Shellless fracturing bomb and burning speed control method thereof

A fracturing bomb and pressure relief technology, which is used in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve problems such as the inability to meet pressure loading, and achieve the goal of increasing the single-well charge, improving the effect, and prolonging the pressure. effect of action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

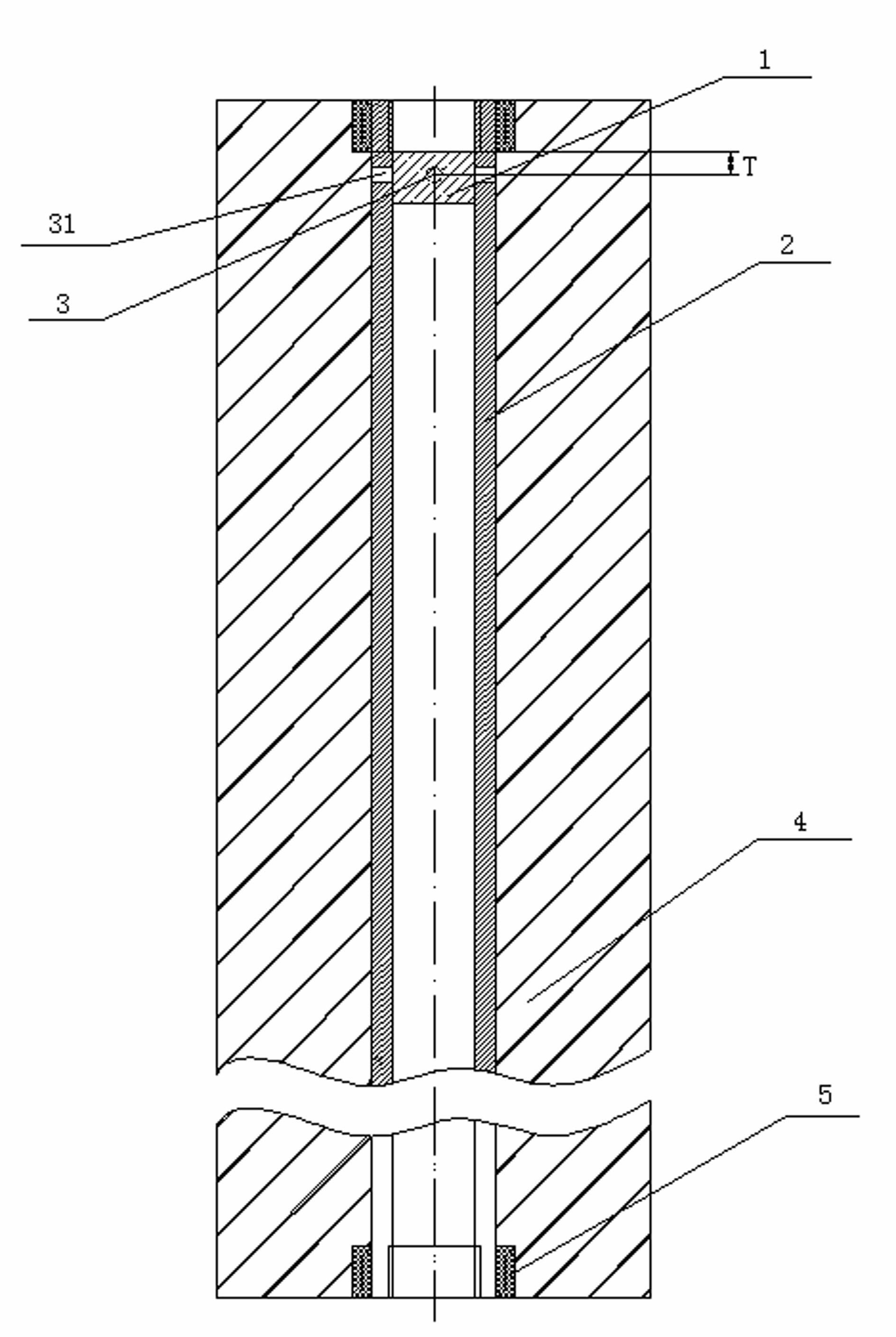

[0028] figure 1 The first embodiment of the present invention is shown, the side wall of the central tube 2 is provided with a group of ignition holes 31, and the group of ignition holes 31 are located at one end of the central tube 2, and are ignited by the ignition device, and the ignition holes inside the central tube 2 are first ignited. The gunpowder 1 ignites the gunpowder column 4 through the ignition hole 31 on the side wall of the central tube 2 . In this case, since the propellant at one end of the propellant column 4 is ignited first, the propellant column 4 is similar to burning at the end face, which is the slowest burning rate of the caseless fracturing bomb.

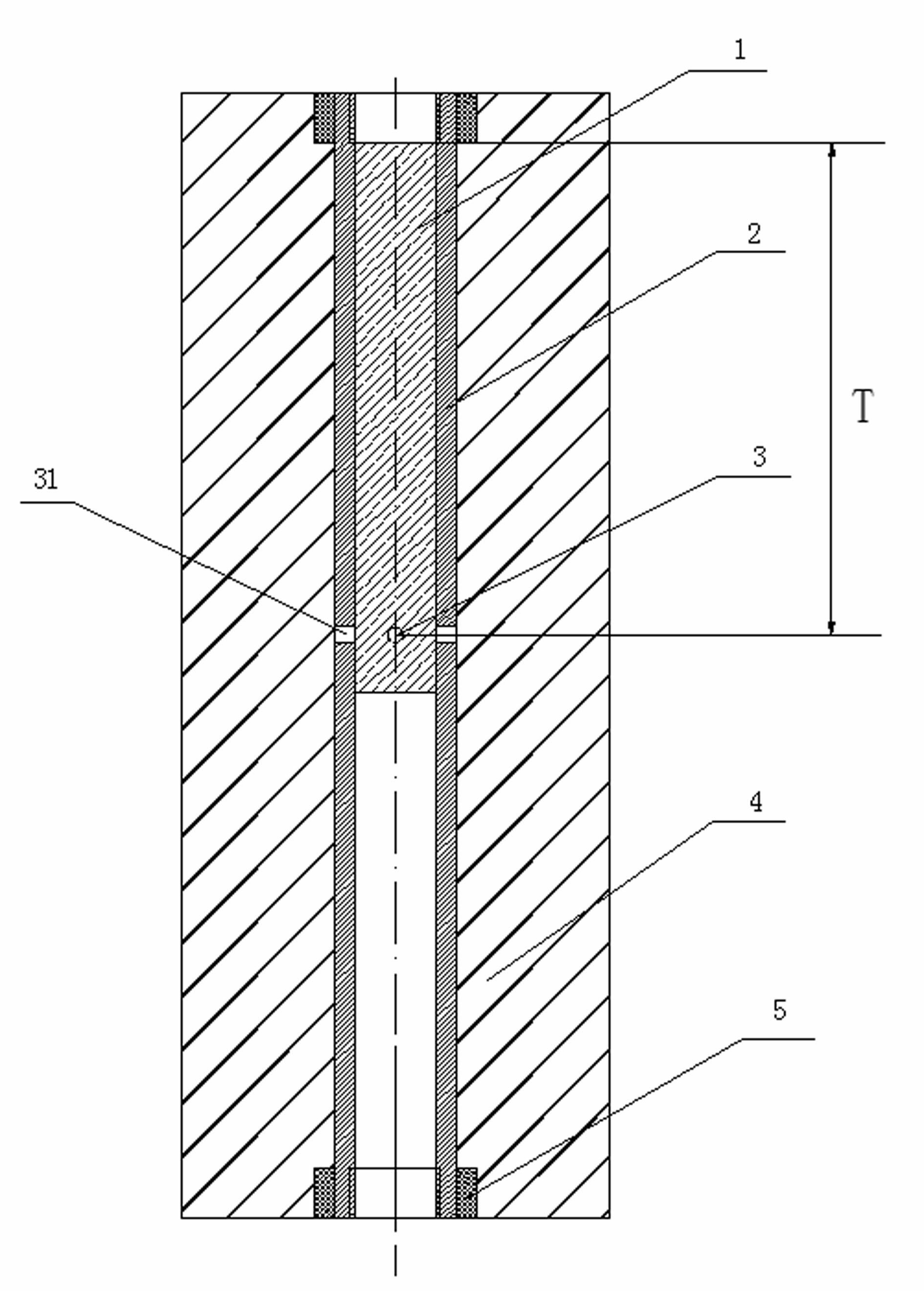

[0029] figure 2 Shows the second embodiment of the present invention, the side wall of the central tube 2 is provided with a group of ignition holes 31, the group of ignition holes 31 are located in the middle of the central tube 2, the ignition device does not illustrate the ignition, and ignites the gu...

Embodiment 1

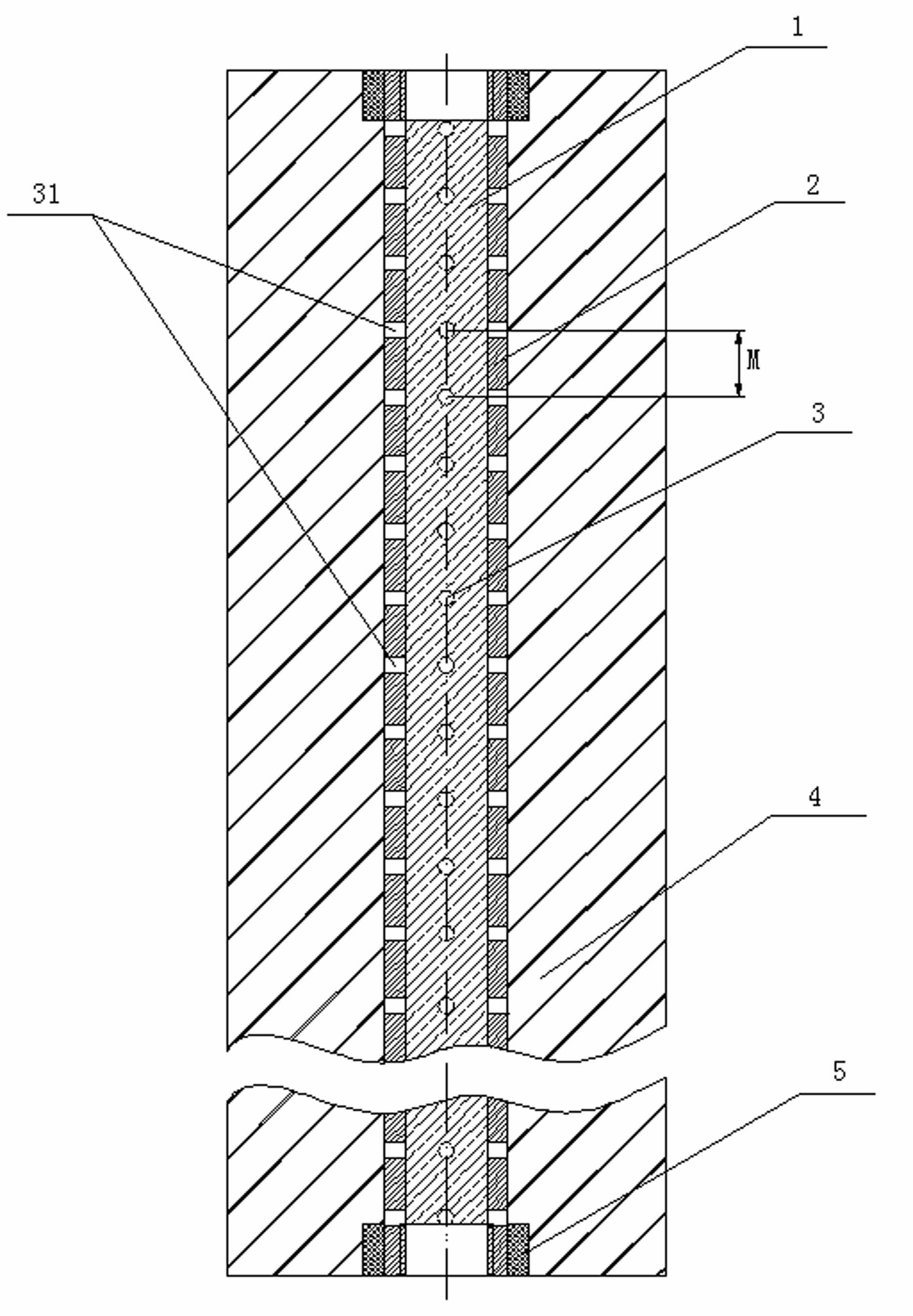

[0038] The caseless fracturing bomb includes two groups of ignition holes 31. When the two groups of ignition holes 31 are located at one end of the central tube 2, the distance M between the two groups of ignition holes 31 is equal to 5 mm, and the group of ignition holes at the end The distance T from the near-end pressure relief part 5 of the central tube 2 is equal to the distance from the ignition hole, the burning time of the caseless fracturing bomb is 114.31s, and the burning rate is 0.06kg / s.

Embodiment 2

[0040] The caseless fracturing bomb includes two sets of ignition holes 31, which are located in the axial direction of the central tube 2 and distributed evenly, and the distance between the two sets of ignition holes 31 is the set of ignition holes at the end to the central tube 2 When the distance of the proximal pressure relief part 5 is twice the distance, the burning time of the caseless fracturing bomb is 26.31s, and the burning rate is 0.25kg / s; when the positions of the two sets of ignition holes 31 are along the axial direction of the central tube When changing, the burning rate of the caseless fracturing bomb varies between 0.06kg / s -0.25kg / s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com