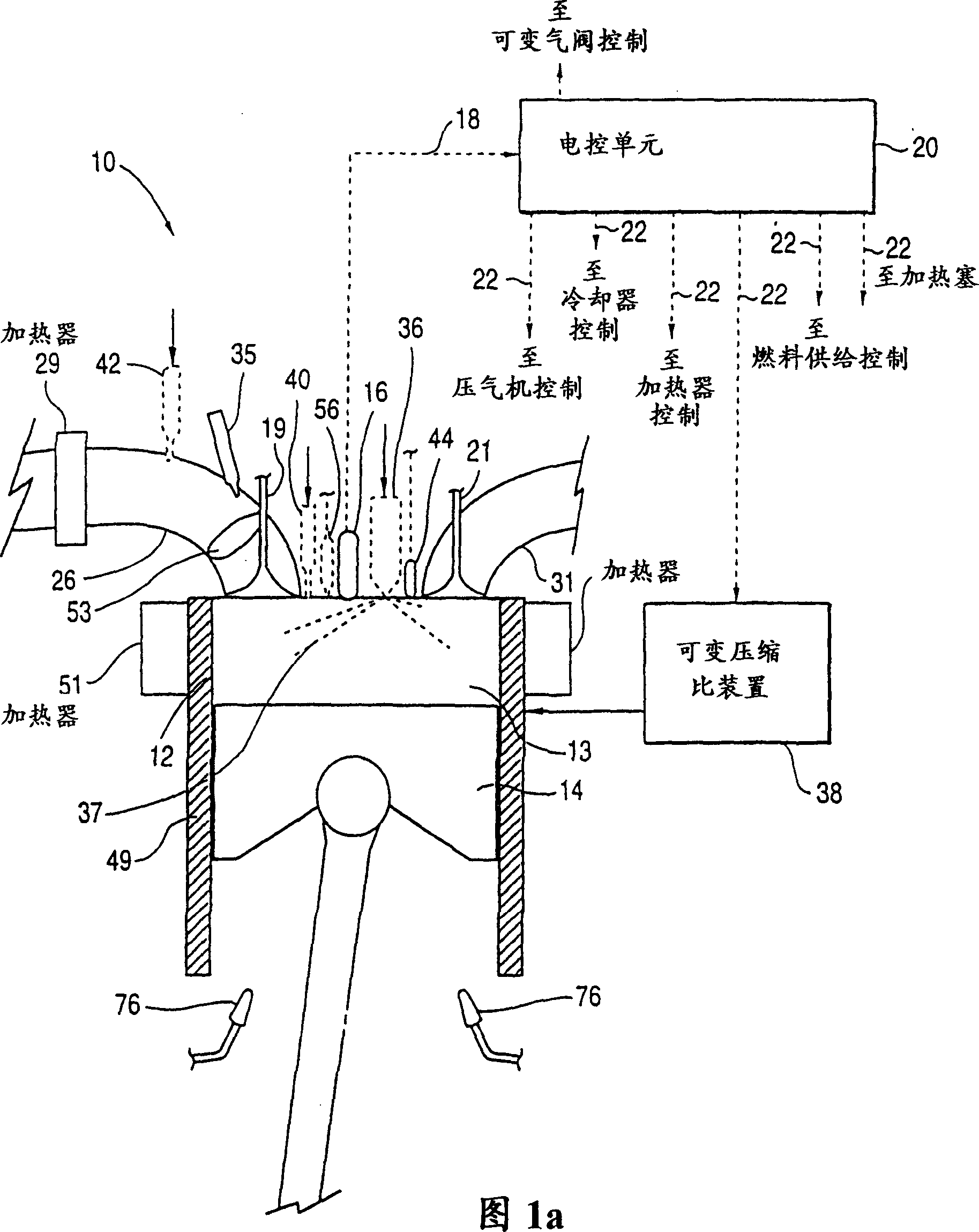

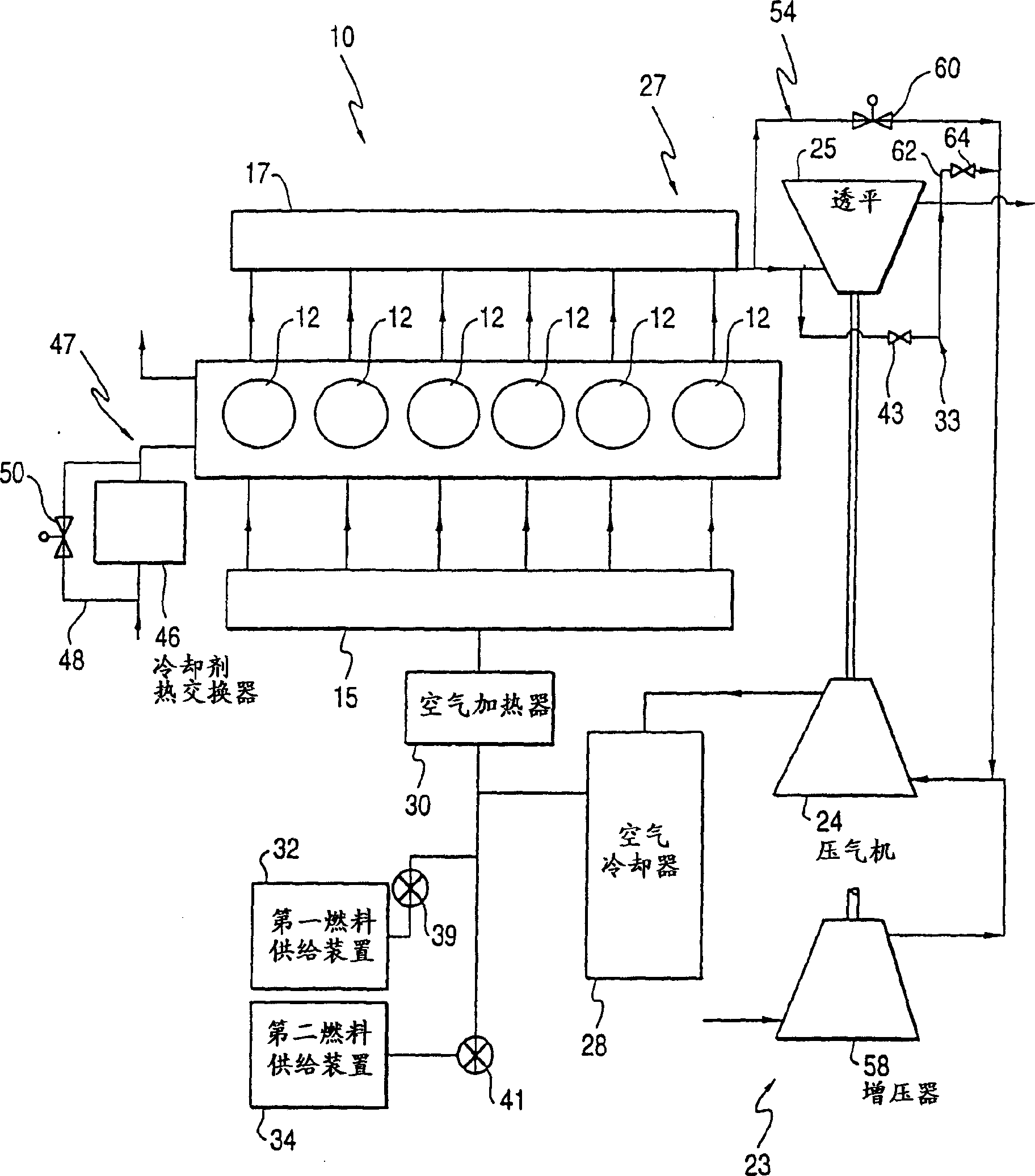

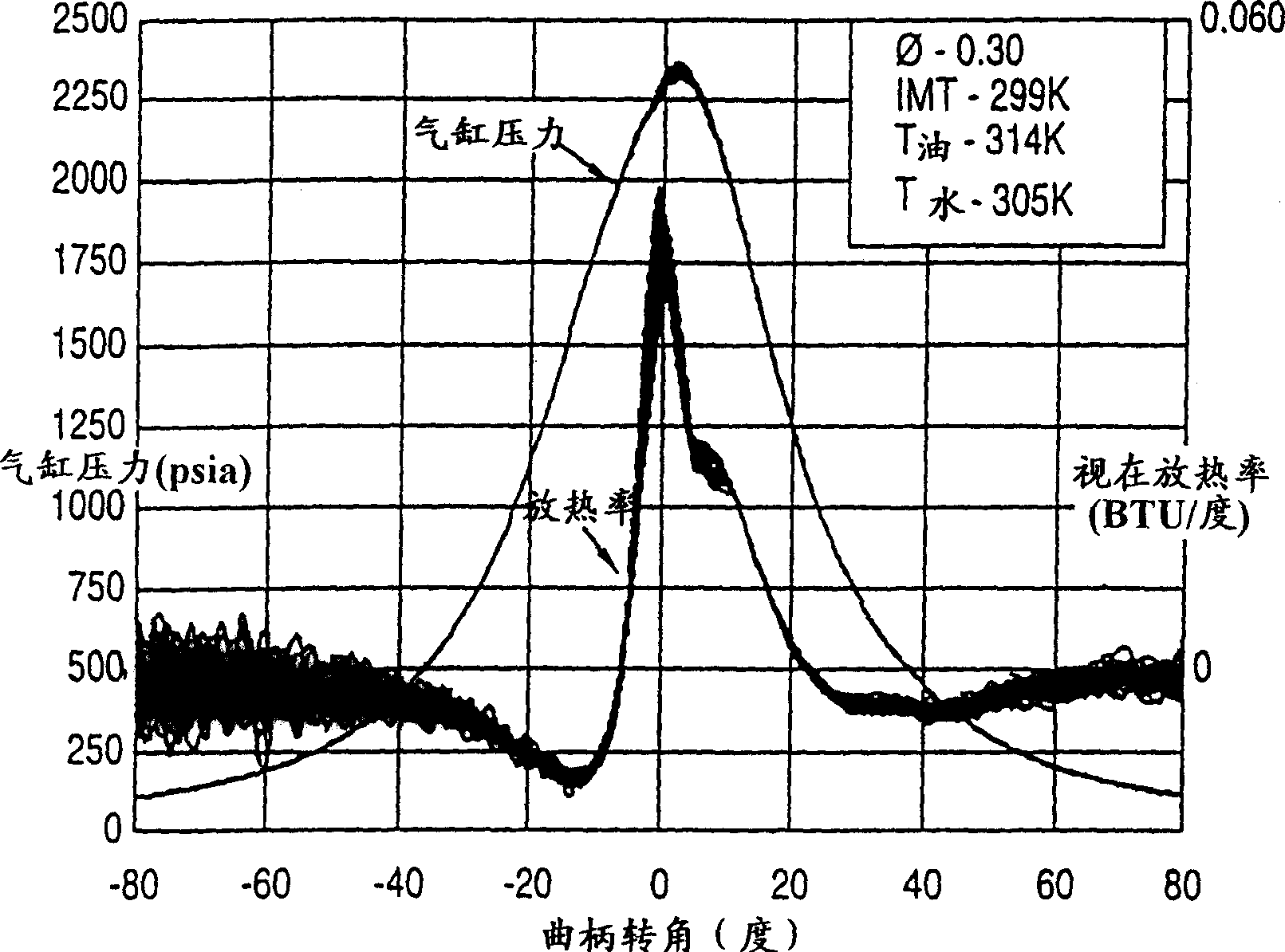

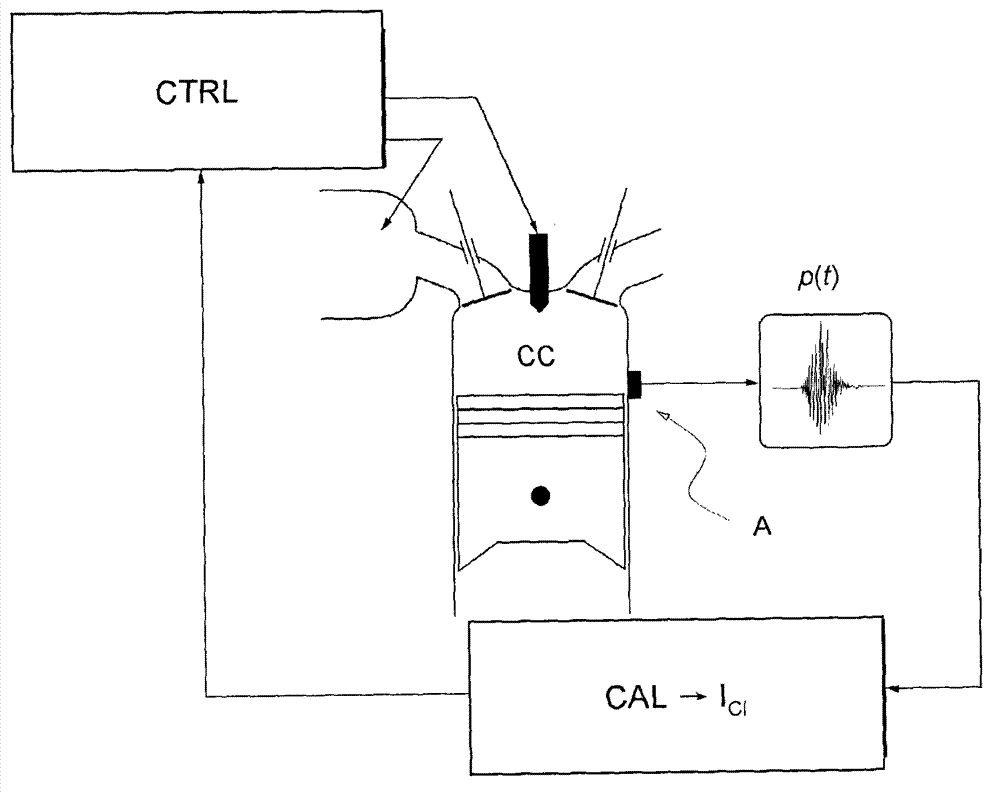

Premixed charge compression ignition engine with optimal combustion control

InactiveCN1624305AControl control systemEffective controlElectrical controlInternal combustion piston enginesTemperature controlActive feedback

The present invention provides a premixed charge compression ignition engine and control system (10), which can effectively trigger combustion and maintain stable combustion by means of compression ignition, while achieving extremely low nitrogen oxide emissions, good overall efficiency and Acceptable combustion noise and cylinder pressure. The engine and control system (10) of the present invention can effectively control the combustion process by controlling certain control variables of temperature control, pressure control, mixture self-ignitability control and equivalence ratio control, that is, the time of combustion initiation, the combustion rate , duration of combustion and / or completeness of combustion. The combustion control system (10) provides active feedback control of combustion and includes a sensor for detecting engine operating conditions representative of a combustion process, such as ignition of combustion, and generating a corresponding engine operating condition signal (18) , such as the pressure sensor (16).

Owner:CUMMINS INC

Method for manufacturing flame-retardant recombined decorative material

InactiveCN1864956AFire and flame retardantChange the pyrolysis processAdhesive processes with surface pretreatmentLaminationEngineeringFire retardant

Owner:庄启程 +1

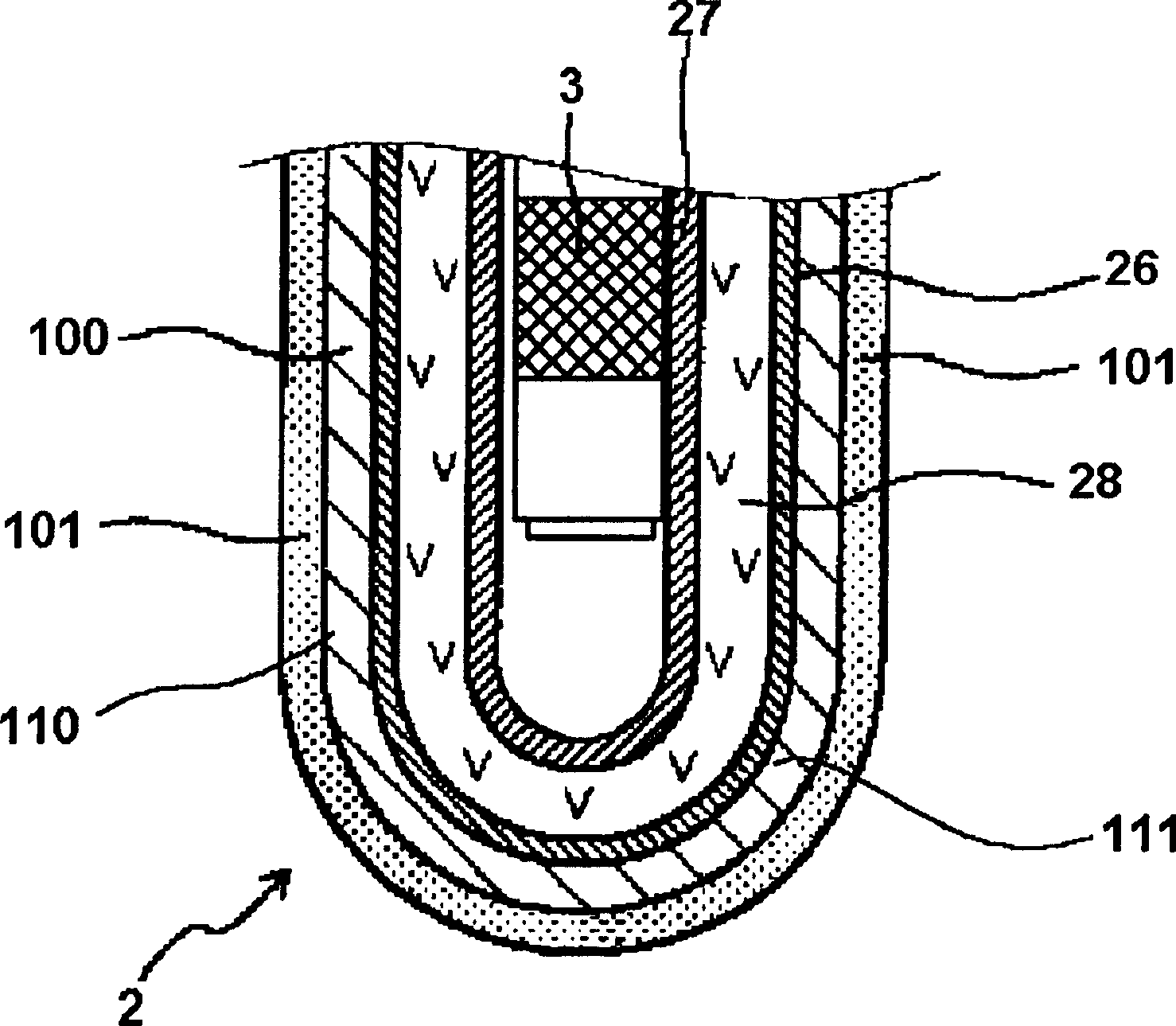

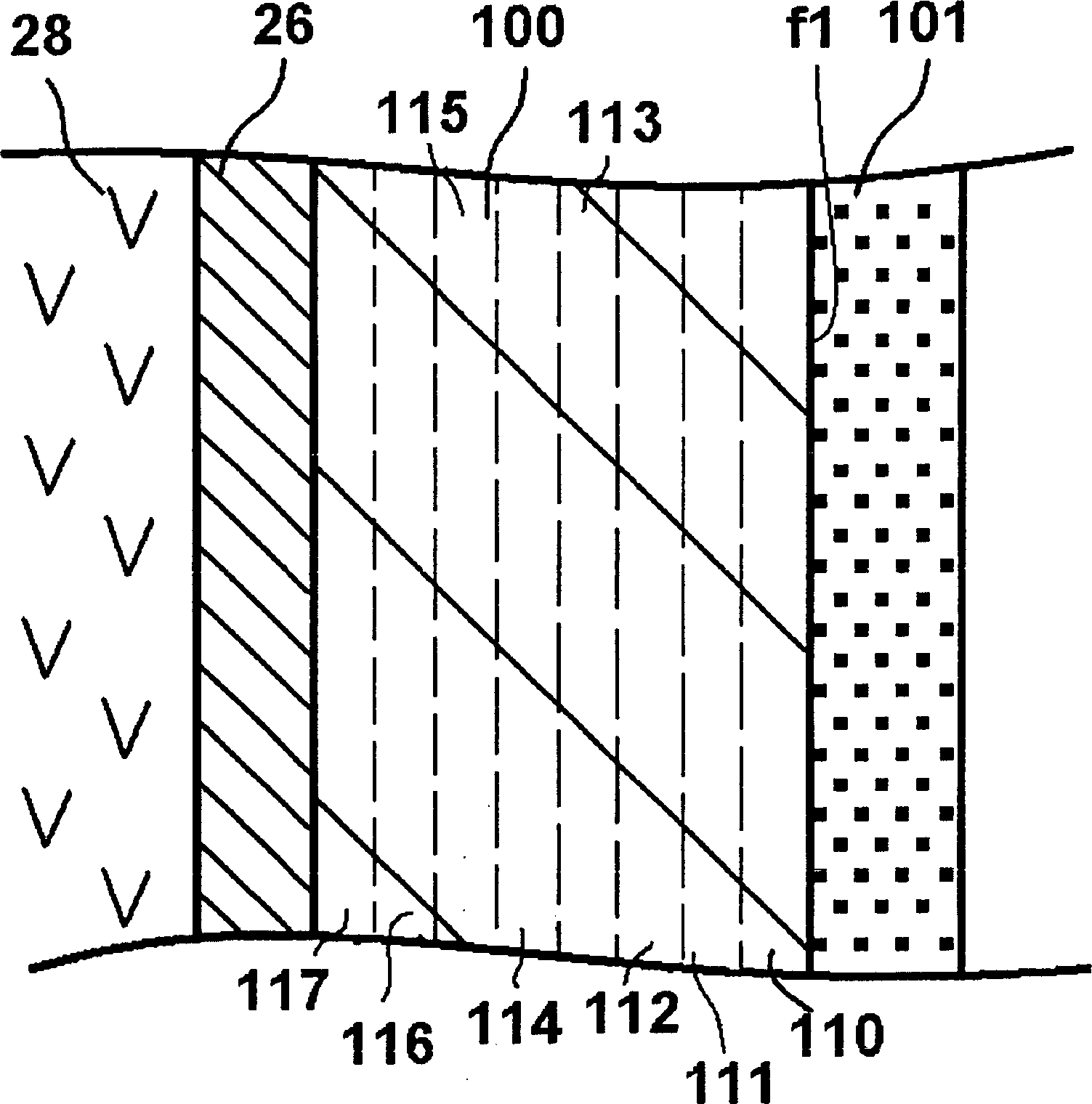

Gas sensor and method for manufacturing the same

ActiveCN1725005AInhibition of volume expansionPrevent peelingMaterial electrochemical variablesOxygen ionsCatalytic metal

The present invention provides a gas sensor having a gas sensor element which includes: a reference electrode; a solid electrolyte layer having oxygen ion conductivity; a detection electrode; and an electrode-protecting layer covering the detection electrode. The electrode-protecting layer is a porous body carrying catalytic metal, and includes: a detection electrode side portion having a catalytic metal loading ratio of more than 0% by weight and not more than 0.005% by weight; and a surface side portion provided closer to the outer surface of the electode-protecting layer than the detection electrode side portion, the surface side portion having a catalytic metal loading ratio of 0.01% by weight or more.

Owner:NGK SPARK PLUG CO LTD

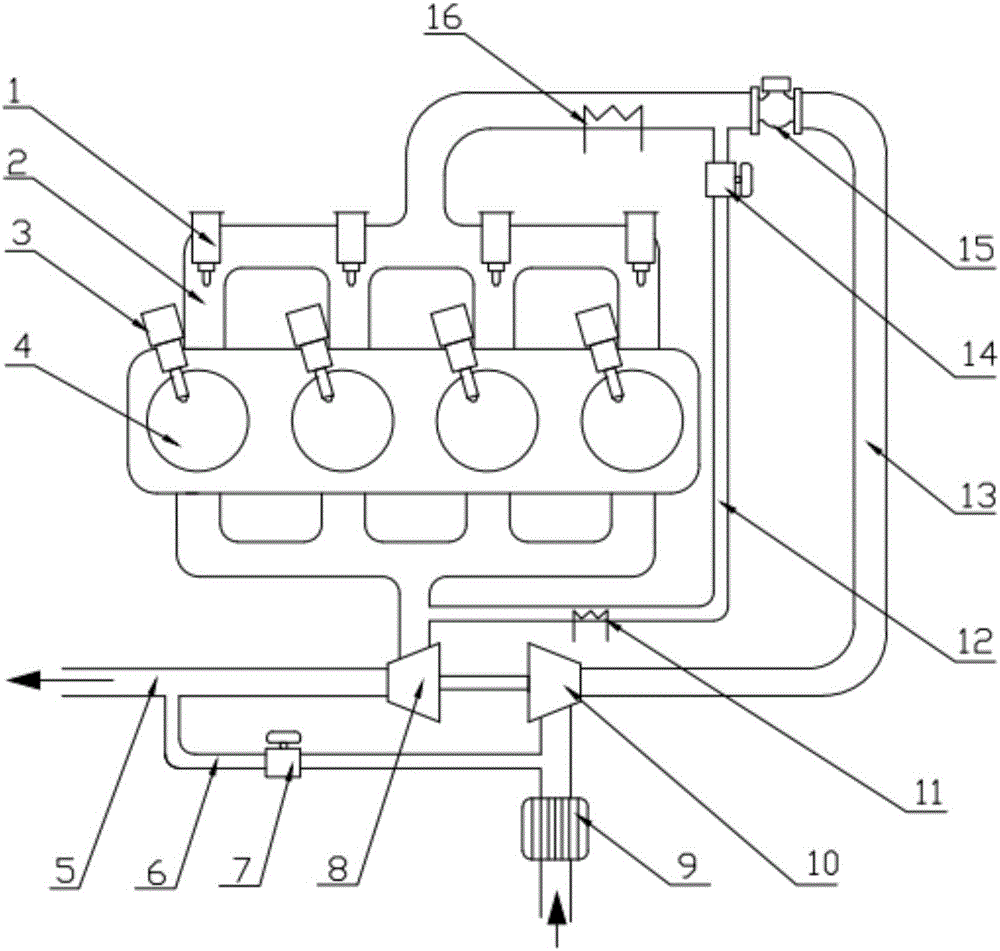

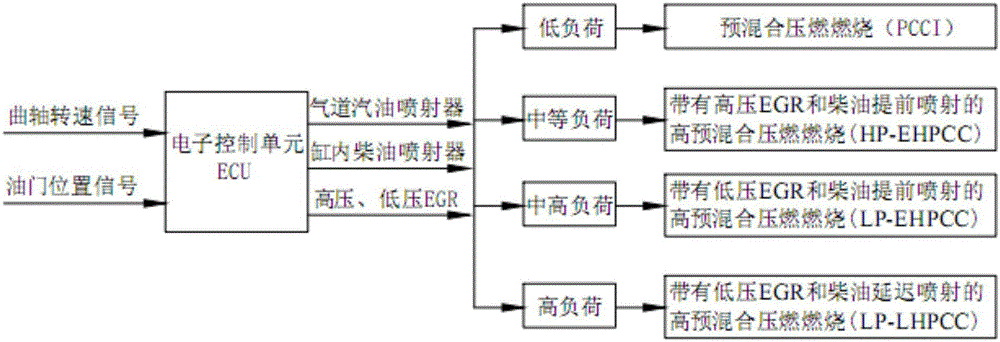

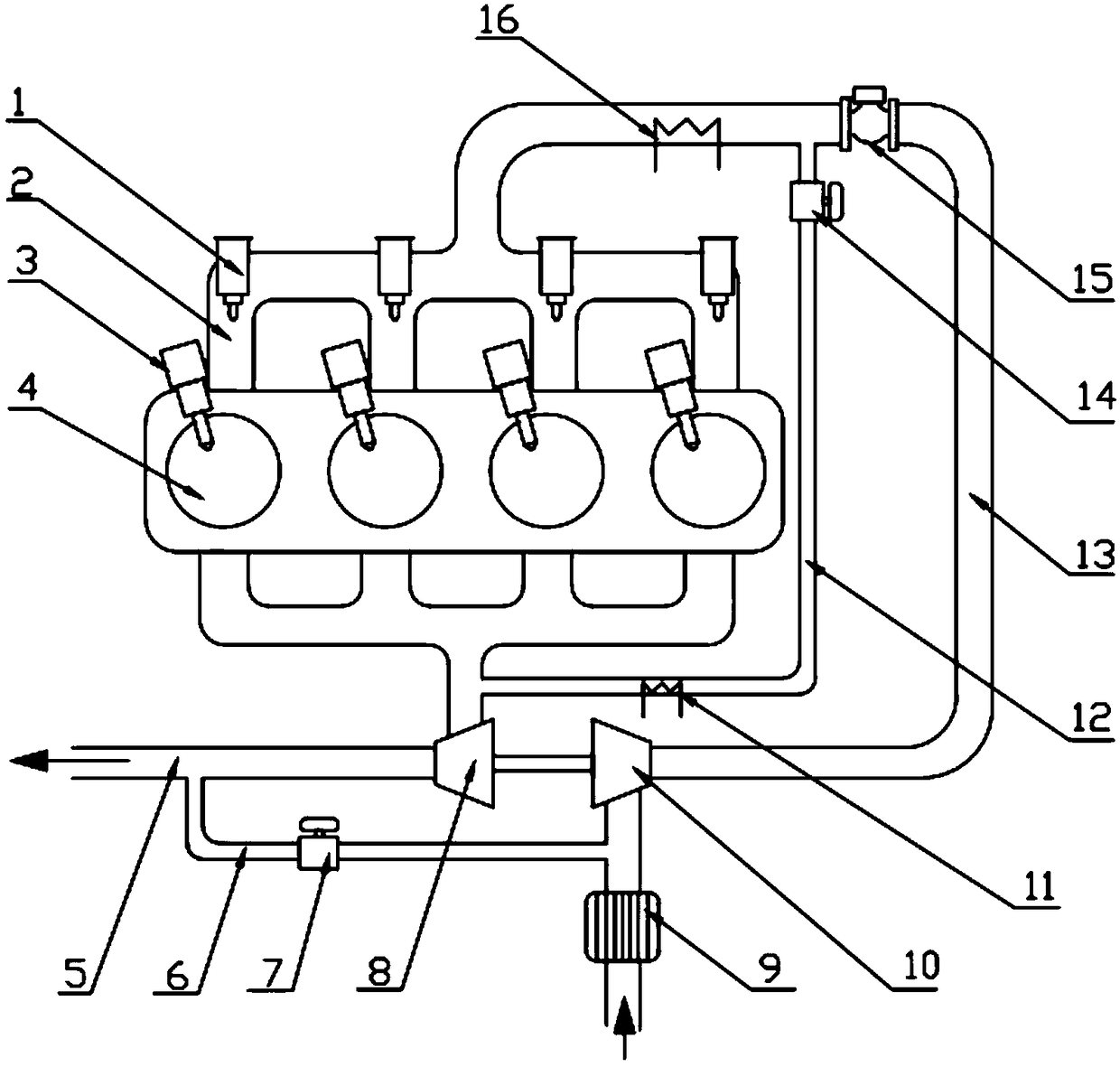

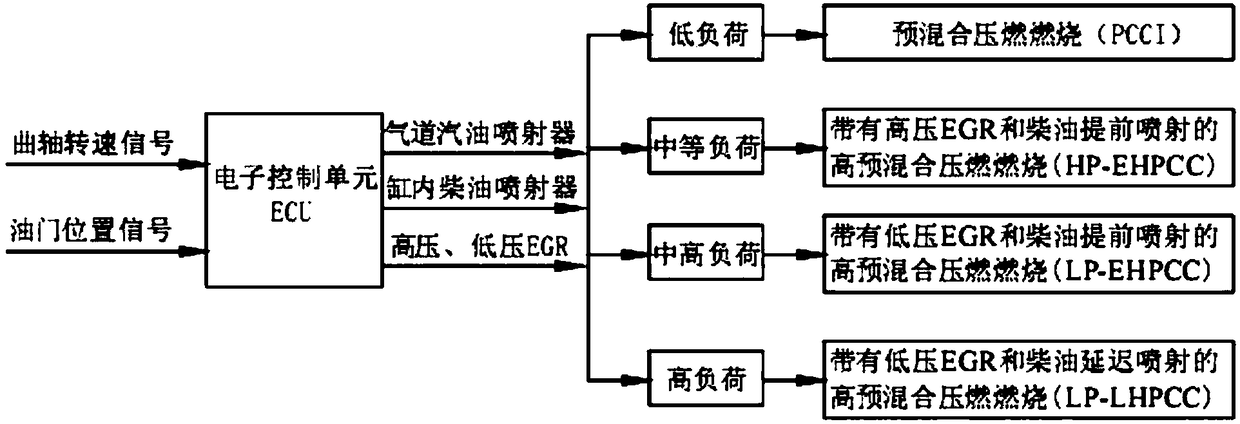

Method for flexibly controlling engine combustion mode

ActiveCN106762294AImprove consumption rateEnsure normal dischargeFuel injection apparatusMachines/enginesCombustionLow load

The invention discloses a method for flexibly controlling an engine combustion mode. Engine speed signals and throttle position signals are read by an electronic control unit to judge the engine operation load according to the read signals; if under the low load condition, an diesel injector is controlled for early injection to form PCCI combustion mode in a cylinder; if under the moderate load condition, the diesel injector is controlled for injection in advance twice, and high-pressure EGR is performed to form HP-EHPCC combustion mode; if under the medium-to-high load condition, the diesel injector is controlled for injection in advance twice, and low-pressure EGR is performed to form LP-EHPCC combustion mode; if under the high load condition, the diesel injector is controlled for delayed injection once, and the low-pressure EGR is performed to form LP-LHPCC combustion mode. High-efficiency clean combustion within a wide load range is implemented through combination of different combustion modes under different working conditions.

Owner:TIANJIN UNIV

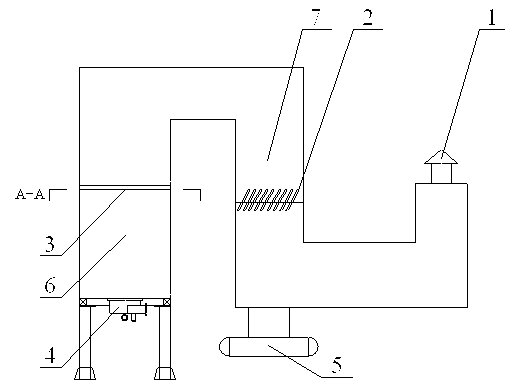

Chemical waste gas boiler furnace for combustion

The invention discloses a chemical waste gas boiler furnace for combustion. The boiler furnace comprises a chimney, an inclined louver, a crossed air distributing pipe, a combustion device, a drain device, a combustion chamber, a fume passage, a first fan and a second fan, wherein the boiler furnace body forms an N shape, the combustion device is positioned at the lower end part of one end of the N-shaped boiler furnace body, the combustion chamber is arranged above one end of the N-shaped boiler furnace body, the upper end of the combustion chamber is connected with the fume passage, the middle part of the boiler combustion chamber is provided with the crossed air distributing pipe, the crossed air distributing pipe is uniformly provided with a plurality of air distributing holes from top to bottom, the end part of the crossed air distributing pipe is respectively connected with the first fan and the second fan, the part of the fume passage on a second curved passage of the N-shaped boiler furnace body, corresponding to the combustion chamber, is provided with the inclined louver, the outer side of the bottom of the lower part of the inclined louver is provided with the drain device, and the upper end part of the other end of the N-shaped boiler furnace body is provided with the chimney. The boiler furnace has the advantage that the boiler body structure is vertically arranged, so the occurrence of aggregating and detonation of residual hydrogen and backfire is avoided, and the safe and reliable running of the device is ensured.

Owner:ZHEJIANG TUFF BOILER

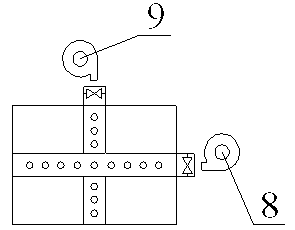

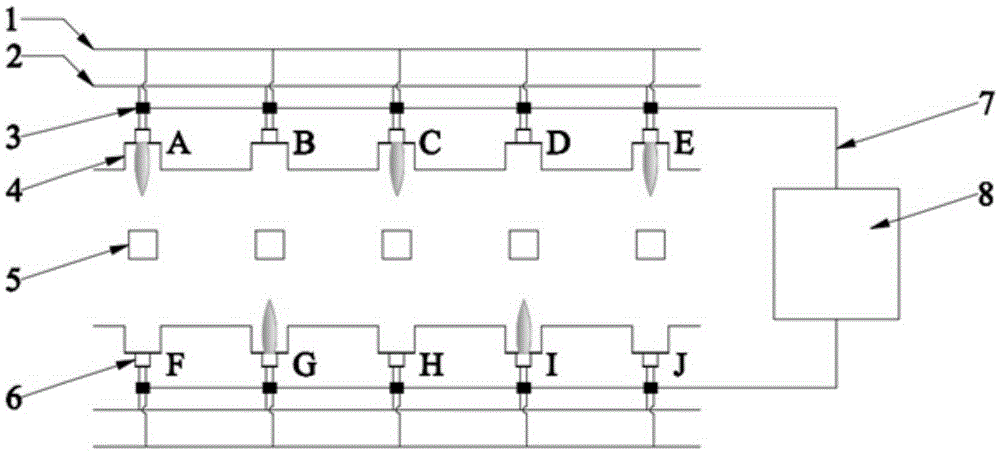

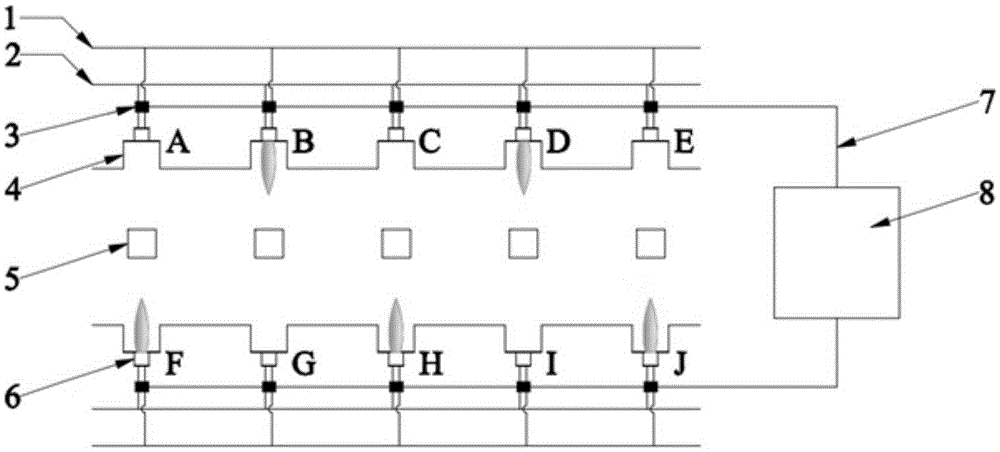

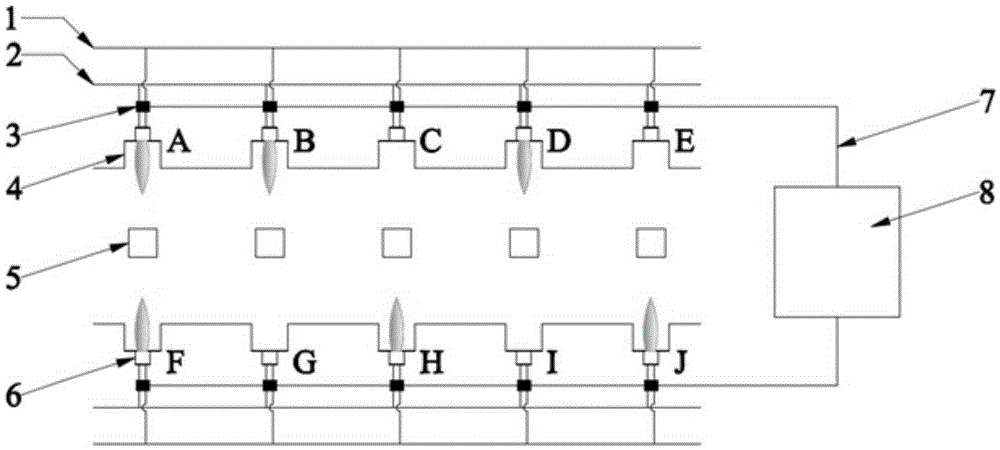

Tunnel kiln and combustion control method thereof

The invention discloses a tunnel kiln. The tunnel kiln comprises combustion chambers, a plurality of opening and closing control switches and controllers, wherein the combustion chambers are arranged at the two sides of the kiln wall of a firing section along the kiln length direction; burners are arranged in the combustion chambers and are used for burning to generate flames so as to heat green bodies in the kiln body of the firing section; the plurality of opening and closing control switches are respectively arranged on pipelines of communicating the burners and gas inlet pipelines in a one-to-one correspondence manner and are used for opening and closing fuels entering the burners, thereby controlling the combustion states of the burners; and the controllers are respectively and electrically connected to the opening and closing control switches, are used for controlling the opening and closing control switches, and further realize the control or adjustment of the combustion states of the burners, so that the combustion states of the burners in the combustion chambers can be variously combined, thereby realizing the uniform distribution of temperature in the kiln. The invention also discloses a combustion control method of the corresponding tunnel kiln. The tunnel kiln and the combustion control method thereof have the beneficial effects that the temperature distribution in the whole combustion section can be evenly adjusted, radiation and convection heat transfer effects are improved, the quality of products is effectively improved, a firing period is shortened, and the energy consumption is reduced.

Owner:南京安唯节能新技术有限公司

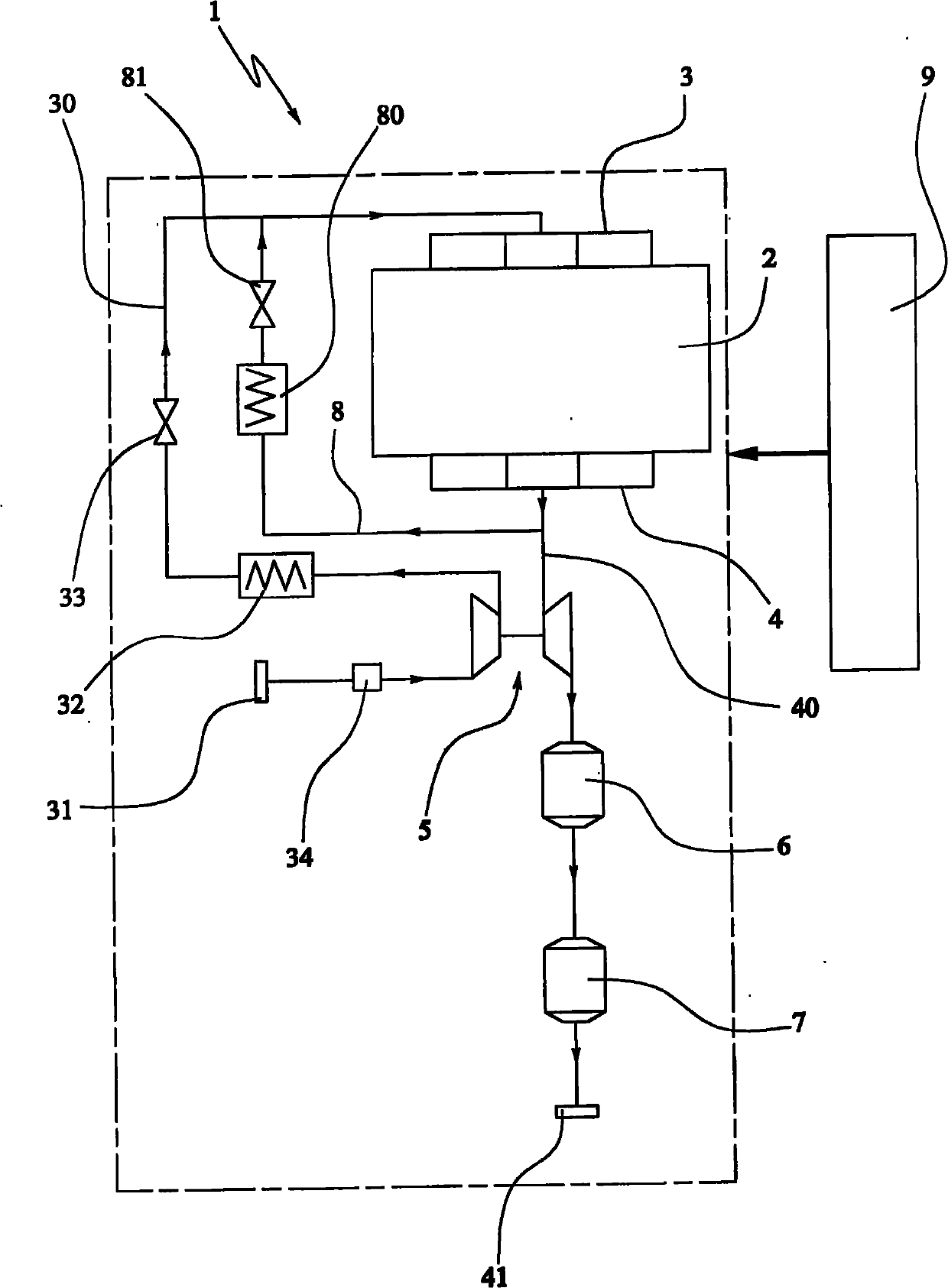

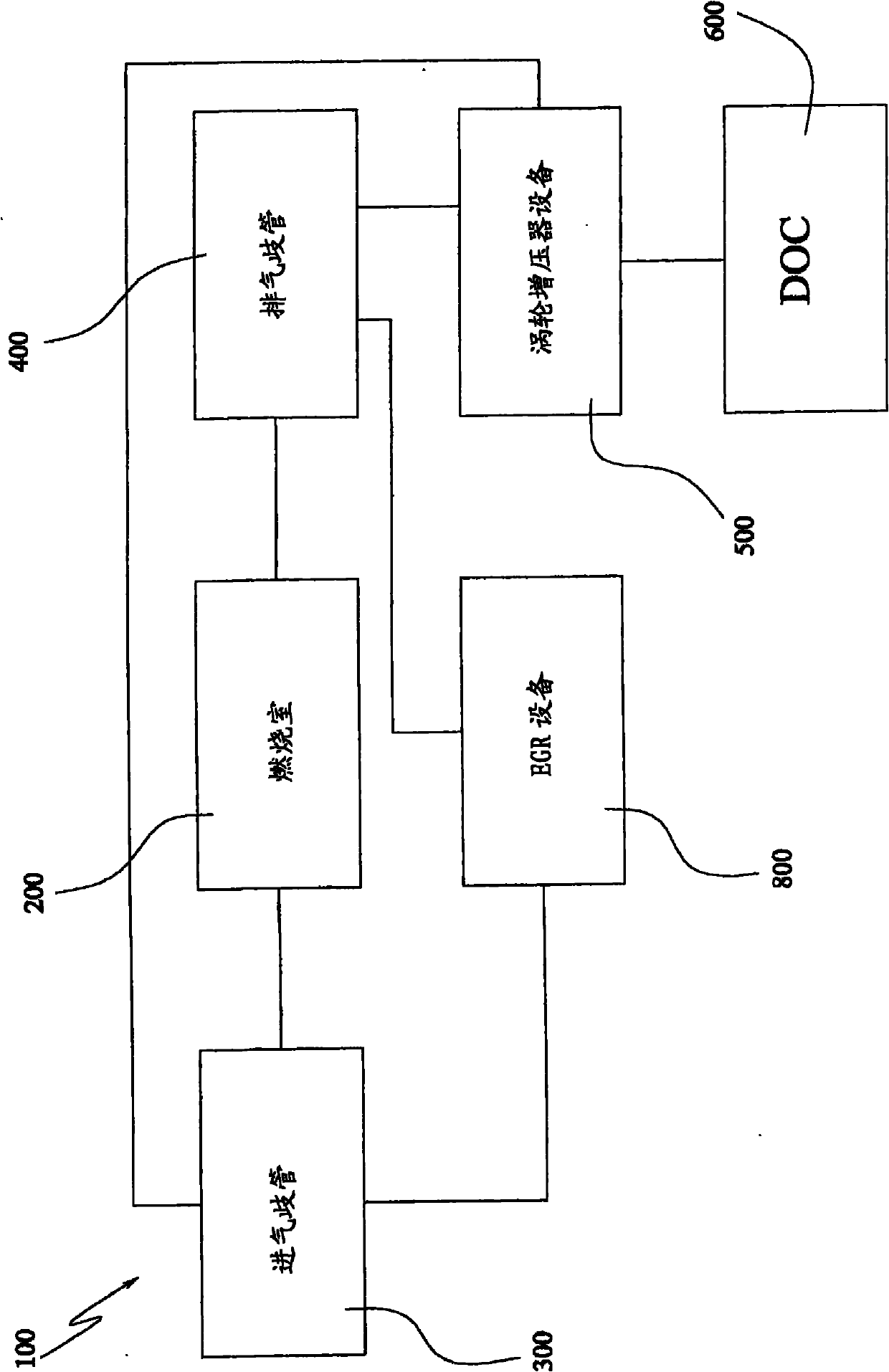

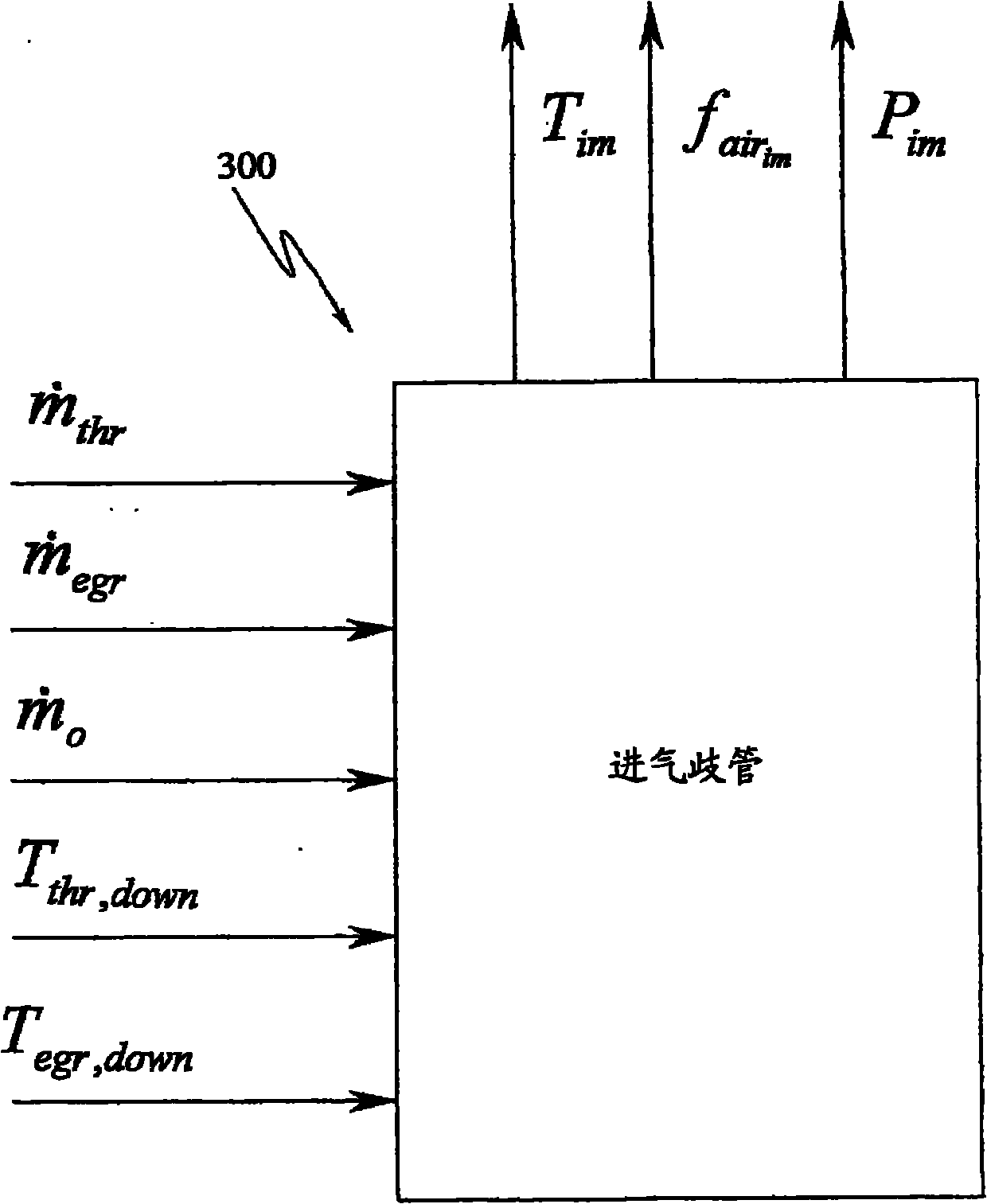

Method for estimating oxygen concentration downstream of diesel oxidation catalyst

InactiveCN101995370AControlled combustionElectrical controlInternal combustion piston enginesDiesel particulate filterFuel mass fraction

A method is disclosed for estimating oxygen concentration downstream of a diesel oxidation catalyst (COC) 6 within a diesel engine system 1 having an intake manifold 3, a combustion chamber and an exhaust manifold 4, the diesel oxidation catalyst 6 being located in the exhaust line upstream of a diesel particulate filter (DPF) 7. The method comprises determining unburned fuel mass flow ejected from the combustion chamber, determining air mass fraction in the exhaust manifold 4, estimating air mass fraction downstream the diesel oxidation catalyst 6 as a function of the unburned fuel mass flow and the air mass fraction in the exhaust manifold 4, and estimating oxygen concentration downstream the diesel oxidation catalyst 6 as a function of the estimated air mass fraction downstream the diesel oxidation catalyst 6.

Owner:GM GLOBAL TECH OPERATIONS LLC

Slag sensible heat recycling system for air-cooling dry slag machine

ActiveCN107741021AAvoid influenceImprove efficiencyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

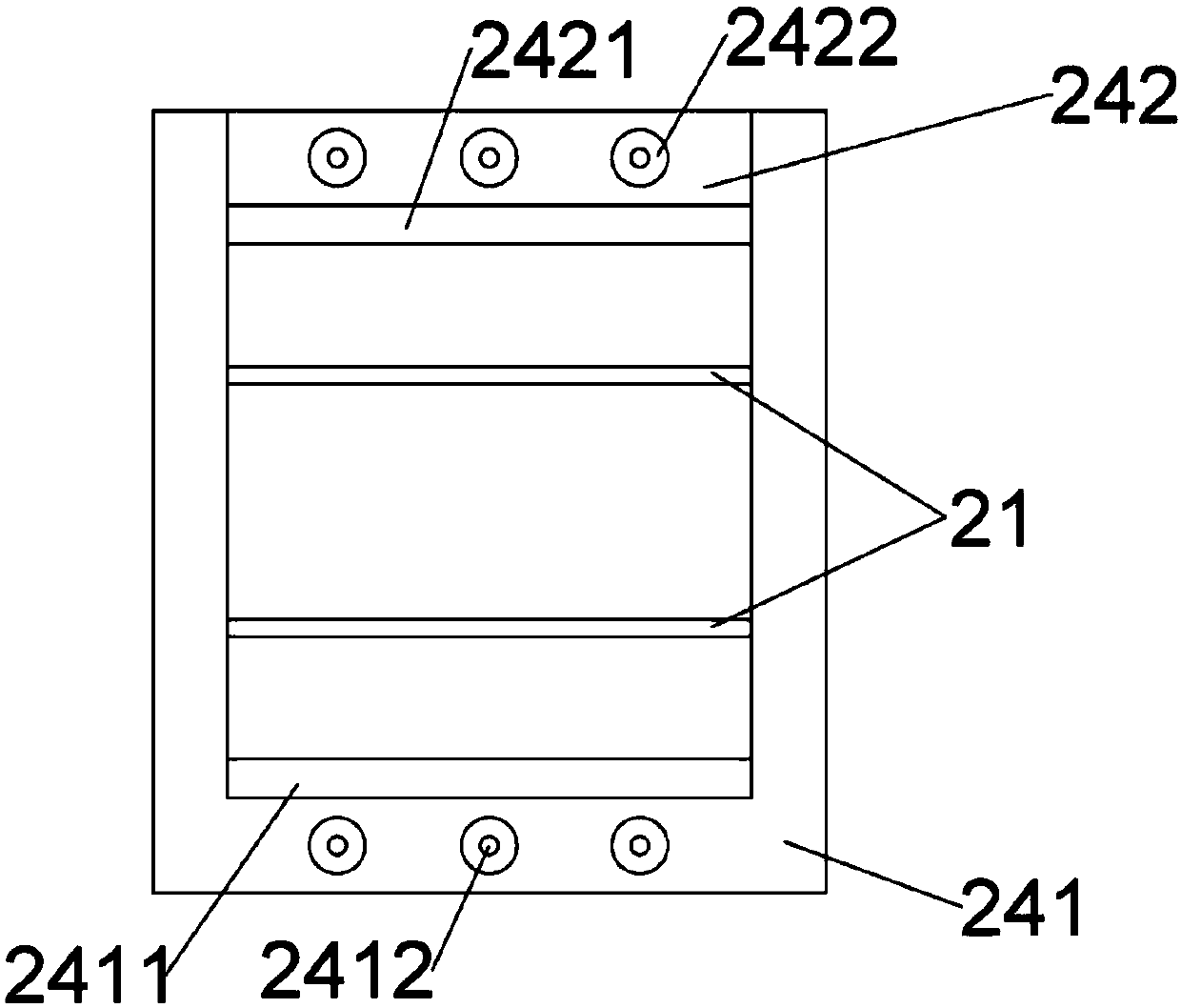

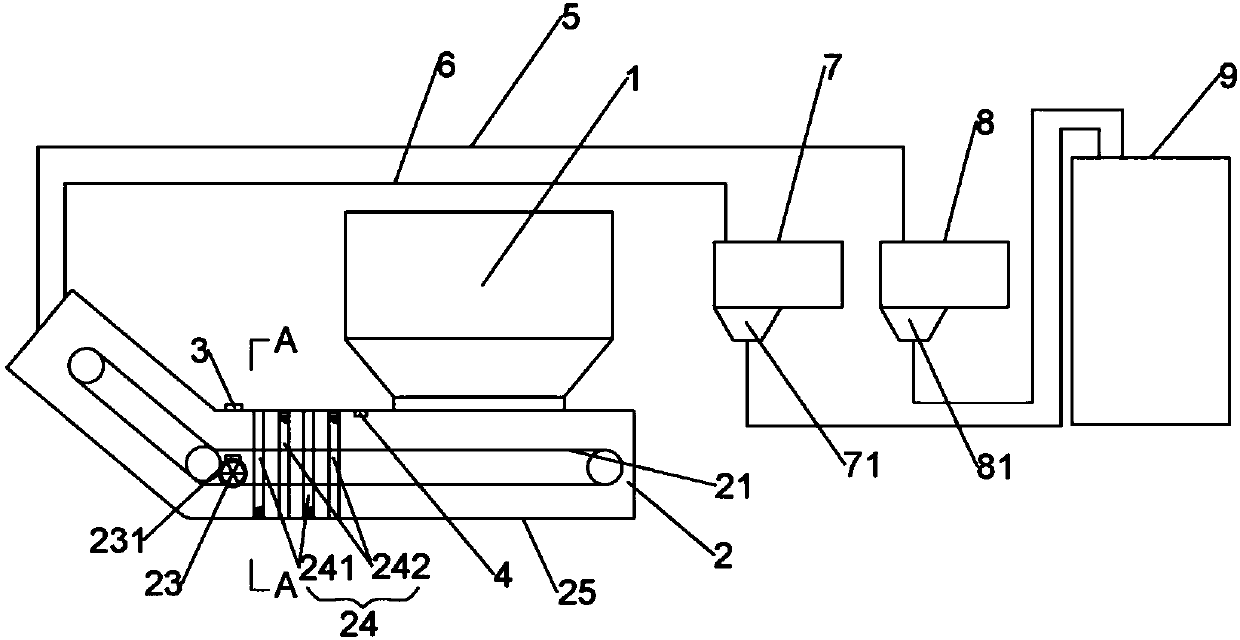

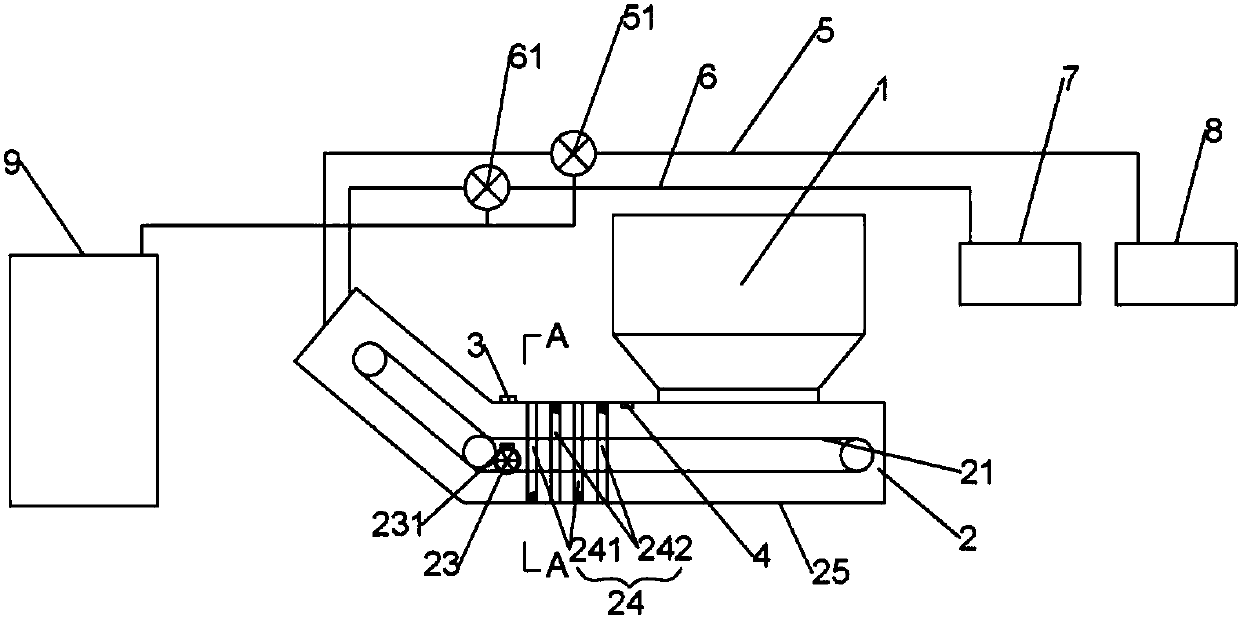

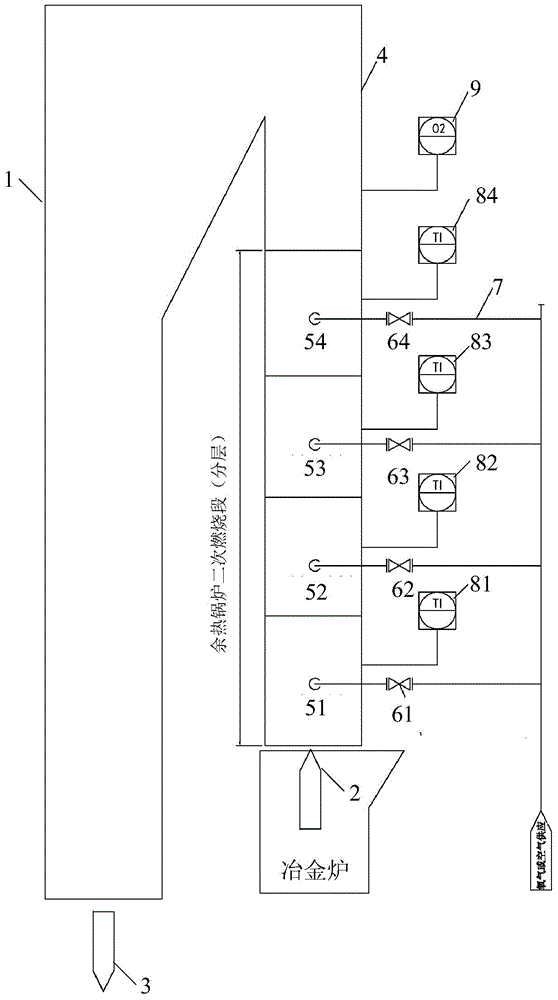

Exhaust-heat boiler

ActiveCN104456497AReduce the degree of high temperature corrosionExtended service lifeAir supply regulationIncreasing energy efficiencyInlet valveEngineering

The invention discloses an exhaust-heat boiler. The exhaust-heat boiler comprises a furnace body, a flue gas inlet, an flue gas outlet, a water-cooling wall arranged in the furnace body, a plurality of nozzles of air supply which are arranged in different height to achieve stratified combustion in the furnace body, a plurality of air inlet valves connected with a plurality of the nozzles of air supply, an air inlet pipeline which is connected with the air inlet valves, a plurality of temperature sensors which are arranged in the furnace body and used for detecting flue gas temperature, an oxygen sensor which is arranged in the furnace body and used for detecting oxygen concentration in the furnace body, and a controller which is used for controlling the air inlet valves according to the flue gas temperature and the oxygen concentration. The exhaust-heat boiler controls the air inlet valves according to the flue gas temperature and the oxygen concentration, thereby achieving secondary combustion of organic matter in the flue gas and achieving control over secondary combustion temperature and deflagration of the organic matter. The exhaust-heat boiler is easy to operate, and the safety and the reliability of the exhaust-heat boiler can be guaranteed.

Owner:CHINA NERIN ENG

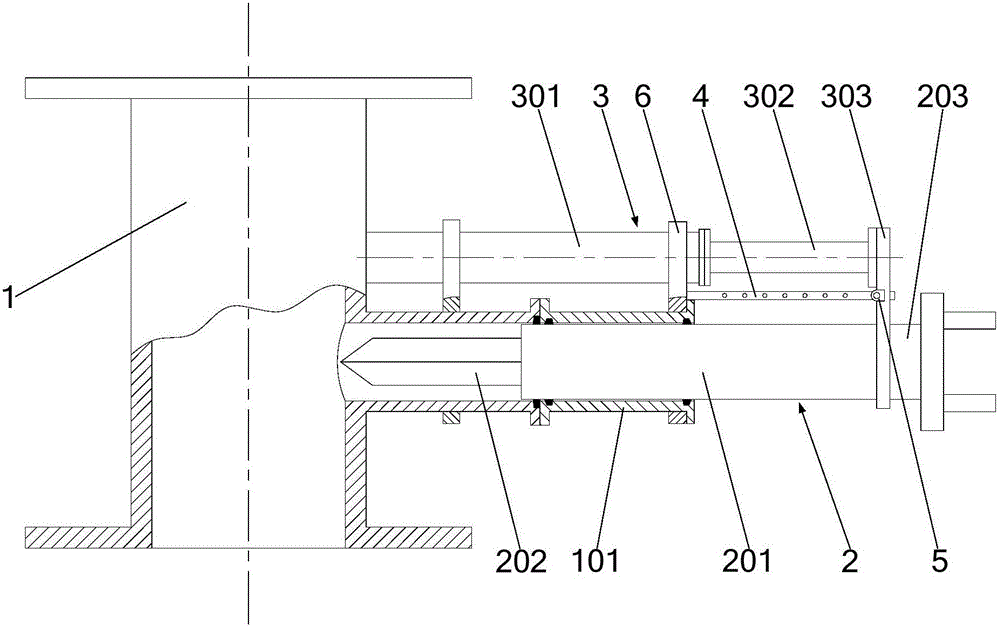

Device for measuring flow of pulverized coal conveyed by wind

PendingCN105865537AControlled combustionAccurate and timely combustionVolume/mass flow measurementVolume meteringCoal pipelineControl system

The invention provides a device for measuring flow of pulverized coal conveyed by wind. The device comprises a measuring pipe, a measuring instrument and a linear drive mechanism, wherein the measuring pipe is connected onto the pulverized coal conveying pipeline, and a measuring branch pipe communicated with measuring pipe is arranged on the measuring pipe; the measuring instrument is slidably assembled in the measuring branch pipe, and the inner end of the measuring instrument is a measuring end; the outer end of the measuring instrument is a signal output end, and the measuring end of the measuring instrument extends to the inner side of the measuring pipe; the linear drive mechanism is fixedly arranged at the outer side of the measuring branch pipe, and the drive end of the linear drive mechanism is connected with the measuring instrument. The device for measuring the flow of pulverized coal conveyed by wind provided by the invention has the advantages that the sampling measurement positions of the measuring instrument are automatically changed under the control of a control system without manual adjustment, so that a large number of manpower is saved, and the multi-position sampling measurement can be simultaneously carried out on the devices for measuring the flow of pulverized coal conveyed by wind on all pulverized coal pipelines, and thus the burning of each pulverized coal furnaces can be precisely and timely controlled.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

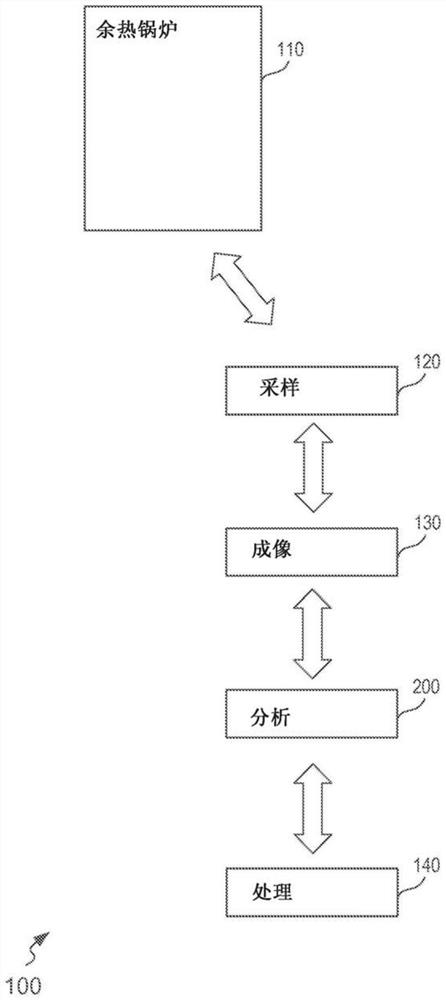

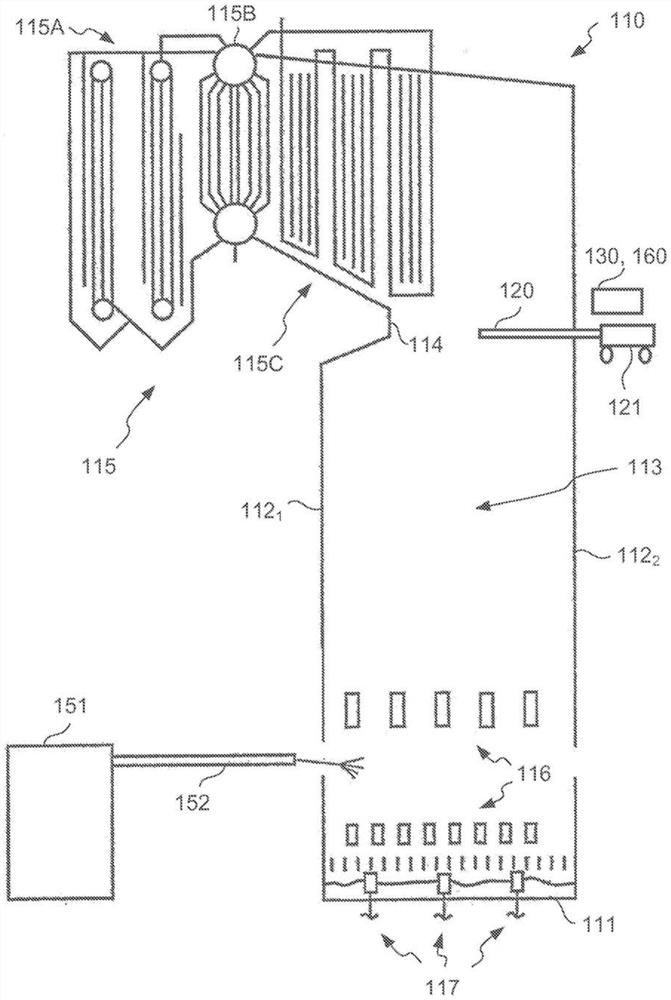

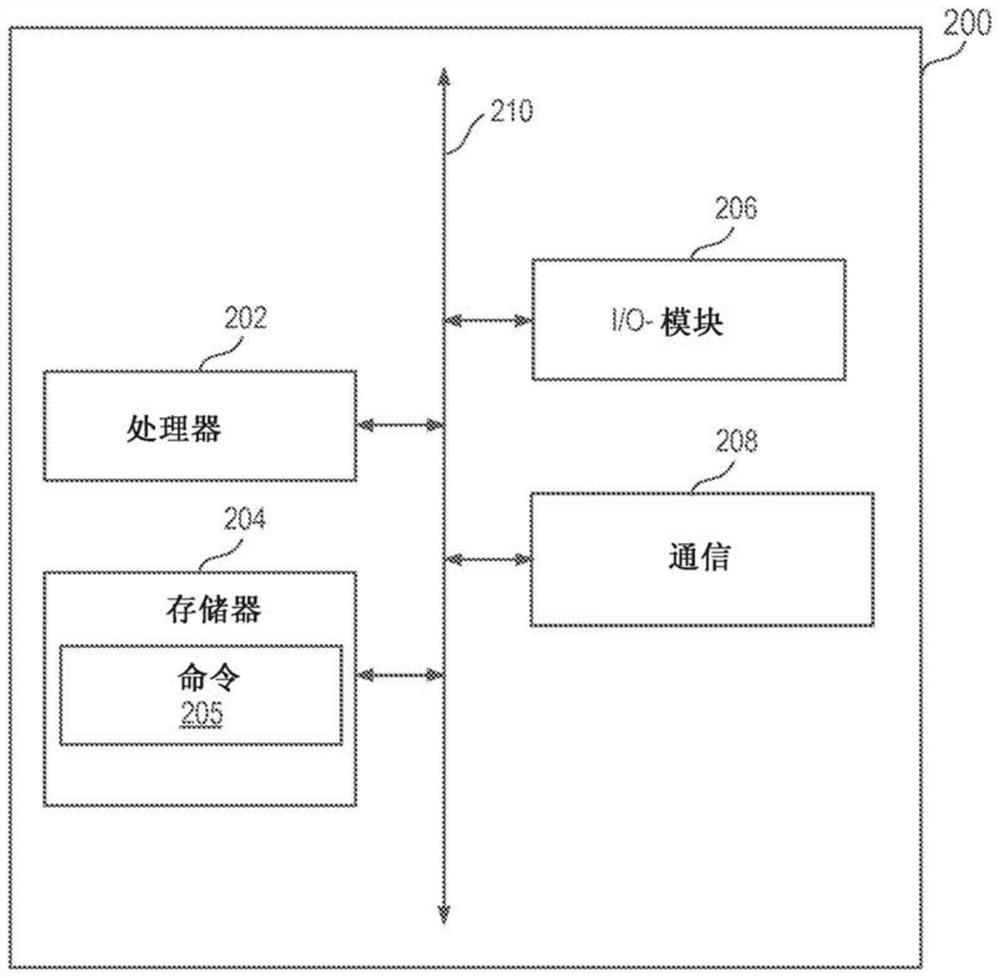

Determining one or more proportional particle group shares in flue gas of a recovery boiler

PendingCN114008679APromote combustionControl cleaningPulp liquors combustionImage analysisThermodynamicsFlue gas

The invention enables determining one or more proportional particle group shares in flue gas of a recovery boiler (110) based on optical information gained from a flue gas sample. A processor (202) is used to read (301) a digital frame comprising the area under consideration, which represents at least a part of the surface of a sampler (120) kept in the flue gas flow of a recovery boiler. Particle group areas matching a colour characteristic of the particle group comprised in the flue gas is determined (302) from the area under consideration. The joint area of the identified particle group areas is determined (304), and the share of the joint area from the total area is determined (305) as the proportional particle group share of the particle group.

Owner:ANDRITZ AG

Gas sensor and method for manufacturing the same

ActiveCN100520391CInhibition of volume expansionPrevent peelingMaterial electrochemical variablesOxygen ionsProtection layer

A gas sensor including a gas sensor element including: a reference electrode; a solid electrolyte layer having oxygen ion conductivity; a detection electrode; and an electrode protection layer covering the detection electrode. The electrode protective layer is a porous body carrying a metal functioning as a catalyst, and includes: a detection electrode side portion having a charge ratio of the metal functioning as a catalyst of more than 0% and not more than 0.005% by weight; and the surface A side portion provided closer to the outer surface of the electrode protection layer than the detection electrode side portion, the surface side portion having a charge ratio of the metal functioning as a catalyst of 0.01% by weight or more.

Owner:NGK SPARK PLUG CO LTD

Internal combustion engine operated according to premixed charge compression ignition mode

InactiveCN1188589CControl control systemEffective controlElectrical controlInternal combustion piston enginesCombustion noiseEquivalence ratio

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low oxides of nitrogen emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

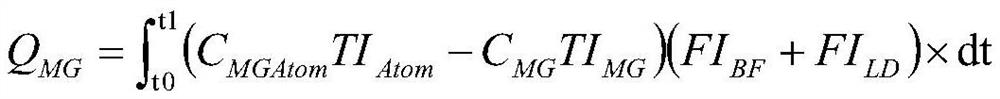

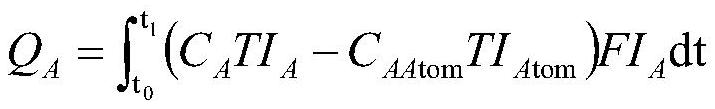

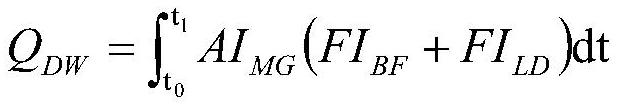

Burning control heat balance technology for large blast furnace hot blast stove

PendingCN112981018AReduce excess heat storageReduce heat lossBlast furnace detailsFlue gasHot air oven

The invention discloses a burning control heat balance technology of a large blast furnace hot blast stove. Gas for the blast furnace hot blast stove is formed by mixing pipe network blast furnace gas and converter gas, and calculation of large blast furnace hot blast stove burning control heat balance is carried out based on a heat balance formula: Q<MG>+Q+Q<DW>-Q<Fm>-Q<L>=Q<HB>-Q<CB>, in the formula, Q<MG> is physical sensible heat brought by the mixed gas; Q is physical sensible heat brought by combustion-supporting air; Q<DW> is chemical heat generated by combustion; Q<Fm> is physical sensible heat taken away by flue gas; Q<L> is comprehensive heat loss; Q<HB> is physical sensible heat taken away by hot air; and Q<CB> is heat brought by cold air. The real-time heat balance calculation based on the second level of a PLC layer is realized, and the coal gas amount required by stove burning can be calculated according to the target air temperature, so that the burning of the hot blast stove is controlled, and the heat balance of burning and air supply is realized. According to the technology, the amount of coal gas needed by combustion of the hot blast stove can be well controlled, the needed high air temperature can be stably sent out, excessive heat storage of the hot blast stove can be reduced, heat loss is reduced, energy consumption is reduced, and energy conservation and cost reduction are achieved.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

W-shape flame boiler for preventing side wall water cooling wall slagging scorification

ActiveCN101050854BAccelerated slagging problemReduce the temperatureSteam boilersCombustion chambersScarificationWing wall

A W type of flame boiler enabling to prevent water-cooled wall of wing walls from slagging scarification is prepared for setting four wall-wind fans separately on external sides of four wing walls andarranging ventilation gap on each of four wing walls.

Owner:HARBIN INST OF TECH

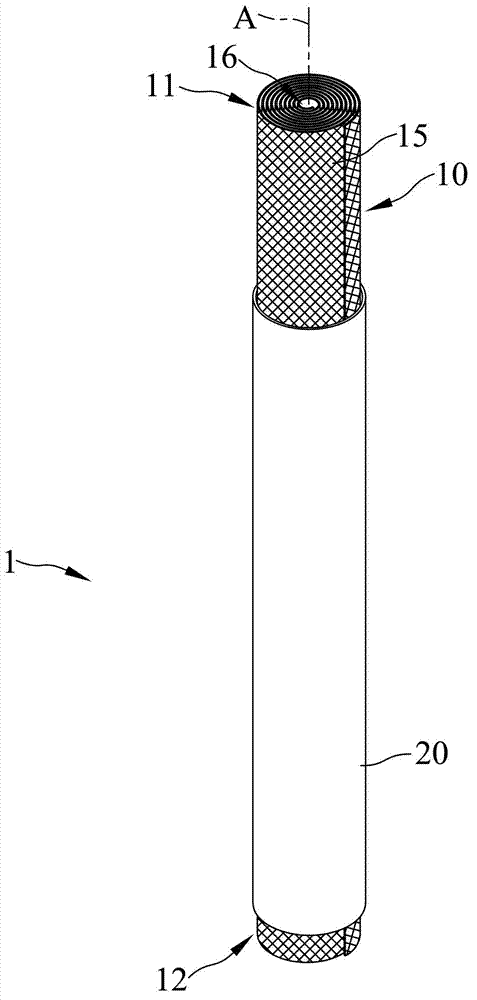

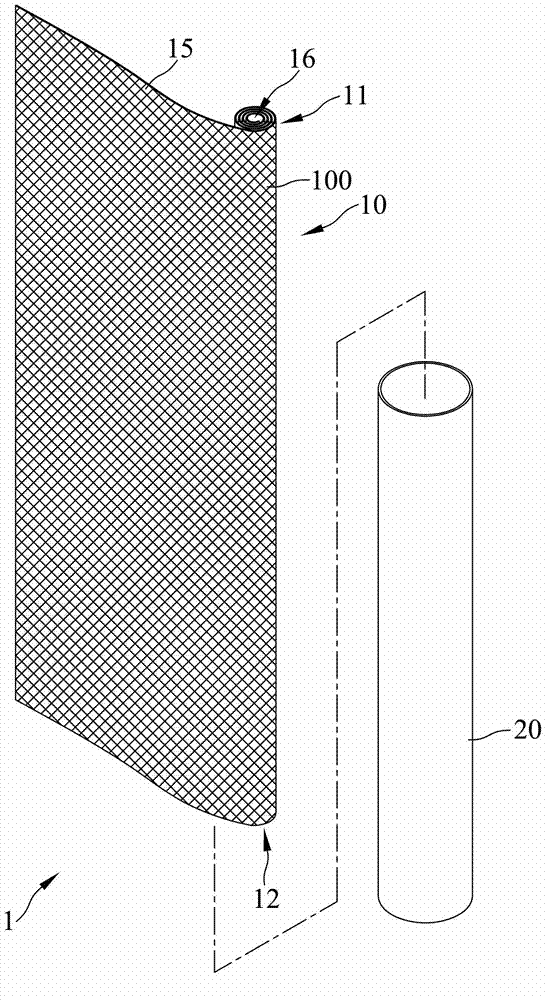

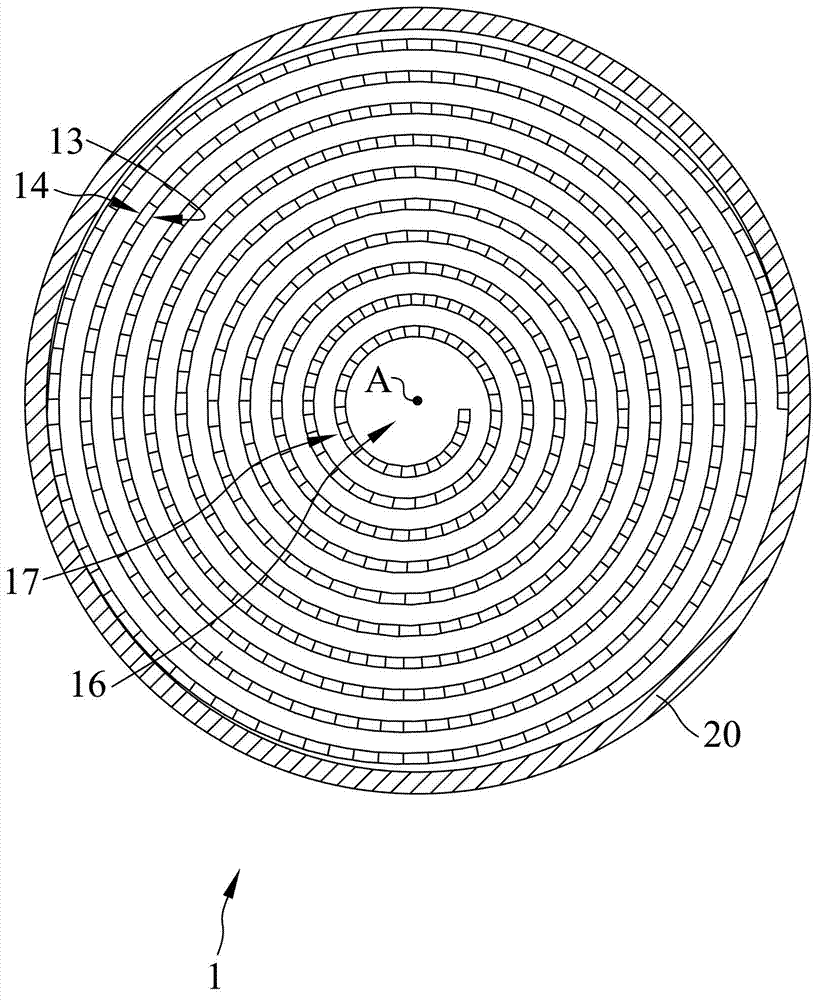

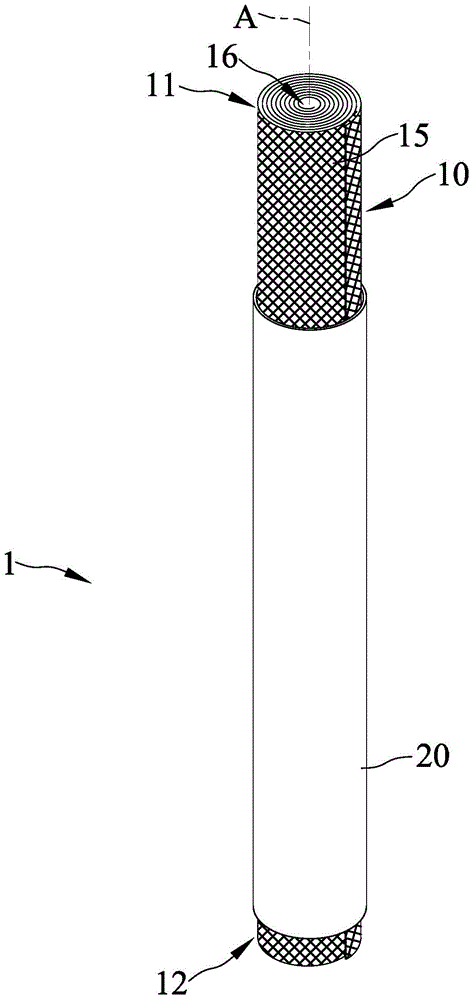

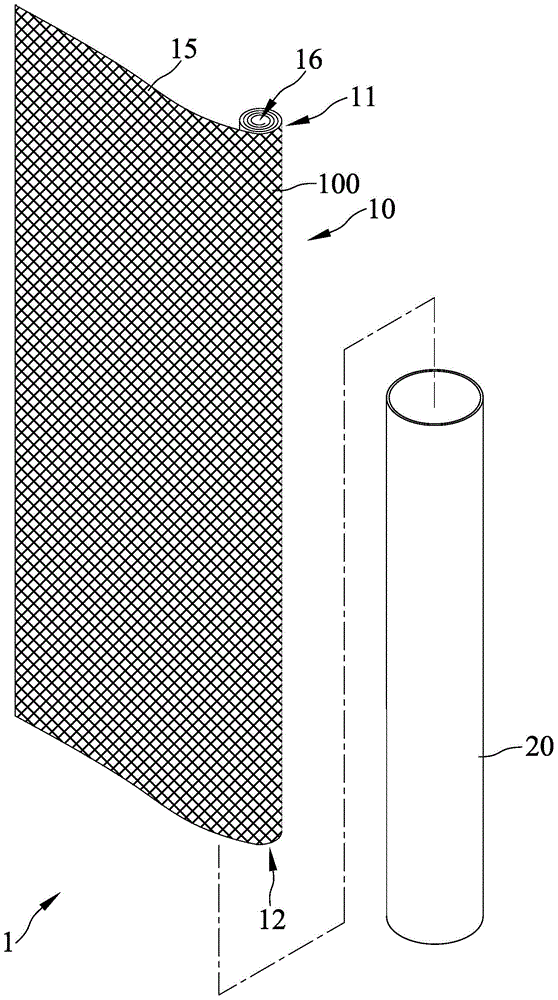

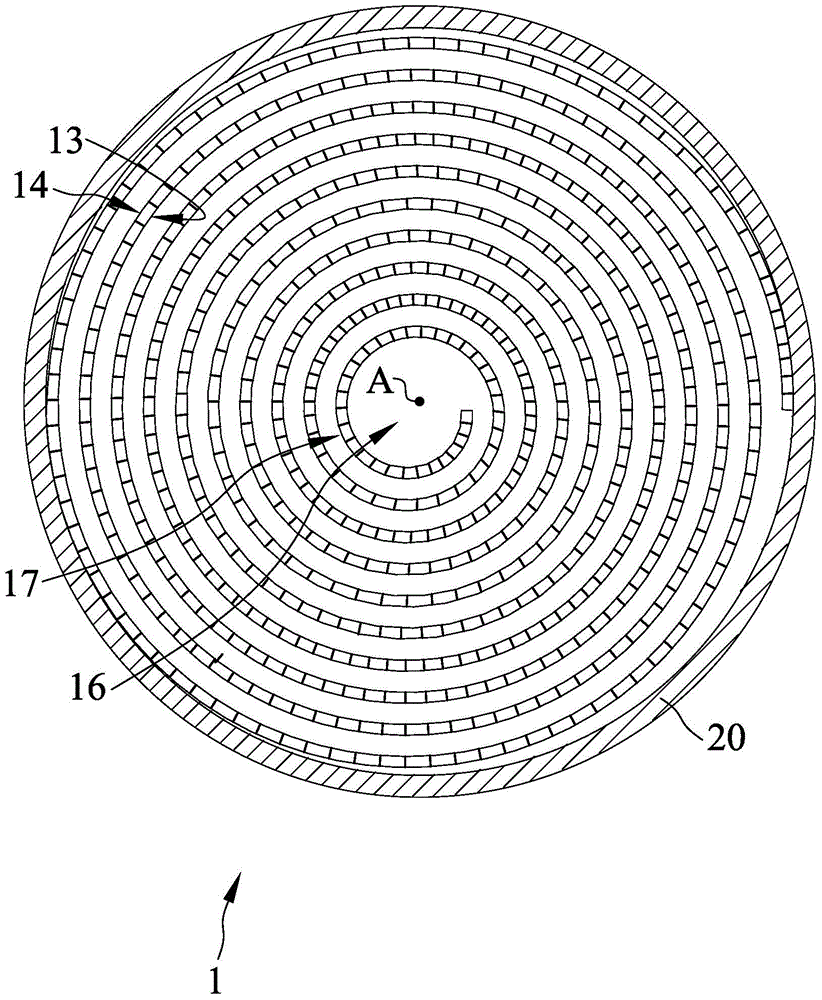

Lamp wick with flame size adjusting function

ActiveCN103712209AControlled combustionControl transfer capabilityCapillary burnersTransmission channelEngineering

The invention discloses a lamp wick with a flame size adjusting function. The lamp wick comprises a wick and a sleeve. Two opposite ends of the wick are respectively defined as a first end and a second end, the wick comprises at least one transmission channel and a plurality of grids, the first end is communicated with the second end via the transmission channels, flame can be ignited at the first end of the wick, and the tip of the first end of the wick is separated from the tip of the second end of the wick by a first length; the sleeve is hollow, is sleeved on the wick and has a second length axially, and the second length is smaller than the first length. The lamp wick has the advantages that sleeve can be repositioned relative to the wick, so that an exposed degree of the first end of the wick can be further controlled, and the size of the flame can be adjusted.

Owner:PRO IRODA INDS

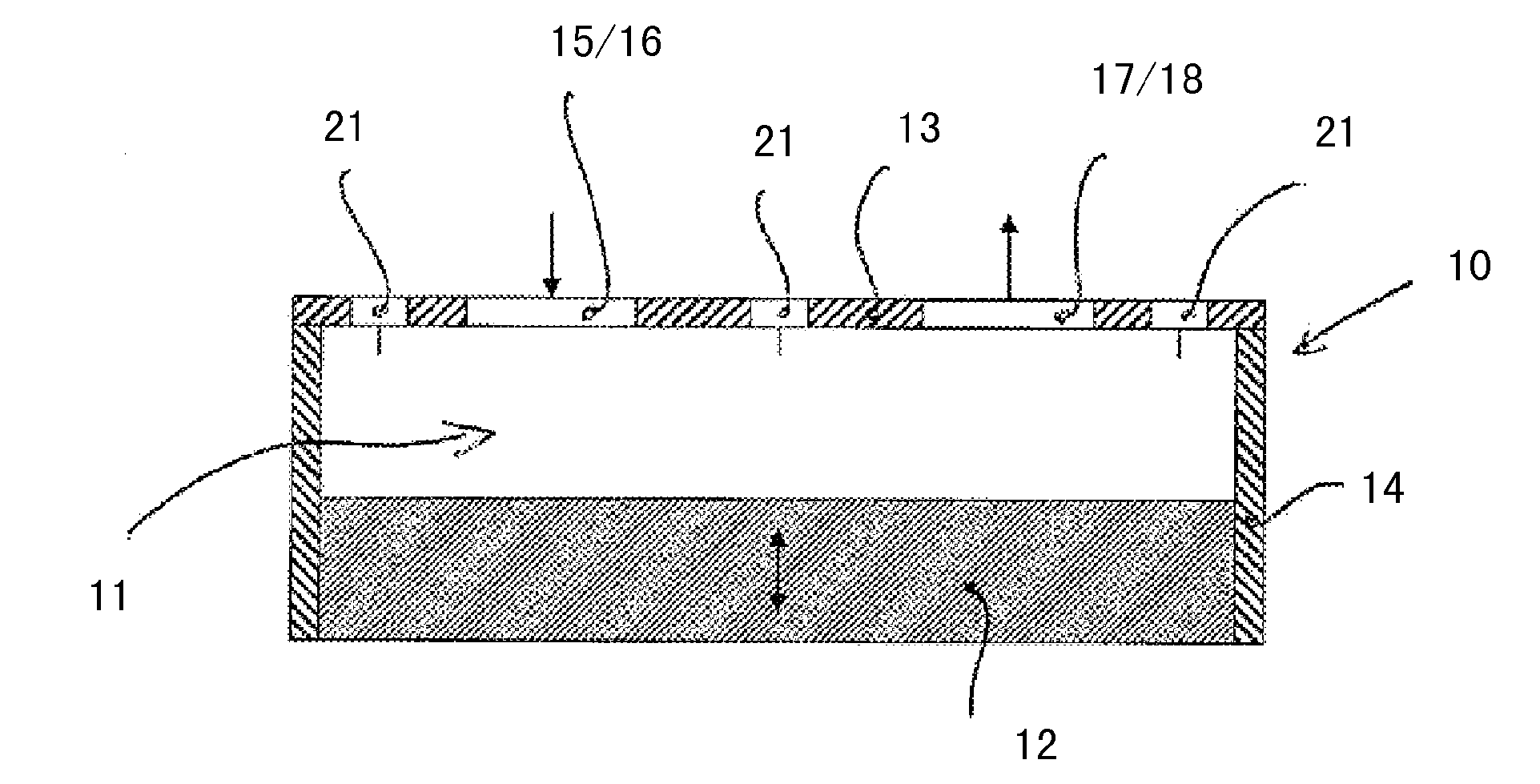

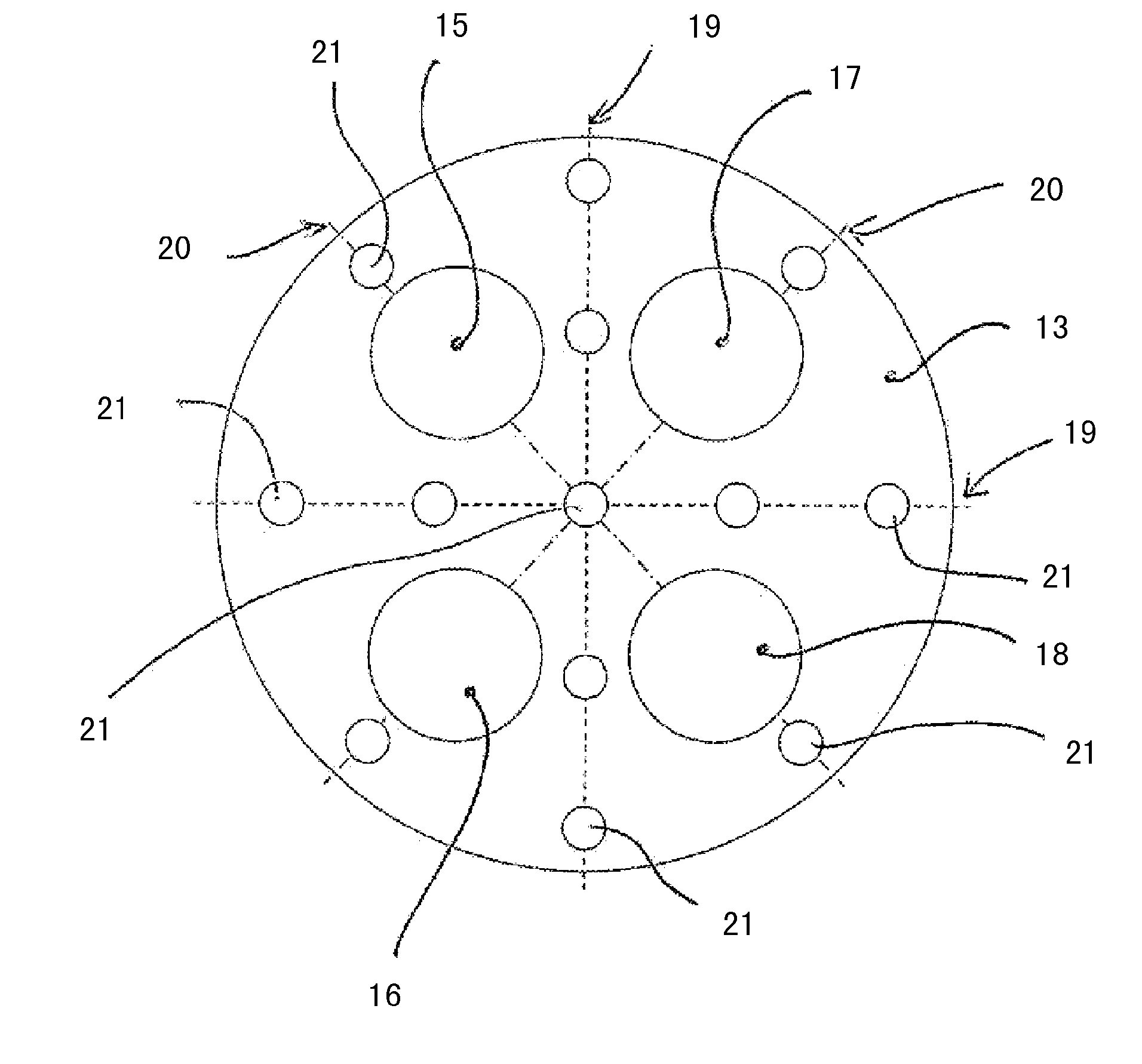

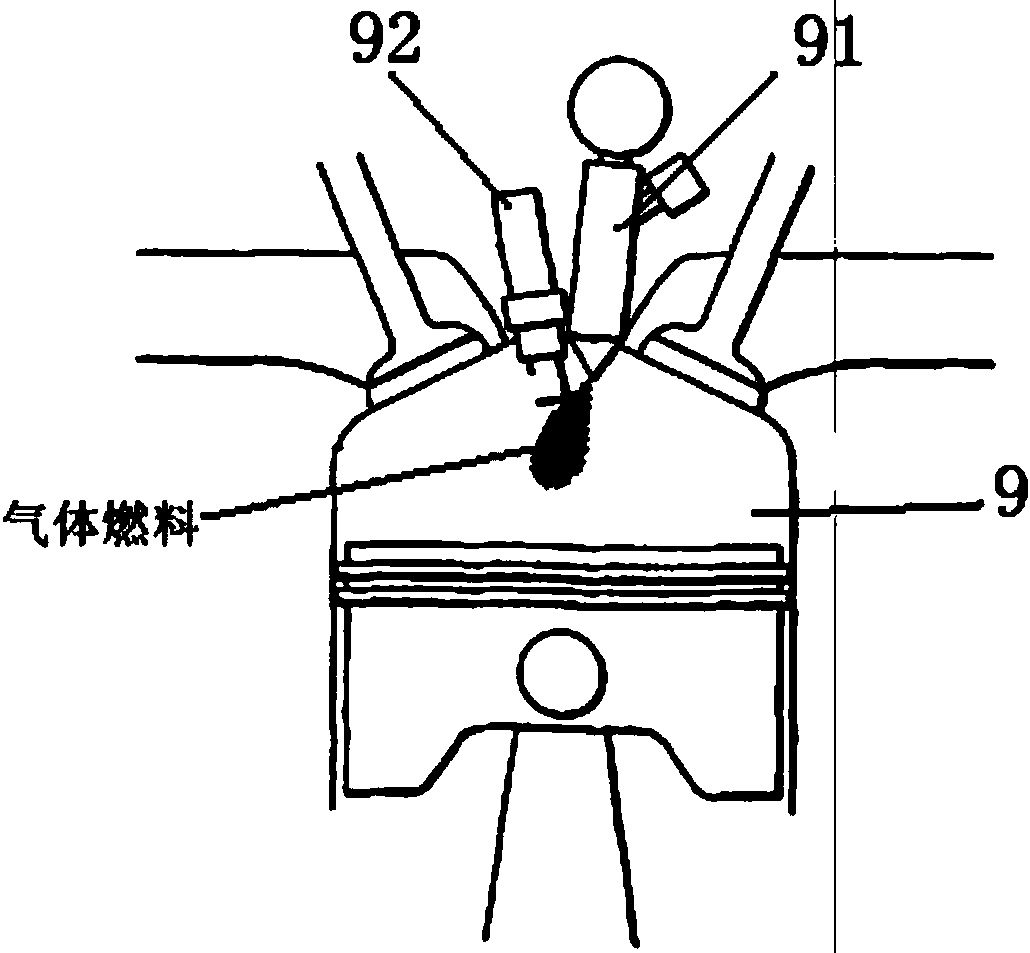

Internal combustion machine

InactiveCN103423014AGuaranteed uptimeBurn quicklyValve arrangementsElectrical controlCombustion chamberReciprocating motion

An internal combustion machine, i.e., a gasoline gas engine, which is used for burning fuel mixture consisting of gaseous fuel oil and air and relatively lack of oil, has at least one cylinder (10), wherein each cylinder (10) defines a combustion chamber (11) which is defined by a piston (12) of the cylinder at ones side of the combustion chamber, the piston being capable of supporting in a manner of reciprocating motion, and the combustion chamber is defined by a flame top cap (13) at an opposite side, wherein the flame top cap (13) is provided with at least one inlet air valve (15, 16) of the fuel mixture consisting of the gaseous fuel oil and air and at least one outlet air valve (17, 18) for exhaust gas, and a plurality of ignition mechanisms (21) are distributed on the flame top cap (13) which are used for directly igniting the fuel mixture in the combustion chamber (11) of a corresponding cylinder (10).

Owner:MAN DIESEL & TURBO SE

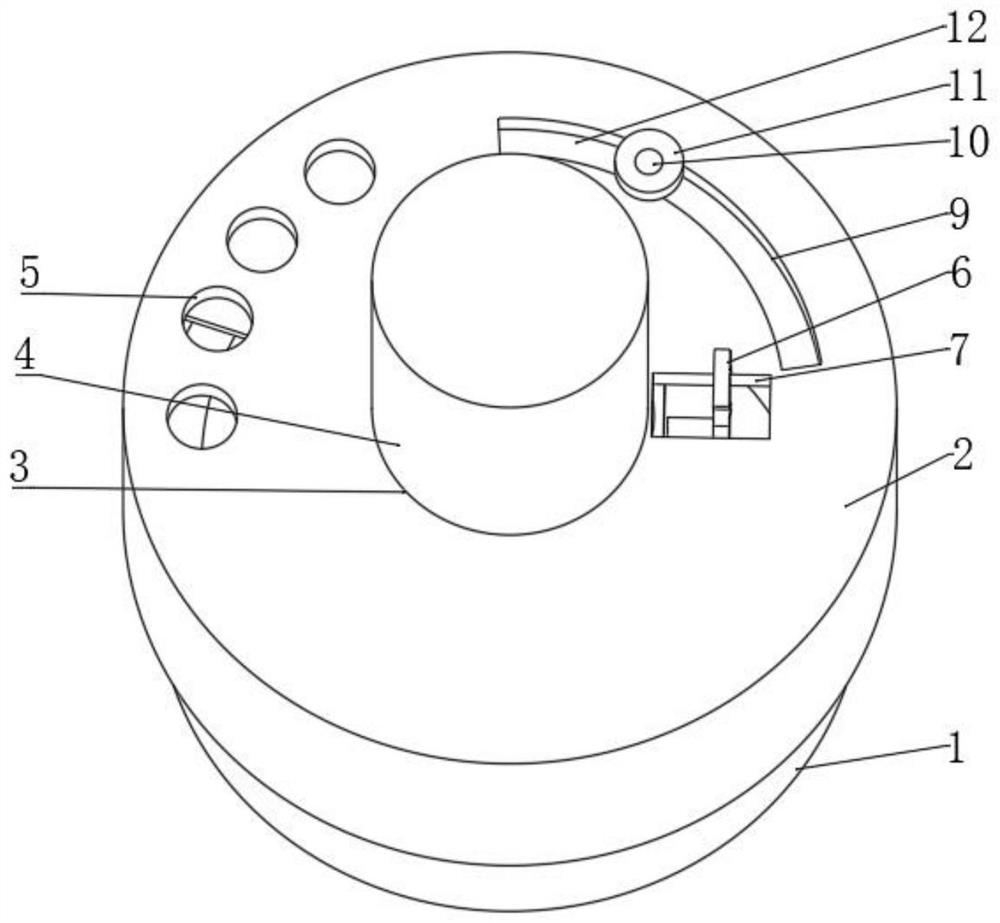

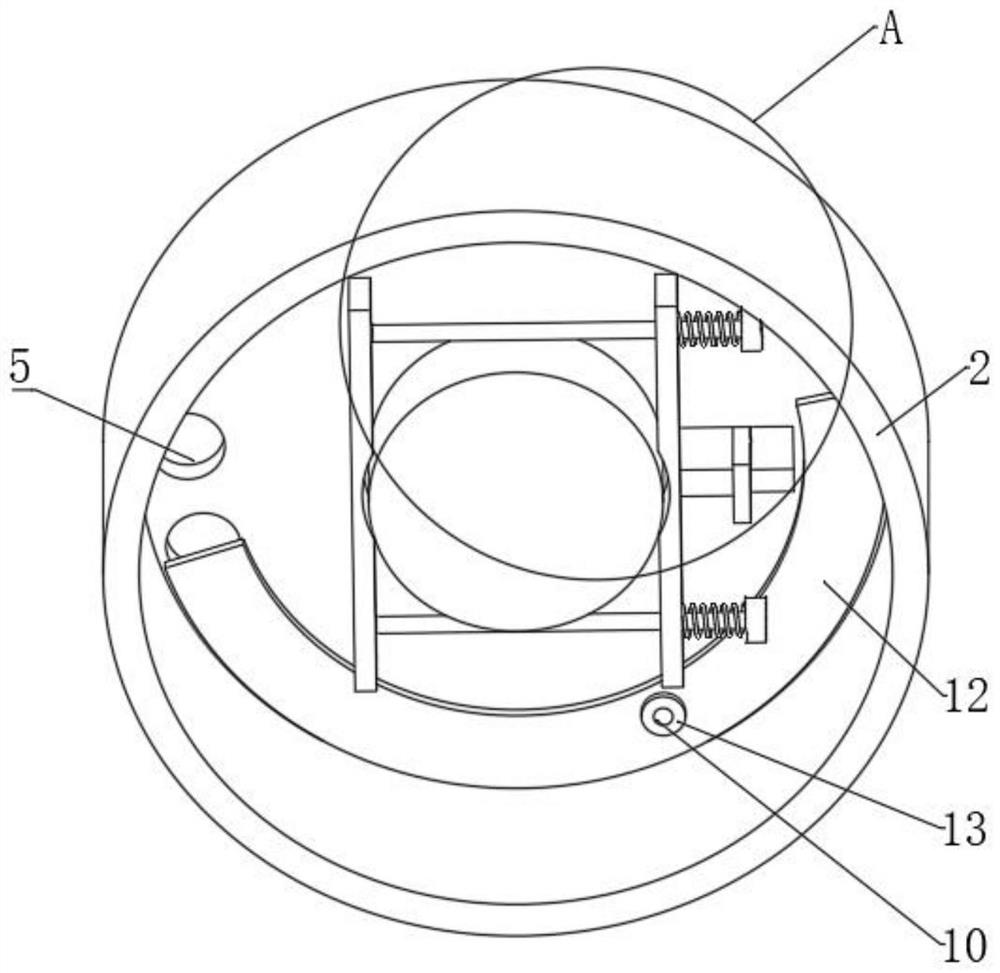

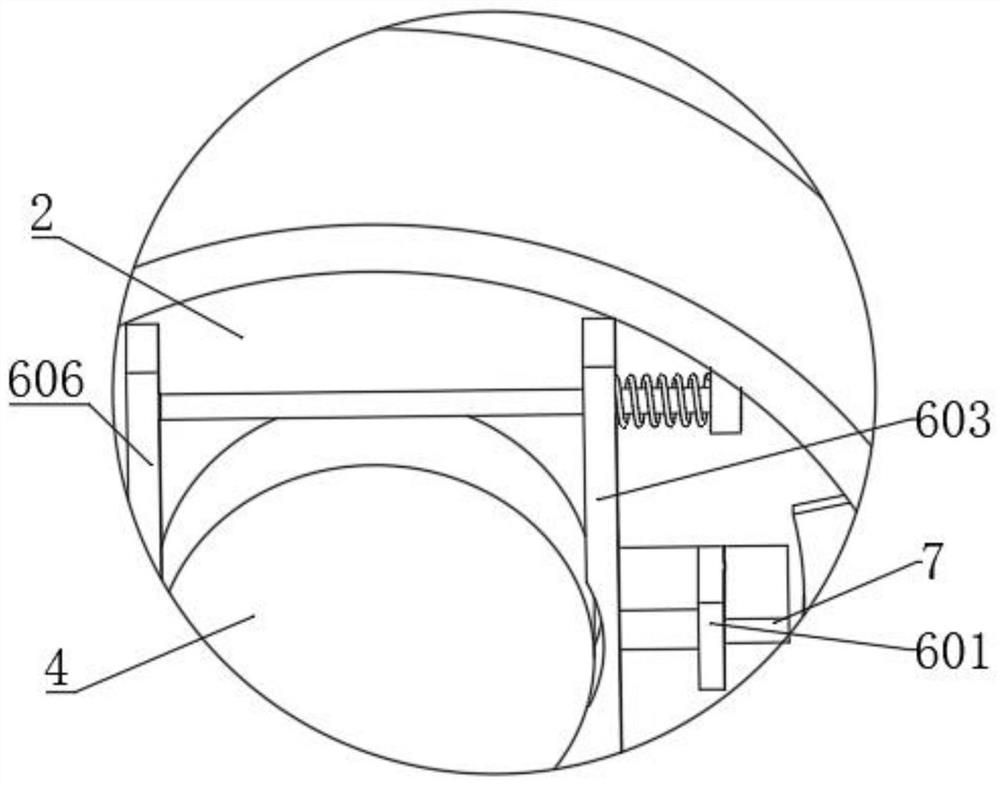

Moxibustion treatment device for internal medicine of traditional Chinese medicine

PendingCN114344148AControlled combustionChange sizeDevices for heating/cooling reflex pointsSurgeryMechanical engineering

The invention provides a moxibustion treatment device for internal medicine of traditional Chinese medicine, and relates to the technical field of moxibustion treatment.The moxibustion treatment device comprises a bottom box, a plurality of heat conduction holes are formed in the bottom wall of the bottom box, moxa cones penetrate into the connecting holes, and a fixing assembly is further arranged on the top wall of a box cover and comprises a second connecting plate and a first connecting plate; the second connecting plate and the first connecting plate are symmetrical about the center of the box cover, a connecting rod is fixedly installed on the surface of one end of the first connecting plate, and one end of the connecting rod is fixedly connected with the pulling plate. Through cooperation of a pulling plate and a spring, the distance between a first connecting plate and a second connecting plate can be changed, the effect of fixing moxa cones of most specifications is achieved, meanwhile, after the moxa cones are burnt, the distance between the bottoms and acupuncture points is increased, the pulling plate can be pulled, the first connecting plate does not abut against the moxa cones any more, and then the moxa cones can be moved downwards or upwards; the effect of changing the distance between the moxa cone and the acupoint is achieved, and the treatment effect is improved.

Owner:郏县中医院

A wick that can adjust the size of the flame

ActiveCN103712209BControlled combustionControl transfer capabilityCapillary burnersEngineeringCandle wick

The invention discloses a lamp wick with a flame size adjusting function. The lamp wick comprises a wick and a sleeve. Two opposite ends of the wick are respectively defined as a first end and a second end, the wick comprises at least one transmission channel and a plurality of grids, the first end is communicated with the second end via the transmission channels, flame can be ignited at the first end of the wick, and the tip of the first end of the wick is separated from the tip of the second end of the wick by a first length; the sleeve is hollow, is sleeved on the wick and has a second length axially, and the second length is smaller than the first length. The lamp wick has the advantages that sleeve can be repositioned relative to the wick, so that an exposed degree of the first end of the wick can be further controlled, and the size of the flame can be adjusted.

Owner:PRO IRODA INDS

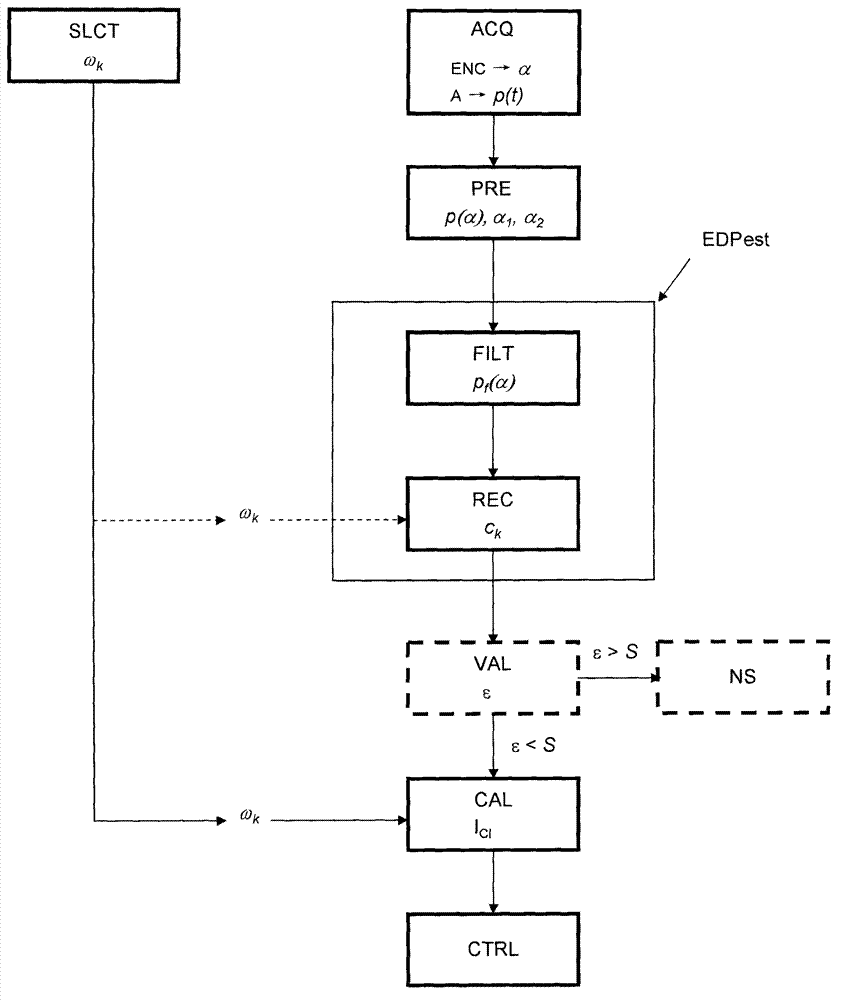

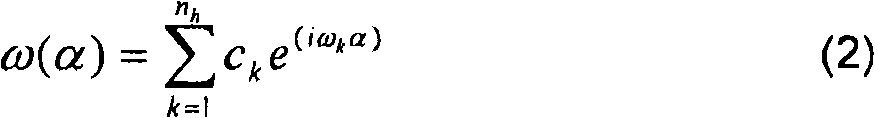

Method for estimating the pinking intensity of an internal combustion engine by inverting a wave equation

InactiveCN102808700AControlled combustionInternal-combustion engine testingInternal combustion piston enginesCombustionDecomposition

A method of real-time estimation of the intensity of the knocking of an internal combustion engine utilizing a vibratory sensor is disclosed which is useful for control of internal combustion. A vibratory signal representing vibrations of the engine is continuously acquired as a function of the crankshaft angle. A model of a wave equation propagating through the cylinder-head is constructed. The coefficients of a Fourier decomposition of the vibratory signal are determined in real time by inverting the dynamics of the wave equation model using an estimator. The energy contained in the signal is computed by summing the squares of the coefficients of the Fourier decomposition. A parameter correlated with the intensity of knocking equal to the square root of the maximum of the energy is determined in real time.

Owner:INST FR DU PETROLE

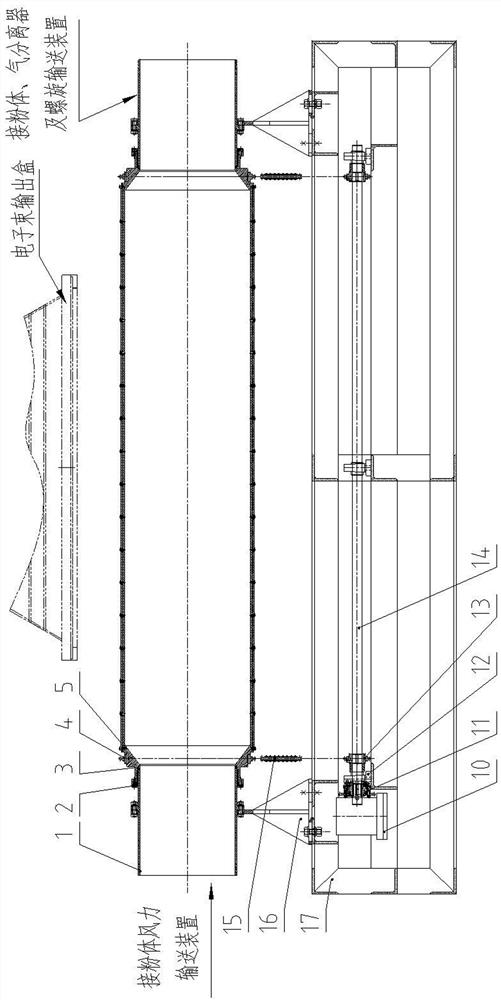

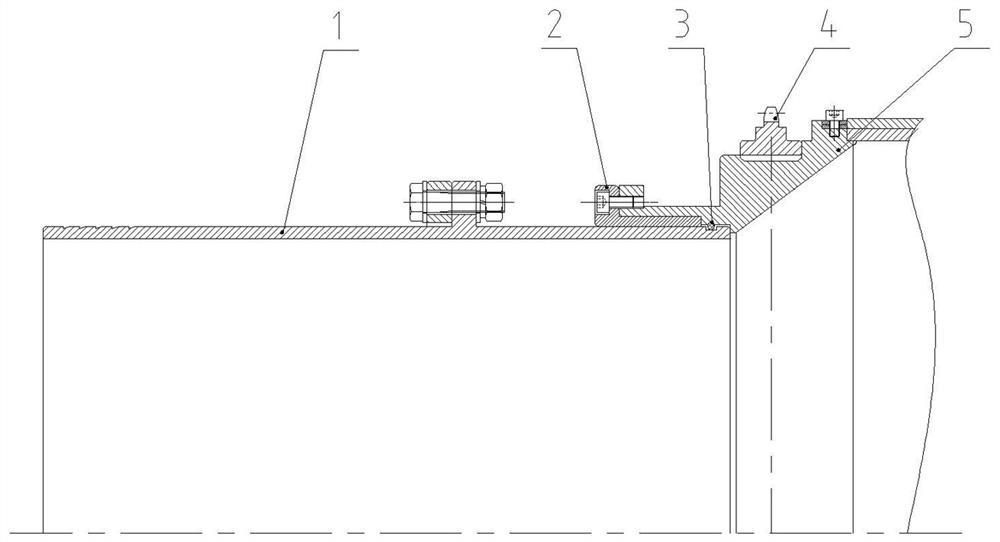

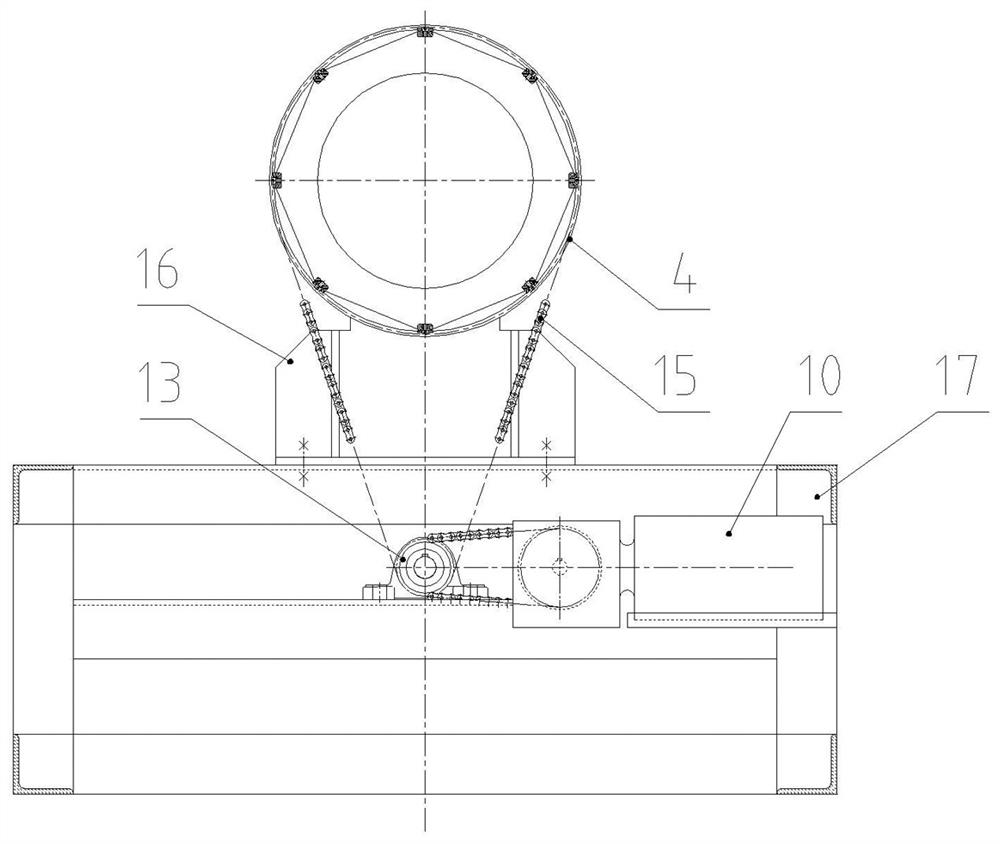

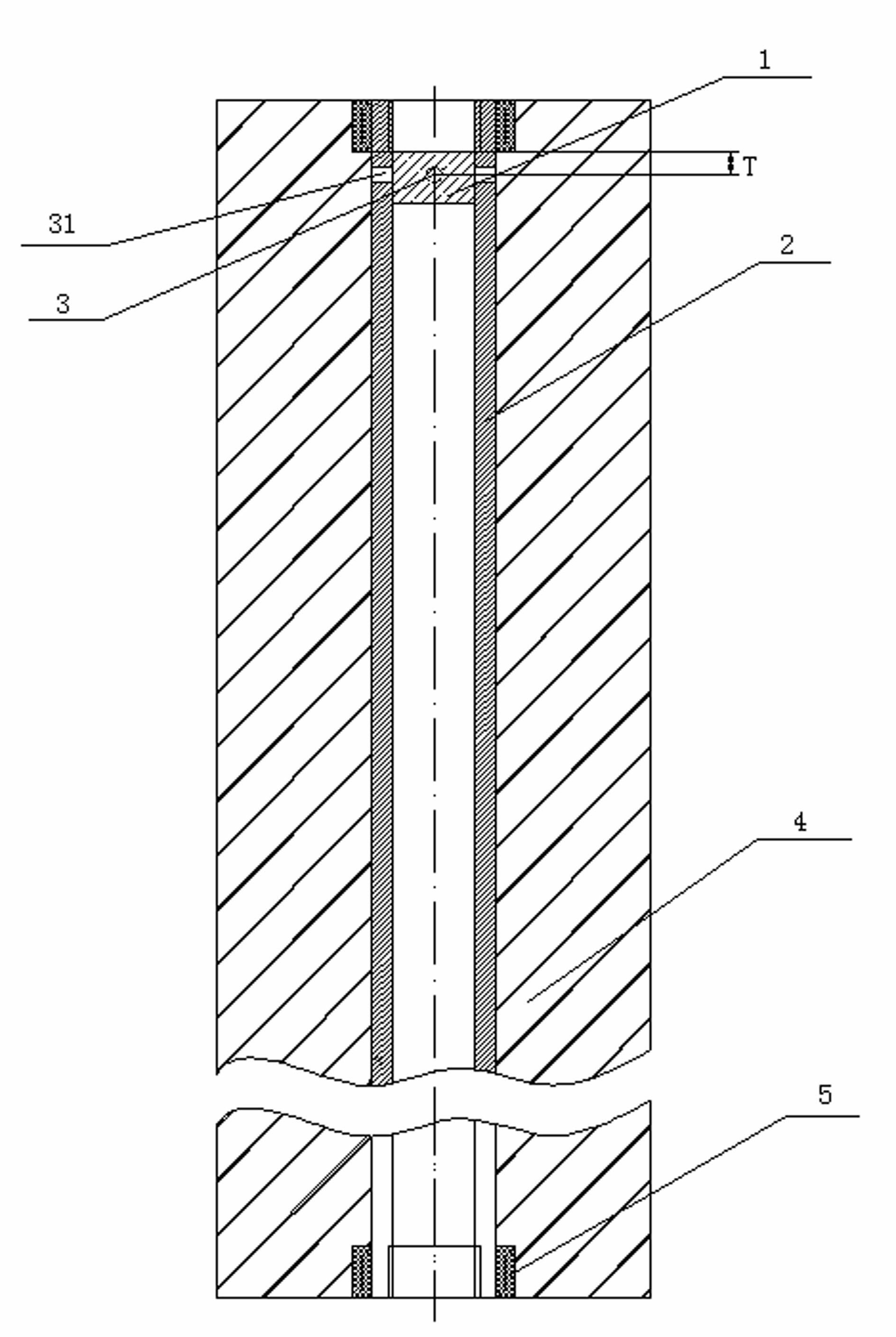

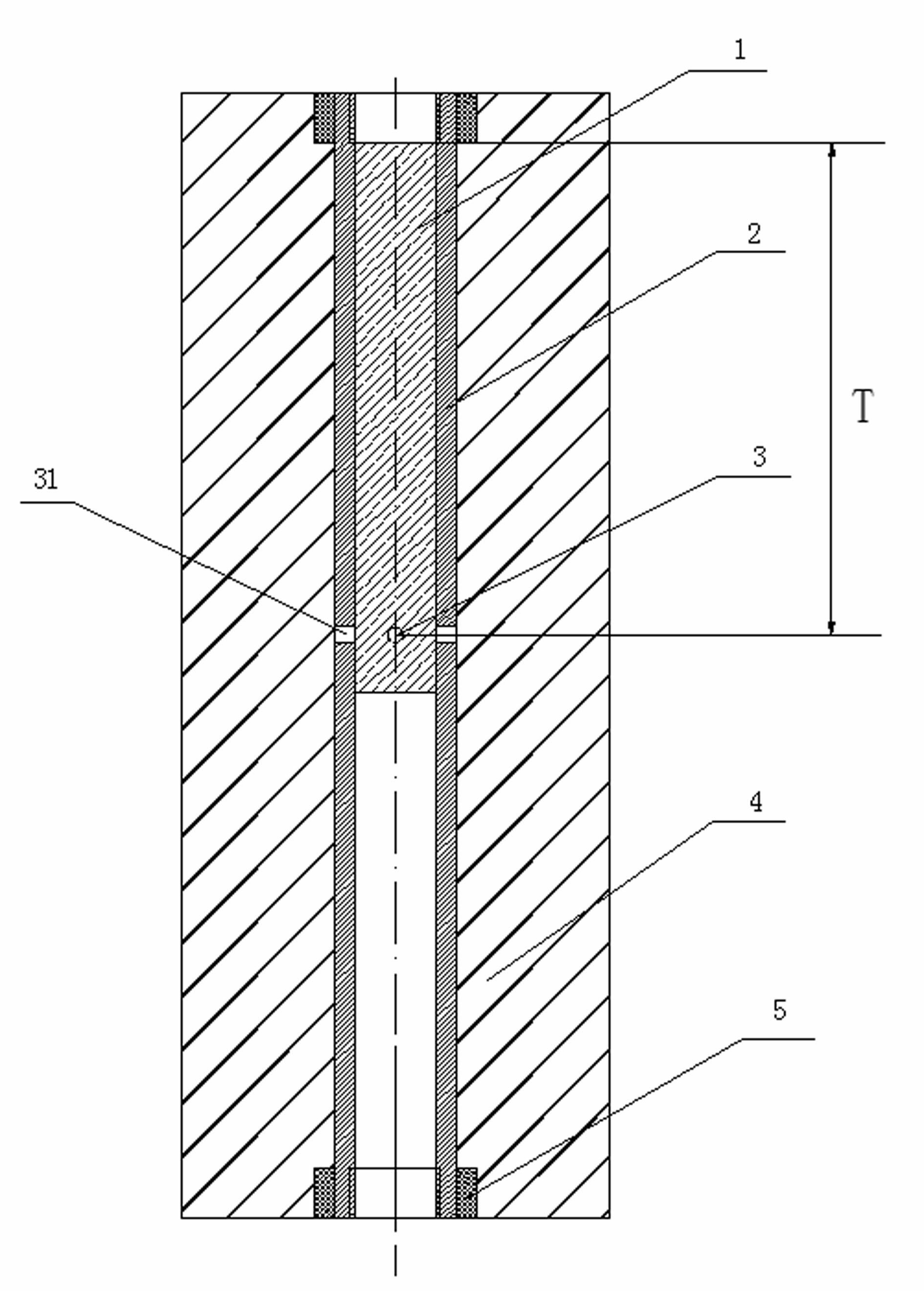

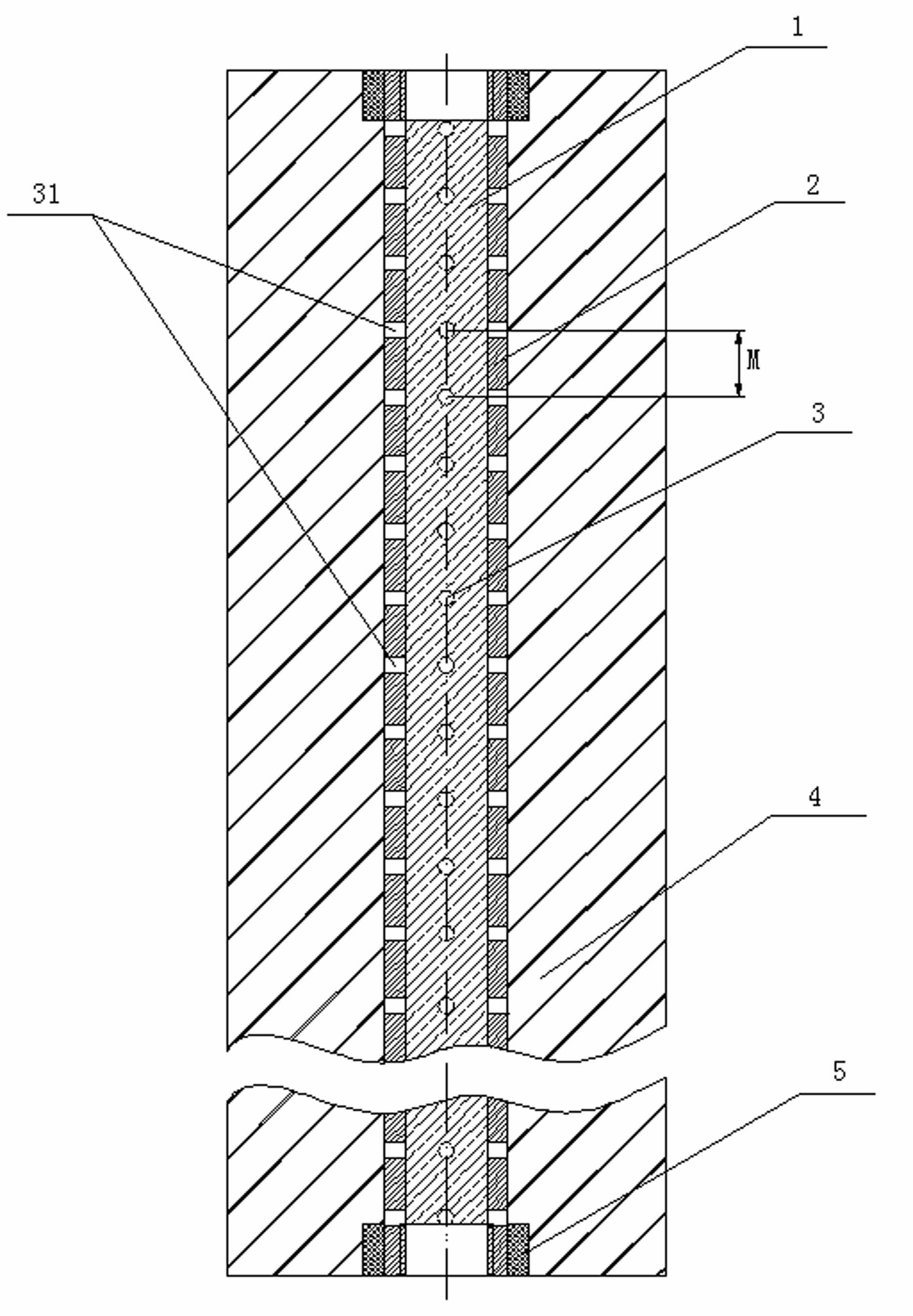

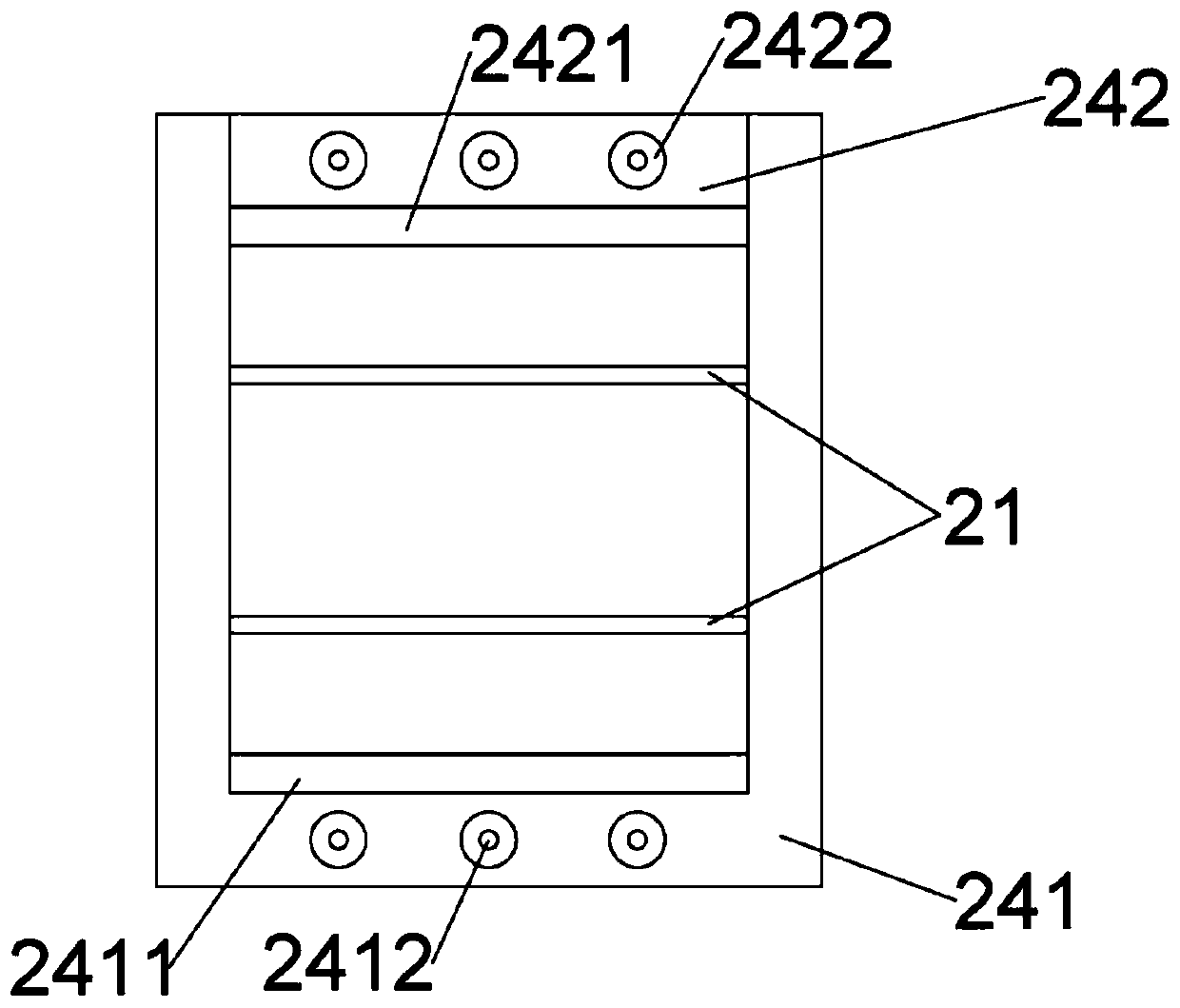

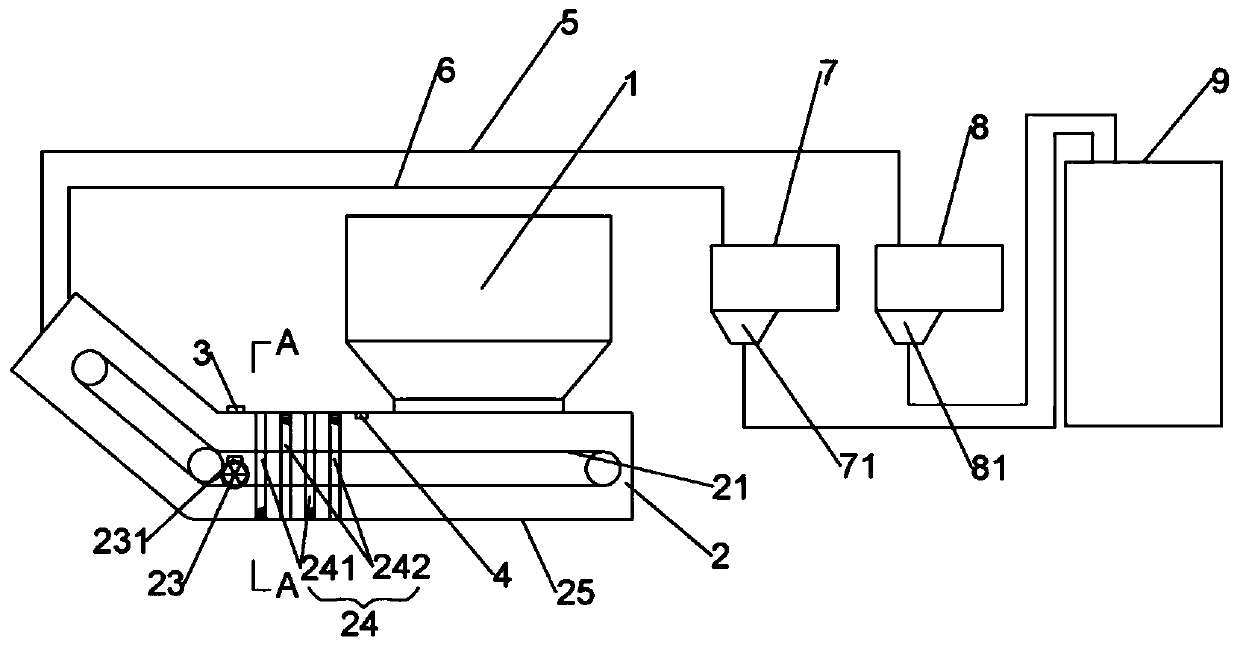

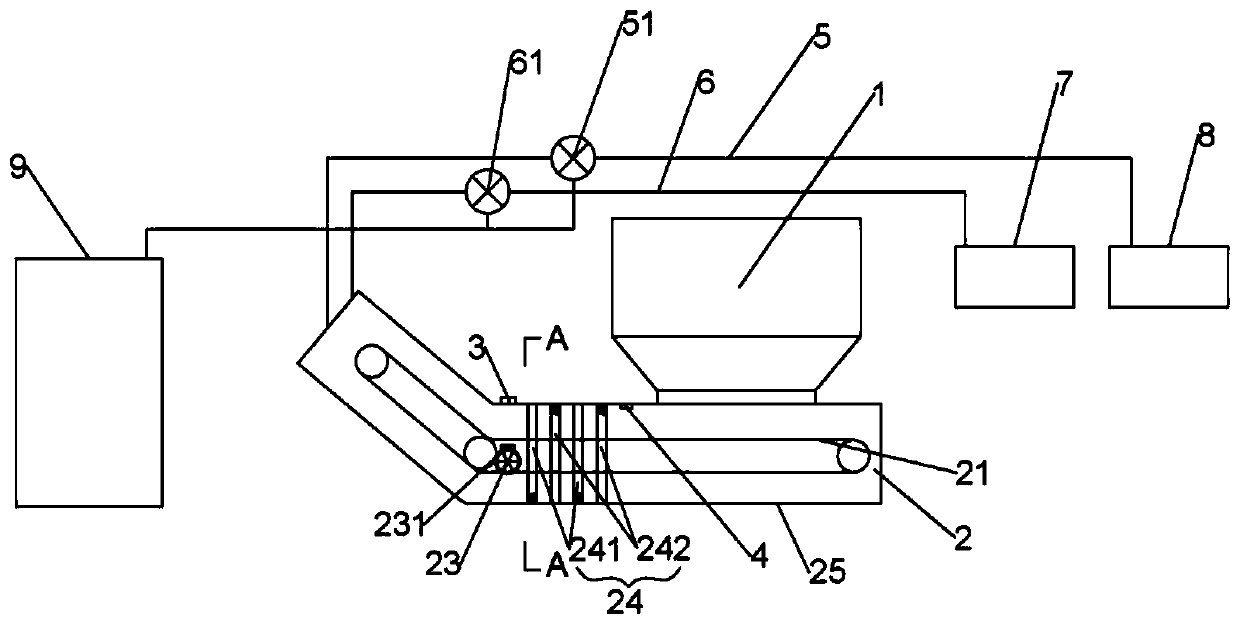

Electron accelerator under-beam device for powder material irradiation

InactiveCN113194597AUniform irradiationDamage controlAcceleratorsCooling/ventilation/heating modificationsEngineeringBeam scanning

The invention discloses an electron accelerator under-beam device for powder material irradiation, and relates to an electron accelerator irradiation technology. The device is characterized by comprising an irradiation unit, a conveying unit, a power unit and a supporting unit, the irradiation unit is in a multi-edge hollow cylinder shape, the cylindrical outer surface is completely coated with a titanium film, the conveying unit comprises a powder connecting cylinder and a rotating copper sleeve, the power unit comprises a speed reducer and an overrun clutch to drive a driving shaft to rotate, and power chain wheels and chains are arranged at the two ends of the driving shaft respectively and used for driving the irradiation unit to rotate; and the device has the beneficial effects that wind power for blowing powder is used for air cooling, and the under-beam irradiation unit keeps rotating, so that the powder hung on the wall inside is cooled when rotating to the outside of a beam scanning line, powder combustion caused by continuous irradiation is further avoided, the whole under-beam powder conveying is in a closed space, pollution caused by external dust is avoided, and continuous production is facilitated.

Owner:SHANDONG LANFU HIGH ENERGY PHYSICS TECH CO LTD

Shellless fracturing bomb and burning speed control method thereof

The invention discloses a shellless fracturing bomb and a burning speed control method thereof, which solve the problem that the existing shellless fracturing bomb cannot satisfy pressure loading matched with oil well oil layer characteristics. The shellless fracturing bomb comprises ignition powder, a central tube, a powder column and pressure relief portions. The pressure relief portions symmetrically arranged at two ends of the powder column, the side wall of the central tube is provided with at least one group of ignition holes, and each group of ignition holes includes three to six ignition holes is positioned on a same plane axially perpendicular to the central tube. The burning speed control method of the shellless fracturing bomb includes steps: determining group amount of the ignition holes according to required burning speed of the shellless fracturing bomb, and arranging the position of each group of ignition holes on the side wall of the central tube according to the group amount of the ignition holes. Pressure loading conditions under different well conditions and geological conditions can be met, fracturing production increasing and injection increasing effect can be improved, and protection of an oil well shaft can be benefited.

Owner:GANSU RES INSTION OF CHEM IND GRICI +1

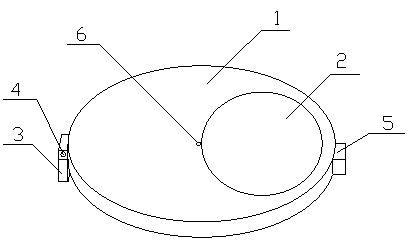

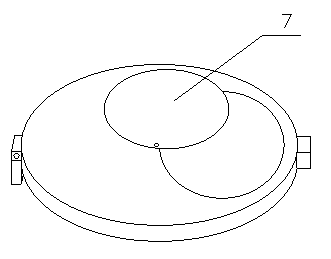

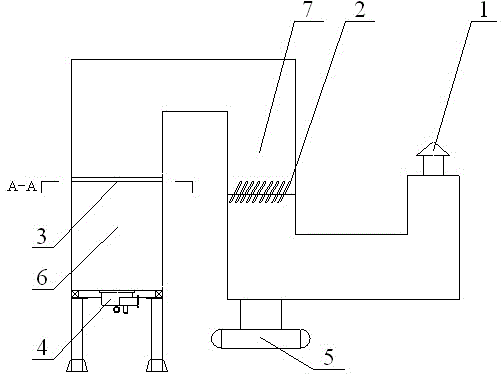

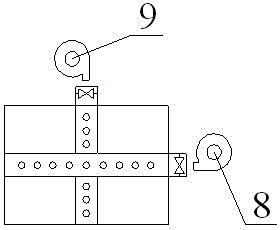

Temperature control cover of copper hot pot

InactiveCN103735173AAvoid burnsImprove securityCooking-vessel lids/coversTemperature controlEngineering

The invention discloses a temperature control cover of a copper hot pot. The temperature control cover comprises a first cover body, a second cover body and a fixing piece, wherein the fixing piece is used for fixing the fixing piece at the top of a charcoal burning cavity of the copper hot pot. The first cover body is provided with a through hole, the second cover body is used for adjusting the opening size of the through hole, the air circulation amount inside the charcoal burning cavity of the copper hot pot is adjusted by adjusting the opening size of the through hole, and the charcoal fire strength is controlled. The temperature control cover is provided with the first cover body at the upper portion of the charcoal burning cavity of the copper hot pot, the through hole is formed in the upper portion of the first cover body, the opening size of the through hole is controlled through the second cover body, the air circulation degree inside the charcoal burning cavity is further controlled, and charcoal burning is controlled, so that the temperature of the copper hot pot can be controlled.

Owner:SUZHOU HUANYAN ELECTRIC

Chemical waste gas boiler furnace for combustion

The invention discloses a chemical waste gas boiler furnace for combustion. The boiler furnace comprises a chimney, an inclined louver, a crossed air distributing pipe, a combustion device, a drain device, a combustion chamber, a fume passage, a first fan and a second fan, wherein the boiler furnace body forms an N shape, the combustion device is positioned at the lower end part of one end of the N-shaped boiler furnace body, the combustion chamber is arranged above one end of the N-shaped boiler furnace body, the upper end of the combustion chamber is connected with the fume passage, the middle part of the boiler combustion chamber is provided with the crossed air distributing pipe, the crossed air distributing pipe is uniformly provided with a plurality of air distributing holes from top to bottom, the end part of the crossed air distributing pipe is respectively connected with the first fan and the second fan, the part of the fume passage on a second curved passage of the N-shaped boiler furnace body, corresponding to the combustion chamber, is provided with the inclined louver, the outer side of the bottom of the lower part of the inclined louver is provided with the drain device, and the upper end part of the other end of the N-shaped boiler furnace body is provided with the chimney. The boiler furnace has the advantage that the boiler body structure is vertically arranged, so the occurrence of aggregating and detonation of residual hydrogen and backfire is avoided, and the safe and reliable running of the device is ensured.

Owner:ZHEJIANG TUFF BOILER

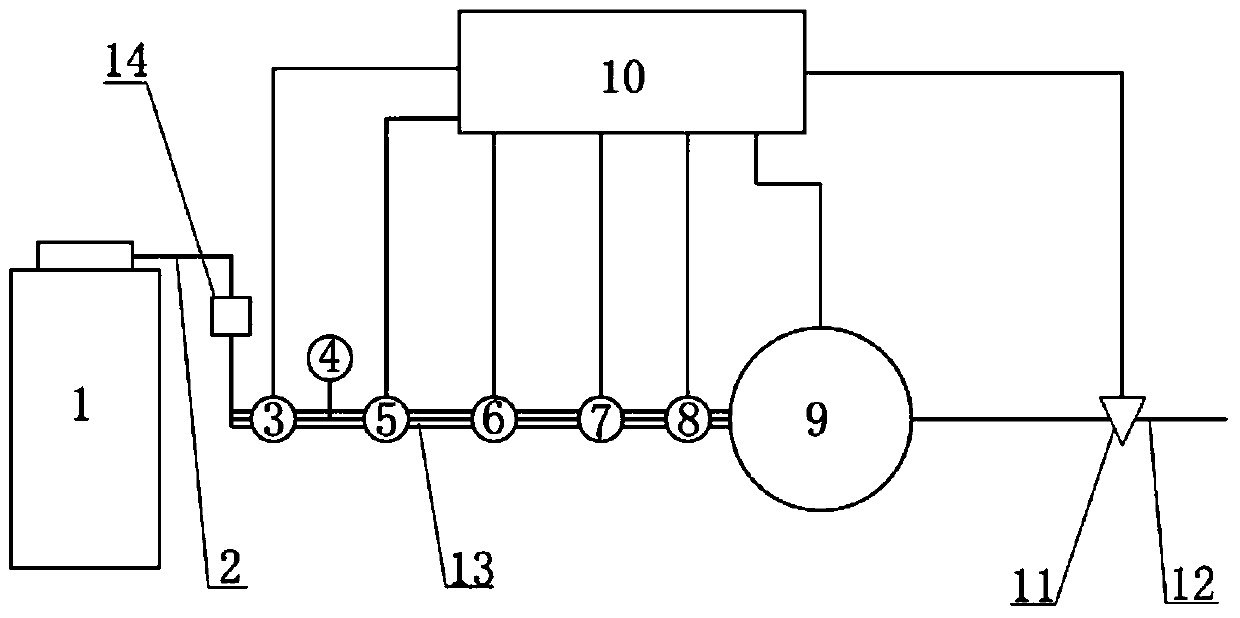

A Novel Adaptive Gas Fuel Control System

InactiveCN105020032BControlled combustionRealize automatic switching controlInternal combustion piston enginesEngine controllersHardware structureFuel type

The invention relates to a novel self-adaptation gas fuel control system. The system can automatically recognize and control internal combustion engine vehicles, ships or power generator sets in various gas fuel types. The novel self-adaptation gas fuel control system achieves self-adaptation adjustment and control over corresponding gas fuel. The control system comprises a gas fuel box, a gas inlet pipeline, an electromagnetic valve, a first pressure sensor, a second pressure sensor, a pressure reducing valve, an internal combustion engine and an electronic control unit. The control system has the effects that a combustible gas concentration sensor and the single electronic control unit or an ECU are used for controlling gas fuel with any component; automatic changeover control over various kinds of gas fuel is achieved; hardware structures are simple, cost is low, and use and maintenance are convenient; meanwhile, when no sensor exists or starts, a user can select the type and the proportion of preset fuel or input fuel, the ECU calls a matched excess air coefficient and injection pulse width, and combustion is controlled.

Owner:毛志明

A method for flexibly controlling engine combustion mode

ActiveCN106762294BImprove consumption rateEnsure normal dischargeFuel injection apparatusMachines/enginesCombustionLow load

The invention discloses a method for flexibly controlling an engine combustion mode. Engine speed signals and throttle position signals are read by an electronic control unit to judge the engine operation load according to the read signals; if under the low load condition, an diesel injector is controlled for early injection to form PCCI combustion mode in a cylinder; if under the moderate load condition, the diesel injector is controlled for injection in advance twice, and high-pressure EGR is performed to form HP-EHPCC combustion mode; if under the medium-to-high load condition, the diesel injector is controlled for injection in advance twice, and low-pressure EGR is performed to form LP-EHPCC combustion mode; if under the high load condition, the diesel injector is controlled for delayed injection once, and the low-pressure EGR is performed to form LP-LHPCC combustion mode. High-efficiency clean combustion within a wide load range is implemented through combination of different combustion modes under different working conditions.

Owner:TIANJIN UNIV

An air-cooled slag drying machine slag sensible heat recovery system

ActiveCN107741021BAvoid enteringPrevent returnIndirect carbon-dioxide mitigationAir/fuel supply for combustionAir preheaterAir volume

The invention relates to a slag sensible heat recycling system for an air-cooling dry slag machine. A horizontal segment, close to one side of a lifting segment, of the dry slag machine is provided with a shutter rotation opening-closing mechanism air inlet; the side, away from the lifting segment, of the air inlet is provided with an isolating device; the position, on the inner side of the top ofan outer shell, close to a joint of the dry slag machine and a boiler is provided with a temperature sensor; and the outer wall of the outer shell is provided with a controller, and the top of the dry-slag-machine lifting segment in the air-cooling dry slag machine is connected with a second air preheater and a first air preheater correspondingly through air pipes. The slag sensible heat recycling system for the air-cooling dry slag machine is reasonable in design, the influence of cold air on the operation of the boiler can be effectively avoided, the slag cooling efficiency is improved, meanwhile the slag sensible heat is used sufficiently, the low temperature corrosion environment of the air preheaters is improved, the tail gas temperature of the boiler is raised, at the same time theheat can be recycled by a low temperature economizer to raise the feed-water temperature, the total air volume entering the boiler is controlled, the low nitrogen combustion and low oxygen combustionare achieved, the discharging of NOX from boiler combustion is lowered, the amount of ammonia spraying in SCR area is reduced, and the efficiency of the boiler is improved.

Owner:史震伟

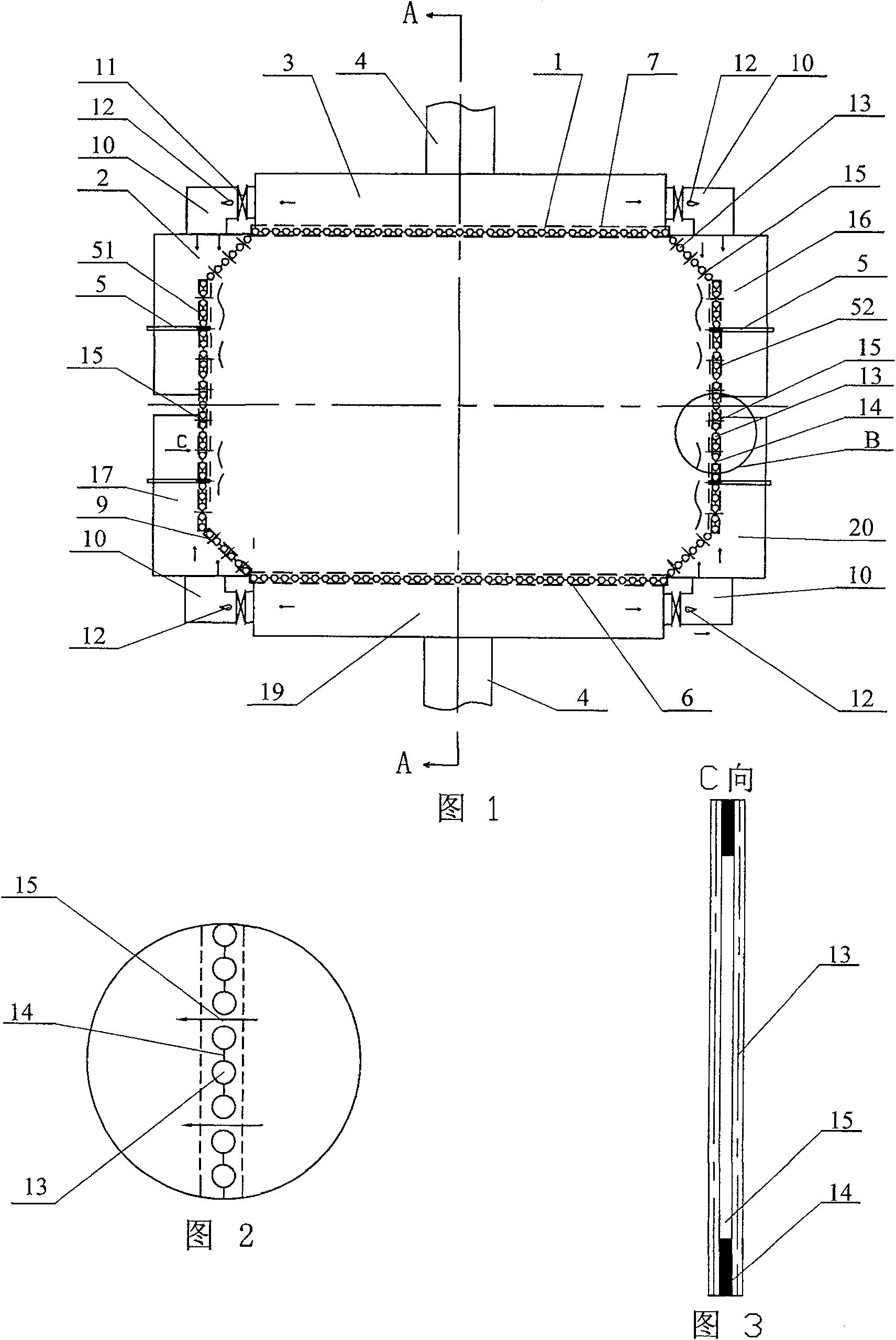

W type flame boiler local ventilation side-proof wall and wing wall water-cooled wall slagging apparatus

ActiveCN100557307CPromote meltingHigh melting pointSteam boilersCombustion chambersWing wallLeft wall

The utility model relates to a local ventilation anti-slagging device of a side wall and a wing wall water wall of a W-shaped flame boiler, which relates to a W-shaped flame boiler. Aiming at the problem of slagging in the wing wall and the side wall of the existing W-shaped flame boiler. The first and fourth wall-attached bellows are located at the rear and front sides of the left wall and the corresponding wing walls; the third and second wall-attached bellows are located at the front and rear of the right wall and the corresponding wing walls; the first Between the main bellows and the first and second wall-attached bellows, between the second main bellows and the third and fourth wall-attached bellows are connected through the wall-attached air duct, the first and second main bellows and the secondary air The first and second air supply boxes are connected with the second main air box, the third and fourth air supply boxes are connected with the first main air box, and the fins on the wing wall and the upper part of the side wall are provided with gaps to form the side wall and wing wall The wall-attached tuyere, the fins between the water-cooled wall tubes of the part of the furnace arch close to the wing wall are provided with gaps to form the wing wall-attached tuyere. The invention has the advantages of reasonable structural design and no slagging of wing walls and side walls.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com