A method for flexibly controlling engine combustion mode

A combustion mode and engine technology, applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of poor spontaneous combustion of gasoline, low exhaust gas temperature, and failure to consider exhaust gas recirculation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

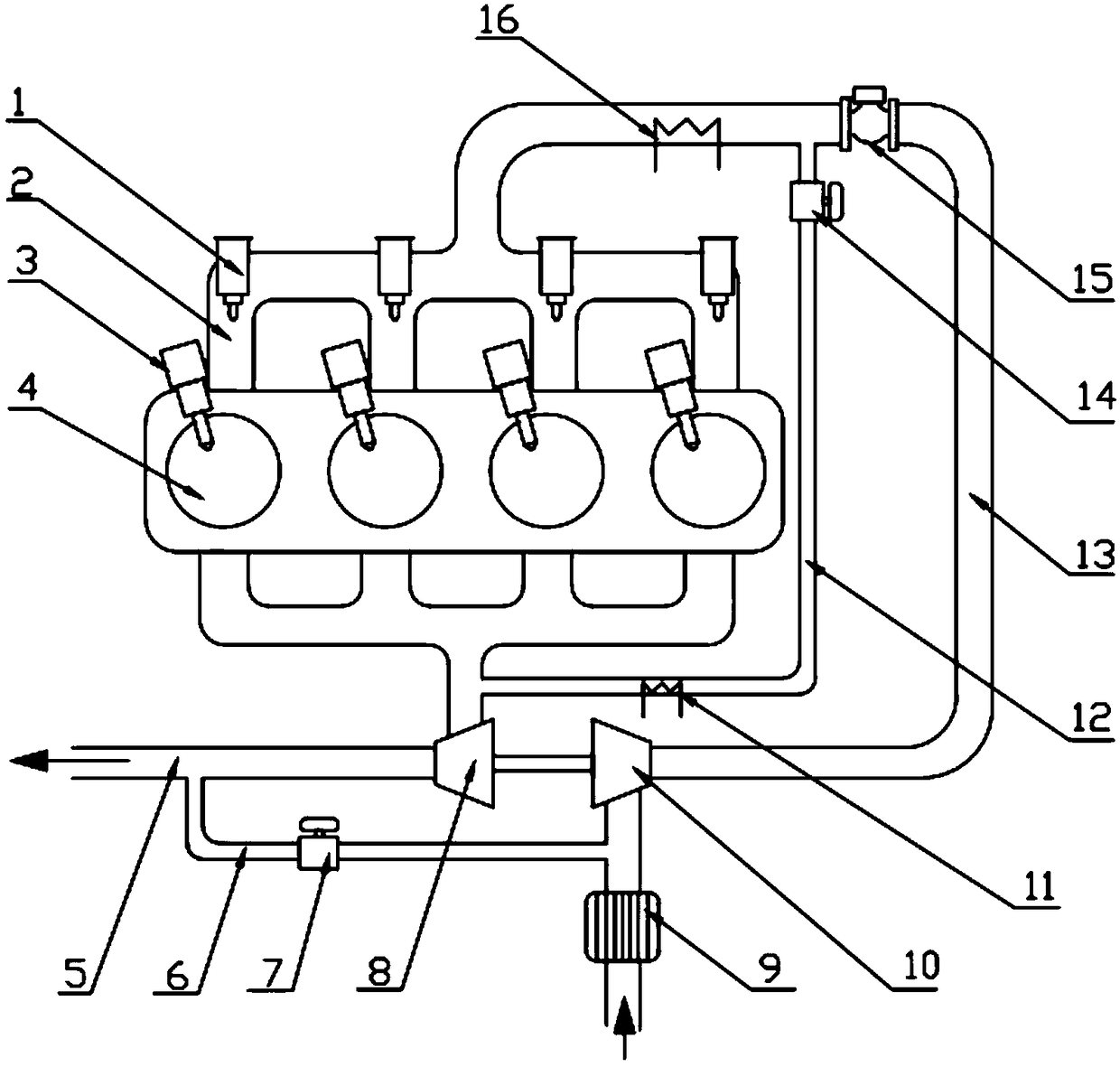

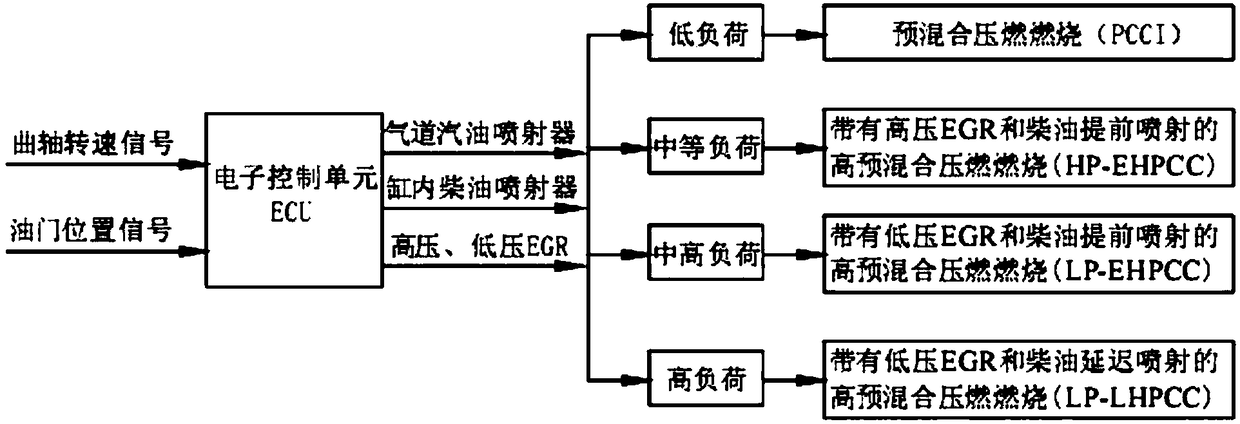

[0027] (1) The electronic control unit reads the speed signal of the sensor installed on the crankshaft of the engine with gasoline port injection and diesel direct injection, and the position signal of the sensor installed on the accelerator pedal, and judges the engine based on the read signal. Operating load.

[0028] (2) If the judgment result in step (1) is a small load condition (the load average effective pressure (BMEP) of engine operation) <0.5MPa), the electronic control unit controls the port gasoline injector 1 installed on the intake manifold 2 to close, controls the low pressure exhaust gas recirculation valve 7 installed on the low pressure exhaust gas recirculation loop 6 and the high pressure exhaust gas recirculation The high-pressure exhaust gas recirculation valve 14 on the circuit is closed. After the air passes through the air filter 9, it is compressed by the compressor 10, and then enters the cylinder 4 through the throttle valve 15, the intake intercooler ...

Embodiment 2

[0034] (1) The electronic control unit reads the speed signal of the sensor installed on the crankshaft of the engine with gasoline port injection and diesel direct injection, and the position signal of the sensor installed on the accelerator pedal, and judges the engine based on the read signal. Operating load.

[0035] (2) If the judgment result in step (1) is a small load condition (the load average effective pressure (BMEP) of engine operation) <0.5MPa), the electronic control unit controls the port gasoline injector 1 installed on the intake manifold 2 to close, controls the low pressure exhaust gas recirculation valve 7 installed on the low pressure exhaust gas recirculation loop 6 and the high pressure exhaust gas recirculation The high-pressure exhaust gas recirculation valve 14 on the circuit is closed. After the air passes through the air filter 9, it is compressed by the compressor 10, and then enters the cylinder 4 through the throttle valve 15, the intake intercooler ...

Embodiment 3

[0041] (1) The electronic control unit reads the speed signal of the sensor installed on the crankshaft of the engine with gasoline port injection and diesel direct injection, and the position signal of the sensor installed on the accelerator pedal, and judges the engine based on the read signal. Operating load.

[0042] (2) If the judgment result in step (1) is a small load condition (the load average effective pressure (BMEP) of engine operation) <0.5MPa), the electronic control unit controls the port gasoline injector 1 installed on the intake manifold 2 to close, controls the low pressure exhaust gas recirculation valve 7 installed on the low pressure exhaust gas recirculation loop 6 and the high pressure exhaust gas recirculation The high-pressure exhaust gas recirculation valve 14 on the circuit is closed. After the air passes through the air filter 9, it is compressed by the compressor 10, and then enters the cylinder 4 through the throttle valve 15, the intake intercooler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com