W type flame boiler local ventilation side-proof wall and wing wall water-cooled wall slagging apparatus

A local ventilation and water-cooled wall technology, applied in steam boilers, combustion methods, combustion chambers, etc., can solve problems such as wing wall and side wall slagging, and achieve the effect of preventing slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

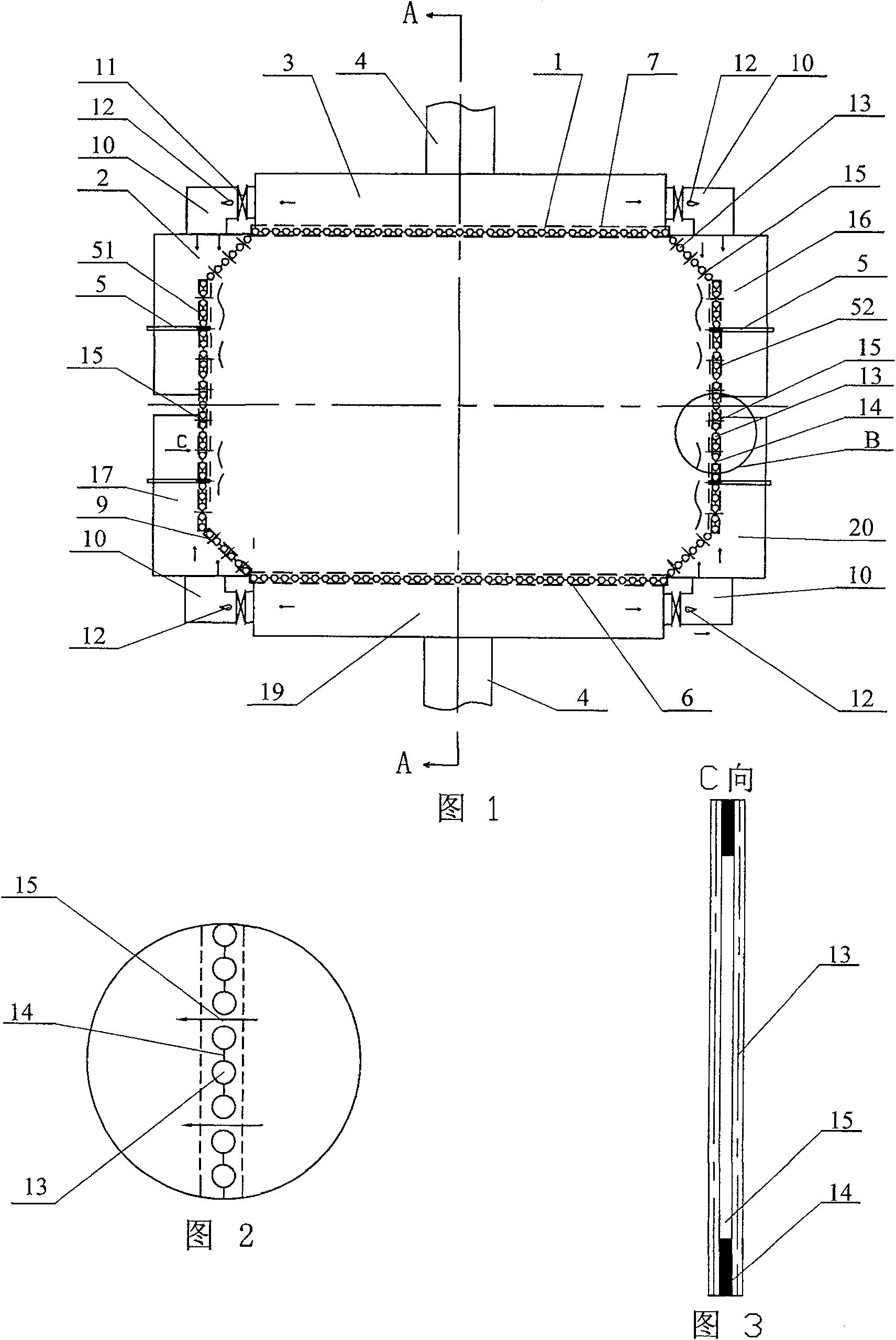

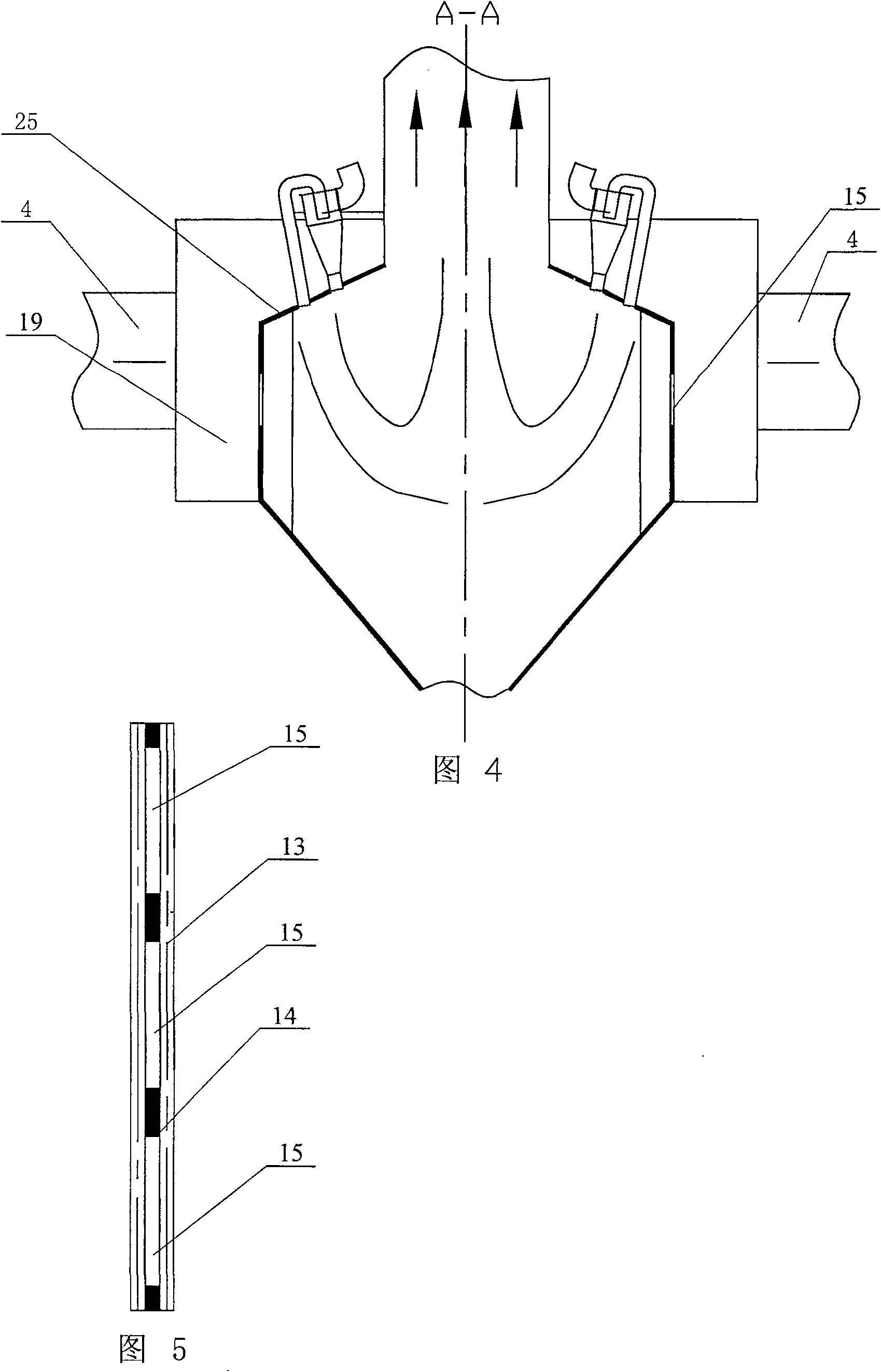

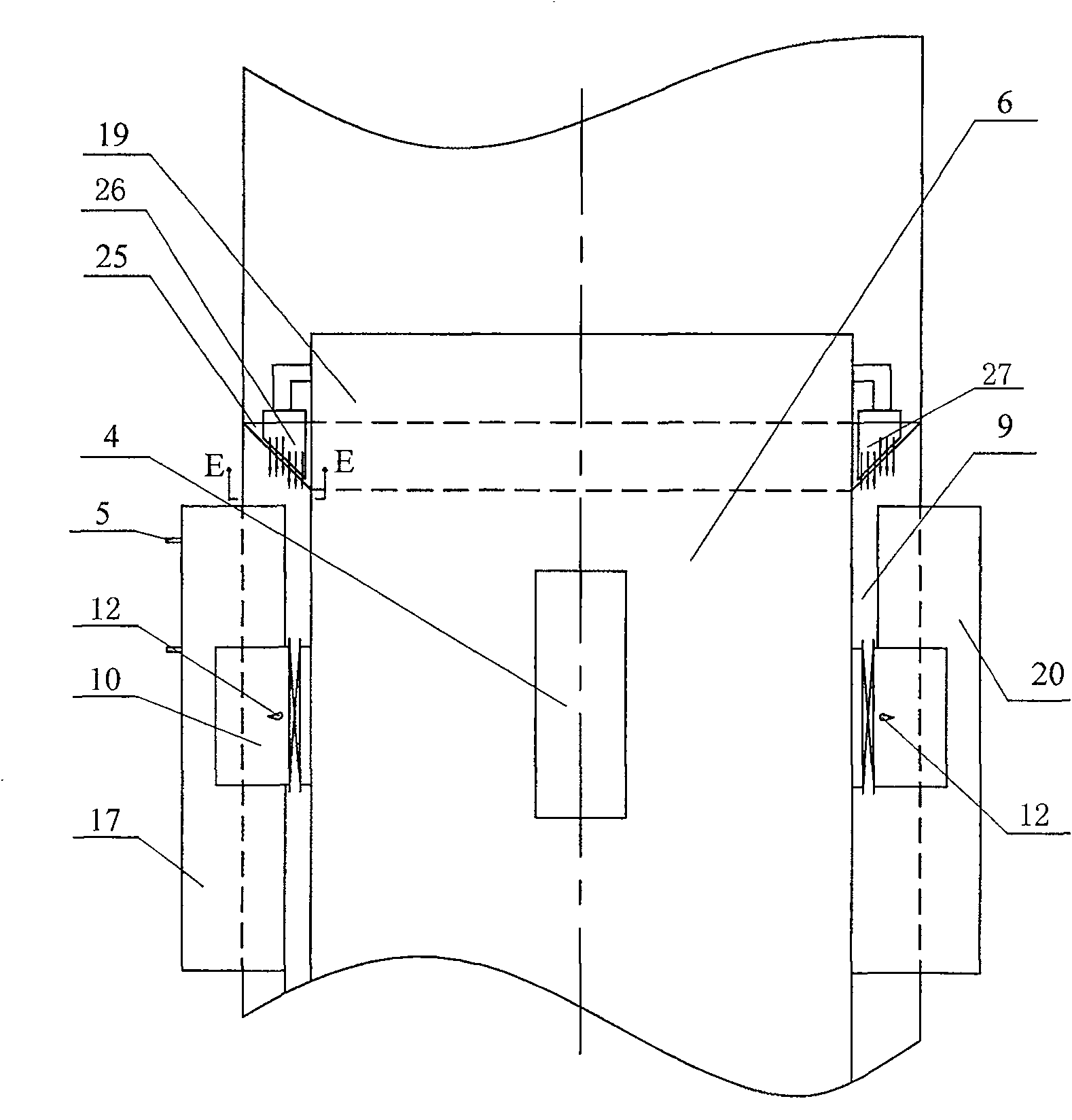

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 4 , Figure 6 , Figure 7 and Figure 9 Describe this embodiment, the anti-slagging device of this embodiment includes a furnace body, a first wall-mounted wind box 2, a first main wind box 3, two secondary air ducts 4, four wall-mounted air ducts 10, a second The wall-attached wind box 16, the third wall-attached wind box 20, the fourth wall-attached wind box 17 and the second main wind box 19; 9 and two furnace arches 25; The wing walls 9 are connected, and the two furnace arches 25 are arranged on the upper end surfaces of the front wall 6, the rear wall 7, the side walls and the four wing walls 9, the front wall 6, the rear wall 7, the two side walls, The four wing walls 9 and the two furnace arches 25 are respectively composed of water-cooled wall tubes 13 and fins 14 arranged alternately and fixed together. The first main air box 3 is arranged on the outside of the rear wall 7, and the second main ai...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To illustrate this embodiment, there are 2 to 7 fins 14 between each wing wall 9 and two adjacent side wall wing wall-attached tuyeres 15 on each side wall in this embodiment. In this embodiment, since only some of the fins 14 are provided with side wall wing wall-attached tuyeres 15, the entire furnace body can be divided into many small pieces. The fin 14 portion of the wall-mounted tuyere 15 may still be slagging, but this slag is a small piece, which will not form a large area of slagging on the entire furnace wall, so that the large slag fire extinguishing phenomenon is not easy to occur. The application of this embodiment on a 300MW boiler burning bituminous coal shows that after adopting this embodiment, the combustion efficiency of the boiler does not decrease, the slagging of the water wall does not occur, and the fire accidents are greatly reduced. Other components and connections are the same as those ...

specific Embodiment approach 3

[0009] Specific implementation mode three: combinationfigure 1 The present embodiment is described, and the wall-attached tuyeres 15 of the side wall and wing wall of this embodiment are evenly distributed on each wing wall 9 and each side wall. The invention patent application publication number as described in the background technology is CN 101050854A, the publication date is October 10, 2007, and the name is "W-type flame boiler for preventing side wall water-cooled wall slagging" is to make the wing wall close to the side wall The water-cooled wall pipe is pulled back to form spouts on both sides of the side wall, and then the wind boxes on the front and rear walls are supplied to the wall here to form an oxidative atmosphere in the side wall area. Anti-slagging method. The disadvantage of this method is that the momentum of the secondary air supplied by the edge of the side wall is weak, and often cannot reach the middle of the side wall, so that this part of the area is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com